Overcoming Key Technical Hurdles in Biomass Gasification for Sustainable Aviation Fuel Production

This article provides a comprehensive analysis of the principal technical barriers impeding the commercialization of biomass gasification for Sustainable Aviation Fuel (SAF) synthesis.

Overcoming Key Technical Hurdles in Biomass Gasification for Sustainable Aviation Fuel Production

Abstract

This article provides a comprehensive analysis of the principal technical barriers impeding the commercialization of biomass gasification for Sustainable Aviation Fuel (SAF) synthesis. Targeting researchers, scientists, and process development engineers, it explores the foundational science of feedstock variability and tar formation, details advanced gasification and syngas conditioning methodologies, offers systematic troubleshooting for operational challenges like ash slagging and catalyst deactivation, and validates performance through comparative assessments of reactor designs and integration pathways. The analysis synthesizes current research to outline a roadmap for overcoming these barriers to enable scalable, cost-effective bio-SAF production.

Understanding the Core Challenges: Feedstock Heterogeneity and Syngas Impurities

Troubleshooting Guide & FAQ

Q1: Why do my gasification product yields (syngas composition: H₂, CO, CO₂) vary significantly between batches when using the same nominal feedstock (e.g., corn stover)?

A: This is a direct result of inherent feedstock variability. Key compositional factors impacting gasification include:

- Moisture Content: High moisture consumes energy for drying, lowers reactor temperature, and favors water-gas shift reactions, increasing H₂/CO ratio.

- Ash Content & Composition: High alkali (K, Na) ash can act as a catalyst but also cause slagging and fouling. Silica can inhibit catalytic pathways.

- Lignin vs. Cellulose/Hemicellulose Ratio: Higher lignin content typically requires higher gasification temperatures and can lead to higher tar yields.

Mitigation Protocol: Implement a strict feedstock pre-characterization and blending protocol.

- Characterize each batch for: proximate analysis (moisture, volatiles, fixed carbon, ash), ultimate analysis (CHNSO), ash elemental analysis (via ICP-MS), and structural carbohydrate/lignin (via NREL/TP-510-42618).

- Blend multiple batches to achieve a consistent average composition before processing.

- Adjust gasification parameters (temperature, equivalence ratio, catalyst load) based on the characterized feedstock profile.

Q2: How can I reduce tar formation during biomass gasification, which clogs my downstream systems and poisons my Fischer-Tropsch catalyst for SAF synthesis?

A: Tar formation is highly dependent on feedstock reactivity and gasification conditions.

Primary Solutions:

- Optimize Primary Gasification Conditions: Increase temperature (>800°C) and use oxygen/steam as agents to crack tars in the reactor.

- Use In-Bed Catalysts: Add low-cost, naturally high-potassium ash biomass (e.g., wheat straw) as a blend to the primary feedstock to catalyze tar cracking. Alternatively, use doped olivine or dolomite catalysts.

- Implement Secondary Catalytic Tar Reforming: Install a fixed-bed reformer downstream using Ni-based or noble metal catalysts on a CeO₂ or Al₂O₃ support. Critical: Ensure rigorous feedstock particulate removal (see Q3) to prevent catalyst deactivation.

Experimental Protocol for Tar Measurement (Cold Trap Method):

- Apparatus: Set up a series of impinger bottles cooled in an isopropanol/dry ice bath (-20°C) placed in the sampling line.

- Sampling: Isokinetically extract a known volume of producer gas through the bottles containing a validated solvent (e.g., acetone, dichloromethane).

- Analysis: Combine and evaporate the solvent traps. Weigh the residual tar mass (gravimetric tar). Analyze via GC-MS for speciated tar composition (e.g., naphthalene, toluene).

Q3: What is the best method to prepare and feed highly variable, low-bulk-density biomass into a high-pressure gasifier consistently?

A: Inconsistent feeding is a major technical barrier. The solution is robust preprocessing.

Standardized Preprocessing Protocol:

- Size Reduction: Mill all feedstock to <2 mm particle size using a knife mill with a 2 mm screen.

- Drying: Dry in a forced-air oven at 105°C for ≥24 hours to achieve <10% moisture.

- Pelletization/Densification: Feed the dried, milled material into a single-pellet press or commercial pellet mill. Use a binding agent (e.g., 1-3% starch) if necessary for fragile feedstocks.

- Feeding System: Use a lock-hopper system with twin-screw feeders designed for fibrous solids. For research-scale units, a piston feeder often provides more consistent feed for pellets.

Q4: My catalyst for syngas conditioning (water-gas shift, tar reforming) deactivates rapidly. How do I diagnose if feedstock variability is the cause?

A: Feedstock variability can lead to poisoning (S, Cl) and fouling (ash, tars).

Diagnostic Experimental Workflow:

- Post-mortem Catalyst Analysis:

- Thermogravimetric Analysis (TGA): Measure weight loss in air to quantify coke deposition.

- Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES): Dissolve catalyst sample and analyze for S, K, Na, Ca, Si deposition from feedstock ash.

- X-ray Photoelectron Spectroscopy (XPS): Surface analysis to confirm sulfur or carbonaceous species.

- Correlate with Feedstock Analysis: Cross-reference catalyst poisoning elements with the ultimate and ash analysis (see Q1) of the specific feedstock batch used.

- Solution: Implement more stringent gas cleaning (cyclones, ceramic filters, scrubbers) upstream of the catalyst bed. Consider guard beds or switch to more poison-resistant catalyst formulations (e.g., Rh-based).

Table 1: Representative Compositional Variability of Common Lignocellulosic Feedstocks

| Feedstock | Cellulose (wt%) | Hemicellulose (wt%) | Lignin (wt%) | Ash (wt%) | Higher Heating Value (MJ/kg) |

|---|---|---|---|---|---|

| Corn Stover | 35-40 | 20-25 | 15-20 | 4-7 | 17-18 |

| Pine Wood | 40-45 | 20-25 | 25-30 | 0.5-1 | 19-20 |

| Wheat Straw | 33-38 | 20-25 | 15-20 | 6-10 | 17-18 |

| Switchgrass | 30-35 | 25-30 | 15-20 | 4-6 | 18-19 |

Table 2: Impact of Key Feedstock Parameters on Gasification Outcomes for SAF Production

| Parameter | High Value Impact on Syngas | Risk for Downstream SAF Catalysis (F-T) | Recommended Mitigation |

|---|---|---|---|

| High Moisture (>30%) | Low H₂, increased CO₂, lower temp | Deactivates F-T catalyst via oxidation | Pre-drying to <10% |

| High Alkali Ash (K>2%) | Can enhance tar cracking | Ash deposition, reactor slagging, catalyst bed fouling | Leaching pretreatment, use of additives |

| High Sulfur (>0.1%) | Minor direct impact | Permanent poisoning of F-T & reforming catalysts | Desulfurization bed (e.g., ZnO) |

| High Fines Content | Incomplete conversion, high particulate | Erosion, filter clogging, catalyst pore blocking | Densification (pelletizing) |

Visualizations

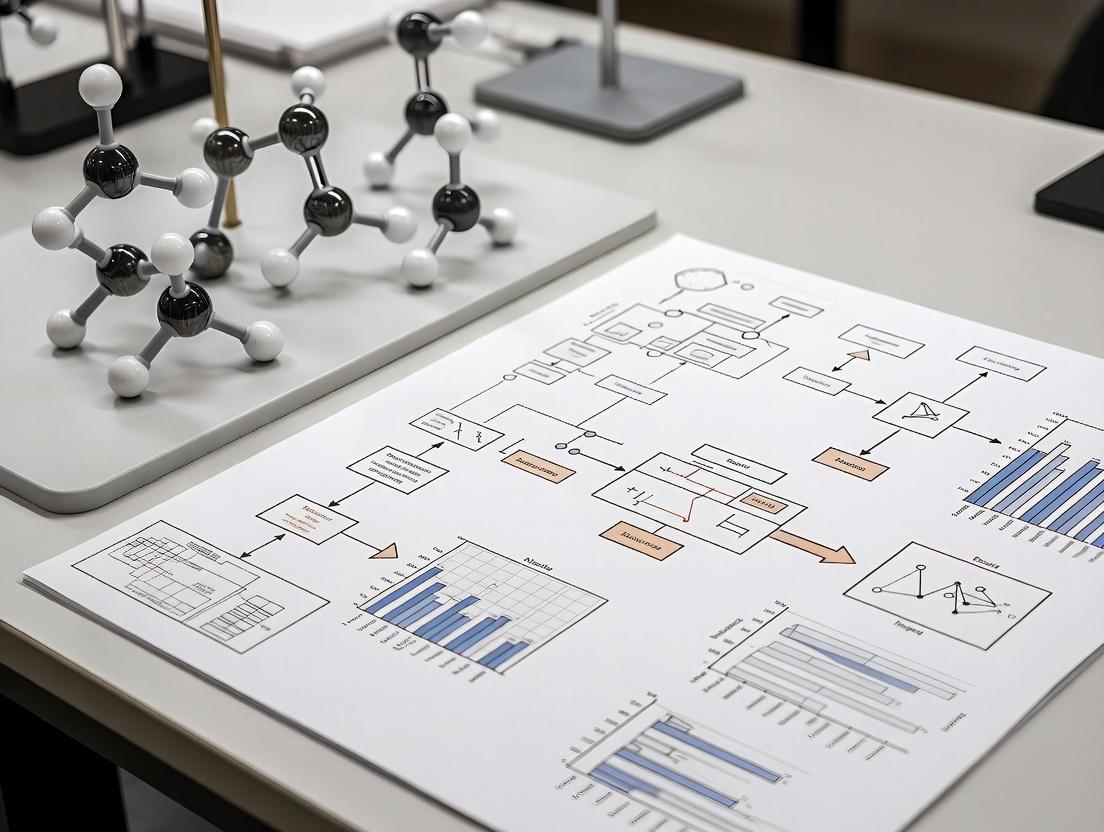

Diagram Title: Feedstock Variability Impact & Mitigation Pathway

Diagram Title: Catalyst Deactivation Diagnostic Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function/Application in Biomass-to-SAF Research |

|---|---|

| NREL Standard Biomass Analytical Methods (LAPs) | Provides the definitive, validated protocols for compositional analysis (e.g., carbohydrates, lignin, ash). Essential for quantifying feedstock variability. |

| Olivine Sand (Mg,Fe)₂SiO₄ | A common, low-cost in-bed catalyst for fluidized bed gasifiers. Can be doped with Ni or other metals to enhance tar cracking activity. |

| Nickel on Alumina Catalyst (Ni/Al₂O₃) | A benchmark catalyst for secondary tar reforming and the water-gas shift reaction. Used in fixed-bed reactors downstream of the gasifier. |

| Ceramic Hot Gas Filters (Candle Filters) | Critical for removing particulate matter (ash, char) from raw syngas before catalytic steps to prevent catalyst fouling. |

| ZnO Sorbents | Used in guard beds for sulfur removal (H₂S, COS) from syngas to protect sensitive Fischer-Tropsch and reforming catalysts from poisoning. |

| Isopropanol/Dry Ice Cold Trap | Standard setup for sampling and quantifying tar content in producer gas according to established "tar protocol" methods. |

| Micro-GC with TCD Detector | For rapid, online analysis of permanent gas composition (H₂, CO, CO₂, CH₄, N₂) from the gasifier outlet, enabling process control. |

