Optimizing Biomass Drying with CFD: A Comprehensive Guide to Airflow Simulation for Pharmaceutical Applications

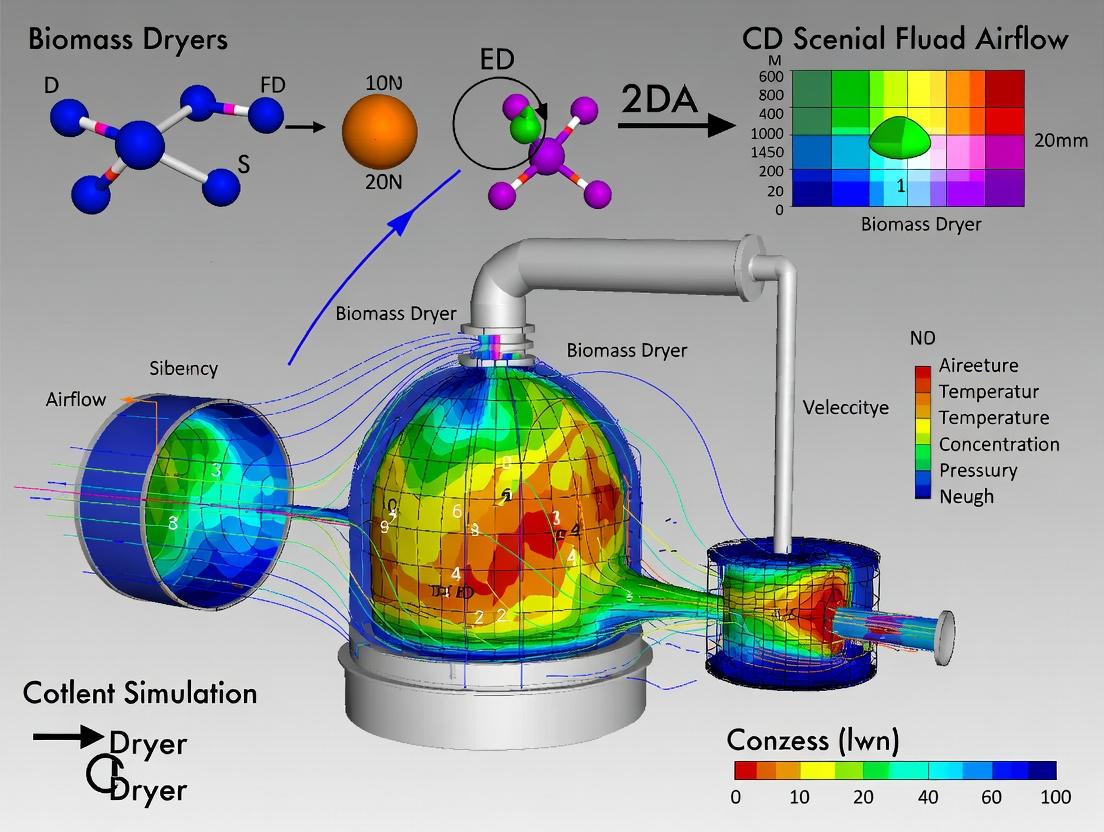

This article provides a detailed exploration of Computational Fluid Dynamics (CFD) for simulating airflow in biomass dryers, with a focus on applications relevant to pharmaceutical research and drug development.

Optimizing Biomass Drying with CFD: A Comprehensive Guide to Airflow Simulation for Pharmaceutical Applications

Abstract

This article provides a detailed exploration of Computational Fluid Dynamics (CFD) for simulating airflow in biomass dryers, with a focus on applications relevant to pharmaceutical research and drug development. We cover the fundamental principles of dryer aerodynamics and their importance for bioactive compound preservation. The guide details step-by-step methodologies for building accurate CFD models, including mesh generation, solver selection, and boundary condition setup. It addresses common simulation challenges, performance optimization techniques, and strategies for mitigating non-uniform drying. Furthermore, we examine methods for validating CFD results against experimental data and compare different dryer designs (e.g., tray, conveyor, fluidized bed). The conclusion synthesizes key insights, highlighting how precise airflow control enabled by CFD can enhance drying efficiency, improve product quality, and accelerate the development of biomass-derived therapeutics.

The Science of Drying: Fundamentals of Airflow Dynamics in Biomass Dryers for Pharmaceutical Processing

Why Airflow Distribution is Critical for Pharmaceutical Biomass Drying

1. Introduction & Context

Within the broader research thesis on Computational Fluid Dynamics (CFD) simulation of airflow in biomass dryers, the drying of active pharmaceutical ingredient (API)-producing biomass (e.g., fungal mycelia, bacterial pellets, algal mats) presents a unique challenge. Uniform and controlled airflow distribution is not merely an engineering efficiency goal; it is a critical determinant of product quality, process consistency, and regulatory compliance. Non-uniform airflow leads to localized over-drying or under-drying, causing variability in moisture content, thermal degradation of heat-sensitive compounds, and inconsistent downstream processing performance. This application note details the critical parameters, experimental protocols, and modeling approaches for characterizing and optimizing airflow distribution in pharmaceutical biomass drying operations.

2. Critical Parameters & Quantitative Data

Optimal drying preserves bioactivity while reducing moisture to levels that inhibit microbial growth and facilitate milling (<10% w/w). Key parameters are summarized below.

Table 1: Critical Airflow & Drying Parameters for Pharmaceutical Biomass

| Parameter | Target Range | Impact of Deviation | Measurement Method |

|---|---|---|---|

| Air Velocity (m/s) | 0.5 - 2.0 (across bed) | <0.5: Poor drying, bed compaction; >2.0: Particle entrainment, biomass degradation | Anemometer, Hot-wire probe |

| Temperature (°C) | 30 - 45 (Heat-sensitive) | >50: Denaturation of APIs, loss of potency | Calibrated RTD/ Thermocouple |

| Relative Humidity (%) | 10 - 30 (inlet) | >40: Prolonged drying, risk of spoilage; <10: Case-hardening, crust formation | Hygrometer |

| Bed Porosity (%) | 60 - 80 | <60: High pressure drop, channeling; >80: Short-circuiting, non-uniform contact | Bulk & Tapped Density |

| Final Moisture Content (% w/w) | 5 - 10 | >10: Microbial instability; <5: Excessive brittleness, yield loss | Loss-on-Drying (LOD), Karl Fischer |

Table 2: Consequences of Non-Uniform Airflow Distribution

| Airflow Defect | Local Effect on Biomass | Batch-Level Consequence |

|---|---|---|

| Channeling | High velocity in channels (over-dry), stagnant zones (wet) | High moisture variability, failed QC, unreproducible extraction yields. |

| Dead Zones | No airflow, microbial growth, spoilage | Contaminated batch, loss of API, cleaning validation failure. |

| Hot Spots | Localized high temperature | Thermal degradation of API, formation of impurities. |

| Maldistribution | Uneven residence time | Inconsistent particle size post-milling, affecting formulation blend uniformity. |

3. Experimental Protocol: Mapping Airflow Distribution in a Tray Dryer

This protocol provides a methodology for empirical validation of CFD simulation results.

Objective: To spatially map the airflow velocity and temperature profile across a loaded tray dryer to identify maldistribution. Materials: See "The Scientist's Toolkit" below. Procedure:

- Biomass Preparation & Loading:

- Prepare a standardized wet biomass cake with known initial moisture content (e.g., 70% w/w).

- Using a controlled spreading tool, load the biomass onto dryer trays to a consistent bed depth (e.g., 3 cm) and record the loaded weight per tray.

- Install trays in the dryer according to the manufacturer's layout.

Sensor Grid Deployment:

- Prior to loading, establish a 3D coordinate grid within the dryer chamber (X, Y for tray area; Z for vertical height).

- Calibrate all anemometers and thermocouples.

- For a representative tray, position anemometer probes at 9 predefined points (3x3 grid) within the biomass bed, ensuring the sensing element is positioned at the mid-depth of the bed.

- Position additional probes in the free air space above and below the tray.

Data Acquisition:

- Start the dryer with set-point parameters (e.g., 40°C inlet, 20% RH, fan speed 100%).

- Allow the system to reach steady-state (approx. 15-30 mins).

- Simultaneously record velocity (m/s) and temperature (°C) from all probes at 30-second intervals for a period of 10 minutes.

- Repeat measurements at different fan speed settings (60%, 80%, 100%).

Data Analysis:

- For each probe location, calculate the mean velocity and temperature.

- Generate contour plots (or 3D surface maps) of velocity and temperature distribution across the tray.

- Calculate the Coefficient of Variation (CV = Standard Deviation / Mean) for velocity across the 9 points. A CV > 15% indicates significant maldistribution.

- Correlate local airflow velocity with the final moisture content of biomass samples taken from corresponding locations post-drying.

4. CFD Simulation Workflow for Dryer Optimization

The experimental data serves to validate and refine CFD models.

Title: CFD Simulation & Validation Workflow for Dryer Design

5. The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Airflow Distribution Research

| Item / Reagent | Function / Purpose |

|---|---|

| Calibrated Hot-Wire Anemometer | High-resolution measurement of localized air velocity without significant flow disruption. |

| RTD (Resistance Temperature Detector) Arrays | Accurate, stable multi-point temperature mapping within the dryer chamber and biomass bed. |

| Data Acquisition System (DAQ) | Synchronized, high-frequency logging from multiple sensor inputs for time-series analysis. |

| Standardized Wet Biomass Cake | A consistent, reproducible mock or real API-producing biomass with characterized rheology. |

| Porous Media Model Parameters | Experimentally derived Ergun equation coefficients (viscous & inertial resistance) for the specific biomass bed for accurate CFD modeling. |

| Tracer Particles (e.g., Fog, Helium) | For flow visualization studies to identify channeling and dead zones experimentally. |

| CFD Software (e.g., ANSYS Fluent, COMSOL) | For building, solving, and visualizing the multiphase flow and conjugate heat transfer models. |

6. Pathway: Impact of Airflow on Final Product Quality

The logical chain from airflow distribution to critical quality attributes (CQAs) is direct.

