Mitigating Technology Performance Risk in Biofuel Supply Chains: Strategies for Drug Development Research Stability

This article examines the critical challenge of technology performance risk within biofuel supply chains and its direct implications for the reliability of raw materials in biomedical and clinical research.

Mitigating Technology Performance Risk in Biofuel Supply Chains: Strategies for Drug Development Research Stability

Abstract

This article examines the critical challenge of technology performance risk within biofuel supply chains and its direct implications for the reliability of raw materials in biomedical and clinical research. Targeted at researchers, scientists, and drug development professionals, we explore the foundational sources of risk, present advanced modeling and mitigation methodologies, detail troubleshooting protocols for process optimization, and compare validation frameworks. The synthesis provides a strategic roadmap for securing robust, high-quality bio-derived solvents and feedstocks essential for reproducible scientific outcomes.

Understanding Technology Performance Risk: Defining Biofuel Supply Chain Vulnerabilities for Research

Defining Technology Performance Risk in the Biofuel Context

Technical Support Center

Troubleshooting Guides & FAQs

Feedstock Pre-Treatment & Hydrolysis

Q1: Our enzymatic hydrolysis of lignocellulosic biomass yields consistently lower sugar conversion than literature values. What are the primary factors to investigate?

A: Low sugar conversion is a critical technology performance risk. Investigate these factors systematically:

- Feedstock Variability: Particle size and lignin content vary between batches. Use a standardized milling/screening protocol.

- Inhibitor Presence: Pretreatment (e.g., dilute acid, steam explosion) generates furans and phenolics that inhibit enzymes. Assay for furfural, HMF, and phenolic acids.

- Enzyme Cocktail Efficiency: Commercial cellulase/hemicellulase blends may be suboptimal for your specific feedstock. Titrate enzyme loadings and consider supplementing with β-glucosidase.

- Process Parameters: Verify and tightly control pH (typically 4.8-5.0), temperature (50°C), and mixing shear force.

Experimental Protocol: Inhibitor Analysis via HPLC

- Method: High-Performance Liquid Chromatography (HPLC) with UV/RI detection.

- Column: Bio-Rad Aminex HPX-87H (for organic acids, alcohols, furans) or equivalent.

- Mobile Phase: 5 mM H₂SO₄, isocratic.

- Flow Rate: 0.6 mL/min.

- Temperature: 50°C.

- Detection: Refractive Index (RI) for sugars/alcohols; UV at 210/280 nm for acids/furans/phenolics.

- Sample Prep: Centrifuge hydrolysate, filter through 0.2 μm syringe filter, dilute as needed.

Q2: How can we rapidly assess feedstock composition to predict hydrolysis performance risk?

A: Implement the NREL/TP-510-42618 standard protocol for compositional analysis. Key metrics are listed in Table 1.

Table 1: Critical Feedstock Composition Metrics & Performance Risk Indicators

| Component | Target Range (Dry wt%) | Low Risk | High-Risk Indicator | Mitigation Action |

|---|---|---|---|---|

| Glucan | 35-50% | >40% | <35% | Blend feedstocks; optimize pretreatment. |

| Xylan | 15-25% | 20-25% | <15% | Adjust hemicellulase loading. |

| Acid-Insoluble Lignin | 10-20% | <15% | >25% | Consider alternative pretreatment (e.g., alkaline). |

| Ash | <5% | <3% | >10% | May inhibit catalysts; consider washing. |

| Extractives | <5% | <3% | >8% | Can foul equipment; pre-extract feedstock. |

Fermentation & Microbial Contamination

Q3: Our fermentation with S. cerevisiae shows sudden drops in ethanol productivity and elevated lactate. Is this metabolic shift or contamination?

A: Elevated lactate strongly indicates bacterial contamination (e.g., Lactobacillus). This is a severe operational risk.

Experimental Protocol: Contamination Diagnostic

- Microscopy: Perform Gram staining on broth sample. Look for rod-shaped Gram-positive bacteria alongside yeast cells.