Technical Support Center: Troubleshooting Biomass Gasification for SAF

Frequently Asked Questions (FAQs)

Q1: Why is there a sudden, severe increase in tar yield in my downdraft gasifier, leading to rapid filter clogging? A: This is commonly caused by a drop in the reactor's peak temperature below 800-850°C. Tar cracking reactions are highly temperature-sensitive. First, verify your temperature sensors are calibrated. Then, check:

- Feedstock Moisture: Excess moisture (>20% wet basis) consumes energy for evaporation, lowering gasification temperature. Pre-dry feedstock to 10-15% moisture.

- Air-to-Fuel Ratio: An overly high ratio can cool the oxidation zone, while a low ratio reduces energy generation. Re-optimize the equivalence ratio (ER) for your specific feedstock; typically, ER=0.25-0.35 is targeted.

- Feedstock Size/Grade: Large, uneven particles create channeling, leading to uneven temperatures and poor tar destruction.

Q2: Our GC-MS analysis shows a shift from lighter tars (like benzene, toluene) to heavier, more complex polycyclic aromatic hydrocarbons (PAHs like naphthalene, pyrene). What does this indicate? A: This shift indicates secondary tar formation occurring in your system. Lighter, primary tars formed in the pyrolysis zone are not being effectively cracked or reformed as they pass through the hot zone. Instead, they are undergoing polymerization and condensation reactions. This is a critical barrier for downstream SAF catalysts. The cause is typically insufficient residence time at high temperature or a cold spot in the reactor. Increase the hot zone length or insulate the reactor to ensure a consistent >800°C environment for gas/vapor.

Q3: During catalytic tar reforming for syngas conditioning, we observe rapid deactivation of our nickel-based catalyst. What are the likely mechanisms and solutions? A: Nickel catalysts deactivate via three primary mechanisms, identifiable by post-mortem analysis (XRD, TPO, SEM-EDS):

| Deactivation Mechanism | Primary Cause | Observable Consequence | Mitigation Strategy |

|---|---|---|---|

| Carbon Fouling (Coking) | Low steam-to-carbon ratio; Temp <700°C. | Black deposits, pressure drop increase. | Increase S/C ratio to >2.0; Operate reformer >750°C. |

| Sintering | Localized overheating (>850°C). | Loss of active surface area; visible catalyst agglomeration. | Improve heat distribution; use a promoter (e.g., MgO) to stabilize Ni particles. |

| Sulfur Poisoning | Sulfur in biomass (e.g., from certain grasses). | Irreversible chemisorption of H₂S. | Pre-clean syngas with ZnO guard beds; use sulfur-tolerant catalysts (e.g., Rh-based). |

Q4: What is the best protocol for quantitative tar sampling and analysis to ensure reproducible data for our techno-economic model? A: Adhere to the "Tar Protocol" (CEN/TS 15439). Key steps:

- Isokinetic Sampling: Use a heated probe and filter (200°C) to collect particulates and heavy tars.

- Cold Solvent Trapping: Pass the gas through a series of impinger bottles placed in an ice bath (0°C) containing a known volume of analytical-grade acetone or isopropanol.

- Sample Recovery: Rinse all sampling lines with the same solvent. Combine all washings.

- Analysis: Use GC-MS with an internal standard (e.g., deuterated naphthalene) for identification and quantification. For gravimetric tar, evaporate the solvent under nitrogen and weigh the residue.

Experimental Protocols

Protocol 1: Gravimetric Tar Yield Determination Objective: Quantify total condensable tar mass from a gasifier. Materials: Tar sampling train (heated probe/filter, impingers, pump, flow meter), ice bath, acetone, analytical balance, nitrogen purge line. Method:

- Pre-weigh the clean, dry impinger bottles.

- Assemble the train. Fill impingers 1-3 with 100 mL of chilled acetone. Maintain impingers at 0°C.

- Connect to sampling port. Start gas flow, ensuring isokinetic conditions. Sample a known gas volume (typically 1-2 Nm³).

- Stop sampling. Rinse the probe, filter holder, and connecting lines with acetone into the impinger contents.

- Carefully evaporate the acetone from the combined solvent under a gentle stream of nitrogen in a pre-weighed beaker, at a temperature not exceeding 40°C.

- Place the beaker in a desiccator to cool, then weigh. The mass difference is the gravimetric tar. Report as mg/Nm³.

Protocol 2: Accelerated Catalyst Deactivation Test Objective: Simulate long-term coking of a reforming catalyst. Materials: Fixed-bed micro-reactor, mass flow controllers, syringe pump, online GC, Ni/Al₂O₃ catalyst (60-80 mesh), steam generator. Method:

- Load 0.5 g catalyst in reactor. Reduce in 20% H₂/N₂ at 650°C for 2 hours.

- Set reactor to test temperature (e.g., 750°C). Introduce a model tar compound (e.g., 5,000 ppmv toluene in N₂) at a high space velocity (e.g., 15,000 h⁻¹) with a low steam-to-carbon ratio (S/C=1.0).

- Monitor toluene conversion via online GC every 15 minutes.

- Run until conversion drops to 50% of its initial steady-state value. Perform Temperature-Programmed Oxidation (TPO) on spent catalyst to characterize carbon type.

Mandatory Visualizations

Title: Tar Formation Reaction Pathways

Title: Tar Yield Troubleshooting Logic

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Tar Research |

|---|---|

| Model Tar Compounds (e.g., Toluene, Naphthalene) | Simplifies system complexity for fundamental catalytic reforming studies. |

| Internal Standards for GC-MS (e.g., d₈-Naphthalene, d₁₀-Phenanthrene) | Corrects for sample loss during preparation, enabling precise quantification. |

| Certified Gas Mixtures (e.g., 5% H₂S in N₂, 5000 ppm Toluene in N₂) | Calibrates analyzers and simulates poisoning/feed conditions. |

| Catalyst Precursors (e.g., Ni(NO₃)₂·6H₂O, (NH₄)₆H₂W₁₂O₄₀) | For synthesizing and promoting (e.g., with W) custom reforming catalysts. |

| Solvents for Tar Trapping (ACS Grade Acetone or Isopropanol) | High-purity solvents prevent contamination in tar sampling protocols. |

| Porous Support Materials (γ-Al₂O₃, ZrO₂, CeO₂ pellets/powder) | Provides high-surface-area support for active catalytic phases. |

Technical Support Center

Troubleshooting Guides

Issue 1: Rapid Catalyst Deactivation in Syngas Conditioning

- Problem: Catalyst activity drops sharply within hours during tar reforming or water-gas shift.

- Diagnosis: Likely due to alkali (e.g., KCl, NaCl) deposition or reaction with sulfur (H₂S, COS). Check for operating temperature below alkali dew point or insufficient sulfur guard bed capacity.

- Solution: Increase gas inlet temperature above the calculated alkali dew point (see Table 1). Verify and replace upstream sorbent beds (e.g., zinc oxide for sulfur). Implement a regular catalyst regeneration protocol with controlled air/steam cycles.

Issue 2: Corrosion and Salt Deposition in Downstream Heat Exchangers

- Problem: Metal corrosion and/or solid salt deposits observed in syngas coolers and piping.

- Diagnosis: Primarily caused by condensation of alkali chlorides (KCl, NaCl) and reactions involving HCl(g). Chlorine content in biomass >0.1 wt% significantly increases risk.

- Solution: Install a high-temperature particulate filter (>500°C) to remove alkali-laden particulates. Consider injection of a sorbent (e.g., kaolin) upstream to capture alkalis in the gas phase. For corrosion, ensure materials are upgraded to high-nickel alloys (e.g., Inconel 600) for critical sections.

Issue 3: High NOx Emissions During Syngas Combustion in Test Rigs

- Problem: Syngas flame produces unexpectedly high levels of NOx during combustion testing.

- Diagnosis: Fuel-bound nitrogen from biomass (protein content) converts to NH₃ and HCN in syngas. These species form "fuel-NOx" upon combustion.

- Solution: Optimize gasifier operating conditions (e.g., higher temperature, specific air/fuel ratio) to maximize conversion of fuel-N to N₂ instead of NH₃. Consider catalytic decomposition of NH₃ over a nickel or iron-based catalyst post-gasification.

Issue 4: Inaccurate Measurement of Trace Contaminant Concentrations

- Problem: Inconsistent or implausible readings for H₂S, HCl, or NH₃ concentrations.

- Diagnosis: Loss of analytes due to condensation or adsorption in sampling lines, or interference in analytical method (e.g., FTIR, GC).

- Solution: Heat entire sampling line to >250°C. Use inert, coated lines (SilcoTek). Implement a standardized calibration protocol using certified gas mixtures. For speciated analysis, use tandem methods (e.g., impinger trains followed by IC for Cl, N).

Frequently Asked Questions (FAQs)

Q1: What are the most critical trace contaminants for Fischer-Tropsch synthesis catalysts when producing SAF from syngas? A: Sulfur (H₂S, COS) is the primary poison for Co and Fe FT catalysts, with tolerance often <0.1 ppmv. Alkalis (K, Na) can also cause catalyst sintering and pore blockage. Chlorine (HCl) induces corrosion and can lead to catalyst volatility issues. A rigorous multi-stage cleaning train is essential.

Q2: What is a reliable method to continuously monitor ultra-low levels of H₂S in cleaned syngas? A: For continuous, real-time monitoring at ppbv levels, laser-based tunable diode laser absorption spectroscopy (TDLAS) is recommended. For discontinuous validation, use standardized wet chemistry methods (e.g., methylene blue method after adsorption on Cd(OH)₂).