Title: Airflow Impact on Pharmaceutical Product Quality Pathway

7. Conclusion & Protocol Integration

A rigorous, data-driven approach combining CFD simulation with empirical validation protocols is essential for understanding and controlling airflow distribution. Implementing the outlined experimental protocol provides the necessary ground-truth data to calibrate models. The validated CFD model then becomes a powerful tool for optimizing dryer design (e.g., baffle placement, inlet diffusers) and operating parameters without costly and time-consuming full-scale trials. For researchers and process scientists, this integrated approach ensures that the critical step of biomass drying contributes reliably to the production of consistent, high-quality, and potent pharmaceutical products.

Application Notes

This document outlines the critical aerodynamic principles applied within a thesis research program focused on Computational Fluid Dynamics (CFD) simulation of airflow distribution in biomass dryers. Understanding these principles is essential for optimizing dryer design to achieve uniform moisture removal, minimize energy consumption, and prevent spoilage.

- Laminar vs. Turbulent Flow: The flow regime within a dryer directly impacts heat and mass transfer rates. Laminar flow is characterized by smooth, orderly layers but results in poor lateral mixing, leading to uneven drying. Turbulent flow, while requiring more energy to sustain, enhances mixing and promotes uniformity. The Reynolds number (Re) dictates the transition, typically around Re > 4000 for pipe flow, but dryer-specific geometries alter this threshold.

- Pressure Drops: Pressure losses occur due to friction and flow separation as air moves through ductwork, biomass piles, and perforated trays. Excessive pressure drops necessitate higher fan power, increasing operational costs. Accurate prediction via CFD is vital for sizing auxiliary equipment.

- Recirculation Zones: These are regions of reversed or stagnant flow, often found behind obstacles or in sudden expansions. In biomass dryers, they cause localized over-drying or under-drying, reducing product quality and efficiency. Identifying and mitigating these zones is a primary goal of simulation.

Experimental Protocols

Protocol 1: Determining Local Flow Regime in a Pilot-Scale Biomass Dryer

Objective: To empirically map zones of laminar, transitional, and turbulent flow within a pilot-scale dryer for CFD model validation. Materials: Pilot-scale conveyor dryer, hot-wire anemometer system, tracer gas (SF₆) and detector, thermocouples, data acquisition system. Procedure:

- Operate the dryer at a standard design air velocity (e.g., 1.5 m/s) and temperature (60°C).

- Using a 3D traversing system, position the hot-wire anemometer probe at pre-defined grid points (every 0.1m in a representative section).

- At each point, record the mean velocity and the velocity fluctuation RMS (Root Mean Square) over a 60-second period.

- Calculate the local turbulence intensity (TI) as TI = (Velocity RMS / Mean Velocity) * 100%.

- At key locations, inject a pulse of SF₆ tracer gas upstream and record the concentration-time profile downstream to characterize mixing/dispersion.

- Classify flow: Laminar (TI < 1%), Transitional (1% < TI < 10%), Fully Turbulent (TI > 10%).

- Repeat for different main air velocities (0.5, 2.0 m/s).

Protocol 2: Measuring System Pressure Drop Across a Biomass Bed

Objective: To quantify the relationship between air velocity and pressure drop across a bed of biomass particles (Darcy-Forchheimer coefficients). Materials: Packed column test rig, differential pressure transducer, calibrated fan, flow straightener, moisture-controlled biomass sample (e.g., wood chips), precision scale. Procedure:

- Fill the column with a known mass of biomass. Record the bed height (L) and cross-sectional area (A).

- Connect the pressure transducer ports to the inlet and outlet plenums of the test section.

- Set the fan to a specific flow rate. Measure the volumetric flow rate (Q) using a calibrated orifice meter.

- Calculate the superficial velocity, V = Q/A.

- Record the steady-state pressure difference (ΔP) across the bed.

- Incrementally increase the flow rate over a range covering expected operational velocities (0.1 to 3.0 m/s).

- For each data point, calculate the pressure gradient (ΔP/L).

- Fit the data (ΔP/L vs. V) to the Darcy-Forchheimer equation: ΔP/L = μ/K * V + ρ/β * V², to determine permeability (K) and inertial coefficient (β).

Data Tables

Table 1: Flow Regime Classification Based on Measured Turbulence Intensity

| Location in Dryer (Zone) | Mean Velocity (m/s) | Turbulence Intensity (%) | Classified Flow Regime |

|---|---|---|---|

| Main Supply Duct | 2.5 | 4.5 | Transitional |

| Above Conveyor (Upstream) | 1.6 | 2.1 | Transitional |

| Within Biomass Bed (Mid) | 0.3 | 0.8 | Laminar |

| Behind Tray Support | 0.1 | 28.7 | Turbulent (Recirculation) |

| Exhaust Plenum | 1.0 | 12.3 | Turbulent |

Table 2: Pressure Drop Parameters for Different Biomass Types (at 10% Moisture Content)

| Biomass Type | Particle Size (mm) | Bed Porosity (-) | Permeability, K (m²) | Inertial Coefficient, β (m) |

|---|---|---|---|---|

| Wood Chips | 10-15 | 0.55 | 1.2e-7 | 0.045 |

| Wheat Straw (Chopped) | 30-50 | 0.85 | 5.8e-6 | 0.012 |

| Corn Stover (Milled) | 5-10 | 0.65 | 3.4e-8 | 0.098 |

| Bark Fines | 1-3 | 0.45 | 5.5e-9 | 0.210 |

Visualization Diagrams

Diagram Title: CFD-Driven Aerodynamic Analysis Workflow

Diagram Title: Biomass Dryer Airflow Zoning & Effects

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials for Aerodynamic Studies in Biomass Drying

| Item | Function in Research |

|---|---|

| CFD Software (e.g., ANSYS Fluent, OpenFOAM) | Solves the governing Navier-Stokes equations numerically to predict velocity, pressure, and turbulence fields within the virtual dryer model. |

| Hot-Wire Anemometry System | Provides high-frequency, point-wise measurements of air velocity and turbulence intensity for experimental validation of CFD models. |

| Differential Pressure Transducer | Precisely measures the static pressure drop across biomass beds or dryer components to quantify resistance and validate simulated pressure losses. |

| Tracer Gas (Sulfur Hexafluoride - SF₆) & Analyzer | Used in residence time distribution (RTD) studies to characterize mixing efficiency and identify short-circuiting or dead zones (recirculation). |

| Moisture-Controlled Biomass Samples | Standardized feedstock with known moisture content, particle size distribution, and porosity is essential for repeatable experiments and accurate material property input in CFD. |

| 3D Optical Scanner or CAD Software | Creates an accurate digital geometry of the experimental or industrial dryer, which is the critical first step in the meshing and CFD simulation process. |

| k-ε RANS Turbulence Model | A widely used, computationally efficient Reynolds-Averaged Navier-Stokes model for simulating turbulent flow in industrial dryers, balancing accuracy and resource demand. |

Within the context of computational fluid dynamics (CFD) simulation research for optimizing airflow distribution, the selection of dryer type is paramount. Each dryer system presents unique airflow patterns, heat and mass transfer characteristics, and scale-up challenges that directly influence drying kinetics and final biomass quality. These application notes detail the operational principles, key applications, and CFD-relevant parameters for four primary industrial biomass dryer types.

Dryer Types: Comparative Analysis

Table 1: Comparative Overview of Industrial Biomass Dryers

| Dryer Type | Typical Airflow Configuration | Key Biomass Applications | Typical Residence Time | Energy Efficiency (Relative) | Key CFD Simulation Challenge |

|---|---|---|---|---|---|

| Tray (Cabinet) | Cross-flow or Through-flow | Pharmaceutical herbs, high-value botanicals, R&D-scale samples | 0.5 - 8 hours | Low-Moderate | Modeling static bed porosity and localized airflow bypass. |

| Conveyor (Belt) | Through-flow (perpendicular to belt) | Wood chips, pellets, fibrous agricultural residues (e.g., bagasse) | 5 minutes - 2 hours | Moderate-High | Tracking moving bed interface with continuous airflow. |

| Rotary Drum | Co-current or Counter-current direct contact | Municipal solid waste (MSW), sawdust, bark, distillers' grains | 10 - 60 minutes | Moderate | Simulating particle cascading and airborne phase interactions. |

| Fluidized Bed | Upward flow at minimum fluidization velocity | Granular biomass (e.g., sand-like pellets), grains, powder pre-treatment | 2 - 30 minutes | High | Captulating bubble dynamics and particle-gas turbulence. |

Table 2: Typical Operational Parameters for CFD Model Input

| Parameter | Tray Dryer | Conveyor Dryer | Rotary Dryer | Fluidized Bed Dryer |

|---|---|---|---|---|

| Air Temperature Range (°C) | 30-70 | 50-150 | 200-600 | 40-120 |

| Superficial Air Velocity (m/s) | 0.5 - 2.0 | 1.0 - 3.0 | 1.5 - 5.0 | 1.0 - 5.0 (Umf+) |

| Bed Void Fraction (ε) | 0.4 - 0.6 | 0.5 - 0.7 | 0.6 - 0.9 (dynamic) | 0.7 - 0.9 |

| Biomass Moisture In/Out (% w.b.) | 80/10 | 60/15 | 55/12 | 30/5 |

Experimental Protocols for CFD Validation

Protocol EP-1: Tracer Gas Residence Time Distribution (RTD) Analysis for Dryer Validation

Purpose: To experimentally determine the airflow distribution and mixing patterns within a dryer for direct validation of CFD models. Materials: See "Research Reagent Solutions" below. Method:

- System Preparation: Operate the dryer at target thermal conditions (temperature, airflow rate) without biomass.

