Modeling Biomass Drying in ANSYS FLUENT: A Guide for Pharmaceutical and Bioprocess Researchers

This article provides a comprehensive, step-by-step guide to setting up a computational fluid dynamics (CFD) simulation of a biomass drying chamber using ANSYS FLUENT.

Modeling Biomass Drying in ANSYS FLUENT: A Guide for Pharmaceutical and Bioprocess Researchers

Abstract

This article provides a comprehensive, step-by-step guide to setting up a computational fluid dynamics (CFD) simulation of a biomass drying chamber using ANSYS FLUENT. Aimed at researchers and scientists in drug development and bioprocessing, it covers the foundational physics of porous media and multiphase flow, a detailed methodological workflow from geometry to solution, common troubleshooting and mesh optimization techniques, and strategies for model validation against experimental data. The content is designed to empower users to create accurate, efficient simulations to optimize critical drying parameters for sensitive biomaterials, thereby accelerating process development and scale-up.

Understanding the Physics: Core Principles for Modeling Biomass Drying in CFD

Within the context of an ANSYS FLUENT-based thesis investigating heat and mass transfer phenomena, the biomass drying chamber is defined as a controlled enclosure where convective, conductive, and/or radiative energy is applied to reduce the moisture content of lignocellulosic or organic feedstock. Accurate computational fluid dynamics (CFD) modeling in FLUENT requires a precise digital twin of the physical system, mandating a detailed understanding of its key components, their interrelationships, and operational parameters.

Key Physical Components and Their Quantitative Parameters

The chamber's performance is dictated by the specification and interaction of the following core components.

Table 1: Key Structural & Mechanical Components

| Component | Primary Function | Common Materials | Key Design Parameters (Typical Range) |

|---|---|---|---|

| Enclosure/Casing | Contains the process, provides insulation. | Stainless steel (304, 316), carbon steel with coating, insulated panels. | Wall thickness: 2-10 mm. Insulation thickness (mineral wool/rockwool): 50-200 mm. K-value: 0.03-0.05 W/m·K. |

| Air Handling Unit (AHU) | Circulates, heats, and conditions the drying medium. | Steel housing, copper/aluminum fins and tubes. | Airflow rate: 0.5 - 5.0 m³/s. Static pressure: 500 - 2000 Pa. Fan power: 2 - 50 kW. |

| Heating System | Supplies thermal energy to the drying medium. | Electrical resistance heaters, finned-tube heat exchangers (steam/hot water). | Capacity: 50 - 2000 kW. Temperature range: 50°C - 300°C. Response time: Varies by type. |

| Biomass Conveyance | Transports biomass through the chamber. | Perforated belts (mesh), rotary drums, trays, trucks. | Belt speed: 0.005 - 0.1 m/s. Load capacity: 20 - 150 kg/m². Open area: 30-50%. |

| Exhaust/ Ventilation | Removes moisture-laden air, controls pressure. | Dampers, exhaust fans, ductwork. | Exhaust air ratio: 10-40% of total airflow. Humidity control: 10-90% RH (outlet). |

| Sensors & Probes | Monitors process variables for control & CFD validation. | PT100/1000 RTDs, capacitive humidity sensors, anemometers. | Temp. accuracy: ±0.1°C - ±0.5°C. Humidity accuracy: ±1% - ±3% RH. |

Table 2: Critical Process Parameters for FLUENT Setup

| Parameter | Symbol | Typical Range | Impact on CFD Model |

|---|---|---|---|

| Inlet Air Temperature | T_in | 50°C - 300°C | Primary boundary condition; affects buoyancy & reaction rates. |

| Inlet Air Velocity | v_in | 0.5 - 5.0 m/s | Defines flow regime (Re); key for convective transfer. |

| Inlet Air Relative Humidity | RH_in | 5% - 30% | Drives mass transfer potential. |

| Initial Biomass Moisture Content (wet basis) | MCwbinitial | 30% - 60% | Initial condition for porous media model. |

| Final Target Moisture Content | MCwbfinal | 8% - 15% | Defines simulation stop criterion. |

| Biomass Bulk Density | ρ_bulk | 150 - 400 kg/m³ | Affects porosity and pressure drop in porous zone. |

| Bed Porosity | ε | 0.4 - 0.7 | Critical for porous media settings in FLUENT. |

| Specific Heat Capacity of Biomass | c_p | 1100 - 2500 J/kg·K | Material property for energy equation. |

Experimental Protocols for Parameterization and Validation

Protocol 1: Determination of Biomass Sorption Isotherms for Moisture Content Boundary Conditions Purpose: To establish equilibrium moisture content (EMC) data as a function of air temperature and relative humidity for defining biomass material properties in FLUENT. Materials: Gravimetric analyzer or dynamic vapor sorption (DVS) instrument; pre-dried biomass samples (particle size 1-2 mm); controlled temperature bath. Procedure:

- Pre-dry biomass samples in an oven at 105°C for 24 hours to achieve bone-dry state (MC ~0%).

- Place sample in the analyzer chamber. Set a constant temperature (e.g., 40°C, 60°C, 80°C).

- Program a stepwise increase in relative humidity (e.g., from 5% to 95% in 10% increments).

- At each RH step, hold until change in sample mass is < 0.01% per minute for 10 consecutive minutes (equilibrium).

- Record the equilibrium mass. Calculate EMC (dry basis):

EMC = (M_eq - M_dry) / M_dry * 100%. - Repeat for multiple temperatures. Fit data to a sorption model (e.g., Guggenheim-Anderson-de Boer - GAB) for implementation in FLUENT via user-defined functions (UDFs).

Protocol 2: Characterization of Bed Porosity and Pressure Drop for Porous Media Model Purpose: To determine the porosity and permeability coefficients (Darcy-Forchheimer) for the biomass bed to accurately configure the porous zone model in FLUENT. Materials: Test column of known diameter (D); biomass sample; differential pressure transducer; calibrated airflow source; flow meter. Procedure:

- Fill the test column uniformly with biomass at a known, representative bulk density (ρ_bulk).

- Calculate the bed porosity (ε):

ε = 1 - (ρ_bulk / ρ_particle), where ρ_particle is the true particle density (e.g., from pycnometer). - Connect the air supply to the bottom of the column. Measure airflow rate (Q) and the corresponding pressure drop (ΔP) across the bed height (L).

- Repeat for a range of superficial velocities (v_s = Q / column area), ensuring laminar flow within the bed.

- Use the Forchheimer equation to fit data:

ΔP/L = (μ/α) v_s + (C2 * ρ) v_s², where μ is viscosity, ρ is density. - Extract viscous resistance coefficient (

1/α) and inertial resistance coefficient (C2) for input into the FLUENT porous media dialog box.

Protocol 3: Thermal Imaging & Anemometry for CFD Validation Purpose: To collect spatial temperature and velocity data at the chamber outlet or within the freeboard for comparison with FLUENT simulation results. Materials: Infrared thermal camera; hot-wire or vane anemometer; data logging system; fixed positioning grid. Procedure:

- Under steady-state operating conditions, establish a measurement grid at the plane of interest (e.g., 10x10 points).

- Using the thermal camera (emissivity calibrated for the surfaces), record the temperature at each grid point.

- Using the anemometer, record the air velocity magnitude at the same grid points. For 3D vectors, use a 3D sonic anemometer or take measurements in multiple orientations.

- Log all data with spatial coordinates.

- In ANSYS FLUENT, after simulation convergence, extract temperature and velocity data at the corresponding plane.

- Perform quantitative validation using statistical metrics like Root Mean Square Error (RMSE) and coefficient of determination (R²).

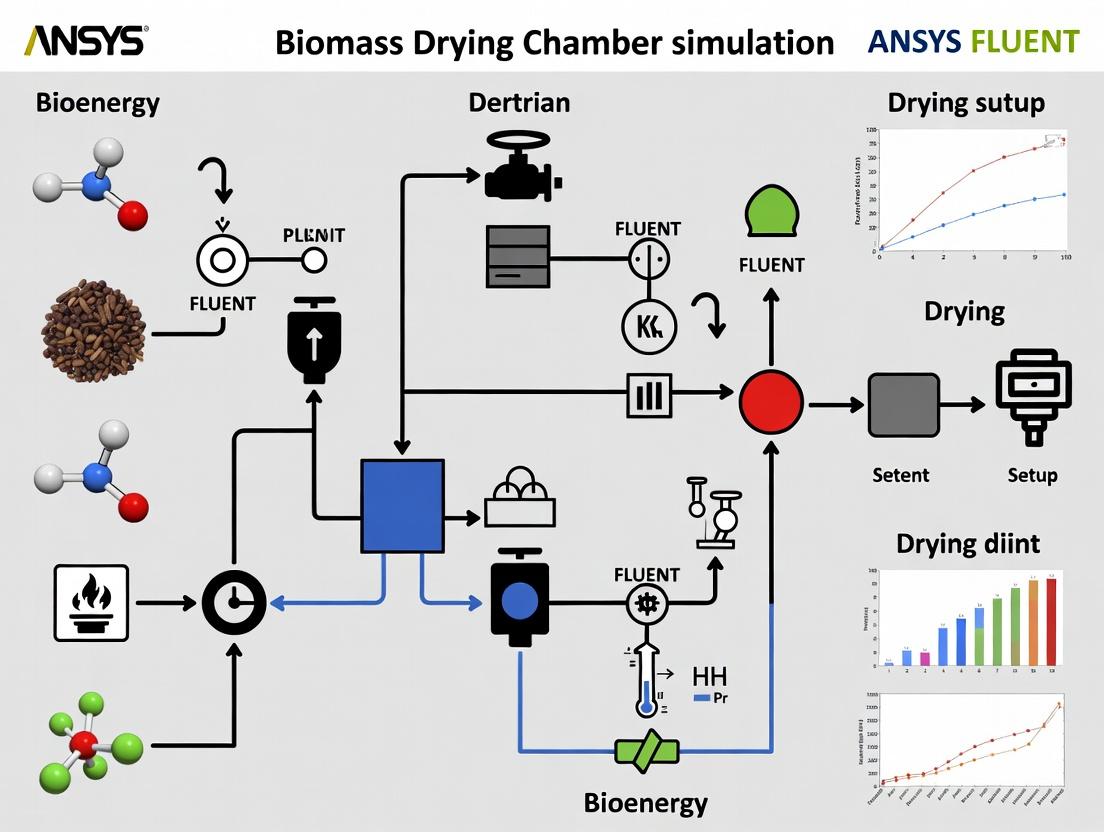

Diagram: Biomass Drying Chamber System for CFD Modeling

Diagram Title: ANSYS FLUENT System Definition & Dataflow for a Biomass Drying Chamber