Q3: How can I effectively remove HCl from raw syngas in a pilot-scale system? A: Dry sorption using fixed beds of sodium bicarbonate (NaHCO₃) or calcium carbonate (CaCO₃) at temperatures between 150-400°C is highly effective. Wet scrubbing with alkaline water (NaOH) is also common but generates wastewater.

Q4: Does biomass leaching (pre-treatment) effectively reduce all critical trace elements? A: Water leaching effectively removes water-soluble K, Cl, and some S. However, it is less effective for organically bound nitrogen and some refractory sulfur forms. It is a helpful pre-treatment but not a complete solution.

Q5: What analytical technique is best for quantifying different nitrogen species (NH₃, HCN, NOx) in syngas? A: Fourier Transform Infrared (FTIR) spectroscopy allows for real-time, simultaneous quantification of multiple gaseous species including NH₃, HCN, and HCNO. For absolute validation, isokinetic sampling through specific impinger solutions (e.g., H₂SO₄ for NH₃, NaOH for HCN) followed by ion chromatography or spectrophotometry is advised.

Data Presentation

Table 1: Key Trace Contaminants in Biomass-Derived Syngas and Their Impacts

| Contaminant Class | Typical Compounds | Concentration Range (Raw Syngas) | Primary Impact on SAF Synthesis | Tolerance Limit for FT Catalysts |

|---|---|---|---|---|

| Alkalis | KCl(g), NaCl(g), KOH(g) | 1 - 200 ppmv | Deposit on surfaces, catalyst deactivation, corrosion | <0.1 ppmv (varies) |

| Sulfur | H₂S, COS, CS₂ | 20 - 200 ppmv (H₂S) | Permanent catalyst poisoning | <0.1 - 1 ppmv |

| Chlorine | HCl(g), KCl(g), NaCl(g) | 10 - 1000 ppmv (HCl) | Corrosion, promotes alkali deposition, catalyst volatility | <0.1 ppmv |

| Nitrogen | NH₃, HCN, NOx | 500 - 5000 ppmv (NH₃) | Fuel-NOx emissions, potential catalyst nitridation | Not primary poison, but <100 ppmv common |

Table 2: Common Syngas Cleaning Technologies for Trace Contaminants

| Target Contaminant | Technology | Operating Principle & Typical Material | Efficiency | Temperature Range |

|---|---|---|---|---|

| Alkali Metals | High-Temp Filtration | Physical removal of alkali-laden particulates (Ceramic candle filter) | >99% (particulates) | 400 - 800°C |

| HCl & Sulfur | Dry Sorption | Chemical adsorption on solid sorbent (e.g., NaHCO₃, ZnO) | >95% | 150 - 400°C |

| H₂S (Bulk) | Wet Scrubbing | Absorption in liquid solvent (e.g., Amine-based, Selexol) | >99% | 20 - 60°C |

| NH₃ | Catalytic Decomposition | Thermal cracking over Ni-based catalyst | >90% | 700 - 900°C |

Experimental Protocols

Protocol 1: Determination of Alkali Metal Concentration in Syngas via Condensation Sampling

- Objective: Quantify gaseous alkali concentration (K, Na) in hot syngas.

- Equipment: Isokinetic sampling probe, electrically heated filter (>500°C), series of three condensation tubes (quartz), diaphragm pump, gas meter, temperature controllers.

- Procedure: a. Heat probe and filter to gas stream temperature (typically 500-700°C) to prevent early condensation. b. Maintain first condensation tube at 550°C, the second at 450°C, and the third at 350°C, creating a controlled temperature gradient. c. Draw a known volume of syngas (typically 50-100 L) through the system at a constant rate. d. Dissolve condensed deposits from each tube in a known volume of dilute nitric acid (2% v/v). e. Analyze solutions for K⁺ and Na⁺ using Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES). f. Calculate concentration based on total mass collected and total gas volume sampled.

Protocol 2: Evaluation of ZnO Sorbent for H₂S Removal in a Fixed-Bed Reactor

- Objective: Measure breakthrough capacity and efficiency of a ZnO sorbent.

- Equipment: Fixed-bed reactor (SS tube), mass flow controllers, 1000 ppmv H₂S in N₂ calibration gas, humidification system, online H₂S analyzer (e.g., TDLAS or electrochemical), furnace, ZnO sorbent pellets.

- Procedure: a. Pack reactor with a known mass (e.g., 5g) of ZnO sorbent between quartz wool plugs. b. Condition sorbent under N₂ flow at 350°C for 1 hour. c. Switch inlet gas to a simulated syngas mixture containing 200 ppmv H₂S, 20% H₂, 20% CO, 10% CO₂, balanced N₂, with 5% H₂O (steam added via saturator). Maintain Gas Hourly Space Velocity (GHSV) at 5000 h⁻¹. d. Continuously monitor H₂S concentration at reactor outlet until breakthrough (e.g., >1 ppmv H₂S). e. Calculate sulfur loading capacity of sorbent as grams of S captured per 100g of fresh sorbent.

Mandatory Visualization

Trace Contaminant Removal Path for SAF Syngas

Experimental Workflow for Contaminant Fate Analysis

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

| Item Name | Function/Brief Explanation | Typical Specification/Note |

|---|---|---|

| Zinc Oxide (ZnO) Sorbent Pellets | High-temperature removal of H₂S and COS via chemical adsorption to ZnS. | High surface area (>50 m²/g), often doped with promoters like CuO or MoO₃. |

| Sodium Bicarbonate (NaHCO₃) Powder | Dry sorbent for HCl removal via reaction to NaCl, CO₂, and H₂O. | Technical grade, finely ground for high reactivity. Can be injected as powder. |

| Kaolin (Al₂Si₂O₅(OH)₄) Clay | Additive to capture gaseous alkalis via reaction forming high-melting-point aluminosilicates. | Used as bed material or co-fed with biomass. |

| Certified Calibration Gas Mixtures | Essential for calibrating online analyzers (FTIR, GC, TDLAS). | Key mixtures: H₂S/N₂ (e.g., 100 ppmv), NH₃/N₂, HCl/N₂, COS/CO. |

| SilcoNert or SilcoTek Coated Sampling Lines | Heated, inert-coated tubing to prevent analyte loss via adsorption/condensation. | Coating ensures surface inertness for polar molecules like NH₃, HCl. |

| Quartz Wool & Frits | For packing sorbent beds, providing support and gas distribution in microreactors. | High-purity, annealed to prevent shedding. |

| Ceramic Candle Filter Elements | High-temperature particulate filtration to remove alkali-laden dust and soot. | Pore size 1-5 µm, capable of operation at 500-800°C. |

| Impingers & Absorption Solutions | For wet chemical sampling validation (e.g., H₂SO₄ for NH₃, Cd(OH)₂ for H₂S). | Used in a series (EPA Method 5 style) for quantitative capture. |

| Nickel-Based Catalyst (e.g., Ni/Al₂O₃) | For experimental studies on NH₃ decomposition or tar reforming. | Often pre-reduced (5-20% Ni load), sensitive to sulfur poisoning. |

Troubleshooting Guides & FAQs

FAQ 1: What are the primary ash-forming elements in biomass that contribute to slagging and fouling in gasifiers?

The primary problematic inorganic elements (ash-forming) vary by biomass feedstock but consistently involve alkali and alkaline earth metals (AAEM), silicon, and chlorine. Their interaction leads to deposit formation.

Table 1: Common Problematic Ash-Forming Elements in Biomass

| Element | Typical Source in Biomass | Primary Problem Caused | Common Form in Gasifier |

|---|---|---|---|

| Potassium (K) | Herbaceous crops (straw, grass), wood bark | Bed agglomeration, slagging, fouling | KCl(g), K₂SiO₃(l), K₂CO₃(l) |

| Sodium (Na) | Straw, manure, agricultural residues | Catalyzes ash melting, fouling | NaCl(g), Na₂SiO₃(l) |

| Calcium (Ca) | Wood, bark, straw, shells | Can mitigate slagging at low T, but contributes at high T | CaSiO₃, Ca₃(PO₄)₂, CaCO₃ |

| Silicon (Si) | Soil contamination, rice husk, straw | Forms low-melting silicates with K/Na | SiO₂ (quartz, cristobalite) |

| Chlorine (Cl) | Straw, grass, biomass from fertilized land | Volatilizes alkali metals, promotes corrosion | HCl(g), KCl(g), NaCl(g) |

| Phosphorus (P) | Agricultural residues, manure | Forms sticky phosphates with Ca/K | Ca₃(PO₄)₂, K-Ca phosphates |

FAQ 2: How can I predict the slagging and fouling propensity of a new biomass feedstock before pilot-scale gasification?

Use a combination of ash composition analysis, ash fusion tests, and empirical indices calculated from proximate/ultimate analysis.

Experimental Protocol: Feedstock Slagging & Fouling Propensity Assessment

Materials: Muffle furnace, crucibles, X-ray fluorescence (XRF) or Inductively Coupled Plasma (ICP) analyzer, ash fusion temperature (AFT) analyzer, scanning electron microscope with energy-dispersive X-ray spectroscopy (SEM-EDX).

Methodology:

- Prepare Ash Sample: Perform standard proximate analysis to determine ash content. Create laboratory ash by slow ashing the biomass at 550°C in a muffle furnace (following ASTM D1102).

- Quantify Ash Composition: Use XRF or ICP analysis on the laboratory ash to determine the concentration (wt.%) of key oxides (SiO₂, Al₂O₃, Fe₂O₃, CaO, MgO, K₂O, Na₂O, P₂O₅).

- Calculate Empirical Indices: Use composition data to calculate the following indices (summarized in Table 2).

- Determine Ash Fusion Temperatures (AFT): Using an AFT analyzer, determine the characteristic temperatures (Initial Deformation, Softening, Hemispherical, Fluid) under oxidizing and reducing atmospheres (critical for gasification).

- Microscopic Analysis: Use SEM-EDX on lab ash or deposits to identify morphology and elemental associations of early-forming sticky phases.