- Tracer Injection: At the dryer air inlet, introduce a pulse of inert tracer gas (e.g., Helium, SF₆). Use a calibrated solenoid injection system with injection duration << mean residence time.

- Concentration Monitoring: Position multiple gas samplers at strategic locations (e.g., above the bed, at exhaust). Use a mass spectrometer or gas chromatograph to record tracer concentration at high frequency (≥10 Hz).

- Data Processing: For each sampling point, plot normalized concentration (C/C₀) vs. time. Calculate mean residence time and variance. Compare with CFD-predicted RTD curves at identical locations.

- Validation Metric: Use the normalized mean square error (NMSE) between experimental and CFD-predicted concentration-time curves as a key validation metric.

Protocol EP-2: Moisture Profiling in a Static Bed (Tray/Conveyor Simulation)

Purpose: To obtain spatial moisture distribution data in a biomass bed for validating coupled CFD and mass transfer models. Method:

- Bed Preparation: Fill a representative drying chamber or a section of a conveyor dryer with biomass of uniform initial moisture content. Instrument the bed with a pre-calibrated, multi-point moisture sensor array or establish pre-marked sampling locations.

- Drying Run: Initiate drying under controlled conditions (air T, V, RH).

- Sampling: At pre-determined time intervals (t=0, 15, 30, 60 mins...), rapidly extract small biomass samples from specific 3D coordinates (top, middle, bottom; inlet, center, outlet).

- Analysis: Immediately determine the moisture content of each sample using a standard oven-drying method (105°C until constant weight).

- Spatial Mapping: Create 2D/3D contour plots of moisture content vs. position and time. These maps serve as the ground truth for validating the accuracy of the CFD-simulated drying fronts.

Diagram: CFD Simulation Workflow for Dryer Analysis

Title: CFD Simulation and Validation Workflow for Biomass Dryers

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Tools for Dryer Airflow Research

| Item | Function/Justification |

|---|---|

| Anemometer (Hot-wire/ Vane) | Measures local air velocity at specific points for BC setup and spot-validation of CFD results. |

| Differential Pressure Transducer | Measures pressure drop across biomass beds, a critical parameter for fluidized bed and through-flow system modeling. |

| Calibrated Humidity & Temperature Probes | Provides accurate inlet and exhaust air conditions essential for defining BCs and validating heat transfer models. |

| Tracer Gas (e.g., Sulfur Hexafluoride, SF₆) | Inert, detectable at low concentrations. Used in RTD studies (Protocol EP-1) to characterize airflow mixing and dead zones. |

| Portable Mass Spectrometer/Gas Chromatograph | For high-frequency measurement of tracer gas concentration during RTD experiments. |

| Dielectric Moisture Sensor Array | Allows for non-destructive, in-situ monitoring of moisture content at multiple points within a static bed. |

| Biomass Property Test Kit | Includes instruments for measuring particle size distribution, bulk density, and equilibrium moisture content isotherms—all critical inputs for accurate CFD modeling. |

| High-Fidelity 3D Scanner | To create precise digital geometry of dryer internals (baffles, ducting) for mesh generation. |

This application note details protocols and analytical frameworks for investigating the impact of heterogeneous airflow distribution on biomass drying processes. The work is situated within a broader thesis employing Computational Fluid Dynamics (CFD) simulation to model and optimize airflow patterns in industrial-scale convective dryers. The primary objective is to establish empirically validated relationships between localized airflow parameters (velocity, temperature, uniformity), drying kinetics, and critical quality attributes (CQA) of the dried biomass, specifically final moisture content and the retention of bioactive compounds.

Table 1: Impact of Airflow Velocity on Drying Kinetics of Medicinal Plant Leaves (Example: Ocimum basilicum)

| Airflow Velocity (m/s) | Drying Time to 10% MC (min) | Effective Moisture Diffusivity (m²/s) | Page's Model Constant (k) |

|---|---|---|---|

| 0.5 | 420 ± 15 | 3.25 x 10⁻¹¹ ± 0.21 | 0.0018 ± 0.0001 |

| 1.0 | 285 ± 10 | 5.10 x 10⁻¹¹ ± 0.18 | 0.0027 ± 0.0002 |

| 1.5 | 210 ± 8 | 7.45 x 10⁻¹¹ ± 0.25 | 0.0035 ± 0.0001 |

| 2.0 | 180 ± 7 | 8.90 x 10⁻¹¹ ± 0.30 | 0.0040 ± 0.0003 |

MC: Moisture Content (wet basis). Drying temperature constant at 50°C. Data is illustrative based on recent literature synthesis.

Table 2: Correlation Between Airflow Uniformity (from CFD) and Final Product Quality

| CFD-Derived Uniformity Index (UI)* | Final MC Variation (% Std. Dev.) | Total Phenolic Content Retention (%) | Antioxidant Activity (DPPH) Retention (%) |

|---|---|---|---|

| Low (UI: 0.65) | 8.5 ± 1.2 | 72.3 ± 3.1 | 68.5 ± 2.8 |

| Medium (UI: 0.80) | 4.2 ± 0.8 | 84.7 ± 2.5 | 81.2 ± 3.1 |

| High (UI: 0.95) | 1.8 ± 0.5 | 92.5 ± 1.8 | 90.1 ± 2.0 |

UI = (1 - (Standard Deviation of Velocity / Mean Velocity)). Drying conditions constant.

Experimental Protocols

Protocol 1: Coupled CFD-Experimental Validation of Airflow Distribution

Objective: To validate CFD-predicted airflow distribution within a laboratory-scale tray dryer using physical sensors. Materials: Laboratory tray dryer, 3D anemometer array (hot-wire or ultrasonic), data logger, CAD model of dryer chamber. Procedure:

- Develop a 3D CAD model of the empty dryer chamber, including inlet, outlet, and tray positions.

- Generate a computational mesh and run a steady-state CFD simulation (k-ε RNG turbulence model) at set operating conditions (e.g., 1.5 m/s inlet velocity, 50°C).

- Export predicted velocity and temperature fields at specific sensor locations.

- Physically install the anemometer array at the exact coordinates corresponding to CFD probe points.

- Operate the dryer under identical conditions and record velocity/temperature data for 30 minutes at 1 Hz.

- Compare experimental and CFD data using statistical metrics (Mean Absolute Percentage Error - MAPE, R²).

Protocol 2: Drying Kinetics and Bioactivity Assessment Under Controlled Airflow

Objective: To determine the drying curve and final quality of biomass samples placed in zones of characterized airflow. Materials: Fresh biomass (e.g., Echinacea purpurea root), precision balance, dryer, UV-Vis spectrophotometer, HPLC system, grinding mill. Procedure:

- Sample Preparation: Slice biomass to uniform geometry (e.g., 3mm slices). Record initial mass (M₀) and dry mass (M_dry via oven method at 105°C for 24h) for moisture content (MC) calculation.

- Characterized Positioning: Place sample trays in pre-mapped locations representing high, medium, and low airflow velocities (from Protocol 1/CFD).

- Drying Run: Conduct drying at constant temperature. Record sample mass (M_t) at regular intervals.

- Kinetics Modeling: Calculate moisture ratio (MR). Fit MR data to thin-layer models (Page, Henderson-Pabis) using non-linear regression to derive drying constants.

- Post-Drying Analysis: a. Final MC: Determine final MC of each sample. b. Bioactive Extraction: Grind samples. Perform standardized solvent extraction (e.g., 70% ethanol, sonication). c. Quantification: Assay extracts for target bioactives (e.g., echinacoside, cichoric acid via HPLC; total phenolics via Folin-Ciocalteu; antioxidant capacity via DPPH/FRAP).

Visualization of Experimental and Analytical Workflows

Title: Integrated CFD-Experimental Drying Research Workflow

Title: Airflow Impact on Drying and Quality Pathways

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Airflow-Drying Impact Studies

| Item | Function/Explanation |

|---|---|

| 3D Ultrasonic Anemometer Array | Provides non-intrusive, high-frequency measurement of 3D airflow velocity vectors for CFD validation. |

| Thermal Hygrometer Probes | Measures dry-bulb and dew-point temperature simultaneously for calculating absolute humidity of drying air. |

| Data Logging System | Synchronizes data acquisition from multiple sensors (weight, velocity, temperature) for time-series analysis. |

| Standardized Phytochemical Reference Standards (e.g., Rutin, Gallic acid, Trolox) | Essential for calibrating HPLC and spectrophotometric assays to quantify specific bioactive compounds and antioxidant capacity. |

| Folin-Ciocalteu Reagent | A key research reagent solution for the colorimetric quantification of total phenolic content in plant extracts. |

| DPPH (2,2-Diphenyl-1-picrylhydrazyl) Radical | A stable free radical used in spectrophotometric assays to determine the antioxidant activity of dried biomass extracts. |

| Controlled Atmosphere Tray Dryer (Lab-Scale) | Allows independent adjustment of airflow velocity, temperature, and relative humidity for controlled experiments. |

| Mesh Generation & CFD Software (e.g., ANSYS Fluent, OpenFOAM) | For creating the dryer geometry model, simulating airflow distribution, and calculating uniformity indices. |

Core Concepts of Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to solve and analyze problems involving fluid flows. Computers are used to perform the calculations required to simulate the interaction of liquids and gases with surfaces defined by boundary conditions.