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Research Materials for Chamber Characterization & Validation

| Item | Function/Application | Specification Notes |

|---|---|---|

| Dynamic Vapor Sorption (DVS) Analyzer | Measures moisture sorption isotherms of biomass samples with high precision. | Required for generating EMC = f(T, RH) data for material property UDFs. |

| True Density (Pycnometer) Analyzer | Determines the absolute (skeletal) density of biomass particles using gas displacement. | Critical for calculating bed porosity (ε) from bulk density measurements. |

| Hot-Wire Anemometry System | Measures local air velocity and turbulence intensity within the chamber freeboard. | Used for validating CFD velocity flow fields and setting inlet boundary conditions. |

| Infrared Thermal Camera | Captures 2D surface temperature distributions of chamber walls and biomass bed surface. | Essential for validating thermal boundary conditions and identifying hotspots. |

| Data Acquisition System (DAQ) | Logs time-series data from multiple sensors (T, RH, P, velocity). | Synchronizes experimental data for direct comparison with transient CFD results. |

| Calibrated Humidity & Temperature Probes | Provides accurate point measurements of air conditions at inlet, outlet, and critical interior locations. | Used for calibrating the thermal camera and validating species transport models. |

| Reference Biomass Sample | A standardized, homogenized biomass material with characterized properties. | Allows for reproducible experiments and benchmark comparisons between different CFD models. |

| ANSYS FLUENT with UDF Capability | The primary CFD software platform for solving the coupled heat and mass transfer equations. | Must be licensed with the Species Transport, Porous Media, and Multiphase modules. |

Fundamental Governing Equations in ANSYS FLUENT Context

Within ANSYS FLUENT, modeling transport in porous media like a biomass bed requires solving modified forms of the core conservation equations. These are implemented via the "Porous Media" model, which adds momentum sink terms to the standard fluid flow equations.

Table 1: Core Governing Equations for Porous Media in a Biomass Drying Chamber

| Equation Type | General Form in Porous Media (ANSYS FLUENT Context) | Key Terms & Physical Meaning |

|---|---|---|

| Mass (Continuity) | ∂(γρ)/∂t + ∇·(ρv) = 0 | γ: Porosity; ρ: Fluid density; v: Superficial velocity vector. Mass is conserved for the fluid phase. |

| Momentum | ∂(ρv)/∂t + ∇·(ρvv) = -∇p + ∇·τ + Sm | p: Pressure; τ: Stress tensor; Sm: Momentum sink source term (critical for porous media). |

| Energy (Fluid) | ∂(γρEf)/∂t + ∇·(v(ρEf+ p)) = ∇·(kf∇Tf) + hfsAfs(Ts-Tf) + Sf | Ef: Fluid total energy; kf: Fluid thermal conductivity; hfs: Convective heat transfer coefficient; Afs: Specific surface area; Tf, Ts: Fluid/Solid temp. |

| Energy (Solid) | ∂((1-γ)ρscsTs)/∂t = ∇·(ks∇Ts) + hfsAfs(Tf-Ts) + Ss | ρs, cs, ks: Solid density, specific heat, conductivity; Ss: Solid phase energy source (e.g., latent heat of evaporation). |

The momentum sink term Sm is defined using the Extended Darcy-Forchheimer model: Sm = - (μ/α v + C2 ½ ρ |v| v) Where:

- α: Permeability (m²)

- μ: Dynamic viscosity (Pa·s)

- C2: Inertial Resistance Factor (1/m)

- These coefficients are input as diagonal components in FLUENT's porous cell zone conditions.

Application Notes: Implementing Biomass Drying in ANSYS FLUENT

2.1. Porous Zone Setup: The wet biomass is modeled as a stationary, homogeneous porous zone. Porosity (γ) is a critical user-defined input, typically ranging from 0.4 to 0.6 for packed biomass chips. 2.2. Moisture & Energy Coupling (Simplified Approach): The evaporation of moisture is modeled via user-defined functions (UDFs) that introduce source terms (Ss, Sf) into the solid and fluid energy equations, respectively. The mass transfer rate (ṁ) from solid to vapor phase is calculated based on convective driving force: ṁ = hm Afs (ρv,s - ρv,b) Where hm is the mass transfer coefficient, and ρv,s and ρv,b are the vapor densities at the solid surface and in the bulk gas. 2.3. Solver Settings: Use a pressure-based solver. Enable the "Porous Medium" model. For drying, use the species transport model to track water vapor in the air. Enable energy equation. Use the SIMPLE or COUPLED scheme for pressure-velocity coupling.

Experimental Protocols for Parameter Determination

Protocol 1: Determination of Porous Media Resistance Coefficients (α, C₂)

- Objective: Empirically determine permeability and inertial resistance factor for a packed bed of biomass chips.

- Method: Conduct a packed-bed pressure drop experiment using air as the fluid.

- Pack a cylindrical column of known cross-section (A) and length (L) with biomass at a controlled packing density (representative of the drying chamber).

- Measure volumetric air flow rate (Q) using a calibrated flow meter.

- Measure pressure drop (ΔP) across the bed length using a differential manometer or pressure transducers.

- Vary Q over a representative range (5-7 data points).

- Fit the Forchheimer equation to the experimental data: ΔP/L = (μ/α) u + (ρ C₂) u², where u = Q/A is the superficial velocity.

- Perform a quadratic regression of ΔP/L vs. u. The linear coefficient gives (μ/α), and the quadratic coefficient gives (ρ C₂).

Protocol 2: Measurement of Effective Thermal Conductivity (keff) of Biomass Bed

- Objective: Determine the effective thermal conductivity of the wet porous biomass medium for input into the solid energy equation.

- Method: Utilize a transient hot-wire method or guarded heat flow meter.

- Prepare a sample holder filled uniformly with wet biomass at the target moisture content and porosity.

- For hot-wire method: Insert a thin, heated wire (acting as both heat source and temperature sensor) into the sample. Apply a constant heat flux and monitor temperature rise over time. keff is derived from the slope of the temperature vs. ln(time) plot.

- For heat flow meter: Place the sample between two plates with a known temperature gradient. Measure the steady-state heat flux. Calculate keff from Fourier's law: keff = (q * L) / ΔT.

Visualization of ANSYS FLUENT Porous Drying Workflow

Diagram Title: ANSYS FLUENT Biomass Drying Simulation Setup Workflow

Diagram Title: Coupling of Governing Equations in Porous Drying Model

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials and Reagents for Biomass Drying Experiments

| Item | Function/Explanation in Research Context |

|---|---|

| Prepared Biomass Sample | Representative, uniformly sized and moisture-conditioned plant material (e.g., wood chips, agricultural waste). The core porous medium under study. |

| Calibrated Humidity Sensor | Precisely measures absolute/relative humidity of inlet and outlet air streams. Critical for mass transfer validation. |

| Differential Pressure Transducer | Measures the small pressure drop (ΔP) across the porous biomass bed for determining permeability (α) and inertial resistance (C₂). |

| Thermal Property Analyzer | Instrument (e.g., using transient plane source or hot wire method) to measure effective thermal conductivity (k_eff) and specific heat of the packed bed. |

| ANSYS FLUENT with UDF Capability | CFD software platform. User-Defined Functions (UDFs) are mandatory to program custom moisture evaporation source terms and property variations. |

| Controlled Climate Chamber | Provides precise, stable inlet air conditions (Temperature, Humidity, Flow Rate) for both calibration experiments and model validation. |

| Data Acquisition System (DAQ) | Logs time-series data from all sensors (T, P, RH, flow) during experiments for post-processing and direct comparison to simulation results. |

1. Introduction Within the thesis on ANSYS FLUENT setup for biomass drying chamber research, selecting an appropriate multiphase flow model is critical. The chamber involves complex interactions between moist air (gas), water vapor (gas), liquid water droplets (liquid), and solid biomass particles. This application note provides a protocol for selecting and implementing the Mixture, Eulerian, and Volume of Fluid (VOF) models in this context.