Table 2: Key Empirical Indices for Slagging/Fouling Prediction

| Index Name | Formula | Interpretation | Thresholds for Biomass |

|---|---|---|---|

| Base-to-Acid Ratio (B/A) | (Fe₂O₃ + CaO + MgO + K₂O + Na₂O) / (SiO₂ + Al₂O₃ + TiO₂) | Predicts slagging tendency. Higher B/A (>0.5) indicates higher slagging propensity. | Low: <0.5, High: >1.0 |

| Slagging Index (R_s) | B/A * %S (dry basis) | More comprehensive for biomass. | Low: <0.6, Medium: 0.6-2.0, High: 2.0-2.6, Severe: >2.6 |

| Fouling Index (R_f) | (B/A) * (Na₂O + K₂O) | Predicts convective pass fouling. | Low: <0.2, Medium: 0.2-0.5, High: 0.5-1.0, Severe: >1.0 |

| Bed Agglomeration Index (BAI) | (K₂O + Na₂O) / (SiO₂ + CaO) | High index (>1) suggests high risk of bed material coating and agglomeration in fluidized beds. | Low Risk: <0.15, High Risk: >0.4 |

FAQ 3: What are proven mitigation strategies for bed agglomeration in fluidized bed gasifiers?

Mitigation focuses on altering ash chemistry through feedstock blending, bed material selection, or additives.

Table 3: Bed Agglomeration Mitigation Strategies

| Strategy | Mechanism of Action | Experimental Protocol Consideration | Potential Drawback |

|---|---|---|---|

| Use High-Silica Bed Material (e.g., Olivine, Quartz Sand) | Silica reacts with sticky potassium silicates to form higher-melting K-Al-Si or K-Ca-Si phases. | In bench-scale FB reactor, compare agglomeration time for different bed materials at constant T (800-900°C). | May not prevent coating; can reduce gasification efficiency. |

| Additive Injection (Kaolin, Alumina, Bauxite) | Alumina (Al₂O₃) in additives captures potassium into high-melting K-Al silicates (e.g., KAlSi₃O₈). | Premix additive with fuel (1-5 wt.%) or inject into bed. Monitor pressure drop and analyze agglomerates with XRD. | Increases ash load; cost of additive. |

| Fuel Leaching/ Washing | Removes water-soluble K, Na, and Cl from fuel before gasification. | Soak biomass in water (25°C or 60°C) for 1-2 hours, then dry. Measure alkali reduction via ICP. | Energy-intensive drying; loss of organics. |

| Fuel Blending | Blend high-alkali fuel (straw) with low-alkali fuel (wood) to dilute problematic elements. | Conduct gasification trials with blends (e.g., 25:75, 50:50 straw:wood). Monitor bed temperature uniformity. | Requires secure supply of blending fuel. |

| Temperature Control | Operate below the initial melting point of the sticky ash phase. | Determine the sticky temperature of your fuel ash via advanced thermal analysis (e.g., TMA). | May conflict with tar cracking temperature requirements. |

FAQ 4: How do I diagnose the root cause of a specific slag deposit or agglomerate from my gasifier?

Follow a post-mortem analytical workflow to determine the chemical and physical mechanisms.

Experimental Protocol: Post-Mortem Ash Deposit Analysis

Workflow Diagram:

Title: Ash Deposit Diagnostic Analysis Workflow

Methodology:

- Sample Collection: Carefully extract deposits from the gasifier syngas cooler (fouling) or the bed (agglomerates). Note the precise location.

- Macroscopic Inspection: Photograph and document physical properties.

- Cross-Section Preparation: Embed sample in epoxy resin, cut, and polish to reveal internal layers.

- SEM-EDX Analysis: Examine the cross-section. Backscattered electron imaging shows phase contrast. Use EDX point analysis and elemental mapping to identify distributions of K, Na, Ca, Si, Al, Fe, Cl, P, S.

- XRD Analysis: Crush a portion of the deposit. Identify the crystalline compounds present (e.g., Sylvite-KCl, Arcanite-K₂SO₄, Silicates like KAlSi₃O₈).

- Synthesis: Correlate data. A layered structure suggests condensation/fouling. A melted, homogeneous structure suggests slagging. Cemented bed particles with a K-Si-rich coating indicate alkali-induced bed agglomeration.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Ash Behavior Experiments

| Item | Function / Purpose | Specific Application Example |

|---|---|---|

| Kaolin (Al₂Si₂O₅(OH)₄) | Alumina-rich additive to capture alkali metals. | Mitigation experiments for bed agglomeration in fluidized beds. |

| Olivine ((Mg,Fe)₂SiO₄) | High-silica, high-melting point bed material. | Alternative to quartz sand to study K-silicate reaction mechanisms. |

| Analytical Grade Ash Standards (e.g., NIST 1633b) | Calibration standards for XRF/ICP analysis. | Ensuring accuracy in quantitative ash composition analysis. |

| Platinum Crucibles | Inert, high-temperature resistant containers. | Ash fusion temperature tests and precise sample ashing for analysis. |

| Inert Alumina Bed Particles (α-Al₂O₃) | Chemically inert bed material for baseline studies. | Isolating the ash interaction effects of other bed materials (e.g., olivine). |

| Deionized Water | Leaching agent for pre-treatment. | Studying the effect of removing water-soluble alkalis from biomass. |

| High-Temperature Epoxy Resin | For mounting fragile ash/agglomerate samples. | Preparing cross-sections for SEM-EDX analysis without disturbing structure. |

| Certified Reference Biomass (e.g., from IEA Bioenergy Task 33) | Standardized fuel with known ash properties. | Inter-laboratory comparison and validation of experimental methods. |

Advanced Gasification & Conditioning Techniques for Clean Syngas Production

Technical Support Center: Troubleshooting & FAQs

This support center addresses common operational challenges in advanced gasification reactors for biomass-to-SAF research, framed within the thesis: Addressing technical barriers in biomass gasification for SAF research.

Frequently Asked Questions (FAQs)

Q1: In our Bubbling Fluidized Bed (BFB) gasifier, we are experiencing poor fluidization and channeling with high-ash biomass. What are the primary corrective actions? A1: Poor fluidization often stems from particle size and distribution issues.

- Action 1: Sieve your biomass feedstock to ensure a narrow particle size distribution (optimal range: 0.5-4 mm). Fines (<0.2 mm) can elutriate, while large particles (>6 mm) disrupt bubbles.

- Action 2: Pre-mix the biomass with bed material (e.g., silica sand, olivine) to improve heat transfer and break up agglomerates. A typical starting ratio is 1:3 (biomass:bed material) by volume.

- Action 3: Check your distributor plate design. Ensure nozzles are not clogged and the pressure drop across the plate (ΔP_dist) is sufficient (target: >15% of total bed pressure drop).

Q2: Our Circulating Fluidized Bed (CFB) system has excessive cyclone attrition and material loss. How can we mitigate this? A2: High attrition reduces catalyst/bed material lifetime and increases particulate loading.

- Check Gas Velocity: Superficial gas velocity in the riser should typically be 3-8 m/s. Velocities >10 m/s significantly increase attrition. Re-calibrate your flow controllers.

- Material Selection: Switch to more attrition-resistant bed materials. Consider using alumina (Al₂O₃) or dedicated high-strength catalyst supports instead of standard silica sand.

- Cyclone Inspection: Examine the cyclone interior for abrasion and ensure there are no air leaks, which can reduce separation efficiency.

Q3: In an Entrained Flow Gasifier (EFG) for biomass, we face persistent slagging and reactor wall fouling. What operational parameters should we adjust? A3: Slagging is related to the ash fusion characteristics and temperature.

- Adjust Ash Fusion Temperature (AFT): Incorporate an additive (e.g., kaolin, limestone) to raise the AFT. A typical dose is 2-5 wt% of biomass feed.

- Optimize Equivalence Ratio (ER): Slightly increase the ER (the ratio of actual air/fuel to stoichiometric air/fuel). This lowers the peak temperature, potentially keeping it below the ash softening point. Monitor syngas quality (H₂/CO ratio) as this adjustment will affect it.

- Biomass Pre-treatment: Use torrefied biomass, which typically has more favorable ash behavior and higher energy density.

Q4: Our Dual Fluidized Bed (DFB) system for steam gasification struggles to maintain stable temperature between the gasifier and combustor loops. A4: Temperature instability indicates an imbalance in the heat transfer mediated by the circulating bed material.

- Verify Circulation Rate: Use a dedicated solids flow meter or calculate from pressure loop data. Increase the circulation rate to transfer more heat from the combustor to the gasifier. A typical target circulation rate is 10-50 kg/m²s.

- Check Fuel Feed to Combustor: The auxiliary fuel (often char or gas) fed to the combustor must be precisely controlled to compensate for the endothermic gasification reactions. Implement a PID controller tied to the gasifier's bottom bed temperature (Target: 850-900°C).

- Seal Integrity: Ensure loop seals are fluidized correctly and are gas-tight to prevent cross-gas contamination, which disrupts reactions and heat balance.

Troubleshooting Guide: Common Issues & Protocols

Issue: Low Carbon Conversion & Syngas Yield

Probable Causes: Inadequate temperature, insufficient residence time, or poor gas-solid contact.

Diagnostic Protocol:

- Measure: Record exact bed/zone temperatures (minimum 3 points per reactor) using calibrated thermocouples.

- Analyze: Perform immediate gas analysis via online GC/MS for CO, CO₂, H₂, CH₄. Calculate carbon conversion efficiency: CCE = (Carbon in outlet gas / Carbon in inlet biomass) x 100%.

- Compare to Baseline: Use the following benchmark table for expected performance:

| Reactor Type | Typical Temp. Range (°C) | Expected CCE (Wood) | Optimal Steam/Biomass (S/B) Ratio |

|---|---|---|---|

| Bubbling FB | 750-900 | 85-95% | 0.6-1.0 |

| Circulating FB | 800-950 | 90-98% | 0.8-1.2 |

| Entrained Flow | >1200 | >99% | N/A (Uses O₂) |

| Dual FB (Steam) | 850-900 (Gasifier) | 95-99% | 1.5-2.5 |

Resolution Steps:

- If temperature is low, incrementally increase combustor fuel (DFB), air flow (BFB/CFB), or oxygen (EFG).

- If gas composition is off-target (e.g., high CO₂), adjust the S/B ratio or ER as per your experimental design matrix.

- For BFBs, consider adding/refreshing a catalytic bed material (e.g., olivine, dolomite).

Issue: Tar Fouling in Downstream Filters and Lines

Probable Causes: Gasification temperature too low, or reactor design does not facilitate in-situ tar cracking.