Governing Equations: All CFD simulations are based on solving the fundamental conservation laws of physics. These are mathematically expressed as partial differential equations:

- Conservation of Mass (Continuity Equation): Ensures mass is neither created nor destroyed.

- Conservation of Momentum (Navier-Stokes Equations): Newton's second law applied to fluid motion.

- Conservation of Energy: First law of thermodynamics, accounting for heat transfer.

The CFD Workflow: A standard simulation follows a defined protocol:

Table 1: Standard CFD Workflow Protocol

| Step | Protocol Description | Key Output/Deliverable |

|---|---|---|

| 1. Pre-processing | Geometry creation/import, mesh generation, physics definition, boundary condition specification, material property assignment. | A discretized computational domain ready for solver. |

| 2. Solution | Iterative numerical solving of the discretized governing equations using selected algorithms (e.g., SIMPLE, PISO). | Converged numerical solution file containing field data (velocity, pressure, temperature). |

| 3. Post-processing | Visualization and quantitative analysis of results (contours, vectors, streamlines, graphs, integrals). | Reports, images, and datasets for analysis and validation. |

Key Numerical Concepts:

- Discretization: The process of converting the governing PDEs into a system of algebraic equations. The two primary methods are:

- Finite Volume Method (FVM): The most common method in commercial CFD. Integrates equations over control volumes, conserving fluxes.

- Finite Element Method (FEM): Often used for complex structural interactions.

- Turbulence Modeling: Critical for realistic dryer simulation. Common models include:

- k-ε (RANS): Robust, industry-standard for general airflow.

- k-ω SST: Better for boundary layers and adverse pressure gradients.

- Large Eddy Simulation (LES): More accurate for transient, large-scale vortices but computationally expensive.

Title: Standard CFD Analysis Workflow

Application to Biomass Dryer Analysis: Protocols and Data

Within the thesis context of CFD simulation of airflow distribution in biomass dryers, the core application is to optimize dryer design for uniform drying, energy efficiency, and preservation of bioactive compounds in pharmaceutical-grade biomass.

Key Performance Indicators (KPIs) for Dryer Analysis:

- Airflow Uniformity: Measured by velocity coefficient of variation (CV) across the product bed.

- Temperature Distribution: Critical for heat-sensitive materials.

- Residence Time Distribution: Impacts final moisture content uniformity.

- Pressure Drop: Directly related to fan energy consumption.

Table 2: Quantitative Metrics from a Typical Virtual Dryer Study

| Metric | Target Value | Simulation Output | Measurement Method in CFD |

|---|---|---|---|

| Air Velocity CV at Bed | < 15% (Excellent) | 22.5% (Initial Design) | Std. Dev. / Mean across sample plane |

| Max ΔT Across Bed | < 5 °C | 8.7 °C | (Tmax - Tmin) at bed mid-plane |

| System Pressure Drop | Minimize | 125 Pa | Static pressure inlet-to-outlet difference |

| Airflow Maldistribution Factor | ~1.0 (Ideal) | 1.42 | (Qmax - Qmin) / Q_avg for bed sections |

Experimental Protocol P-01: Virtual Dryer Performance Analysis

Objective: To evaluate and compare the airflow and thermal performance of three conceptual biomass dryer duct designs using CFD.

Methodology:

- Geometry Preparation: Create 3D CAD models of three dryer designs (A: Straight baffle, B: Perforated plate, C: Curved deflector) ensuring identical inlet/outlet and bed dimensions.

- Meshing: Generate a polyhedral mesh with prism layers near walls. Target y+ ~30 for k-ε models. Perform mesh independence study (see Protocol P-02).

- Physics Setup:

- Solver: Steady-state, pressure-based, double precision.

- Turbulence Model: Realizable k-ε with Enhanced Wall Treatment.

- Material: Air (ideal gas if significant heating), biomass bed modeled as porous zone with defined permeability and inertial loss coefficients.

- Boundary Conditions: Inlet: Velocity (1.5 m/s) & Temperature (60°C). Outlet: Pressure-outlet. Walls: Adiabatic, no-slip.

- Solution: Run simulation until scaled residuals plateau below 1e-4 and monitor bed-plane averages for stability.

- Post-processing: Extract data for Table 2 metrics. Generate contour plots of velocity and temperature on the bed mid-plane and streamlines from the inlet.

Title: Virtual Dryer Design Comparison Protocol

Experimental Protocol P-02: Mesh Independence Study

Objective: To ensure CFD results are not dependent on the spatial discretization (cell count).

Methodology:

- Create four mesh versions for a baseline dryer model: Coarse (~500k cells), Medium (~1.5M), Fine (~3.5M), Very Fine (~6M).

- Run identical simulations on all four meshes.

- Monitor the key output variable, e.g., pressure drop across the bed (ΔP_bed).

- Apply the Grid Convergence Index (GCI) method or observe asymptotic convergence.

Table 3: Sample Mesh Independence Study Data

| Mesh Name | Cell Count | ΔP_bed (Pa) | % Change from Previous | Solution Time (hrs) |

|---|---|---|---|---|

| Coarse | 512,000 | 142.1 | - | 1.2 |

| Medium | 1,450,000 | 128.7 | -9.4% | 3.5 |

| Fine | 3,650,000 | 124.6 | -3.2% | 8.1 |

| Very Fine | 6,200,000 | 123.8 | -0.6% | 15.0 |

Conclusion: The "Fine" mesh (3.65M cells) is selected, as the change to the "Very Fine" mesh is <1%, indicating acceptable independence.

The Scientist's Toolkit: Research Reagent Solutions for CFD Dryer Analysis

Table 4: Essential Software & Material Tools for Virtual Dryer Research

| Tool Category / Name | Function in Dryer CFD Research | Typical Application Note |

|---|---|---|

| Commercial CFD Solver (ANSYS Fluent, Siemens Star-CCM+) | Primary numerical engine for solving governing equations. | Used for setting up physics, solving, and basic post-processing of complex multiphase or conjugate heat transfer models. |

| Open-Source Solver (OpenFOAM) | Flexible, customizable platform for advanced research code development. | Implementing custom boundary conditions, novel drying models, or specialized porous media treatments. |

| CAD Software (SOLIDWORKS, AutoCAD) | Creation and modification of the precise 3D geometric model of the dryer. | Designing new baffle configurations or biomass tray geometries for performance optimization. |

| High-Performance Computing (HPC) Cluster | Reduces solution time for large, transient, or multiphase simulations. | Essential for LES turbulence studies or parametric sweeps of multiple design variables. |

| Biomass Porous Media Properties Database | Experimental data for permeability and inertial resistance coefficients of specific biomass (e.g., ginseng root, hemp). | Critical input for accurate modeling of the biomass bed's resistance to airflow. Measured via experiment. |

| Scripting Language (Python, MATLAB) | Automates pre/post-processing, batch runs, and custom data analysis. | Calculating uniformity indices from raw field data or generating comparative performance charts across 50 design iterations. |

Role in Virtual Design: Accelerating Drug Development

For researchers and drug development professionals, CFD serves as a virtual prototyping and digital twin tool. It allows for:

- Risk Mitigation: Identifying dead zones (where biomass may spoil) or high-velocity zones (where material may degrade) before physical build.

- Design of Experiments (DoE): Systematically varying inlet air angle, baffle placement, or heater location to find an optimal configuration.

- Scale-up Support: Predicting performance in a full-scale production dryer based on lab-scale data and simulations, reducing scale-up risks for critical pharmaceutical biomass.

- Quality by Design (QbD): Establishing a design space for dryer operation (e.g., inlet temperature range, airflow limits) that ensures final product moisture content specifications are met, directly supporting regulatory filings.

The integration of CFD into biomass dryer research provides a powerful, data-driven pathway to optimize drying processes, ensuring the efficient production of high-quality, bioactive plant material for downstream pharmaceutical extraction and formulation.

Building Your Simulation: A Step-by-Step CFD Methodology for Biomass Dryer Analysis

Within the context of Computational Fluid Dynamics (CFD) simulation for biomass dryer airflow distribution research, the geometry pre-processing stage is critical. The accuracy and computational efficiency of the simulation are directly contingent upon the quality of the geometric model. This document outlines application notes and detailed protocols for the creation and simplification of dryer component geometries, targeting researchers and engineers in process development.

Core Principles of Geometry Simplification

The primary goal is to reduce geometric complexity while preserving the essential features that influence airflow patterns. Overly detailed models lead to excessive computational meshes, while over-simplified models yield non-physical results.

Key Criteria for Feature Retention/Removal:

- Retain: Features with a characteristic dimension (D) where D > 0.05 * Dh (Dh is the local hydraulic diameter). Features causing flow separation, recirculation, or significant pressure drop (e.g., sharp bends, baffles, inlet/outlet geometries).

- Simplify/Remove: Small fillets, bolts, nuts, non-functional brackets, surface textures, and gaps significantly smaller than the main flow path.

Quantitative Guidelines for Simplification

Based on current industry practices and mesh independence studies, the following quantitative thresholds are recommended for biomass dryer components.