- Selective Plating: Plate serial dilutions on MRS agar (for Lactobacillus) and YPD agar with cycloheximide (for yeast). Incubate anaerobically (MRS) and aerobically (YPD). Compare colony counts.

- PCR Assay: Use universal 16S rRNA primers (27F/1492R) on broth DNA. If positive, sequence to identify contaminant.

Q4: What are best practices to mitigate fermentation contamination risk in a pilot-scale bioreactor?

A:

- Sterilization: Validate steam-in-place (SIP) cycles for all lines and the vessel. Use biological indicators (e.g., Bacillus stearothermophilus spore strips).

- Inoculum Purity: Maintain sterile, master cell banks. Use pre-culture media with antibiotics (e.g., kanamycin) if the production strain is resistant.

- Process Control: Maintain a slight positive pressure in the reactor headspace with sterile air/N₂.

- Antimicrobial Agents: For non-recombinant yeast, consider adding 2-4 ppm of hop acids (isohumulones), which are effective against many Gram-positive bacteria.

Catalytic Upgrading & Catalyst Deactivation

Q5: Our hydrodeoxygenation (HDO) catalyst shows rapid deactivation (<50 hours) when upgrading bio-oil to hydrocarbons. What are the likely mechanisms?

A: Catalyst deactivation is a major technology performance risk. Likely mechanisms are fouling (coke), poisoning, and sintering.

Experimental Protocol: Post-Mortem Catalyst Analysis

- Thermogravimetric Analysis (TGA): Measure weight loss in air up to 800°C to quantify carbonaceous coke deposit.

- Temperature-Programmed Oxidation (TPO): Profile CO₂ evolution to determine coke reactivity/types.

- Inductively Coupled Plasma (ICP): Analyze spent catalyst for metal impurities (e.g., K, Na, Ca, P) leached from biomass.

- Physisorption/BET: Measure surface area loss to assess pore blocking/sintering.

- X-ray Diffraction (XRD): Check for changes in active metal crystallite size (sintering) or phase changes.

Table 2: Common Catalyst Deactivation Mechanisms in Bio-Oil HDO

| Mechanism | Primary Evidence | Common Cause in Bio-Oil | Potential Mitigation |

|---|---|---|---|

| Coking/Fouling | High C content (TGA), Pore volume loss (BET) | Polymerization of unsaturated/oxygenates | Lower T, increase H₂ pressure, use milder HDO steps. |

| Poisoning | Detection of K, Na, S, P on surface (ICP/MS) | Alkali/alkaline earth metals, biomass inorganics | Strict feedstock filtration/demineralization. |

| Sintering | Crystallite growth (XRD), Surface area loss (BET) | Local overheating, steam | Improve reactor temp control, add promoter (e.g., Sn). |

| Attrition | Fines in product, Pressure drop increase | Mechanical stress from mixing/flow | Use stronger catalyst supports (e.g., TiO₂, ZrO₂). |