2. Comparative Summary of Multiphase Models

Table 1: Quantitative Comparison of Multiphase Flow Models for Biomass Drying Simulation

| Feature | Mixture Model | Eulerian (Euler-Euler) Model | VOF Model |

|---|---|---|---|

| Phase Treatment | Interpenetrating continua; phases share velocity field with slip | Interpenetrating continua; each phase has its own momentum equation | Tracks interfaces between immiscible fluids; phases share velocity field |

| Max. Phases Supported | Multiple (>2) | Multiple (>2) | Typically 2-3 per simulation |

| Interface Resolution | No explicit interface tracking | No explicit interface tracking | Explicitly resolves interfaces |

| Computational Cost | Low to Moderate | High | Moderate to High (depends on interface complexity) |

| Primary Drying Chamber Application | Spray drying of droplet-laden gas, initial particle-laden flow screening | Detailed particle/particle & particle/fluid interactions in fluidized beds or dense suspensions | Surface moisture evaporation, free-surface flows in wet biomass, condensate film formation |

| Typical Volume Fractions | Secondary phase(s) < 10-20% (dilute) | All phases can be significant (10-100%) | Applicable for any fraction, but interface must exist |

| Interphase Drag Models | Schiller-Naumann, Syamlal-O'Brien, etc. | Gidaspow, Syamlal-O'Brien, etc. | Not applicable (shared velocity) |

3. Protocol: Model Selection and Setup Workflow

Title: Multiphase Model Selection Decision Tree

4. Detailed Experimental Protocols

Protocol 4.1: Eulerian Model Setup for Fluidized Bed Drying

- Objective: Simulate coupled heat and mass transfer between hot gas and dense biomass particles.

- Methodology:

- Preprocessing: In ANSYS FLUENT, enable the Eulerian Multiphase Model with 2 phases: primary (air) and secondary (biomass particles, modeled as a granular phase with defined diameter and density).

- Physics Setup: Enable Interfacial Area and Heat Transfer models. Select the Syamlal-O'Brien drag model for granular flows. Activate the Species Transport model to simulate water vapor transfer.

- Boundary Conditions: Set inlet as velocity inlet with specified volume fraction for particles (e.g., 0.3). Set outlet as pressure-outlet.

- Material Definition: Create a custom moist air mixture and a custom biomass material with appropriate density, specific heat, and granular properties.

- Solution: Use the Phase Coupled SIMPLE algorithm. Initialize with a patched volume fraction for the particle bed.

Protocol 4.2: VOF Model Setup for Surface Moisture Evaporation

- Objective: Model the shrinking of a liquid water film on a biomass pellet surface.

- Methodology:

- Preprocessing: Enable the Volume of Fluid (VOF) model with 2 phases (air, liquid water). Enable Implicit Body Force Formulation and Open Channel Flow if applicable.

- Interface Modeling: Enable Surface Tension with wall adhesion. Define appropriate contact angles for the biomass wall material.

- Species & Reactions: Enable Species Transport with volumetric reactions. Define a user-defined function (UDF) for the evaporation source term, linking mass transfer to local temperature and vapor concentration.

- Solution: Use the Geo-Reconstruct scheme for interface tracking. Employ a fine mesh near the wall and interface region.

5. The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Materials and Models for FLUENT Biomass Drying Simulations

| Item/Model Name | Category | Function in Simulation |

|---|---|---|

| Custom Biomass Material | Material Property | Defines density, specific heat, and thermal conductivity of the solid biomass phase. |

| Water Vapor (H₂O) | Species | The key species transferred from the wet biomass into the gas phase during drying. |

| User-Defined Function (UDF) | Software Tool | Custom C code to define complex boundary conditions, source terms (evaporation rate), or material properties. |

| Granular Temperature Model | Physics Model | (Eulerian) Kinetic theory-based model for predicting particle-phase stresses and viscosity in dense flows. |

| Schiller-Naumann Drag Model | Interphase Model | (Mixture/Eulerian) Calculates drag force between fluid and spherical particles/droplets. |

| Lee Model | Phase Change Model | (VOF/Mixture) A common mass transfer model for evaporation and condensation. |

| High-Performance Computing (HPC) Cluster | Hardware | Essential for running computationally intensive Eulerian or transient VOF simulations within feasible time. |

This application note details the implementation and validation of moisture transport mechanisms—diffusion, convection, and evaporation source terms—within an ANSYS FLUENT framework for biomass drying chamber research. Accurate modeling of these coupled phenomena is critical for optimizing drying kinetics, preserving bioactive compounds in pharmaceutical biomass (e.g., plant-based precursors), and ensuring scalable process design.

Core Mechanisms & Mathematical Models

Moisture transport in a porous biomass matrix is governed by three primary mechanisms.

Liquid Diffusion (Fickian)

Internal moisture movement within biomass particles is modeled as a diffusion process.

J_diff = -ρ_s * D_eff * ∇X

Where J_diff is the moisture flux (kg/m²s), ρ_s is the dry solid density, D_eff is the effective diffusivity, and X is the dry-basis moisture content.

Convective Mass Transfer

At the solid-gas interface, moisture removal is driven by convection.

ṁ_conv = h_m * A * (ρ_v,s - ρ_v,b)

Where ṁ_conv is the convective mass transfer rate (kg/s), h_m is the convective mass transfer coefficient, A is surface area, and ρ_v are water vapor densities at surface and bulk.

Evaporation Source Term

The phase change from liquid to vapor within the biomass is introduced as a negative energy source and positive species source in the governing equations.

S_m = -ṁ_evap (for continuity)

S_h = -ṁ_evap * h_fg (for energy)

S_v = +ṁ_evap (for vapor species)

Where h_fg is the latent heat of vaporization.

Table 1: Typical Material Properties & Transport Coefficients for Pharmaceutical Biomass

| Parameter | Symbol | Value Range | Units | Notes |

|---|---|---|---|---|

| Effective Diffusivity | D_eff | 1.0e-10 – 1.0e-8 | m²/s | Function of temperature (T) & moisture content (X) |

| Convective Mass Transfer Coeff. | h_m | 0.01 – 0.05 | m/s | Depends on airflow velocity & geometry |

| Latent Heat of Vaporization | h_fg | 2.26e6 – 2.40e6 | J/kg | Slight variation with material & T |

| Dry Solid Density | ρ_s | 300 – 700 | kg/m³ | Plant-based biomass varies widely |

| Equilibrium Moisture Content | X_eq | 0.03 – 0.15 | kg/kg dry | Function of air RH & temperature |

Table 2: Key FLUENT Model Settings for Coupled Drying Simulation

| Model Category | Setting | Recommended Choice | Justification |

|---|---|---|---|

| Solver | Type | Pressure-Based, Transient | Captures time-dependent drying kinetics |

| Viscous Model | k-ε | Realizable k-ε with Enhanced Wall Treatment | Robust for internal forced convection |

| Species Transport | Enabled | Yes, with Water Vapor & Air | Tracks vapor concentration field |

| Energy Equation | Enabled | Yes | Required for thermal coupling |

| Porous Media | Treatment | User-Defined Function (UDF) | To define biomass zone with source terms |

| Evaporation Source | Implementation | User-Defined Scalar (UDS) & UDF | Most flexible for custom phase change logic |

Experimental Protocols for Model Validation

Protocol 4.1: Determination of Effective Moisture Diffusivity (D_eff)

Objective: Obtain D_eff for use in FLUENT's diffusion source term UDF.

Materials: Thin-layer biomass sample, precision balance, controlled climate chamber.

Procedure:

- Prepare thin slices (<5mm thick) of biomass to ensure 1-D diffusion.

- Saturate samples to uniform high moisture content.

- Place samples in climate chamber at constant T (e.g., 50°C) and RH (e.g., 30%).

- Record sample mass loss at regular intervals until equilibrium.

- Apply Fick’s second law solution for slab geometry:

MR = (X_t - X_eq)/(X_0 - X_eq) = (8/π²) Σ exp(-D_eff (2n+1)² π² t / 4L²). - Plot Ln(MR) vs. time;

D_effis derived from the slope of the linear segment.

Protocol 4.2: Measurement of Convective Mass Transfer Coefficient (h_m)

Objective: Empirically determine h_m for validation of FLUENT's surface convection.

Materials: Wet porous membrane (simulating saturated surface), wind tunnel, hygrometer, anemometer.

Procedure:

- Mount a water-saturated, non-deformable porous surface in wind tunnel test section.

- Set constant air velocity (U) and temperature (Tbulk). Measure vapor density in bulk (ρv,b).

- Assume surface is at saturation vapor density (ρ_v,sat) corresponding to surface temperature.

- Measure mass loss of the membrane over a precise interval to get

ṁ_conv. - Calculate

h_m = ṁ_conv / [A * (ρ_v,sat - ρ_v,b)]. - Repeat for a range of U to correlate

h_m = f(Re, Sc).

Protocol 4.3: In-situ Drying Kinetics for Source Term Calibration

Objective: Generate data to calibrate the evaporation source term rate (ṁ_evap).

Materials: Instrumented pilot-scale drying chamber, biomass trays, sensors (T, RH, weight).

Procedure:

- Load chamber with biomass at known initial moisture content

X_0. - Set constant inlet air conditions (velocity, temperature, humidity).

- Continuously log: a) Weight of biomass sample, b) Inlet/Outlet T & RH, c) Air velocity.

- Calculate instantaneous drying rate:

ṁ_evap = - (dm/dt) / (number of particles or volume). - Correlate

ṁ_evapwith simulated parameters (e.g., local vapor concentration gradient, T) to define source term function in UDF.

Diagrams

Title: Sequential Moisture Transport Mechanisms

Title: FLUENT Drying Model Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Materials for Biomass Drying Research

| Item | Function/Application | Specification Notes |

|---|---|---|

| Model Biomass | Representative porous medium for controlled experiments. | Should mimic target material's porosity & composition. E.g., Ginkgo biloba leaves for flavonoid preservation studies. |

| Humidity & Temperature Sensors | In-situ monitoring of drying chamber climate. | High accuracy (±1% RH, ±0.2°C). Must be robust at elevated T (up to 80°C). |

| Precision Analytical Balance | Continuous measurement of sample mass loss. | Capacity >500g, resolution ≤0.001g, with data logging capability. |

| ANSYS FLUENT License | Computational Fluid Dynamics (CFD) simulation platform. | Required modules: Species Transport, UDF, Porous Media. |

| User-Defined Function (UDF) Code | Implements custom diffusion, evaporation, and property rules. | Written in C, compiled and hooked into FLUENT solver. |

| Data Acquisition System (DAQ) | Synchronizes sensor and balance readings. | Multi-channel, compatible with sensor outputs (e.g., 4-20mA, 0-10V). |

| Controlled Climate Chamber | Provides reproducible inlet air conditions (T, RH, V). | Range: 20-80°C, 10-90% RH, adjustable air velocity. |

| Thermal Property Analyzer | Measures key biomass properties (k, Cp, density). | e.g., Transient Plane Source (TPS) method for thermal conductivity. |

1. Introduction Within the broader thesis on ANSYS FLUENT modeling of biomass drying chambers, defining accurate porous media properties for the biomass is critical. The convective drying process is governed by heat and mass transfer, directly dependent on the material's porosity, permeability, and moisture saturation. This document provides application notes and protocols for empirically determining these key properties and establishing correlations for implementation in Computational Fluid Dynamics (CFD) simulations.