Table 1: Geometry Simplification Thresholds for Dryer Components

| Component Type | Feature to Simplify | Recommended Threshold | Rationale |

|---|---|---|---|

| Ductwork & Chambers | Small Fillets & Rounds | Radius < 2% of duct width | Negligible impact on bulk flow direction. |

| Surface Imperfections | Amplitude < 1mm | Below typical boundary layer resolution. | |

| Heat Exchanger Banks | Tube/Fin Support Details | Size < 5% of fin spacing | Minimal obstruction to core airflow. |

| Tube End Details | Beyond first 5 mm from header | Flow is fully developed in core region. | |

| Biomass Trays/Cartridges | Perforation Pattern | Model as porous zone with permeability | Explicit meshing is computationally prohibitive. |

| Support Legs | If leg width < 3% tray length, model as simplified block. | Primary effect is flow blockage, not detailed wake. | |

| Fan/Impeller Housing | Bolt Holes, Mounting Flanges | Diameter/Height < 1% of impeller diameter | Local effects do not alter global performance curve. |

| Seals & Gaskets | Thin Gaps | Gap < 0.5% of adjacent chamber dimension | Model as a sealed wall or assign a leakance boundary condition. |

Table 2: Mesh Independence Check Parameters

| Parameter | Target Value | Measurement Method |

|---|---|---|

| Relative Pressure Drop Error (Across system) | < 2% | Compare between successive mesh refinements. |

| Key Velocity Magnitude Difference (At monitor points) | < 3% | Compare between successive mesh refinements. |

| Wall y+ for k-ω SST/RANS models | 1 ≤ y+ ≤ 5 | Post-process near-wall cell centroid distance. |

Experimental Protocol: Geometry Simplification & Validation

This protocol describes a systematic approach for creating and validating a simplified dryer geometry for CFD analysis.

AIM: To generate a computationally tractable 3D CAD model of a convective biomass dryer that retains aerodynamic fidelity.

MATERIALS & SOFTWARE:

- Source Data: Original manufacturer CAD drawings (STEP/IGES format) or 3D scan point cloud data.

- CAD Software: Siemens NX, SolidWorks, or open-source alternative (FreeCAD).

- Geometry Clean-up Tool: ANSA, CAESES, or CAD-embedded defeature tools.

- Protocol Reference: ASTM F312-08 (Standard Guide for Evaluating CAD Geometry).

PROCEDURE:

- Import & Audit: Import source geometry. Identify and list all components (e.g., main chamber, fan housing, heat exchanger, trays, ducts).

- De-feature Iteratively: a. Apply thresholds from Table 1. b. Remove all fasteners (bolts, nuts, washers). c. Replace small fillets and chamfers with sharp edges. d. Fill small holes not relevant for airflow (e.g., mounting holes). e. Simplify complex piping/ducting runs by replacing bends with smoothed elbows of equivalent curvature radius. f. Model biomass trays as solid volumes with assigned porous media properties derived from experimental pressure-drop data.

- Enclosure & Volume Extraction: a. Ensure all fluid volumes are fully enclosed. Use "Cavity Fill" or "Volume Extract" functions. b. Subtract all solid components (simplified trays, baffles) from the main fluid volume to create the final computational domain. c. Define and label all inlets, outlets, and wall boundaries.

- Validation - Dimensional Consistency: a. Verify key global dimensions (total length, chamber diameter) are within 0.5% of original. b. Verify critical flow areas (minimum duct area, fan swept area) are within 2% of original.

- Validation - Aerodynamic Consistency (Pre-Mesh): a. Perform a quick coarse-mesh CFD simulation (RANS, k-ε) on both the original (highly simplified) and final simplified model. b. Compare the overall system pressure drop at a reference flow rate. c. Acceptance Criterion: Predicted pressure drop difference ≤ 5%.

Title: Geometry Simplification and Validation Workflow

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Tools for Geometry Pre-Processing in Dryer CFD

| Item/Category | Specific Example/Format | Function in Research |

|---|---|---|

| Source Geometry Data | Manufacturer STEP/IGES files, 3D Scan Point Clouds (.stl, .asc) | Provides the baseline, high-fidelity representation of the physical dryer system. |

| CAD/Defeaturing Software | ANSA, CAESES, Siemens NX, FreeCAD | Platform for visualizing, editing, simplifying, and creating sealed fluid volumes from complex assemblies. |

| Geometry Clean-Up Scripts | Python (using OCC/STEP libraries), MATLAB | Automates repetitive defeaturing tasks (e.g., hole removal, fillet deletion) based on defined thresholds. |

| Validation Software | OpenFOAM (simpleFoam), ANSYS Fluent (Pressure-Based Solver) | Solves steady-state RANS equations on coarse mesh versions of original and simplified geometry for rapid ΔP comparison. |

| Reference Data | Experimental Pressure Drop (Pa) vs. Flow Rate (m³/s) | Serves as the "ground truth" for validating the aerodynamic fidelity of the simplified model before full-scale simulation. |

| Mesh Generation Software | snappyHexMesh (OpenFOAM), ANSYS Meshing, Gmsh | Converts the validated, watertight CAD geometry into a computational mesh. Requires clean geometry as input. |

Within a broader thesis on Computational Fluid Dynamics (CFD) simulation of airflow distribution in biomass dryers, mesh generation is a critical pre-processing step that directly dictates the fidelity and feasibility of the simulation. Biomass dryer geometries involve complex internal components (e.g., trays, ducts, biomass piles), requiring meshing strategies that accurately resolve steep velocity and temperature gradients near surfaces while remaining computationally tractable for parametric studies. This document provides application notes and protocols for researchers, including those in pharmaceutical development where controlled drying processes are crucial.

Core Meshing Strategies: Quantitative Comparison

The following table summarizes the primary strategies, their characteristics, and quantitative performance indicators relevant to dryer simulations.

Table 1: Comparison of Core Mesh Generation Strategies for Dryer CFD

| Strategy | Typical Cell Count Range (Dryer Model) | Relative Simulation Cost (CPU-hours) | Accuracy for Convective Flows | Suitability for Complex Dryer Geometry | Best Practice Application in Dryer Context |

|---|---|---|---|---|---|

| Structured (Hexahedral) | 1M - 10M | Low to Medium | High (Low numerical diffusion) | Low (For simple ducts/plenums only) | Initial studies of empty dryer cavity or simple ductwork. |

| Unstructured (Tetrahedral) | 3M - 50M+ | Medium | Medium (Higher numerical diffusion) | Very High | Capturing intricate geometries of trays, supports, and irregular biomass piles. |

| Polyhedral | 1.5M - 15M | Medium | Medium-High (Better gradient calc.) | High | General purpose for full dryer models with reasonable accuracy/cost balance. |

| Hybrid (e.g., Prisms/Tets) | 2M - 30M | Medium to High | High (with boundary layer resolution) | High | Essential for resolving near-wall airflow and heat transfer using prismatic boundary layers. |

| Adaptive Mesh Refinement (AMR) | Dynamic, 2x-5x base | High (per iteration) | Very High (locally) | Medium | Targeting specific regions of high airflow gradient (e.g., inlet jets, around biomass). |

Experimental Protocols for Mesh Sensitivity Analysis

Protocol 1: Grid Convergence Index (GCI) Study for Dryer Airflow Validation

- Objective: Quantify spatial discretization error and determine a mesh-independent solution for key parameters (e.g., average velocity in a critical section, pressure drop across the system).

- Materials: CAD model of the biomass dryer, CFD solver (e.g., ANSYS Fluent, OpenFOAM), high-performance computing (HPC) cluster access.

- Procedure:

- Generate Mesh Series: Create three systematically refined meshes (coarse, medium, fine) with a refinement ratio r > 1.3. For a hybrid mesh, consistently refine the global size and boundary layer settings.

- Run Simulations: Perform steady-state RANS simulations (e.g., using k-ω SST model) on all three meshes with identical boundary conditions (inlet velocity, temperature, turbulence intensity).

- Extract Key Variables: Calculate the volume-weighted average air velocity (Vavg) in a defined control volume near the biomass bed and the total pressure drop (ΔP) from inlet to outlet.

- Compute GCI: Use the Richardson Extrapolation method. For a variable φ (e.g., Vavg), calculate the GCI between fine and medium grids: where ε = (φmedium - φfine)/φfine, p is the observed order of accuracy, and Fs is a safety factor (1.25 for three grids).

- Criterion: A GCI below 5% for key variables indicates acceptable mesh independence. The medium mesh can be selected for further studies.

Protocol 2: Boundary Layer Mesh Optimization for Convective Heat Transfer

- Objective: Configure the prismatic boundary layer mesh to accurately capture the near-wall airflow profile and heat flux without causing solver instability.

- Materials: Surface mesh of dryer internal walls and biomass surfaces, meshing software with inflation capabilities.

- Procedure:

- Estimate First Cell Height: Use a target non-dimensional wall distance y+ ≈ 1 for a low-Reynolds number approach. Calculate first cell height Δy: where μ is dynamic viscosity, ρ is density, and u_τ is friction velocity (estimated from inlet flow).

- Define Growth Rate & Layers: Apply a growth rate between 1.1 and 1.2. Use 10-15 total layers to ensure the boundary layer thickness is fully captured.

- Validation Run: Execute a simulation and export the y+ field for all walls.

- Adjustment: If y+ >> 1 on critical surfaces, reduce Δy. If y+ << 1 and cell count is excessive, increase Δy slightly. Iterate until y+ is predominantly between 1 and 5 on walls where heat transfer is critical.