Mitigation Experiment Protocol: Objective: To evaluate the effectiveness of in-bed catalytic additives for primary tar reduction.

- Baseline Run: Gasify 5 kg of standard pine wood chips at your standard conditions (e.g., 850°C, S/B=1.0). Sample tar downstream using the solid-phase adsorption (SPA) method or cold trapping. Quantify gravimetrically or via GC.

- Catalytic Test Run: Load the reactor with 3 kg of olivine sand mixed with 10 wt% of a catalyst additive (e.g., dolomite, Ni-based catalyst). Repeat the gasification run under identical conditions.

- Analysis: Compare tar yields (g/Nm³) and composition. Calculate percentage reduction.

Experimental Protocols

Protocol 1: Determining Minimum Fluidization Velocity (Umf) for a Novel Biomass Feedstock Purpose: Essential for BFB/CFB design and scaling. Method:

- Fill a cold-flow transparent column with a known mass (M) of inert bed material.

- Introduce gas (air/N₂) at the bottom at a very low flow rate. Gradually increase flow in small increments.

- Record pressure drop (ΔP) across the bed vs. superficial gas velocity (U).

- Umf is identified as the velocity where the ΔP curve deviates from linearity and becomes constant. Plot ΔP vs. U.

- Repeat with a mixture of bed material and 5-10% of your biomass.

Protocol 2: Standard Syngas Sampling and Analysis for Tar/NAPC Purpose: To obtain reproducible data on gas composition and contaminant levels. Method:

- Sampling Point: Use a heated probe (>300°C) and line to sample from the reactor outlet.

- Particulate Removal: Pass gas through a series of heated glass-fiber filters.

- Tar Sampling: Use the SPA method: draw a known volume of gas (1-5 Nl) through a packed cartridge of amino-silicate adsorbent.

- Gas Analysis: Direct a stream to an online micro-GC for permanent gases (H₂, CO, CO₂, CH₄, C₂H₄, N₂).

- Tar Analysis: Elute the SPA cartridge with dichloromethane. Analyze the solution using GC-MS. Quantify major tar species (e.g., toluene, naphthalene, phenol) against calibration standards.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Biomass Gasification SAF Research |

|---|---|

| Olivine ((Mg,Fe)₂SiO₄) | Common natural bed material; exhibits mild catalytic activity for tar cracking. |

| Dolomite (CaMg(CO₃)₂) | Inexpensive in-bed catalyst; catalyzes tar reforming and water-gas shift reactions. |

| Nickel-Based Catalyst | High-activity reforming catalyst for tar removal and syngas adjustment; used in secondary reactors or coated on bed materials. |

| Kaolin Clay | Additive to modify biomass ash behavior, raising ash fusion temperature and reducing slagging. |

| Silica Sand (SiO₂) | Inert bed material for fluidization; provides heat transfer and mixing. |

| Torrefied Biomass | Pre-treated feedstock; more hydrophobic, grindable, and energy-dense than raw biomass, improving feeding and conversion. |

| Calcium Oxide (CaO) | Sorbent for in-situ CO₂ capture (sorption-enhanced gasification), shifting equilibrium for higher H₂ yield. |

System Workflow & Logical Diagrams

Technical Support Center

Troubleshooting Guides

Issue 1: Rapid Tar Deposition & Reactor Fouling During High-Temperature Runs

- Observed Problem: Excessive, sticky tar condensation in downstream pipes and filters shortly after increasing gasifier temperature beyond 850°C.

- Root Cause Analysis: While high temperature (>900°C) favors thermal cracking, an excessively high heating rate of biomass can cause rapid devolatilization, producing unstable intermediate tar compounds that re-polymerize before being fully cracked.

- Solution Protocol:

- Step 1: Immediately reduce the setpoint temperature by 50°C.

- Step 2: Gradually ramp temperature (increase by 25°C/hr) to the target (e.g., 900°C) to allow steady-state conditions to stabilize.

- Step 3: Verify that the Equivalence Ratio (ER) is simultaneously adjusted upward (increase by 0.02 increments) to provide the necessary oxidant for tar oxidation.

- Preventive Measure: Ensure feedstock moisture content is below 15% wt. to avoid heat sink effects that create local cold zones.

Issue 2: Inconsistent Tar Yield Measurements at Varying Equivalence Ratios

- Observed Problem: Tar sampling results show high variability when ER is adjusted, making optimization trends unclear.

- Root Cause Analysis: Inadequate stabilization of the gasifier's fluidization dynamics after an ER change. Tar sampling was initiated before achieving new chemical equilibrium.

- Solution Protocol:

- Step 1: After any ER adjustment, hold the new condition for a minimum of 3-4 times the solid's nominal residence time (e.g., if residence time is 2 seconds, wait 8 seconds).

- Step 2: Use a standardized tar sampling protocol (e.g., based on CEN/TS 15439) with isokinetic probes.

- Step 3: Perform at least three sequential tar samples, each over a 30-minute period, to confirm steady-state operation before recording data.

Issue 3: Insufficient Tar Reduction Despite Long Nominal Residence Time

- Observed Problem: Extended calculated gas residence time in the hot zone does not yield expected reductions in gravimetric tar concentration.

- Root Cause Analysis: Poor mixing and channeling within the reactor create a wide actual residence time distribution (RTD). A significant portion of gas bypasses the high-temperature catalytic zones.

- Solution Protocol:

- Step 1: Conduct a tracer gas study (e.g., using helium pulse injection) to measure the actual RTD.

- Step 2: If channeling is confirmed, modify the gas distributor design or introduce staged gas injection to improve mixing.

- Step 3: Consider adding inert bed materials (e.g., olivine, alumina) to enhance radial heat transfer and disrupt flow channels.

Frequently Asked Questions (FAQs)

Q1: What is the single most influential operating parameter for primary tar reduction? A: Temperature is the dominant parameter. Tar destruction kinetics are highly temperature-dependent. Below 800°C, reforming reactions are slow; the 800-950°C range is critical for significant thermal and catalytic cracking.

Q2: How do Temperature and ER interact, and how should I optimize them jointly? A: Temperature and ER have a strong, non-linear interaction. High temperature with low ER can lead to soot. High ER at moderate temperature can quench reactions. Optimization requires a response surface methodology. See Table 1 for quantitative interplay.

Q3: My goal is to maximize H₂ and CO for downstream synthesis (like SAF). Should I just maximize temperature and ER? A: No. Excessive ER leads to complete combustion, diluting syngas with CO₂ and H₂O. The target is typically a "partial oxidation" regime. An optimal window exists (e.g., 850-900°C, ER 0.25-0.35) that maximizes useful syngas yield while minimizing tars. See Table 2.

Q4: Is there a minimum residence time required for effective tar cracking? A: Yes, but it is temperature-dependent. At 750°C, residence times of >2 seconds may be needed for significant cracking. At 900°C, effective cracking can occur in 0.5-1.0 seconds, provided mixing is efficient.

Q5: What are the best online methods for tar monitoring during parameter optimization? A: While offline gravimetric analysis is the standard, online techniques include:

- Micro-GC/PID: For light tar species (e.g., benzene, toluene).

- FTIR Spectroscopy: Can track functional groups and specific gases indicative of cracking.

- Photoionization Detection (PID): Provides a real-time total tar indicator but is non-speciated.

Data Presentation

Table 1: Interaction of Temperature and ER on Tar Yield (Wood Pellet Gasification)

| Temperature (°C) | Equivalence Ratio (ER) | Gravimetric Tar (g/Nm³) | Major Tar Class Identified |

|---|---|---|---|

| 750 | 0.20 | 35.2 | Heterocyclic (Phenols) |

| 750 | 0.30 | 28.5 | Phenolic Ethers |

| 850 | 0.20 | 12.1 | Aromatic (Alkyl-PAHs) |

| 850 | 0.30 | 6.8 | Light Aromatics (BTX) |

| 850 | 0.40 | 3.5 | Naphthalene |

| 950 | 0.30 | 1.2 | Naphthalene & Smaller |

| 950 | 0.40 | 0.7 | Trace PAHs |

Table 2: Optimized Parameter Windows for Different Gasification Objectives

| Research Objective | Priority Order (Param 1 > 2 > 3) | Recommended Window | Expected Tar Concentration |

|---|---|---|---|

| Maximize Syngas for SAF | T > ER > τ | T: 850-900°C, ER: 0.25-0.35 | 5 - 10 g/Nm³ |

| Minimize Tar for Engine Use | ER > T > τ | T: 900-950°C, ER: 0.30-0.40 | < 2 g/Nm³ |

| Fast Screening of Catalysts | τ > T > ER | T: 850°C, ER: 0.25, τ: 1.0s | Baseline ~15 g/Nm³ |

Experimental Protocols

Protocol 1: Determining the Minimum Cracking Temperature for a Feedstock

- Setup: Operate a lab-scale fluidized bed gasifier with an electrically heated freeboard/cracking zone.

- Stabilization: Fix ER at 0.25 and residence time at 1.5 seconds. Stabilize gasifier bed at 750°C.

- Sampling: Use a heated probe and a standardized tar absorption train (e.g., in isopropanol) to collect tar for 30 minutes.

- Variation: Incrementally increase the freeboard temperature to 775, 800, 825, and 850°C, holding each for 45 minutes before sampling.

- Analysis: Quantify gravimetric tar and analyze composition via GC-MS. The temperature at which tar yield shows a steep decline (e.g., >30% reduction) is the minimum effective cracking temperature.

Protocol 2: Mapping the T-ER Response Surface for Tar Yield

- Design: Implement a Central Composite Design (CCD) with Temperature (T) and Equivalence Ratio (ER) as factors. Residence time is held constant via gas flow control.

- Points: Experiment at 5 levels of T (e.g., 800, 825, 850, 875, 900°C) and 5 levels of ER (e.g., 0.20, 0.25, 0.30, 0.35, 0.40).

- Execution: For each of the 13 experimental runs, allow 1 hour for full system stabilization after parameters are set.

- Replication: Perform each center point (850°C, ER=0.30) in triplicate to estimate experimental error.

- Output: Model gravimetric tar concentration as a quadratic function of T and ER to find the saddle point or minimum.