2. Core Property Definitions & Correlations

- Porosity (ε): The fraction of void space in the total volume of the biomass bed. It dictates the volume available for fluid (air/vapor) flow.

- Permeability (K): A measure of the material's ability to allow fluids to pass through it. It is a key input for the Darcy-Forchheimer momentum source terms in FLUENT.

- Saturation (s): The fraction of the pore volume occupied by liquid moisture. It is a transient variable during drying, affecting both thermal conductivity and permeability.

Empirical correlations are often used to link these properties for simulation. A common model is the Relative Permeability model, where effective permeability for the gas phase ((Kg)) is a function of intrinsic permeability ((K)) and saturation: ( Kg = K \cdot (1 - \hat{s})^n ) where (\hat{s}) is the normalized saturation and (n) is an empirical exponent (often ~3).

3. Quantitative Data Summary

Table 1: Typical Ranges of Biomass Properties for Drying Chamber Modeling

| Biomass Type | Bulk Porosity (ε) | Intrinsic Permeability (K) [m²] | Initial Moisture Saturation (s_initial) | Source / Method |

|---|---|---|---|---|

| Wood Chips (Softwood) | 0.65 - 0.75 | 1.0e-9 – 5.0e-9 | 0.40 - 0.60 | Mercury Porosimetry, Gravimetric |

| Pelletized Herbaceous Biomass | 0.45 - 0.55 | 1.0e-10 – 1.0e-11 | 0.25 - 0.35 | Pycnometry, Darcy Flow Cell |

| Milled Plant Roots (e.g., Ginseng) | 0.35 - 0.50 | 1.0e-12 – 1.0e-13 | 0.60 - 0.80 | Gas Expansion, Sorption Isotherm |

4. Experimental Protocols

Protocol 4.1: Determination of Porosity and Pore Size Distribution

- Objective: Measure the total accessible void fraction and pore size distribution of a prepared biomass sample.

- Method: Gas Pycnometry (for skeletal volume) coupled with Mercury Intrusion Porosimetry (MIP).

- Procedure:

- Sample Preparation: Mill and sieve biomass to a uniform particle size (e.g., 1-2 mm). Dry in an oven at 105°C for 24 hours to remove all moisture. Cool in a desiccator.

- Skeletal Volume (Vskeletal): Using a gas pycnometer (e.g., helium), measure the volume of solid material in a known mass of dry sample.

- Bulk Volume (Vbulk): Precisely measure the volume of a known mass of sample using a calibrated chamber or geometric calculation for pellets.

- Total Porosity Calculation: ( ε = (V{bulk} - V{skeletal}) / V_{bulk} ).

- MIP Analysis: Place the dry sample in the MIP chamber. Mercury is intruded into pores under increasing pressure. Pore diameter (d) is calculated from the intrusion pressure (P) using the Washburn equation: ( d = -4γ \cosθ / P ), where γ is mercury surface tension and θ is contact angle.

Protocol 4.2: Determination of Saturated Permeability

- Objective: Measure the intrinsic permeability of a saturated biomass bed using Darcy's law.

- Method: Constant-head or pressure-driven flow cell.

- Procedure:

- Apparatus Setup: Pack the dried biomass sample uniformly into a cylindrical column of known cross-sectional area (A) and length (L). Ensure full saturation with a low-viscosity inert fluid (e.g., degassed water or nitrogen gas).

- Flow Experiment: Apply a constant pressure difference (ΔP) across the column and measure the steady-state volumetric flow rate (Q).

- Calculation: For liquid flow, use Darcy's Law: ( K = (Q \cdot μ \cdot L) / (A \cdot ΔP) ), where μ is the dynamic viscosity of the fluid. For gas flow, use the Klinkenberg-corrected form.

Protocol 4.3: Establishing Moisture Sorption Isotherms & Correlation

- Objective: Determine equilibrium moisture content at different relative humidities (RH) to correlate saturation with vapor concentration in FLUENT.

- Method: Dynamic Vapor Sorption (DVS).

- Procedure:

- Place a dry, pre-weighed sample in the DVS microbalance.

- Subject the sample to a stepped RH protocol (e.g., 0%, 10%, 20%...90% RH) at constant temperature.

- At each step, record the equilibrium mass change.

- Convert mass increase to moisture saturation using the known pore volume from Protocol 4.1.

- Fit data to a model (e.g., GAB model) to create a function: ( s = f(RH, T) ). This function can be linked to vapor concentration in the FLUENT species transport model.

5. Visualization of Workflow and Correlations

Diagram Title: Biomass Property Characterization Workflow for CFD

Diagram Title: Key Property Correlations for Drying Models

6. The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 2: Essential Materials for Biomass Porous Property Characterization

| Item | Function / Explanation |

|---|---|

| Helium Pycnometer | Determines the absolute (skeletal) volume of solid biomass by gas displacement, crucial for porosity calculation. |

| Mercury Porosimeter | Intrudes mercury under high pressure to measure pore size distribution and total pore volume. Caution: Requires hazardous material handling. |

| Dynamic Vapor Sorption (DVS) Instrument | Precisely measures minute changes in sample mass as a function of relative humidity, enabling sorption isotherm generation. |

| Permeability Flow Cell | A cylindrical column with pressure ports and flow meters to conduct saturated flow experiments per Darcy's law. |

| High-Precision Analytical Balance (≤0.01 mg) | Essential for accurately measuring sample mass changes during drying and sorption experiments. |

| Controlled-Temperature Oven & Desiccator | For standardized sample drying and moisture-free cooling/storage prior to analysis. |

| Inert Test Fluids (Degassed Water, Nitrogen Gas) | Used in permeability tests; inert gases prevent reactions and simplify analysis (Klinkenberg correction). |

Accurate computational fluid dynamics (CFD) simulation of a biomass drying chamber in ANSYS FLUENT is fundamentally dependent on the precise definition of initial and boundary conditions. These conditions dictate the transport of heat, mass (moisture), and momentum within the domain, directly impacting predictions of drying rates, temperature distributions, and final product quality. This document provides application notes and experimental protocols for defining these critical parameters, framed within a research thesis on optimizing industrial biomass drying.

Defining Realistic Boundary Conditions: Data and Protocols

Inlet Conditions (Primary Drying Medium)

The inlet represents the hot air or superheated steam supply. Key parameters are velocity, temperature, turbulence, and species concentration (humidity).

Table 1: Typical Inlet Condition Ranges for Biomass Drying Chambers

| Parameter | Symbol | Typical Range | Units | Measurement Protocol |

|---|---|---|---|---|

| Inlet Air Velocity | (U_{in}) | 0.5 – 5.0 | m/s | Measured via a calibrated hot-wire or vane anemometer at the duct entrance, averaging over multiple points. |

| Inlet Air Temperature | (T_{in}) | 50 – 180 | °C | Measured using a shielded, calibrated K-type thermocouple or RTD. |

| Turbulence Intensity | (I) | 1 – 10 | % | Derived from measurement or estimate: (I = 0.16(Re{Dh})^{-1/8}). For ducts, 3-7% is common. |

| Hydraulic Diameter | (D_h) | Duct-specific | m | Calculated as (D_h = 4A/P), where A is cross-sectional area, P is wetted perimeter. |

| Inlet Specific Humidity | (\omega_{in}) | 0.005 – 0.02 | kg({vap})/kg({air}) | Measured using a calibrated digital hygrometer or calculated from wet/dry bulb psychrometry. |

Protocol 1: Experimental Characterization of Chamber Inlet Flow

- Setup: Install the drying chamber inlet duct. Establish stable operating conditions (heater setpoint, blower speed).

- Velocity Mapping: Using a traversing hot-wire anemometer probe, take velocity readings at a grid of points (minimum 9) across the duct cross-section at the planned simulation inlet plane. Record the average and standard deviation.

- Temperature & Humidity: Position thermocouples and a hygrometer sampling port at the same plane. Log data over a 30-minute stabilized period.

- Data Reduction: Calculate the area-weighted average velocity and temperature. Compute turbulence intensity from the velocity fluctuations or via the empirical formula in Table 1. Calculate specific humidity from relative humidity and temperature readings.

Wall Conditions (Chamber and Biomass Tray Walls)

Walls involve thermal and no-slip velocity boundary conditions. Critical for heat loss and flow regime.