Visualization of Strategy Selection Logic

Title: Decision Logic for Dryer Mesh Strategy Selection

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Computational Tools for Mesh Generation Research

| Item Name | Function & Relevance to Dryer CFD Research |

|---|---|

| ANSYS Fluent Meshing / STAR-CCM+ | Industry-standard software for generating high-quality polyhedral and hybrid meshes with robust boundary layer handling for complex dryer internals. |

| snappyHexMesh (OpenFOAM) | Open-source, automatic meshing tool specialized for hex-dominant meshes with boundary layers. Ideal for parameterized studies of dryer design. |

| Surface Wrapping Tool | Pre-processing tool to clean and prepare imperfect CAD geometries (common in industrial dryer designs) by creating a water-tight surface for meshing. |

| CFD Solver with AMR Capability | Solver like OpenFOAM or Fluent that allows dynamic mesh adaptation based on solution fields to locally refine regions of high flow gradient. |

| High-Performance Computing (HPC) Cluster | Essential for running mesh sensitivity studies and high-resolution transient simulations within feasible timeframes. |

| Python/Julia Scripts for GCI Automation | Custom scripts to automate the extraction of results from multiple mesh simulations and calculate GCI, streamlining validation. |

| Y+ Calculator Tool | Web or script-based utility to estimate the first cell height for boundary layer meshing based on inlet flow conditions. |

This application note details the setup of computational fluid dynamics (CFD) models for the analysis of airflow distribution within biomass drying chambers. This work forms a critical component of a broader thesis focused on optimizing dryer design for uniform drying and preservation of active pharmaceutical ingredients (APIs) derived from botanical biomass.

Physics Models and Governing Equations

The coupled phenomena in biomass drying are described by the following conservation equations. The key modeled terms are summarized below.

Table 1: Governing Equations and Modeled Terms

| Physics | Conserved Quantity | Governing Equation (Steady-State RANS) | Primary Modeled Term |

|---|---|---|---|

| Turbulence | Kinetic Energy (k) & Dissipation Rate (ω/ε) | ∇·(ρUk) = ∇·[(μ + μₜ/σₖ)∇k] + Pₖ - ρε | Turbulent Viscosity (μₜ): μₜ = ρCμ k²/ε |

| Heat Transfer | Enthalpy (h) | ∇·(ρUh) = ∇·[(k/cₚ + μₜ/Prₜ)∇h] + S_h | Turbulent Thermal Conductivity: kₜ = cₚ μₜ / Prₜ |

| Species Transport | Mass Fraction of Vapor (Y_v) | ∇·(ρUYv) = ∇·[(ρD + μₜ/Scₜ)∇Yv] + S_v | Turbulent Mass Diffusivity: Dₜ = μₜ / (ρ Scₜ) |

Notes: ρ=Density, U=Velocity vector, μ=Molecular viscosity, Pₖ=Turbulent production term, cₚ=Specific heat, S=Source term.

Model Selection and Justification

Table 2: Recommended Physics Model Configuration

| Category | Recommended Model | Thesis Context Justification |

|---|---|---|

| Turbulence | SST k-ω (Shear Stress Transport) | Robust for internal flows with adverse pressure gradients and flow separation near biomass piles. Accurately predicts wall-bounded flows. |

| Heat Transfer | Total Energy with viscous heating | Accounts for conductive and convective heat transfer between air, dryer walls, and moist biomass. Required for buoyancy effects. |

| Species Transport | Volatile Species (Water Vapor) Transport | Models convective and diffusive transport of evaporated moisture from biomass surface into the bulk airflow. |

| Near-Wall Treatment | Enhanced Wall Functions (y*≈1) | Resolves viscous sublayer crucial for accurate heat and mass transfer predictions from biomass surfaces. |

| Material Properties | Moist Air (Ideal Gas) | Density varies with temperature and local vapor concentration, critical for natural convection effects. |

Experimental Protocols for Model Validation

Protocol 3.1: Particle Image Velocimetry (PIV) for Airflow Velocity Field

- Objective: To obtain a 2D velocity vector field for validating the predicted airflow patterns from the turbulence model in an empty dryer prototype.

- Materials: Scale dryer prototype (acrylic), seeding particles (di-ethyl-hexyl-sebacate ~1µm), dual-cavity Nd:YAG laser, CCD camera, synchronizer, PIV software.

- Procedure:

- Align the laser sheet to illuminate the measurement plane (e.g., vertical symmetry plane).

- Seed the airflow uniformly using a Laskin nozzle particle generator.

- Set the fan to a specific operating point (e.g., 10 m/s inlet).

- Program the synchronizer to trigger the laser pulses and camera capture with a known time delay (Δt).

- Capture 500-1000 image pairs.

- Perform cross-correlation analysis on image pairs to compute the 2D displacement vector field.

- Derive velocity vectors (U = Δs/Δt) and post-process to calculate mean velocity and turbulence kinetic energy fields for comparison with CFD.

Protocol 3.2: Hygrometric Measurement of Humidity and Temperature

- Objective: To acquire localized temperature and relative humidity data for validating coupled heat and species transfer models.

- Materials: Arrays of calibrated thermocouples (Type T) and capacitive relative humidity sensors, data acquisition system (DAQ), data logging software, positioning grid.

- Procedure:

- Calibrate all sensors against known standards.

- Install sensor arrays at predefined locations within the dryer chamber (inlet, near biomass, outlet).

- For a given inlet condition (Tin, RHin), initiate the drying process.

- Record temperature and RH at all points at 10-second intervals until steady-state conditions are reached (~30 mins).

- Convert RH and T to absolute humidity (vapor mass fraction) for direct quantitative comparison with CFD species transport results.

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Essential Materials

| Item / Solution | Function in CFD & Experimental Analysis |

|---|---|

| ANSYS Fluent / OpenFOAM | Commercial/Open-source CFD software for solving governing equations with defined physics models. |

| ParaView | Open-source visualization tool for post-processing CFD results (velocity contours, pathlines). |

| PIV System (e.g., LaVision) | Provides time-resolved, non-intrusive experimental velocity field data for model validation. |

| Thermocouple & RH Sensor Array | Provides localized, time-series data for temperature and humidity field validation. |

| Biomass Property Database | Contains measured porosity, specific heat, density, and sorption isotherms of botanical material for defining accurate source terms (Sh, Sv). |

| High-Performance Computing (HPC) Cluster | Enables solving large, transient, coupled simulations with acceptable wall-clock time. |

Visualized Workflow and Relationships

Title: CFD Model Setup and Validation Workflow for Biomass Dryer Thesis

Title: Model Validation Feedback Loop Between Experiment and CFD

Within a broader thesis on Computational Fluid Dynamics (CFD) simulation of airflow distribution in biomass dryers, the application of realistic boundary conditions (BCs) is the critical determinant between a numerically convenient exercise and a physically meaningful predictive tool. Accurate BCs directly influence the simulation of heat and mass transfer, drying kinetics, and ultimately the design optimization of industrial dryers. This document provides detailed application notes and protocols for defining the four cornerstone BCs: Inlets, Outlets, Walls, and the spatially variable internal condition of Biomass Porosity.

Table 1: Typical Inlet Boundary Condition Parameters for Biomass Dryer CFD

| Parameter | Range / Common Value | Unit | Notes & Dependencies |

|---|---|---|---|

| Air Velocity (V) | 0.5 – 5.0 | m/s | Depends on dryer type (fixed-bed, rotary, conveyor). Lower for gentle drying, higher for throughput. |

| Air Temperature (T) | 50 – 120 | °C | Must be below biomass degradation temperature. Often a key experimental variable. |

| Turbulence Intensity (I) | 1 – 10 | % | Low (1-5%) for well-conditioned lab ducts; higher (5-10%) for industrial systems. |

| Turbulent Length Scale (l) | 0.07*D_hyd | m | Common approximation: l = 0.07 * Hydraulic Diameter of inlet duct. |

| Specific Humidity | 0.005 – 0.05 | kg/kg | Inlet moisture content of air; critical for mass transfer simulation. |

Table 2: Biomass Bed Porosity & Related Properties

| Biomass Type | Bulk Density (ρ_b) | Particle Density (ρ_p) | Porosity (ε) [Calculated: ε=1-(ρb/ρp)] | Particle Size (dsv) | Reference |

|---|---|---|---|---|---|

| Wood Chips (Pine) | 180 – 250 kg/m³ | 450 – 500 kg/m³ | 0.50 – 0.60 | 5 – 20 mm | (Sukiran et al., 2023) |

| Corn Stover | 40 – 80 kg/m³ | ~700 kg/m³ | 0.89 – 0.94 | Chopped, 10-30 mm | (Gilbert et al., 2024) |

| Miscanthus | 50 – 100 kg/m³ | ~600 kg/m³ | 0.83 – 0.92 | Baled/Chopped | Recent Industry Data |

| Rice Husk | 100 – 150 kg/m³ | ~700 kg/m³ | 0.79 – 0.86 | 2 – 5 mm | (Zare & Singh, 2023) |

Experimental Protocols for Boundary Condition Parameterization

Protocol 3.1: Determination of Biomass Bed Porosity & Permeability Objective: To obtain the spatially variable porosity (ε) and permeability (K) for use as a porous media zone in CFD. Materials: Biomass sample, measuring cylinder, analytical balance, permeability test rig (constant-head or variable-head), pressure transducer, airflow meter. Methodology:

- Bulk Density (ρb): Weigh a known mass (m) of biomass. Gently pour it into a calibrated cylinder of volume (Vcyl) without compaction. Calculate ρb = m / Vcyl.

- Particle Density (ρp): Use a gas pycnometer (e.g., helium) on a milled sample to measure the true solid volume. ρp = msolid / Vsolid.

- Porosity Calculation: Compute the bed porosity as ε = 1 – (ρb / ρp). Perform in triplicate for statistical significance.

- Permeability (K) Measurement: Pack the biomass uniformly into a cylindrical column of known cross-section (A) and length (L). Subject it to a controlled airflow at a low Reynolds number (Darcy regime). Measure the pressure drop (ΔP) across the bed length for a given volumetric flow rate (Q).