Mandatory Visualizations

The Scientist's Toolkit

Research Reagent & Material Solutions for Tar Analysis

| Item | Function/Description | Key Consideration for SAF Research |

|---|---|---|

| Isopropanol (IPA), HPLC Grade | Solvent in tar absorption trains for cold trapping of heavy tars. | Low water content prevents tar dissolution issues; suitable for subsequent GC-MS analysis. |

| Gas Sampling Bags (Tedlar) | Collection of permanent gas samples for offline GC analysis of H₂, CO, CO₂, CH₄. | Must be properly cleaned and tested for leaks to avoid contamination affecting ER calculation. |

| Solid Sorbent Tubes (XAD-2/XAD-4 Resin) | Adsorption of medium-to-heavy tar compounds from hot gas streams for speciation. | Requires careful thermal desorption or solvent extraction protocol for quantitative recovery. |

| Internal Standards (e.g., Deuterated Naphthalene-d₁₀) | Added to tar samples prior to analysis for quantification via GC-MS. | Corrects for losses during sample workup; critical for accurate, reproducible tar yields. |

| Olivine or Dolomite Bed Material | Inexpensive, naturally occurring catalyst for in-bed tar cracking. | Can be pre-calcined to enhance activity; attrition resistance is key for fluidized beds. |

| Calibrated Gas Mixtures (H₂/CO/CO₂/CH₄/N₂) | Calibration of online micro-GC or gas analyzers for precise syngas composition. | Accuracy here directly impacts the calculated Equivalence Ratio (ER) and carbon balance. |

| Heated Transfer Lines & Filters | Maintain gas temperature >350°C to prevent tar condensation before measurement. | Temperature control is vital; cold spots cause tar loss and erroneous concentration data. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Our experimental setup for thermal tar cracking shows rapid coke deposition on reactor walls and outlet pipes, leading to pressure drops and inconsistent product gas composition. What are the primary causes and corrective actions?

A1: Rapid coking is typically due to localized cold spots, excessive tar concentration, or suboptimal temperature profiles.

Primary Causes:

- Temperature Gradient: Wall temperatures significantly lower than the set point in the center.

- Residence Time: Too long, allowing for polymerization reactions.

- Tar Feed Concentration: Exceeding the cracking capacity of the thermal zone.

Corrective Protocol:

- Validate Temperature Profile: Calibrate all thermocouples. Perform an empty reactor temperature mapping experiment from 800°C to 1100°C in 50°C increments.

- Increase Wall Insulation: Upgrade to high-alumina ceramic fiber insulation.

- Modify Operational Parameters: Based on mapping, increase set point to compensate for cold walls. Reduce tar-laden gas flow rate to decrease residence time and lower partial pressure of tars. Introduce a pre-dilution stream with inert gas (N₂).

- Implement a Soot Blower Protocol: For tubular reactors, schedule periodic N₂ purges at high velocity (10-15 m/s) every 30-60 minutes.

Q2: During catalytic reforming experiments with nickel-based catalysts, we observe severe sintering and deactivation within the first 12 hours, contrary to the reported 100-hour stability. What step-by-step diagnostic should we follow?

A2: This indicates accelerated aging, often from thermal or chemical shock.

- Diagnostic Protocol:

- Pre-Treatment Audit: Verify your reduction procedure. A controlled reduction in 10% H₂/N₂ at 5°C/min to 600°C, held for 2 hours, is critical. Rapid heating or direct exposure to reactive atmosphere can sinter nanoparticles.

- Analyze Feed Gases: Use a gas analyzer to check for trace contaminants (H₂S, HCl, AsH₃) in both your tar-simulant stream and reformulating agents (steam, CO₂). Even 1-2 ppm can poison active sites.

- Check for Carbon Whisker Formation: This is a sign of overly reducing conditions. Perform a post-mortem SEM analysis of the catalyst. If confirmed, increase the steam-to-carbon (S/C) ratio from a typical 1.5 to 2.5-3.0.

- Monitor Bed Temperature: Use an axial thermocouple array. A sharp, moving hotspot (>50°C above set point) indicates runaway exothermic reactions (e.g., methanation), leading to local sintering. Dilute the catalyst bed with inert α-alumina rings.

Q3: The conversion efficiency for model tar compounds (e.g., toluene, naphthalene) in our lab-scale reformer does not scale linearly when switching to real producer gas from a fluidized bed gasifier. What key factors are we missing?

A3: Real producer gas introduces complexity not captured by model compounds.

- Key Factors & Experimental Adjustment:

- Radical & Aerosol Presence: Real gas contains reactive radicals and tar aerosols that foul catalyst pores. Protocol: Install an aerosol electrostatic precipitator or a hot ceramic filter (350-400°C) upstream of your catalytic reformer.

- Broad Tar Spectrum: Heavy tars (pyrene, chrysene) deactivate catalysts differently than light tars. Protocol: Perform detailed tar sampling and analysis (e.g., GC-MS following the Solid Phase Adsorption (SPA) method) both before and after your reformer to identify the recalcitrant species.

- Alkali & Particulate Carryover: These can physically block catalyst pores. Protocol: Quantify particulate loading. If >5 g/Nm³, consider a robust guard bed of inexpensive dolomite or olivine before the primary catalyst.

Q4: We are getting conflicting results for tar conversion efficiency when comparing online NDIR gas analysis versus offline GC-TCD/FID. Which is more reliable and what is the proper calibration method?

A4: For tar reforming, offline GC is the benchmark. NDIR can be used for trend monitoring but requires careful calibration.

- Reliability & Calibration Protocol:

- GC (Benchmark): Calibrate using certified standard gas mixtures for permanent gases (H₂, CO, CO₂, CH₄, C₂H₄, C₂H₆) and liquid injection for tar compounds. Use internal standards (e.g., deuterated toluene) for quantitative tar analysis.

- NDIR (For CO/CO₂/CH₄):

- Cross-Interference Correction: CO and CO₂ sensors interfere with each other. Protocol: Use a 4-point calibration with zeros and spans in these combinations: (1) N₂ zero, (2) High CO in N₂, (3) High CO₂ in N₂, (4) A mixture of moderate CO and CO₂. Apply manufacturer's correction algorithms.

- Pressure & Water Vapor Compensation: Always use the same sampling line pressure and install a maintained condenser (4°C) and desiccant tube upstream of the NDIR analyzer.

- Recommended Workflow: Use NDIR for real-time process control. Validate its readings at least every 4 hours by taking a grab sample for offline GC analysis.

Data Presentation

Table 1: Comparison of Catalytic Performance for Naphthalene Reforming (Model Tar)

| Catalyst Type | Temperature (°C) | S/C Ratio | GHSV (h⁻¹) | Initial Conv. (%) | Deactivation Rate (%/h) | Key Deactivation Mode |

|---|---|---|---|---|---|---|

| Ni/γ-Al₂O₃ | 850 | 2.0 | 10,000 | 99.5 | 0.8 | Coke Whiskers |

| Ni-olivine | 900 | 1.5 | 8,000 | 98.2 | 0.2 | Attrition |

| Rh/CeO₂-ZrO₂ | 800 | 1.0 | 15,000 | 99.8 | 0.05 | Sintering |

| Natural Dolomite | 900 | 2.5 | 5,000 | 92.0 | 1.5 | Fragmentation |

Table 2: Thermal Cracking Efficiency for Major Tar Classes at 1100°C, 2s Residence Time

| Tar Class | Example Compound | Avg. Conv. in N₂ (%) | Avg. Conv. in H₂O/CO₂ (%) | Primary Cracked Products |

|---|---|---|---|---|

| Heterocyclic | Benzofuran | 87 | 94 | CO, C₂H₄, C₆H₆ |

| Light Aromatic | Toluene | 76 | 89 | H₂, CH₄, C₂H₂ |

| Heavy PAH | Pyrene | 65 | 82 | Soot, H₂, C₂H₂ |

| Phenolic | m-Cresol | 94 | 98 | CO, CH₄, C₆H₆ |

Experimental Protocols

Protocol 1: Catalyst Activity & Stability Test for Tar Reforming

- Catalyst Preparation: Sieve catalyst to 300-500 µm. Load 0.5 g diluted 1:3 with SiC into a quartz fixed-bed reactor (ID: 10 mm).

- In-situ Reduction: Purge with N₂ (100 mL/min). Heat to 600°C at 5°C/min under 10% H₂/N₂ (100 mL/min). Hold for 2 hours.

- Feed Introduction: Cool to reaction temperature (e.g., 800°C) under N₂. Switch to simulated feed gas: 5 g/Nm³ naphthalene (vaporized), 15% H₂O (via saturator), 15% CO₂, balance N₂. Adjust total flow for desired GHSV (e.g., 10,000 h⁻¹).

- Analysis: Monitor effluent gas hourly via online micro-GC for H₂, CO, CO₂, CH₄, C₂s. Collect tar samples via SPA every 4 hours for offline GC-MS.

- Duration: Run for 24-100 hours. Calculate conversion and deactivation rate.

Protocol 2: Two-Stage Thermal-Catalytic Tar Destruction

- Setup: Configure a sequential reactor system. First reactor is an empty alumina tube (thermal zone). Second is the catalytic bed.

- Thermal Stage: Maintain first reactor at 1000-1200°C. Feed real or simulated producer gas.

- Sampling Point A: Use a heated line (350°C) to sample gas/tars between reactors for analysis (SPA + GC).

- Catalytic Stage: Direct effluent into second reactor containing a noble metal catalyst (e.g., 1% Pt/Al₂O₃) at 750-850°C.

- Sampling Point B: Sample final effluent.

- Data Correlation: Correlate the composition of intermediate tars from Point A with final conversion efficiency and catalyst lifetime at Point B.