Table 2: Wall Boundary Condition Specifications

| Wall Type | Thermal Condition | ANSYS FLUENT Setting | Key Parameter(s) | Determination Method |

|---|---|---|---|---|

| External Chamber Walls | Convective Heat Loss | Convection or Mixed |

Heat Transfer Coefficient (h({ext})), External Temp (T({\infty})) | h({ext}): Use empirical correlations for natural/forced convection. T({\infty}): Ambient room measurement. |

| Internally Insulated Walls | Adiabatic (Approximation) | Heat Flux (0 W/m²) |

- | Valid for well-insulated chambers; verify via surface temperature measurement. |

| Biomass Tray (Metal) | Conduction-Coupled | Coupled or Thin Wall |

Wall Thickness, Material | Measure tray thickness. Use material library for steel/aluminum properties. |

| Internal Baffles/Guides | Stationary, No-Slip | Stationary Wall |

Roughness Height (if significant) | Surface profilometry or manufacturer specification. |

Protocol 2: Determining External Convective Heat Transfer Coefficient

- Instrumentation: Affix thermocouples to the external surface of the chamber wall at several locations. Install an ambient temperature sensor.

- Steady-State Operation: Run the drying chamber until inlet and wall temperatures stabilize (~1-2 hours).

- Heat Flux Measurement: Use a calibrated heat flux sensor (e.g., a thin-foil thermopile type) attached to the external wall at the same location as a surface thermocouple.

- Calculation: The effective external convective coefficient is calculated as: (h{ext} = q'' / (T{wall,ext} - T_{ambient})), where (q'') is the measured heat flux.

Exhaust/Outlet Condition

The outlet is typically defined as a pressure outlet, allowing reverse flow to stabilize the solution.

Table 3: Exhaust Outlet Configuration

| Parameter | Recommended Setting | Rationale |

|---|---|---|

| Gauge Pressure | 0 Pa (atmospheric) | Standard exhaust to the environment. |

| Backflow Conditions | Critical: Set to estimated exhaust temperature and humidity. | Prevents numerical instability and physically inaccurate backflow during solution. |

| Backflow Turbulence | Set to Intensity and Hydraulic Diameter matching downstream duct. |

Ensures realistic turbulence if recirculation occurs. |

Protocol 3: Characterizing Exhaust for Backflow Specification

- Simultaneously measure temperature and humidity at the exhaust duct (using Protocol 1 methods) during steady-state operation.

- Calculate the area-averaged exhaust specific humidity and temperature.

- These averaged values are directly input as the "Backflow Total Temperature" and "Backflow Species Fraction (Water Vapor)" in the ANSYS FLUENT pressure outlet dialog.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 4: Essential Materials for Boundary Condition Characterization

| Item | Function | Specification/Example |

|---|---|---|

| Hot-Wire Anemometer System | Measures local air velocity and temperature with high frequency. | Calibrated system with data logger and traversing mechanism. |

| Thermocouples (Type K or T) | Measure temperature at inlets, walls, exhaust, and ambient. | Calibrated, shielded beads, with data acquisition unit. |

| Digital Hygrometer/Psychrometer | Measures absolute or relative humidity of the air stream. | Device with in-situ probe, range: 5-95% RH, 0-200°C. |

| Heat Flux Sensor | Directly measures heat transfer through chamber walls. | Thin-foil, thermopile-type sensor (e.g., 100mV/(W/m²) sensitivity). |

| Data Acquisition (DAQ) System | Logs synchronized data from all sensors. | Multi-channel system (e.g., NI DAQ) with appropriate software. |

| Surface Roughness Tester | Quantifies wall surface roughness for advanced turbulence modeling. | Portable stylus profilometer. |

| ANSYS FLUENT License | CFD simulation software for implementing and solving the model. | License with Heat Transfer, Species Transport, and Turbulence modules. |

Visualization of ANSYS FLUENT Setup Workflow for Biomass Drying

Diagram Title: ANSYS FLUENT Setup Workflow for Drying Chamber Simulation

Step-by-Step ANSYS FLUENT Workflow: From Geometry to Solution

1. Application Notes

In the context of ANSYS FLUENT setup for biomass drying chamber research, the pre-processing stage involving geometry simplification and cleanup is critical. A complex, "dirty" CAD model directly imported for meshing will lead to meshing failures, excessive element counts, and non-convergent simulations. The primary objective is to create a geometry that is both fluid-dynamically faithful and computationally efficient. This involves removing features irrelevant to the flow and heat transfer analysis while preserving the key physics of the drying process.

Key Principles for Biomass Drying Chambers:

- Target Physics: The focus is on conjugate heat transfer (fluid flow + solid thermal conduction), species transport (moisture/vapor), and often porous media modeling for the biomass bed.

- Feature Removal: Small fillets, bolt holes, mounting brackets, and intricate support structures that do not significantly alter the bulk flow path or heat transfer characteristics should be suppressed.

- Enclosure Creation: The fluid volume (air/vapor mixture) must be explicitly modeled. For internal flows, use the Fill or Enclosure tools to create a negative space of the fluid region.

- Surface Repair: Heal small gaps, misalignments, and overlapping surfaces to ensure a watertight geometry suitable for a high-quality CFD mesh.

Table 1: Quantitative Impact of Geometry Simplification on Mesh & Solver Performance

| Geometry State | Number of Faces | Target Mesh Size (mm) | Resultant Mesh Cell Count | Approx. Solver Iteration Time (Baseline) | Convergence Stability |

|---|---|---|---|---|---|

| Original CAD (Uncleaned) | 850 | 5.0 | Failed (Gaps) | N/A | N/A |

| Repaired & Simplified | 120 | 5.0 | 4.2 million | 1.0x (Baseline) | Stable |

| Highly Simplified | 45 | 5.0 | 3.8 million | 0.87x | Stable, potential loss of local flow detail |

Table 2: Recommended SCFM Tools for Biomass Drying Chamber Preparation

| Tool Category | Specific Tool (SCDM) | Primary Function | Application in Drying Chamber Context |

|---|---|---|---|

| Cleanup | Pull (with Heal option) | Remove small features, extend faces to close gaps. | Remove port flanges, small instrumentation holes. |

| Simplify | Combine | Merge adjacent surfaces. | Simplify internal baffle structures. |

| Fluid Region | Fill | Create internal fluid volume. | Define the air domain within the chamber and around the biomass trays. |

| Preparation | Shared Topology | Merge faces at contacts. | Ensure conformal mesh at fluid-solid interfaces (chamber walls, trays). |

| Repair | Missing Face | Patch openings in surfaces. | Heal unintended gaps from CAD translation. |

2. Experimental Protocols

Protocol 1: Geometry Cleanup and Fluid Volume Creation for a Tray Drying Chamber Objective: To prepare a watertight, mesh-ready geometry of the drying chamber's fluid domain.

- Import & Repair: Import the chamber assembly CAD (e.g., STEP format). Use the Prepare → Heal tool with a tolerance slightly larger than the import tolerance (e.g., 0.1 mm) to fix small gaps and misalignments.

- Suppress Irrelevant Features: Select and Suppress all external mounting lugs, nameplates, bolt holes on outer walls, and small fillets on structural supports. Use the Detail view to select by range (e.g., face radius < 3 mm).

- Create Inlet/Outlet Volumes: Use the Pull tool to extrude the inlet and outlet port faces inward to create short, cylindrical fluid volumes. This aids in later meshing and boundary condition application.

- Define Fluid Domain: a. Select all internal faces of the chamber, including the surfaces of the biomass trays. b. Use Tools → Fill to generate a solid body representing the fluid (air). c. Use the Boolean → Subtract operation to remove the original chamber and tray bodies, leaving only the fluid volume body.

- Apply Shared Topology: Select all bodies (if multiple fluid regions exist) and apply Shared Topology. This ensures nodes are shared at interfaces for accurate heat transfer.

- Named Selections: Create named selections for critical faces:

Inlet,Outlet,Chamber_Walls,Heater_Surfaces,Biomass_Tray_Surfaces.

Protocol 2: Simplification of Complex Biomass Porous Zone Objective: To represent a detailed biomass bed as a simplified porous media region for CFD.

- Original Geometry Handling: Isolate the detailed geometry of the biomass bed (e.g., a pile of wood chips).

- Bounding Box Creation: Use the Create → Box tool to draw a prismatic volume that entirely encompasses the biomass geometry.

- Region Subtraction: Use Boolean → Subtract to remove the original biomass geometry from the bounding box. The resulting void represents the fluid space within the porous bed.

- Porous Zone Definition: The solid bounding box now represents the Porous Zone. In ANSYS FLUENT, this body will be assigned porosity and viscous/inertial resistance coefficients derived from experimental pressure-drop data (See Table 3).

- Interface: Ensure Shared Topology is active between the porous zone body and the main fluid domain.

Table 3: Experimental Data for Porous Media Inputs (Representative Biomass)

| Biomass Type | Particle Size (mm) | Bed Porosity (ε) | Viscous Resistance (1/α) (m²) | Inertial Resistance (C₂) (1/m) | Measurement Method (Source) |

|---|---|---|---|---|---|

| Wood Chips (Pine) | 10-20 | 0.65 | 1.2e+08 | 350 | Pressure drop experiment (Ergun eq.) |

| Pelletized Straw | 8 (Dia.) | 0.52 | 5.8e+08 | 1200 | Packed-bed correlation |

| Chopped Miscanthus | 30-50 | 0.78 | 3.5e+07 | 95 | Experimental data fit |

3. Mandatory Visualization

Diagram 1: SCDM Geometry Pre-Processing Workflow for CFD

Diagram 2: Conjugate Heat Transfer Domains in Drying Chamber Model

4. The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions & Materials for Biomass Drying Experiments

| Item Name | Function/Description | Relevance to CFD Geometry & Validation |

|---|---|---|

| Thermocouples (T-Type/K-Type) | Measure temperature profiles within the drying chamber and biomass bed. | Provides critical data for validating conjugate heat transfer results from the CFD model. |

| Anemometer / Hot-Wire Probe | Measure local air velocity at inlet, outlet, and near trays. | Validates the flow field predicted by the simulation in the simplified fluid domain. |

| Humidity Sensors | Measure absolute/relative humidity of air at key locations. | Essential for validating species transport (moisture) modeling in FLUENT. |

| Pressure Transducer (Differential) | Measure pressure drop across the biomass bed or chamber. | Directly provides experimental data to calculate porous media resistance coefficients (Table 3). |

| Data Acquisition System (DAQ) | Logs time-series data from all sensors. | Enables comparison of transient simulation results with experimental drying curves. |

| Reference Biomass Sample | Prepared, characterized biomass with known initial moisture content, density, and particle size distribution. | Defines the physical properties of the porous zone and allows for consistent, repeatable experiments for model validation. |

Application Notes: Rationale for a Hybrid Mesh Approach

In the numerical simulation of a biomass drying chamber, a primary challenge is the accurate representation of two distinct physical regions within a single computational domain. The free flow region (e.g., hot air stream) and the porous biomass bed (composed of irregularly shaped particles like wood chips, pellets, or agricultural residue) have vastly different geometrical and flow characteristics. A single, uniform meshing strategy is inefficient and often inaccurate for such systems.