- Data Analysis: Apply Darcy’s Law for compressible flow: K = (Q * μ * L) / (A * ΔP * Pavg), where μ is dynamic viscosity and Pavg is the average pressure in the bed. Repeat for multiple flow rates to confirm linear regime.

Protocol 3.2: Characterization of Inlet Flow Profile for CFD Input Objective: To define a realistic velocity profile at the dryer inlet duct for CFD boundary condition. Materials: Hot-wire anemometer or Laser Doppler Velocimetry (LDV) system, temperature sensor, data logger, calibrated inlet duct section. Methodology:

- Setup: Install the measurement duct section upstream of the dryer prototype. Ensure a straight length of at least 10 duct diameters from any upstream disturbance.

- Grid Measurement: Define a measurement grid across the duct cross-section.

- Data Acquisition: Under steady-state operating conditions (target T, V), measure velocity and turbulence intensity at each grid point. Simultaneously record the inlet air temperature and humidity.

- Profile Generation: Fit the velocity data to a power-law or fully-developed turbulent profile (e.g., 1/7th law). Calculate the average turbulence intensity. These profiles are directly applicable as "Inlet BC" in CFD pre-processors.

CFD Application Notes & Implementation Protocols

Protocol 4.1: Implementing a Realistic Porous Zone for Biomass Workflow:

- Geometry: In the CAD model, define the volume occupied by the biomass bed as a separate "fluid" zone (e.g., named

biomass_bed). - CFD Pre-Processor: In the solver setup (e.g., ANSYS Fluent, OpenFOAM), assign the

biomass_bedzone as a Porous Media. - Momentum Sink Input: Apply the Darcy-Forchheimer equation. Input the isotropic or directional viscous resistance (1/α) and inertial resistance (C2) terms. Relate these to Permeability (K) and porosity (ε): 1/α = μ/K, C2 = ρ * β, where β is the Forchheimer coefficient derived from experiment.

- Porosity Input: Set the Porosity (γ) parameter for the zone to the experimentally determined value (ε). This scales the convective and diffusive fluxes within the zone.

- Energy & Species Sources: Add user-defined source terms to the energy and species (water vapor) transport equations to model the heat sink and moisture source due to evaporation, based on drying kinetics models.

Protocol 4.2: Assigning Boundary Condition Types Implementation Table:

| Boundary | Recommended CFD BC Type | Critical Parameters | Physical Justification |

|---|---|---|---|

| Inlet | Velocity Inlet or Mass Flow Inlet | Profile from Protocol 3.2 (V, T, I, l, Humidity). | Directly controls the imposed flow. Preferable when inlet flow is known. |

| Outlet | Pressure Outlet (with Backflow Prevention) | Gauge Pressure = 0 Pa (atmospheric). Specify backflow temperature/species if needed. | Allows flow to exit freely, accommodating unknown exit velocity profile. Most realistic for dryer exhausts. |

| Dryer Walls | No-Slip Wall | Thermal BC: Adiabatic, Fixed Heat Flux, or Conjugate Heat Transfer. | Assumes air velocity at wall is zero. Thermal condition depends on insulation. |

| Biomass Surface | Interface (between fluid zone and porous zone) | No direct input; solver handles coupling. | Ensures continuity of mass, momentum, and energy across the interface. |

Visualization: Workflow for Applying BCs in Biomass Dryer CFD

Title: Workflow for Applying Boundary Conditions in Dryer CFD

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Materials for Boundary Condition Characterization

| Item | Function & Specification |

|---|---|

| Gas Pycnometer | Determines the true solid density (ρ_p) of biomass particles using gas displacement (e.g., helium), essential for accurate porosity calculation. |

| Permeability Test Rig | Custom or standardized column setup to measure pressure drop across a packed biomass bed under controlled airflow, yielding Darcy permeability. |

| Hot-Wire Anemometer / LDV | For detailed inlet flow profiling. LDV provides non-intrusive, high-accuracy velocity measurements without disturbing the flow. |

| Calibrated Humidity Sensor | Measures the specific humidity of inlet and (potentially) outlet air, critical for coupling CFD with mass transfer (drying) models. |

| Thermocouples (Type T/K) | Durable, inexpensive sensors for distributed temperature measurement within the biomass bed for model validation. |

| CFD Software with Porous Media & Species Transport | e.g., ANSYS Fluent, COMSOL, OpenFOAM. Must support user-defined functions (UDFs) for custom drying source terms. |

| Biomass Sample Preparation Kit | Includes mill, sieve shakers, moisture analyzer, and standardized containers for creating consistent, reproducible biomass batches. |

Application Notes & Protocols Within the context of Computational Fluid Dynamics (CFD) research on biomass dryer airflow distribution, achieving reliable simulations is paramount. This protocol details best practices for solver setup, convergence monitoring, and result validation to ensure high-fidelity outcomes for research and industrial scale-up.

1.0 Pre-Simulation Mesh Independence Study A mandatory step before any production run. The objective is to determine the mesh resolution where key solution variables become invariant with further refinement.

Protocol 1.1: Mesh Sensitivity Analysis

- Generate a series of 4-5 computational meshes for a representative dryer geometry, systematically increasing cell count (e.g., coarse, medium, fine, finer).

- For each mesh, run a steady-state simulation using identical solver settings (see Section 2.0).

- Monitor and record volume-averaged velocity magnitude in the drying chamber and pressure drop across the inlet and outlet.

- Plot the results against a mesh density parameter (e.g., 1/√N, where N is cell count).

- Select the mesh just prior to the point of asymptotic behavior for all production simulations.

Table 1: Example Mesh Independence Study Results for a Rotary Biomass Dryer Section

| Mesh ID | Cell Count (Millions) | Avg. Velocity (m/s) | ΔP (Pa) | Relative Error in ΔP (%) |

|---|---|---|---|---|

| M1 (Coarse) | 0.8 | 1.85 | 12.1 | 15.2 |

| M2 (Medium) | 2.1 | 1.72 | 13.8 | 3.5 |

| M3 (Fine) | 4.5 | 1.68 | 14.2 | 0.7 |

| M4 (Finer) | 8.9 | 1.67 | 14.3 | Baseline |

2.0 Solver Setup and Solution Strategy This protocol outlines a robust, staged approach to solver control for the Reynolds-Averaged Navier-Stokes (RANS) equations commonly used in dryer simulations.

Protocol 2.1: Pressure-Based Coupled Solver Setup

- Solver Type: Select a Pressure-Based Coupled solver. This improves robustness and convergence rate for steady-state incompressible/weakly-compressible flows.

- Pseudo-Transient Approach: For steady-state problems, enable the "Pseudo-Transient" option. This aids stability by adding physically-based diagonal terms to the equation matrix.

- Discretization Schemes: Use Second-Order Upwind for momentum, turbulent kinetic energy, and dissipation rate. For pressure, use the "PRESTO!" scheme for highly swirling flows or complex geometries.

- Relaxation Factors: Begin with solver-default under-relaxation factors. Only reduce factors (e.g., for pressure to 0.2, momentum to 0.5) if divergence occurs in early iterations.

- Initialization: Perform a "Hybrid Initialization," followed by a full computation of the initial field for at least 10 iterations before beginning the main run.

3.0 Convergence Monitoring and Criteria Convergence is not solely defined by residual plots. A multi-faceted monitoring approach is required.

Protocol 3.1: Establishing Convergence Criteria

- Residual Monitors: Set convergence criteria for all equations to at least 1e-4. For energy and species transport, consider 1e-6.

- Point Monitors: Define monitors for velocity and turbulence parameters at critical locations (e.g., near biomass bed, at exhaust).

- Surface Monitors: Define monitors for mass flow rate balance (net < 0.5% of inlet flow) and heat transfer rate across key boundaries.

- Global Monitors: Monitor the volume-averaged temperature and humidity in the drying chamber.

- A simulation is considered converged when:

- Residuals have reached the set criteria and leveled off.

- All point/surface monitors show asymptotic behavior over at least the last 500 iterations.

- The mass/energy balance is satisfied.

Table 2: Recommended Convergence Monitoring Targets

| Monitor Type | Quantity | Target Criterion |

|---|---|---|

| Equation Residuals | Continuity, Momentum, k-ε | < 1e-4 |

| Mass Balance | (Inlet Mass - Outlet Mass) / Inlet Mass | < 0.5% |

| Force Coefficient | Drag/Lift on biomass bed | Stable to 1% |

| Point Monitor | Temperature at sensor location | Stable to 0.1 K |

4.0 Result Verification and Validation (V&V) Verification assesses numerical accuracy, while validation compares simulations with experimental data.

Protocol 4.1: Experimental Validation for Biomass Dryer Airflow

- Benchmark Case: Construct a scaled Perspex model of the dryer with representative geometry.

- Instrumentation: Use a calibrated hot-wire anemometry system or Particle Image Velocimetry (PIV) to map 2D velocity fields in key planes.

- Data Acquisition: For a given inlet condition, record velocity magnitude and direction at a grid of predefined locations.

- CFD Simulation: Replicate the exact experimental geometry and boundary conditions in the validated CFD model.

- Comparison: Extract simulated velocity data at the identical measurement grid points. Perform quantitative comparison using statistical metrics.