Mandatory Visualization

Diagram Title: Two-Stage Tar Destruction Process Flow

Diagram Title: Primary Pathways of Catalyst Deactivation in Tar Reforming

The Scientist's Toolkit

Table 3: Research Reagent Solutions for Tar Cracking Experiments

| Item / Reagent | Function & Rationale | Key Specification / Note |

|---|---|---|

| Naphthalene (Certified Standard) | Model heavy tar compound. High stability allows for reproducible cracking/reforming kinetics studies. | >99.9% purity. Use in a dedicated vaporizer maintained 10°C above its melting point. |

| Toluene-d8 (Deuterated Toluene) | Internal standard for quantitative GC-MS tar analysis. Distinguishes feed from products. | 99.5 atom % D. Add to SPA sampling train prior to collection. |

| Certified Calibration Gas Mixture | For accurate quantification of H₂, CO, CO₂, CH₄, C₂H₄, C₂H₆ via GC-TCD/FID. | Balance gas should match carrier (usually N₂ or Ar). Include 5-6 component levels. |

| SPA (Solid Phase Adsorption) Cartridges | Quantitative sampling of tar compounds from hot, humid gas streams without condensation loss. | Packed with amino-silica sorbent. Requires subsequent dichloromethane (DCM) elution for analysis. |

| γ-Al₂O₃ Support (High Surface Area) | Common catalyst support. Provides high dispersion for active metals (Ni, Pt). | BET >150 m²/g, pore volume >0.5 cm³/g. Pre-calcine at 600°C for 4h before impregnation. |

| Nickel(II) Nitrate Hexahydrate | Precursor for Ni-based catalysts via wet impregnation. High solubility and clean decomposition. | ACS reagent grade. Calcination post-impregnation must be slow (<1°C/min) to 500°C to prevent explosion. |

| Silicon Carbide (SiC) Grit | Inert diluent for fixed catalyst beds. Improves heat distribution and reduces pressure drop. | 500-700 µm mesh. Pre-wash with HNO₃ to remove metal impurities. |

| Steam Generator | Provides precisely controlled steam for steam reforming (S/C ratio) experiments. | Must use HPLC-grade water to prevent mineral deposition. Mass flow controller for carrier gas (N₂). |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Why is there a rapid and unacceptable pressure drop increase across our sintered metal filter candle during tar and particulate filtration? A: This is typically caused by the condensation of heavy tars (e.g., pyrene, chrysene) on the filter surface and within the pore structure, creating a viscous, blocking layer. Ensure your upstream operations maintain the filter temperature at least 20-30°C above the dew point of the heaviest tar compounds present. Check for temperature fluctuations or cold spots in the filter housing. A temporary mitigation is a controlled, in-situ regeneration by injecting a hot inert gas (N2) at 500-550°C, if the filter material allows.

Q2: Our wet electrostatic precipitator (WESP) shows poor tar aerosol removal efficiency after the venturi scrubber. What could be the cause? A: The likely issue is inadequate aerosol conditioning. The venturi scrubber must reduce the aerosol particle size to below 2.5 µm and ensure sufficient charge conditioning for the WESP to be effective. Verify the pressure drop across the venturi is maintained consistently (see Table 1). Also, check the conductivity and pH of the scrubbing liquid; poor conductivity can hinder charge dissipation on the collector plates.

Q3: Our zinc oxide (ZnO) guard bed for H2S removal is exhausting (saturating) much faster than the theoretical sulfur capacity calculated. Why? A: This is a common issue in biomass-derived syngas. The likely culprits are chloride species (e.g., HCl, alkali chlorides) or heavy metals (e.g., As, Pb) which poison the ZnO sorbent by forming stable compounds (e.g., ZnCl2) or blocking pores. Ensure upstream chloride scrubbing (e.g., with a Na2CO3 wash) is operating at >99% efficiency. Pre-filtration to sub-micron levels is also critical to reduce heavy metal vapor poisoning.

Q4: We observe carryover of scrubbing solution droplets into our downstream sorption beds, damaging the sorbent. How can we prevent this? A: Install a properly sized demister (mist eliminator) pad, preferably made of polypropylene or PTFE for chemical resistance, immediately after the scrubber vessel. Ensure the gas velocity through the demister is within the manufacturer's specified range (typically 2-5 m/s). A horizontal knockout drum with a change in flow direction before the sorbent beds can provide additional protection.

Q5: Our activated carbon bed for mercury removal shows variable efficiency. What operational parameters are most critical? A: Syngas composition significantly impacts Hg adsorption on activated carbon. The presence of H2S can enhance capture (forming HgS), while NO and SO2 can compete for sites. Ensure the bed temperature is stable between 40-80°C. Monitor the chlorine content in the syngas, as it affects Hg speciation. Most importantly, use a carbon specifically impregnated with sulfur or iodine for reliable Hg capture in reducing gas environments.

Table 1: Performance Benchmarks for Key Syngas Cleaning Units

| Cleaning Unit | Target Impurities | Key Operational Parameter | Typical Efficiency | Pressure Drop |

|---|---|---|---|---|

| Sintered Metal Filter | Soot, Ash, Tar Mist | Temperature: 350-500°C | >99.9% (particulates >1µm) | 50-150 mbar (clean) |

| Venturi Scrubber | Tar Aerosols, Alkali Salts | ∆P: 20-50 mbar | 90-99% (aerosols >3µm) | 20-50 mbar |

| Wet ESP | Sub-micron Tar Aerosols | Voltage: 15-50 kV | >95% (aerosols 0.1-2µm) | 5-15 mbar |

| NaOH Packed Bed Scrubber | HCl, H2S (partial), CO2 | pH of recirc. liquid: >10 | >99.9% (HCl) | 10-30 mbar/m |

| ZnO Sorbent Bed | H2S, COS | Temp: 200-400°C | <0.1 ppmv H2S out | 20-50 mbar/m |

| S-Impregnated Activated Carbon | Hg, AsH3 | Space Velocity: 1000-2000 h⁻¹ | >90% Hg removal | 10-30 mbar/m |

Table 2: Common Sorbent Characteristics & Lifespan Indicators

| Sorbent Type | Primary Function | Typical Saturation Capacity | Common Exhaustion Indicator |

|---|---|---|---|

| ZnO Pellets | H2S Removal | 0.2-0.3 g S/g ZnO | H2S breakthrough >0.1 ppmv |

| Activated Carbon (S-imp.) | Hg Removal | 1-10 mg Hg/g C | Hg breakthrough >0.01 µg/m³ |

| Na-Aluminate Based | Chloride Guard | 0.5-1.0 g Cl⁻/g sorbent | Cl⁻ in effluent gas |

| Zeolite 13X | CO2, H2O (pre- cleaning) | 0.2 kg CO2/kg sorbent | Temp. swing regen. frequency |

Experimental Protocols

Protocol 1: Determination of Tar Dew Point in Syngas for Filter Temperature Setting

- Principle: Sample syngas is cooled at a controlled rate until condensation is observed.

- Method: Draw a representative, filtered (hot) syngas sample through a temperature-controlled, glass-lined condenser. Gradually decrease the temperature from 400°C at a rate of 2°C/minute.

- Measurement: Use a laser-based obscuration sensor or visual inspection via a boroscope to detect the first onset of aerosol formation.

- Calculation: Record the temperature at which a sustained 5% increase in light obscuration occurs. Set the operating temperature of the primary filter at least 30°C above this recorded dew point.

Protocol 2: Bench-Scale Breakthrough Test for H2S Sorbent Capacity

- Setup: Pack a quartz tube (ID = 2 cm) with 50 g of test sorbent (e.g., ZnO). Place in a tubular furnace.

- Gas Mix: Create a simulated syngas blend with 1000 ppmv H2S, 20% H2, 20% CO, 10% CO2, balanced N2.

- Procedure: Heat the bed to 350°C under N2. Switch to the test gas mixture at a fixed flow rate (e.g., 1 L/min, GHSV ≈ 2000 h⁻¹).

- Analysis: Monitor the outlet H2S concentration continuously with an NDIR or electrochemical sensor.

- Endpoint: The sorbent is considered exhausted at H2S breakthrough >1 ppmv. Calculate sulfur capacity: (Total S fed until breakthrough) / (Mass of sorbent).

Mandatory Visualizations

Title: Syngas Cleaning Train Process Flow Diagram

Title: Troubleshooting Filter Pressure Drop Increase

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Syngas Cleaning Experiments

| Item | Function & Specification | Typical Use Case |

|---|---|---|

| Sintered Metal Filter Candles (316L SS) | High-temperature particulate filtration. Pore size: 5-20 µm. | Hot gas filtration of char and soot. |

| ZnO-Based Sorbent Pellets (High Purity) | Chemisorption of H2S and COS to form ZnS. | Deep desulfurization guard bed. |

| Sulfur-Impregnated Activated Carbon | Physisorption/Chemisorption of Hg vapor and arsine. | Trace heavy metal removal. |

| Sodium Carbonate (Na2CO3) Scrub Solution | Alkaline scrubbing for acidic gases (HCl, H2S, CO2). | Primary acid gas removal. |

| Demister Pad (PP or PTFE) | Coalescence and separation of entrained liquid droplets. | Protecting sorbent beds from moisture. |

| Online NDIR Gas Analyzer | Real-time measurement of CO, CO2, CH4. | Process monitoring and mass balance. |

| Electrochemical H2S Sensor | Low-ppmv level detection of hydrogen sulfide. | Sorbent breakthrough testing. |

| Tar Sampling Train (Solid Phase Adsorption) | Quantitative collection of tar compounds per ASTM D7709. | Tar dew point and composition analysis. |

Technical Support Center: Troubleshooting & FAQs for Biomass-to-SAF Research

This technical support center provides targeted guidance for researchers and scientists addressing the water-gas-shift (WGS) reaction's critical function in tuning the H₂/CO ratio for downstream Fischer-Tropsch Synthesis (FTS) within biomass gasification pathways for Sustainable Aviation Fuel (SAF) production.

Frequently Asked Questions (FAQs)

Q1: Our biomass-derived syngas consistently shows a H₂/CO ratio below 0.7, which is too low for conventional Co-based FTS. Should we prioritize the high-temperature (HT) or low-temperature (LT) WGS reaction? A: The choice depends on your syngas composition and system constraints. Use HT-WGS (Fe-Cr or Fe-Cr-Cu catalysts, 310-450°C) if your syngas contains significant CO (e.g., >15%) and you need rapid adjustment. Use LT-WGS (Cu-Zn-Al catalysts, 180-250°C) for finer control near equilibrium when CO concentration is lower (<10%) and you require a higher final H₂/CO ratio (>2.0). LT-WGS is more sensitive to poisoning.

Q2: We observe rapid deactivation of our Cu-based LT-WGS catalyst. What are the most likely causes and solutions? A: In biomass syngas, common causes are:

- Sulfur Poisoning: Trace H₂S from biomass. Solution: Implement robust pre-cleaning (ZnO guard beds) to reduce H₂S to <0.1 ppm.

- Chloride Poisoning: From biomass like MSW or agricultural residues. Solution: Use alkaline scrubbers for syngas conditioning.

- Thermal Sintering: From poor temperature control or hotspot formation. Solution: Ensure excellent heat dissipation and use catalysts with thermal stabilizers (e.g., Al₂O₃).