A hybrid mesh combines structured and unstructured elements to optimize computational cost and solution fidelity. For ANSYS FLUENT setups in drying research, this typically involves:

- Structured Hexahedral Meshes in the free-flow region. These provide high-quality, low-skewness elements ideal for resolving boundary layers and convective flows with minimal numerical diffusion.

- Unstructured Polyhedral or Tetrahedral Meshes in the biomass bed region. These can conform to complex, irregular geometries of packed beds, capturing the porous media effects essential for modeling heat and mass transfer during drying.

The interface between these zones must be carefully managed to ensure conservative interpolation of flow variables (pressure, velocity, temperature, species concentration).

Key Quantitative Considerations for Mesh Independence:

| Parameter | Free Flow Region | Porous Biomass Bed Region | Justification |

|---|---|---|---|

| Element Type | Hexahedral (Structured) | Polyhedral (Unstructured) | Hex for accuracy & efficiency in simple zones; Poly for complex geometry. |

| Base Size (mm) | 2.0 - 5.0 | 0.5 - 1.5 | Bed requires finer resolution for particle-scale phenomena. |

| Inflation Layers | 5-15 layers, Growth Rate 1.2 | Not typically applied | Essential for resolving viscous sublayer in convective flow. |

| Target Skewness | < 0.85 (Optimum < 0.5) | < 0.9 (Optimum < 0.8) | High skewness reduces solution accuracy and stability. |

| Typical Cell Count | 40-60% of total mesh | 40-60% of total mesh | Balance resource allocation based on domain volume & complexity. |

Experimental Protocol: Generating a Hybrid Mesh in ANSYS Meshing

This protocol details the steps for creating a hybrid mesh for a simplified 3D drying chamber model in ANSYS Workbench.

Materials & Software:

- ANSYS Workbench 2024 R1 (or current version).

- Geometry file (.scdoc, .step, .iges) of the drying chamber, with the biomass bed region as a separate body or named selection.

Procedure:

- Geometry Preparation: Import the CAD geometry. Ensure the biomass bed volume is defined as a separate "Body" or create a "Named Selection" encompassing the entire bed region.

- Mesh Method Assignment:

- Open the ANSYS Meshing component.

- In the Outline, select the main fluid domain (including the bed). From the Details, set Physics Preference to CFD and Solver Preference to Fluent.

- Apply a global mesh size (e.g., 5 mm) as an initial setting.

- Define the Biomass Bed Region:

- Right-click on Mesh -> Insert -> Method.

- In the Graphics window, select the geometry of the biomass bed.

- In the Details of the new method, set Method to Polyhedra. Apply a finer local sizing (e.g., 1.0 mm).

- Define the Free Flow Region:

- Insert another Mesh Method.

- Select the remaining fluid volume (the free flow chamber).

- Set Method to Hex Dominant. This creates a primarily hexahedral mesh.

- Inflation Layer Setup:

- Insert an Inflation control.

- Select all chamber walls exposed to the main flow.

- Set Boundary Scoped to the selected faces. Define Number of Layers (e.g., 10), Growth Rate (e.g., 1.2), and First Layer Height based on target y+ value (aim for y+ ≈ 1 for low-Re k-ω SST models).

- Interface Handling:

- Ensure the interface between the bed and free-flow region is correctly defined. Create a Named Selection for this interface face for easy setup in Fluent.

- Generate and Assess Mesh:

- Generate the mesh. Use Mesh Metrics to check Skewness and Orthogonal Quality.

- Refine local sizes if metrics are unacceptable. Perform a mesh independence study by refining global sizes by ~20% and comparing key outputs (e.g., pressure drop across bed, average humidity at outlet).

Workflow Diagram: Hybrid Meshing and Simulation Process

Diagram Title: Workflow for Hybrid Mesh Generation and Simulation in ANSYS

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item / Software Module | Function in Biomass Drying Simulation |

|---|---|

| ANSYS SpaceClaim / DesignModeler | Geometry creation, cleanup, and preparation for meshing; crucial for defining separate bed and flow regions. |

| ANSYS Meshing | Core application for applying hybrid mesh methods (Polyhedral, Hex-Dominant), sizing controls, and inflation. |

| Fluent Porous Media Model | Models the biomass bed as a porous zone by specifying viscous and inertial resistance coefficients, derived from experimental pressure drop data. |

| Species Transport Model | Enables simulation of moist air (water vapor in air) for modeling moisture transfer during drying. |

| User-Defined Function (UDF) | Allows customization, e.g., defining temperature-dependent biomass properties or complex drying kinetics. |

| High-Performance Computing (HPC) Pack | Enables parallel processing to solve the large, complex hybrid mesh models in a reasonable time. |

| CFD-Post / Ensight | Advanced post-processing tools for visualizing velocity streams in free flow, temperature contours in the bed, and generating quantitative plots. |

Within the broader thesis on ANSYS FLUENT setup for simulating a biomass drying chamber, the correct activation of the Energy Equation, Species Transport Model, and the Porous Media Model is critical. These models collectively govern the coupled heat and mass transfer, moisture evaporation, and the fluid flow resistance through the packed bed of biomass material, which is essential for accurate drying kinetics prediction in pharmaceutical and bioprocessing applications.

Model Theory & Setup Protocols

Energy Model Activation Protocol

Objective: Enable heat transfer calculations to account for convective, conductive, and latent heat effects during drying.

- In ANSYS FLUENT, navigate to the

Modelslist in the Setup tab. - Double-click on

Energyin the Models list. - In the

Energydialog box that appears, check the box Enable Energy Equation. - Click

OK. No further sub-models are required at this stage for a basic setup.

Species Transport Model Activation Protocol

Objective: Model the transport of water vapor and air within the drying chamber.

- In the

Modelslist, double-click onSpeciesand selectSpecies Transport. - In the

Species Modeldialog:- Select

Species Transportas the model. - Under

Mixture Properties, clickEdit...to define the mixture material. - In the

Mixture Materialsdialog, setmixture-templatetoair. Use theEdit...button to modify the species list. - In the

Edit Materialdialog, addh2o (vapor)from theFluidchemical species list to theSelected Speciescolumn. The mixture should containairandh2o. - Click

OKto close all dialogs.

- Select

- For drying applications, enable Diffusion Energy Source in the

Species Modeldialog to account for energy transfer due to species diffusion.

Porous Media Model Setup Protocol

Objective: Define the biomass bed as a porous zone to model flow resistance.

- Cell Zone Setup: In the

Cell Zonespanel, select the zone representing the biomass bed. - Porous Zone Activation: Check the

Porous Zoneoption. - Momentum Resistance Definition: In the

Porous Zonetab, selectLaminar ZoneunderDarcy-Forchheimer Modelfor low-speed drying flows. - Define Resistance Coefficients: Input directional viscous resistance coefficients (1/α). For a randomly packed bed of cylindrical biomass particles (e.g., wood chips), use the Ergun equation-derived values. Set these in the

Directional Viscous Resistancefields.

Table 1: Typical Porous Media Parameters for Biomass Packed Beds

| Parameter | Symbol | Typical Value Range (SI) | Source/Calculation Basis |

|---|---|---|---|

| Porosity | ε | 0.5 - 0.7 | Measured bulk property |

| Viscous Resistance (x,y,z) | 1/α | 1e8 - 1e10 m⁻² | Calculated via Ergun Equation |

| Inertial Resistance (x,y,z) | C₂ | 100 - 1000 m⁻¹ | Calculated via Ergun Equation |

| Particle Diameter | d_p | 0.005 - 0.02 m | Characteristic biomass chip size |

Coupling Models: Evaporation as a Volumetric Source

UDF Protocol for Moisture Evaporation

A User-Defined Function (UDF) is required to link species transport (moisture removal) with energy consumption (latent heat).

Protocol: Compiling and Hooking a Simple Evaporation UDF

- UDF Code: Write a

DEFINE_SOURCEUDF in C. The source term for theh2ospecies equation is calculated based on the local temperature, pressure, and saturation concentration. - Compilation: In FLUENT, go to

Define → User-Defined → Functions → Compiled. Add the source file and clickBuild. - Hooking to Species Equation: In the

Materialspanel, edit the mixture material (air-h2o). UnderUser Defined Functions, select the compiled UDF for theMasssource of theh2ospecies. - Energy Coupling: The same UDF should also return a corresponding energy (heat) source term (negative, representing latent heat absorption). Hook this to the

Energyequation's source term in theBoundary Conditionspanel for the porous zone.