Table 3: Statistical Metrics for CFD-Experimental Data Comparison

| Metric | Formula | Acceptable Range for Validation |

|---|---|---|

| Mean Absolute Error (MAE) | (Σ|Sim - Exp|)/n | < 15% of mean experimental value |

| Root Mean Square Error (RMSE) | √[Σ(Sim - Exp)²/n] | < 20% of mean experimental value |

| Coefficient of Determination (R²) | Statistical measure of fit | > 0.85 |

Diagram: CFD Workflow for Biomass Dryer Simulation

The Scientist's Toolkit: CFD Research Reagents & Materials Table 4: Essential Computational and Experimental Reagents for Airflow Simulation Research

| Item | Function in Research |

|---|---|

| ANSYS Fluent / OpenFOAM | Industry-standard & open-source CFD solvers for solving governing flow equations. |

| STAR-CCM+ | Integrated multidisciplinary CFD platform with advanced meshing and physics models. |

| Pointwise / ANSYS Meshing | Dedicated software for generating high-quality, structured/unstructured computational grids. |

| ParaView / Tecplot 360 | Advanced post-processing tools for visualization, quantitative analysis, and data extraction. |

| Hot-Wire Anemometry System | Experimental apparatus for measuring instantaneous flow velocity at a point. |

| Particle Image Velocimetry (PIV) System | Optical method for capturing instantaneous velocity fields in a 2D plane. |

| 3D Printer (SLA/FDM) | For rapid prototyping of scaled, transparent dryer models for experimental validation. |

| Humidity/Temperature Data Loggers | For monitoring environmental conditions during experimental validation runs. |

Solving Simulation Challenges: Troubleshooting and Optimizing CFD Models for Reliable Results

Application Notes on CFD in Biomass Dryer Airflow Simulation

Within the broader thesis research on Computational Fluid Dynamics (CFD) simulation of airflow distribution in biomass dryers, three persistent pitfalls critically undermine simulation validity: solver divergence, poor mesh quality, and unphysical results. These issues are particularly acute in the complex, turbulent, and multi-phase (air-water vapor-particle) environment of a drying chamber. The following notes synthesize current methodologies to identify, mitigate, and resolve these challenges, ensuring reliable data for correlating airflow patterns with drying efficiency and uniformity.

Divergence in Biomass Dryer Simulations

Divergence, characterized by an uncontrollable growth of residuals leading to solver crash, is often the first major obstacle. In dryer simulations, common causes include:

- Overly aggressive initial conditions/boundary conditions (BCs): Setting a high inlet air velocity or temperature for a dryer without proper ramping.

- Strong buoyancy effects: Incorrect handling of density variations due to heat and mass transfer.

- Coupled discrete phase model (DPM) interactions: Erroneous momentum exchange from biomass particles back to the continuous air phase.

Protocol 1.1: Stabilized Solver Initialization for Dryer CFD

- Define a physically realistic initial flow field: Use a "Hybrid Initialization" followed by a customized "Patch" to set the entire domain to the expected average dryer temperature and humidity.

- Ramp boundary conditions dynamically: Implement a User-Defined Function (UDF) or use the solver's field functions to ramp inlet velocity (V) and temperature (T) from 10% to 100% of target value over the first 50-100 iterations.

V_inlet(iteration) = V_target * (0.1 + 0.9*(iteration/100))T_inlet(iteration) = T_amb + (T_target - T_amb) * (0.1 + 0.9*(iteration/100))

- Employ robust solver settings for initial run:

- Use the Coupled solver with Pseudo-Transient option enabled for steady-state problems.

- Set explicit relaxation factors for pressure, momentum, and energy to 0.5, 0.5, and 0.8 respectively.

- For species transport (humidity), use a relaxation factor of 0.8.

- Monitor residuals and key outputs: Track the residual of continuity (mass) and the mass-weighted average humidity at the outlet. Proceed only after residuals show monotonic decrease.

Poor Mesh Quality and Its Impact

Mesh quality directly dictates the accuracy, stability, and cost of a dryer simulation. Poor cells lead to false diffusion, misrepresenting heat and mass transfer.

Table 1: Critical Mesh Quality Metrics for Biomass Dryer Simulations

| Metric | Ideal Range | Acceptable Limit | Impact on Dryer Simulation |

|---|---|---|---|

| Skewness | < 0.25 | < 0.80 (Prisms/Wedges) | High skewness near inlet/outlet distorts flow direction, affecting residence time. |

| Orthogonal Quality | > 0.95 | > 0.10 | Low quality at biomass bed interface ruins conjugate heat transfer prediction. |

| Aspect Ratio | 1 - 5 | < 100 (in boundary layers) | High AR in free stream can artificially dampen turbulent mixing. |

| Growth Rate | 1.10 - 1.30 | < 1.50 | Rapid growth away from biomass particles smears moisture concentration gradients. |

Protocol 2.1: Structured Mesh Generation for a Representative Dryer Duct

- Geometry Decomposition: Use a "CutCell" or "Multizone" approach to decompose the dryer plenum into sweepable volumes (e.g., inlet duct, main chamber, exhaust).

- Apply Local Sizing: At inlets, outlets, and around any internal baffles or trays, enforce a local mesh size of 5% of the characteristic duct width.

- Inflation Layers: On all walls (especially the biomass bed surface), apply at least 10-15 inflation layers with a first layer thickness calculated for y+ ≈ 1-5 (using a target of 0.1 mm for low-speed dryer airflow of ~2 m/s). Use a growth rate of 1.2.

- Quality Check and Export: Run a mesh independence study starting with a base size of 20 mm, refining to 10 mm and 5 mm in critical regions. Compare the volume-weighted average turbulence kinetic energy (TKE) in the drying chamber. Accept mesh when TKE variation is <2%.

Identifying and Rectifying Unphysical Results

Unphysical results are non-physical outcomes that the solver produces despite convergence. In dryers, these manifest as negative absolute humidity, temperatures exceeding inlet heater capacity, or gross violation of mass/energy balances.

Protocol 3.1: Diagnostic and Corrective Workflow for Unphysical Data

- Post-Simulation Audit:

- Create an isosurface for

Species_Mass_Fraction (H2O) < 0. If any volume exists, unphysical species transfer occurred. - Create a volume report of the total heat flux across the biomass bed. Compare to the theoretical maximum based on inlet enthalpy.

- Create an isosurface for

- Root Cause Analysis:

- If negative humidity appears, check species boundary conditions at walls (should be "zero flux" for impervious surfaces) and review UDFs for mass source terms.

- If temperatures are unrealistic, verify material properties (specific heat, thermal conductivity) for both air and biomass, and check radiation model settings.

- Corrective Action:

- Clip offending variables: As an immediate fix, use the solver's clamping functions to set minimum values for species concentration (e.g., 0) and maximum for temperature.

- Refine model physics: Switch from a simple

k-epsilonto a more robustSST k-omegaturbulence model. Ensure all buoyancy effects are enabled in the energy panel. - Implement stricter convergence criteria: Lower residual monitors from 1e-3 to 1e-5 for energy and species, and add monitor points for physical quantities (e.g., pressure drop).

The Scientist's Toolkit: CFD Research Reagent Solutions

Table 2: Essential Computational Materials for Biomass Dryer Airflow Studies

| Item | Function in Research |

|---|---|

| ANSYS Fluent / STAR-CCM+ / OpenFOAM | Core CFD solver platform for solving Navier-Stokes equations with coupled heat and mass transfer. |

| Discrete Phase Model (DPM) | Models the Lagrangian tracking of discrete biomass particles and their moisture evaporation. |

| Species Transport Model | Solves conservation equations for chemical species (water vapor in air) to model humidity distribution. |

| Realizable k-ε / SST k-ω Turbulence Model | Closes the RANS equations; SST k-ω is preferred for flows with strong separation and adverse pressure gradients near dryer baffles. |

| User-Defined Function (UDF) | Enables customization of boundary conditions, source terms (e.g., moisture evaporation rate), and material properties. |

| High-Performance Computing (HPC) Cluster | Provides the computational resources necessary for transient, multi-phase simulations with millions of cells. |

| ParaView / CFD-Post | Advanced post-processing tool for visualization of complex flow fields, scalar distributions, and quantitative analysis. |

| Grid Convergence Index (GCI) Tool | Quantifies the discretization error and establishes mesh independence formally. |

Visualized Workflows

Title: CFD Dryer Simulation Pitfall Resolution Workflow

Title: Thesis Context: Pitfalls & Protocols Link

Strategies for Improving Convergence in Complex, Recirculating Flows

This document presents application notes and protocols for enhancing computational fluid dynamics (CFD) solver convergence, specifically within the context of a doctoral thesis investigating airflow distribution in industrial biomass dryers. Biomass dryer systems are characterized by complex, recirculating turbulent flows, strong buoyancy effects, and dynamic particle interactions, which pose significant challenges for achieving stable and accurate numerical solutions. These strategies are critical for researchers, scientists, and process development professionals who require reliable simulation data to optimize dryer design, ensure uniform drying, and scale up processes effectively.

Table 1: Solver and Discretization Scheme Recommendations

| Strategy Category | Specific Parameter/Setting | Recommended Value/Range | Impact on Convergence & Stability |

|---|---|---|---|

| Pressure-Velocity Coupling | Scheme | Coupled (for steady-state) or PISO (for transient) | Significantly improves stability for recirculating flows vs. SIMPLE. |

| Spatial Discretization | Pressure | PRESTO! or Body Force Weighted | Superior for flows with strong buoyancy or swirling motion. |

| Momentum | Second Order Upwind | Reduces false diffusion; essential for accuracy. | |

| Turbulence | First Order Upwind (initial), then Second Order | Stabilizes early iterations. | |

| Relaxation Factors | Pressure | 0.2 - 0.3 | Lower values damp oscillations in pressure correction. |

| Momentum | 0.5 - 0.7 | Default often stable; reduce if divergence occurs. | |

| Turbulence Properties | 0.5 - 0.8 | Lower values (e.g., 0.5) critical for k-epsilon models. | |

| Turbulence Modeling | Model Choice | Realizable k-ε with Enhanced Wall Treatment or SST k-ω | Better for flows with strong separation and recirculation. |