Q3: During integrated WGS-FTS operation, our FTS catalyst shows unexpected methane selectivity. Is the WGS reactor a potential contributor? A: Yes. If the WGS catalyst is not selective, it can facilitate side methanation reactions (CO + 3H₂ → CH₄), especially over Ni-containing catalysts sometimes found in HT-WGS formulations. Verify your WGS catalyst's methanation activity data. Consider switching to a more selective formulation or introducing a guard layer to trap trace elements that promote methanation.

Q4: How do we accurately model and predict the required WGS conversion to achieve a target H₂/CO ratio for our specific biomass feedstock? A: You must perform a mass balance based on your gasifier's syngas composition. The key relationship is defined by the WGS equilibrium constant: K_eq = [H₂][CO₂] / [CO][H₂O]. Use the following protocol to calculate the needed shift.

Experimental Protocol: Determining Required WGS Conversion for Target H₂/CO Ratio

Objective: To calculate the extent of WGS reaction required to achieve a specific H₂/CO ratio for FTS from a known biomass syngas composition.

Materials:

- Gas Chromatograph (GC) with TCD detector and appropriate columns (e.g., ShinCarbon, MolSieve).

- Syngas sampling system with moisture traps and filters.

- Process simulation software (Aspen Plus, ChemCAD) or equilibrium constant data.

Methodology:

- Characterize Raw Syngas: Take a minimum of three representative samples from your gasifier's output after primary cleaning (tar removal). Analyze for H₂, CO, CO₂, CH₄, and N₂ (internal standard) using GC. Quantify H₂O content via a calibrated moisture sensor or psychrometric data.

- Define Target Ratio: Set your desired FTS feed ratio (e.g., H₂/CO = 2.0 for Co catalysts).

- Perform Equilibrium Calculation:

- Let

xbe the moles of CO converted per mole of dry syngas feed. - The WGS reaction is: CO + H₂O ⇌ CO₂ + H₂.

- Component molar flows after WGS:

- H₂out = H₂in + x

- COout = COin - x

- CO₂out = CO₂in + x

- H₂Oout = H₂Oin - x

- The equilibrium constant is: Keq = ( (CO₂in + x) * (H₂in + x) ) / ( (COin - x) * (H₂O_in - x) ).

- Solve for

xusing the target H₂/CO ratio ( (H₂in + x) / (COin - x) = TargetRatio ) or using Keq at your reaction temperature.

- Let

- Calculate Required Conversion: Required WGS Conversion (%) = (x / CO_in) * 100.

Interpretation: This calculated conversion x guides reactor design (space velocity, catalyst volume) and operating conditions (steam-to-CO ratio, temperature) for your pilot system.

Table 1: Common WGS Catalysts for Biomass Syngas Conditioning

| Catalyst Type | Typical Formulation | Temp. Range (°C) | Key Advantages | Major Deactivation Mechanisms | Ideal Syngas [H₂S] Tolerance |

|---|---|---|---|---|---|

| High-Temp (HT) | Fe₃O₄-Cr₂O₃-CuO | 310 - 450 | Robust, tolerant to poisons, wide operating range. | Sintering, physical degradation. | < 50 ppm |

| Low-Temp (LT) | CuO-ZnO-Al₂O₃ | 180 - 250 | High activity at lower T, favors higher H₂ yield. | Sintering, sulfur/chlorine poisoning. | < 0.1 ppm |

| Sour-Gas | Co-Mo/Al₂O₃ (sulfided) | 250 - 500 | Operates in sulfur-containing gas without deactivation. | Requires constant H₂S stream to stay sulfided. | > 50 ppm (required) |

Table 2: Target H₂/CO Ratios for Fischer-Tropsch Synthesis

| FTS Catalyst Type | Optimal H₂/CO Usage Ratio | Purpose & Notes | Typical Product Focus |

|---|---|---|---|

| Cobalt (Co) | 2.0 - 2.15 | Maximizes C5+ liquid yield, minimizes methane. | Jet fuel (SAF), Diesel |

| Iron (Fe) - LTFT | 1.5 - 1.7 | Inherent WGS activity can use lower ratio syngas. | Olefins, Wax, Diesel |

| Iron (Fe) - HTFT | ~1.0 | High-temperature process favors gasoline/olefins. | Gasoline, Linear Olefins |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for WGS Catalyst Testing & Syngas Analysis

| Item | Function/Description | Example Product/CAS |

|---|---|---|

| HT-WGS Catalyst | For shift reaction at high temperatures; resistant to thermal shock. | Fe-Cr-based catalyst (e.g., 1105A from Clariant) |

| LT-WGS Catalyst | For achieving high equilibrium conversion at lower temperatures. | Cu-Zn-Al₂O₃ catalyst (e.g., C18HC from Johnson Matthey) |

| ZnO Sorbent | Guard bed material for deep removal of H₂S to protect LT catalysts. | Zinc Oxide, desulfurization grade (CAS 1314-13-2) |

| Certified Syngas Calibration Mix | Standard gas for calibrating GC/TCD for accurate H₂, CO, CO₂, CH₄ quantification. | e.g., 40% H₂, 20% CO, 20% CO₂, 20% N₂ balance |

| Silica Gel Moisture Trap | Protects analytical equipment by removing water vapor from syngas samples. | Indicating Silica Gel, 6-16 mesh (CAS 112926-00-8) |

| Steam Generator | Provides precisely controlled steam for adjusting the H₂O/CO ratio in lab-scale reactors. | High-precision syringe pump vaporizing into heated line |

Process Visualization

Title: Biomass to SAF via WGS & FTS Process Flow

Title: WGS Conversion Calculation & Control Logic

Solving Operational Problems: From Feed Preprocessing to Catalyst Lifespan

Technical Support Center: Troubleshooting & FAQs

Troubleshooting Guide: Common Experimental Issues

Issue 1: Inconsistent Product Yield from Torrefaction Symptoms: Variable mass and energy yields between batches using the same feedstock. Root Cause: Inherent feedstock heterogeneity (moisture, particle size) and non-uniform reactor temperature. Solution Steps:

- Pre-dry all biomass to a consistent moisture content (<10% w.b.) using a standardized oven protocol (105°C for 24 hours).

- Implement a standardized size reduction and screening protocol (e.g., grind and sieve to 0.5-1.0 mm).

- Calibrate reactor thermocouples and ensure adequate biomass tumbling or gas flow for uniform heat transfer.

Issue 2: Pyrolysis Bio-Oil with High Water Content & Phase Separation Symptoms: Oily phase separates from an acidic aqueous phase, leading to poor fuel quality. Root Cause: High feedstock moisture and condensation of reaction water from oxygenated compounds. Solution Steps:

- Ensure rigorous feedstock drying (as above).

- Optimize fast pyrolysis parameters: Increase vapor residence time in the hot zone to promote cracking, but limit overall gas residence time to minimize secondary reactions.

- Consider in-situ vapor cracking with a catalyst (e.g., ZSM-5) or post-production stabilization via mild hydrotreating.

Issue 3: Poor Pellet Durability & Density Symptoms: Pellets crumble during handling, failing the tumbling durability test (ASABE S269.5). Root Cause: Insufficient lignin plasticization, low compression pressure, or inadequate particle interlocking. Solution Steps:

- For herbaceous biomass, consider a mild steam pre-treatment (<180°C) to soften lignin.

- Adjust die temperature (typically 80-100°C) and compression force. Monitor amperage on the pellet mill motor as a proxy for pressure.

- Optimize feedstock particle size distribution: fine particles increase density, while some coarse particles enhance interlocking.

Issue 4: Feedstock Bridging in Reactor Feed Systems Symptoms: Intermittent or blocked feedstock flow into the gasifier/reactor, causing process instability. Root Cause: Irregular particle shape/size (from poor preprocessing) leading to mechanical interlocking. Solution Steps:

- Implement a consistent pelletization step after torrefaction/pyrolysis to create uniform cylinders.

- Use force-feeding mechanisms (e.g., screw augers with variable pitch) rather than gravity-fed hoppers.

- Install hopper agitators or vibrators to prevent arch formation.

Frequently Asked Questions (FAQs)

Q1: What is the optimal torrefaction temperature range to maximize energy density while preserving grindability for gasification? A: The optimal range is typically 250-300°C. Below 250°C, decomposition is minimal. Above 300°C, you risk excessive mass loss and entering the pyrolysis regime. The goal is to degrade hemicellulose while largely preserving cellulose and lignin.

Q2: How does fast pyrolysis differ from slow pyrolysis, and which is more relevant for SAF precursor production? A: Fast pyrolysis (high heating rate >100°C/s, short vapor residence time <2s) maximizes liquid bio-oil yield (~60-75%), which can be upgraded to hydrocarbons. Slow pyrolysis (low heating rate, long residence time) maximizes char yield. For SAF, fast pyrolysis for bio-oil is the primary route, though catalytic pyrolysis (in-situ upgrading) is a key research area.

Q3: Why is pelletization often performed after torrefaction rather than before? A: Torrefaction destroys the natural lignin binders in biomass. Pelletizing raw biomass then torrefying causes the pellets to disintegrate. Torrefying first creates a brittle, hydrophobic material that can be ground easily and then re-pelletized using the torrefied lignin as a binder, resulting in a stable, water-resistant "black pellet."

Q4: What analytical techniques are critical for assessing feedstock uniformity after preprocessing? A:

- Proximate & Ultimate Analysis: For consistent composition (Table 1).

- Calorimetry: For Higher Heating Value (HHV) consistency.

- Particle Size Distribution: Laser diffraction or sieve analysis.

- Bulk & Tapped Density: ASTM E873.

- Pellet Durability Index: ASABE S269.5.

Table 1: Comparative Output of Preprocessing Strategies

| Parameter | Raw Biomass (Pine) | Torrefied Biomass (280°C) | Fast Pyrolysis Bio-Oil | Densified Pellet (Torrefied) |

|---|---|---|---|---|

| Mass Yield (wt.%) | 100% | 70-80% | 60-75% (liquid) | ~95% (of input torrefied) |

| Energy Yield (%) | 100% | 85-95% | 65-80% (in liquid) | ~98% (of input torrefied) |

| Energy Density (GJ/m³) | ~8-10 | ~15-18 | ~12-15 (liquid) | ~20-25 |

| Moisture Content (%) | 10-50 (air-dry) | <3 | 15-30 (in bio-oil) | <5 |

| O:C Ratio | ~0.7 | ~0.4 | ~0.3-0.5 | ~0.4 |