Table 2: Key Variables in Evaporation UDF for Biomass Drying

| Variable | Meaning | Unit | Typical Source/Value |

|---|---|---|---|

| C_h2o | Local vapor concentration | kg/m³ | FLUENT variable |

| C_sat(T) | Saturation concentration | kg/m³ | Antoine Equation lookup |

| h_fg | Latent heat of vaporization | J/kg | ~2.26e6 at 100°C |

| k_mass | Mass transfer coefficient | 1/s | User-defined, model tuning |

Title: ANSYS FLUENT Solver Setup Workflow for Biomass Drying

Boundary Conditions & Solution Initialization Protocol

- Inlet: Velocity or pressure inlet with specified temperature (

T_in) and humidity (Mass Fraction of h2o). - Outlet: Pressure outlet.

- Walls: Specify heat flux or temperature for chamber walls.

- Porous Zone: Ensure it is defined as a

Fluidcell zone with porous media parameters activated. - Solution Initialization: Use

Hybrid Initializationfor robust starting point. Patch an initial high moisture concentration in the porous zone.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Materials for FLUENT Drying Simulation

| Item / "Reagent" | Function & Specification |

|---|---|

| ANSYS FLUENT v2024 R1 | Primary CFD platform for solving coupled multiphase transport equations. |

| Biomass Material Database | User-created database containing porosity, particle size distribution, and sorption isotherm data for specific biomass (e.g., Ginkgo biloba leaves, pine wood chips). |

| Evaporation UDF Script | Custom C code defining the mass and energy source terms for moisture evaporation, acting as the "kinetic model" for drying. |

| Thermophysical Property File | Modified property file (.prop) specifying temperature-dependent density, viscosity, and diffusion coefficients for the air-vapor mixture. |

| High-Performance Computing (HPC) Cluster | Computational resource for running high-fidelity, transient simulations with refined meshes (>5 million cells). |

| Mesh Independence Study Protocol | A defined procedure (script) to sequentially refine the mesh and compare key outputs (e.g., average moisture content) to ensure results are grid-independent. |

The numerical simulation of a biomass drying chamber in ANSYS FLUENT requires accurate material property definitions to model the coupled heat and mass transfer phenomena. The standard database lacks specific properties for moist air across a wide humidity/temperature range relevant to drying and for heterogeneous, evolving biomass materials. This protocol details the creation of custom materials to enhance simulation fidelity, a critical step in a thesis focusing on optimizing dryer design for pharmaceutical-grade biomass (e.g., medicinal plants, fermentation residues) where precise moisture control impacts final bioactive compound quality.

Defining Custom Moist Air Properties

Moist air is treated as a mixture of dry air and water vapor. Its properties (density, specific heat, thermal conductivity, viscosity) are strongly dependent on temperature and humidity ratio.

Key Property Correlations & Data

The following correlations, valid for typical drying conditions (0-100°C, 0-0.3 kg/kg dry air), are implemented.

Table 1: Thermophysical Property Correlations for Moist Air

| Property | Correlation | Units | Validity Range |

|---|---|---|---|

| Humidity Ratio (ω) | ω = 0.62198 * (p_v / (p_atm - p_v)) |

kgw/kgda | - |

| Saturation Vapor Pressure (p_sat) | p_sat = exp(77.3450 + 0.0057*T - 7235.0/T) / T^8.2 (Hyland-Wexler) |

Pa | 0°C < T < 200°C |

| Density (ρ) | ρ = (p_atm / (R_da * T)) * (1 + ω) / (1 + 1.609*ω) |

kg/m³ | Ideal Gas Mix |

| Specific Heat (Cp) | Cp = (Cpd_a + ω * Cp_v) / (1 + ω) |

J/kg-K | Cpda=1006, Cpv=1870 |

| Thermal Conductivity (k) | k = (k_da + 1.608*ω*k_v) / (1 + 1.608*ω) |

W/m-K | kda & kv from REFPROP |

| Viscosity (μ) | μ = (μ_da + 1.608*ω*μ_v) / (1 + 1.608*ω) |

kg/m-s | μda & μv from REFPROP |

Abbreviations: p_v: partial pressure of vapor, p_atm: total pressure, T: Temperature (K), R_da: specific gas const. for dry air (287.058 J/kg·K).

Protocol: Implementing Custom Moist Air in ANSYS FLUENT

- Create a New Mixture Material: In the

Materialstask pane, create a new material of typemixture. Name itcustom_moist_air. - Define Mixture Components: Add

air(from the database) andwater-vapor(from the database) as the mixture components. - Set Mass Fraction: Define the initial mass fraction of water-vapor based on the desired initial humidity ratio (e.g., 0.02 for 20 g/kg). FLUENT will compute air fraction automatically.

- Define Property Methods: For each property (

density,cp,thermal-conductivity,viscosity), selectmixing-laworideal-gas-mixing-lawas a temporary placeholder. Implement User-Defined Functions (UDFs): a. Write a compiled UDF (in C) for each property using the correlations in Table 1. The UDF must access the mixture temperature and species mass fractions. b. Example skeleton for density (

DEFINE_PROPERTYmacro):c. Compile and load the UDF library in FLUENT.

- Assign UDFs to Properties: For each property in the

custom_moist_airmaterial, selectuser-definedand choose the corresponding compiled function from the dropdown list.

Defining User-Defined Biomass Properties

Biomass is modeled as a porous, hygroscopic solid with properties that change with moisture content (M) on a dry basis.

Table 2: Typical Property Models for Biomass (Example: Ginkgo biloba Leaves)

| Property | Model / Value | Parameters / Explanation |

|---|---|---|

| Density (ρ_b) | ρ_b = (1 + M) / (1/ρ_ds + M/ρ_w) |

ρds: Dry solid density (~500 kg/m³), ρw: Water density |

| Specific Heat (Cp_b) | Cp_b = (Cp_ds + M * Cp_w) / (1 + M) |

Cpds: Dry biomass Cp (~1500 J/kg·K), Cpw: 4180 J/kg·K |

| Thermal Conductivity (k_b) | k_b = k_ds * (1 + β*M) |

k_ds: Dry conductivity (~0.1 W/m·K), β: empirical coefficient (~0.5) |

| Desorption Isotherm (Equilibrium MC) | GAB Model: X_eq = (X_m * C * K * a_w) / ((1 - K*a_w)*(1 - K*a_w + C*K*a_w)) |

Xm, C, K: fitted parameters. aw: water activity. Critical for drying kinetics. |

| Porosity (ε) | Constant or function of M (ε = 1 - ρ_b/ρ_particle) |

Typically 0.6-0.9 for leafy biomass. |

| Transport Properties | Effective Diffusivity (D_eff): D_eff = ε/τ * D_water_vapor. Permeability (K): From Darcy's law, fitted to experimental data. |

τ: Tortuosity (1.5-3). K ~ 1e-12 to 1e-10 m² for packed beds. |

Protocol: Implementing User-Defined Biomass in ANSYS FLUENT

- Model Setup: Enable the

Porous ZoneandSpecies Transportmodels. For hygroscopic modeling, consider using aUser-Defined Scalarfor bound moisture transport. - Create a New Solid Material: Create a new material of type

solid. Name itcustom_biomass. - Define Constant Properties: Input isotropic, constant placeholder values for density, conductivity, and specific heat.

Develop Property UDFs: a. Write UDFs for

density,specific heat, andthermal conductivitythat access the stored user-defined memory (UDM) for the local moisture content (M) in the biomass. b. The UDFs implement the models from Table 2. Example for specific heat:Assign UDFs and Define Porosity: Assign the compiled UDFs to the biomass material properties. In the porous zone conditions, specify the

Porosity(constant or via a UDF) and theViscous Resistancecoefficients (1/K for each direction) derived from permeability data.

Title: Workflow for Defining Custom Moist Air in FLUENT

Title: Input-Output Relationship for Biomass Properties

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Key Materials and Tools for Model Development and Validation

| Item | Function in Research Context |

|---|---|

| ANSYS FLUENT with UDF Capability | Primary CFD platform for implementing custom materials and solving transport equations. |

| REFPROP (NIST Reference Fluid Properties) | Source of accurate thermophysical data for dry air and water vapor for correlation validation. |

| Thermogravimetric Analyzer (TGA) | Measures mass loss (moisture content) of biomass as a function of temperature/time. Critical for validating drying kinetics models. |

| Dynamic Vapor Sorption (DVS) Analyzer | Determines the desorption isotherm (equilibrium moisture content vs. water activity) for GAB model parameter fitting. |

| Guarded Hot Plate Apparatus | Measures thermal conductivity of bulk biomass samples at different moisture contents. |

| Data Acquisition System (DAQ) | Logs temperature and humidity data from physical drying chamber experiments for CFD model boundary condition setup and validation. |

| Custom C Compiler (e.g., Microsoft Visual Studio) | Required for compiling and linking user-defined functions (UDFs) to the ANSYS FLUENT solver. |

| Parameter Estimation Software (e.g., MATLAB, Python SciPy) | Used to fit empirical coefficients (e.g., for diffusivity, permeability, GAB constants) to experimental data. |

Application Notes

Within the broader thesis on ANSYS FLUENT setup for biomass drying chamber research, accurately defining the phase change between liquid water and water vapor is critical. This process models the convective drying of porous biomass, where evaporation is the primary mechanism of moisture removal. These protocols are designed for researchers and scientists, including those in pharmaceutical development where precise thermal processing of biological materials is required.

Core Physics Setup: The evaporation of moisture from biomass is modeled as a mass transfer process between two phases (liquid water and water vapor) within a multi-phase framework (e.g., Eulerian multiphase or Wet Steam model). The reaction is defined as a saturated liquid-vapor transition, governed by latent heat and vapor pressure equilibrium.

Key Quantitative Parameters: The following table summarizes essential physical properties and model constants required for the simulation.

Table 1: Essential Physical Properties & Model Parameters for Water Evaporation

| Parameter / Property | Symbol | Value / Expression | Notes / Source |

|---|---|---|---|

| Latent Heat of Vaporization | h_fg | ~2257 kJ/kg at 100°C | Temperature-dependent. Crucial for energy sink/source. |

| Saturation Vapor Pressure | P_sat | Antoine Equation: log₁₀(P) = A - (B/(T+C)) | A=8.07131, B=1730.63, C=233.426 (T in °C, P in mmHg) for 1-100°C. |

| Evaporation-Condensation Coefficient | β | 0.1 - 1.0 (dimensionless) | User-defined tuning parameter for mass transfer rate. |

| Molecular Weight of Vapor | M_v | 18.01528 kg/kmol | |

| Ideal Gas Law Density | ρ_v | (P * M_v)/(R * T) | Applied to water vapor phase. R = 8314.46 J/(kmol·K). |

| Lee Model Mass Transfer Rate | ṁ | β * Asf * ρl * (Tl - Tsat)/T_sat | Common empirical model in FLUENT. A_sf is interfacial area density. |

Experimental Protocols

Protocol 2.1: Defining Phases in ANSYS FLUENT for a Biomass Drying Chamber

Objective: To configure the primary and secondary phases and their interactions for a drying simulation.

- Launch Setup: In the ANSYS FLUENT Setup module, navigate to Models > Multiphase. Select the Eulerian model. Set the Number of Eulerian Phases to 2.

- Define Primary Phase: Click on Primary Phase. Set the Phase Material to

water-vapor(orairif vapor is a mixture component). Rename the phase tovapor_phase. - Define Secondary Phase: Click on Secondary Phase. Set the Phase Material to

water-liquid. Rename the phase toliquid_water_phase. Ensure the Granular option is deselected for a liquid droplet simulation. - Interfacial Interaction: Under the Phases panel, select Interaction. In the Interaction dialog box:

- Verify the Surface Tension Coefficient is set appropriately (0.072 N/m for water-air at 20°C).

- Go to the Mass tab. This is where the evaporation reaction is defined.

- Define Evaporation Reaction:

- Click Edit... for the mass transfer mechanism.

- Select Evaporation-Condensation from the Mechanism dropdown.

- Set From Phase to

liquid_water_phaseand To Phase tovapor_phase. - In the Evaporation-Condensation Parameters, input the Saturation Temperature (T_sat). This can be a constant value (e.g., 373.15 K) or defined via a user-defined function (UDF) for variable pressure.

- Input the Evaporation Coefficient and Condensation Coefficient (β). Start with a value of 0.1 and calibrate against experimental data.

- Energy Exchange: Ensure the Heat Transfer option is enabled in the Interaction dialog. The latent heat value is automatically linked to the enthalpy of the defined

water-liquidandwater-vapormaterials.

Protocol 2.2: Configuring Material Properties for Water and Vapor

Objective: To accurately define the thermodynamic properties of the participating species.

- Access Materials Database: Go to Setup > Materials.

- Create/Edit Liquid Water:

- Find

water-liquidin the Fluid Materials list. If unavailable, copy from the FLUENT database. - Set Density to

constant(998.2 kg/m³) orpiecewise-linearif temperature variation is significant. - Set Specific Heat (Cp) to

constant(4182 J/kg·K) or a polynomial. - Set Thermal Conductivity and Viscosity to appropriate temperature-dependent functions for accuracy.

- Find

- Create/Edit Water Vapor:

- Find

water-vaporor create it. For vapor as a pure species, set Density toideal-gas. - Set Cp to

mixedor a polynomial (NASAcoefficients are recommended for wide temperature ranges). - Set Molecular Weight to 18.01528 kg/kmol.

- Find

- Verify Mixture (if applicable): If the vapor phase is a mixture (e.g., air and water vapor), define a separate

gas-mixturematerial. Addairandwater-vaporas Mixture Species. Set the Mixing Law for each property (e.g.,mass-weighted-mixing-lawfor viscosity).

Visualizations

Title: FLUENT Evaporation Model Setup Workflow

Title: Mass & Energy Transfer During Phase Change

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions & Computational Materials

| Item / Component | Function / Role in Simulation | Notes for Configuration |

|---|---|---|

| Water Liquid (H₂O(l)) | Represents the free and bound moisture within the biomass matrix or as droplets. | Define as a secondary, granular or non-granular Eulerian phase. Use temperature-dependent properties. |

| Water Vapor (H₂O(g)) | Represents the gaseous moisture transported by the drying medium. | Define as the primary phase or a component in a mixture. Use ideal-gas density. |

| Dry Air (O₂, N₂ mixture) | Represents the bulk drying gas (e.g., hot air). Often the primary carrier phase. | Use ideal-gas or incompressible-ideal-gas density. Define as a mixture material. |

| Evaporation-Condensation Model (Lee Model) | The user-defined function (UDF) or built-in model governing the mass transfer rate between liquid and vapor. | Calibrate the coefficient (β) against experimental drying kinetics. |

| Porous Biomass Zone | A fluid cell zone conditioned with porosity and inertial/viscous resistance to model the solid biomass bed. | Defined in the Cell Zone Conditions. Momentum sink terms simulate flow through the bed. |

| User-Defined Function (UDF) | Custom C code to define complex phenomena (e.g., variable T_sat, moisture-dependent β). | Compiled and hooked in FLUENT to override standard model parameters. |

| Species Transport Model | Required if modeling vapor as a species within a gas mixture (e.g., air and vapor). | Enabled in Models > Species. Mixture template must include all gaseous species. |

1. Introduction & Thesis Context Within the broader thesis on optimizing biomass drying chamber performance using ANSYS FLUENT, the precise configuration of boundary conditions (BCs) and porous media settings is critical. These settings dictate the thermo-fluidic environment directly influencing drying kinetics, product uniformity, and energy efficiency. This protocol details the application-specific setup for simulating a convective drying chamber where hot air flows through a porous bed of biomass particles.

2. Boundary Condition Configuration Protocols

2.1 Inlet Velocity & Temperature (Mass Flow Inlet)

- Rationale: For drying applications, defining a mass flow inlet is often more physically accurate than velocity inlet, as it directly accounts for density variations with temperature.

- Protocol:

- In the FLUENT Boundary Conditions panel, select the inlet face zone.

- Set the type to

mass-flow-inlet. - Specify the Mass Flow Rate (kg/s) based on experimental air blower data and the chamber's cross-sectional area.

- Under Thermal, set the Temperature (K) to the desired drying air temperature.

- For Turbulence, specify Intensity and Hydraulic Diameter based on inlet duct geometry.

- For species transport (moist air), set the Species Mass Fractions for water vapor and dry air appropriately.

2.2 Outlet Pressure (Pressure Outlet)

- Rationale: A pressure outlet boundary is suitable for incompressible and weakly compressible flows where the static pressure at the outlet is known or can be reasonably approximated.

- Protocol:

- Select the outlet face zone and set the type to

pressure-outlet. - Specify the Gauge Pressure (pascal). For chambers venting to atmosphere, this is typically 0 Pa.

- Set the Backflow Temperature (K) to a value near the expected outlet temperature to improve stability.

- Define the Backflow Turbulent Intensity and Hydraulic Diameter.

- If using species, define the Backflow Species Mass Fractions. These are only used if reverse flow occurs.

- Select the outlet face zone and set the type to

2.3 Porous Zone Settings

- Rationale: The biomass bed is modeled as a porous medium, introducing a momentum sink to simulate flow resistance.

- Protocol:

- Create a cell zone encompassing the biomass bed geometry.

- In the Cell Zone Conditions panel, enable Porous Zone.

- Select the Laminar or Turbulent flow model based on the particle Reynolds number.

- Configure the Momentum resistance coefficients. For a homogeneous packed bed, use the Velocity method with coefficients derived from the Ergun equation:

- Viscous Resistance (

1/α):(150*μ*(1-ε)^2)/(Dp^2 * ε^3) - Inertial Resistance (

C2):(1.75*ρ*(1-ε))/(Dp * ε^3)

- Viscous Resistance (

- Enable Porous Treatment in the Energy model to account for thermal conduction in the solid phase.

- If modeling moisture evaporation, define a user-defined scalar (UDS) source term for mass transfer within this zone.

3. Summary of Key Parameters & Quantitative Data

Table 1: Typical Boundary Condition Ranges for Biomass Drying Chamber Simulation

| Parameter | Symbol | Typical Range | Unit | Notes |

|---|---|---|---|---|

| Inlet Air Temperature | T_in | 323 - 363 | K | Depends on biomass thermal sensitivity. |

| Inlet Mass Flow Rate | ṁ | 0.01 - 0.1 | kg/s | Scales with chamber size. |

| Outlet Gauge Pressure | P_out | 0 (atmospheric) | Pa | Often ambient. |

| Bed Porosity | ε | 0.4 - 0.6 | - | Measured or estimated from packing. |

| Particle Diameter | D_p | 0.005 - 0.02 | m | Characteristic size of biomass granules. |

| Bed Viscous Resistance | 1/α | 1e7 - 1e10 | 1/m² | Calculated from Ergun eq. |

| Bed Inertial Resistance | C2 | 1e3 - 1e5 | 1/m | Calculated from Ergun eq. |

4. Experimental & Numerical Validation Protocol

- Objective: Validate the ANSYS FLUENT porous drying model against experimental data.

- Materials: Pilot-scale drying chamber, airflow and heating system, thermocouples, humidity sensors, data logger, biomass sample.

- Methodology:

- Conduct a drying experiment at fixed inlet temperature and airflow rate.

- Record transient temperature at multiple chamber locations and the outlet humidity.

- Replicate the exact chamber geometry and operational BCs in ANSYS FLUENT.

- Run a transient simulation matching the experimental duration.

- Extract simulated temperature and humidity data at the corresponding monitor points.