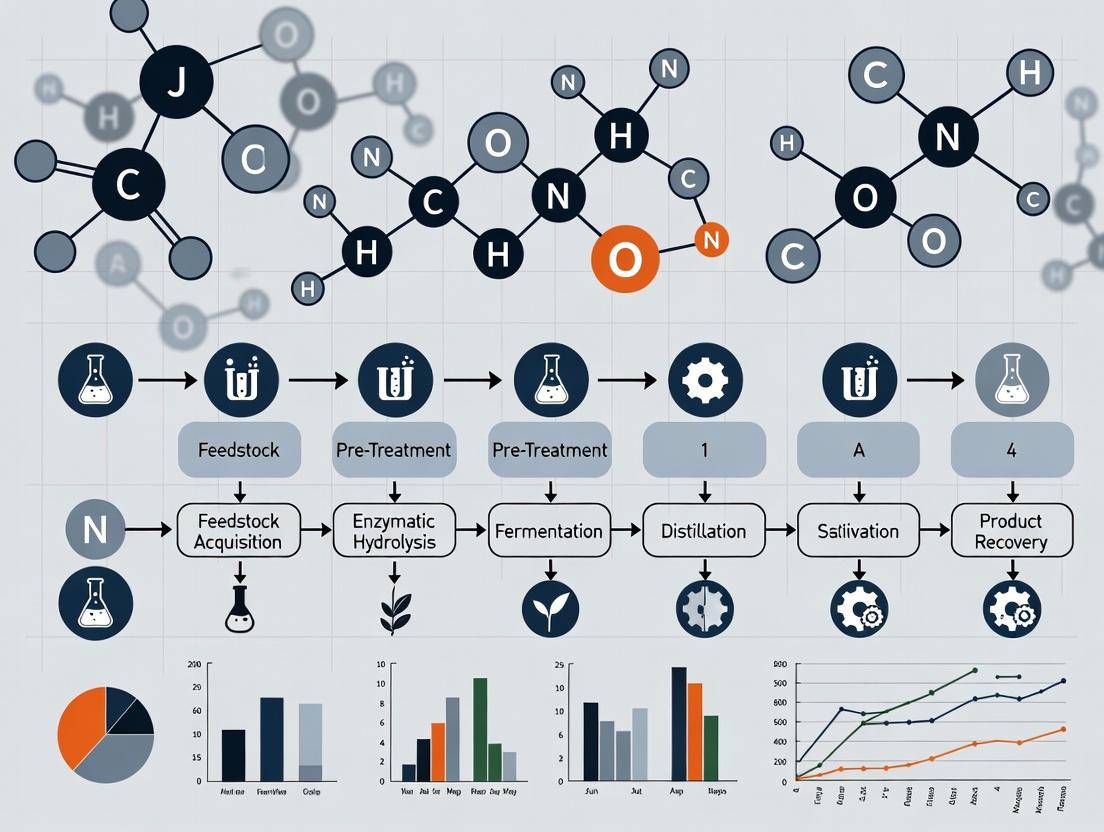

Signaling Pathway & Experimental Workflow

Diagram Title: Biofuel Process Risk Cascade

Diagram Title: Troubleshooting Protocol Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Biofuel Technology Risk Research

| Reagent/Material | Supplier Examples | Function in Risk Analysis |

|---|---|---|

| Commercial Cellulase Cocktail (e.g., CTec3, HTec3) | Novozymes, Dupont | Standardized enzyme blend for hydrolysis yield benchmarking. |

| NREL Standard Biomass (e.g., corn stover, poplar) | NIST/INREL | Control feedstock to isolate process variables from feedstock variability. |

| Anhydrous Sugar Standards (Glucose, Xylose, etc.) | Sigma-Aldrich, RESTEK | HPLC calibration for accurate yield quantification. |

| Inhibitor Standard Mix (Furfural, HMF, Acetic acid, etc.) | Sigma-Aldrich, Agilent | HPLC/GC calibration for inhibitor identification/quantification. |

| Selective Agar Media (MRS, YPD+Cycloheximide) | BD Difco, Thermo Fisher | Diagnostic for identifying microbial contamination types. |

| Model Bio-Oil Compounds (Guaiacol, Acetic acid) | TCI America, Alfa Aesar | Simpler substrates for controlled catalyst deactivation studies. |

| Catalyst Supports (γ-Al₂O₃, ZrO₂, Carbon) | Sigma-Aldrich, Alfa Aesar | Benchmarks for testing custom catalyst formulations. |

| DNA Extraction Kit (Microbial) | Qiagen, Mo Bio | For molecular identification of contaminants via 16S rRNA sequencing. |

Technical Support Center: Troubleshooting Bio-Conversion Experimental Processes

Welcome to the technical support center. This resource is designed within the context of broader research on addressing technology performance risk in biofuel supply chains. It provides targeted FAQs and protocols to help researchers mitigate key vulnerabilities related to feedstock inconsistency and process inefficiency.

FAQ & Troubleshooting Guide

Q1: Our lignocellulosic hydrolysis yields are inconsistent despite using a standard protocol. What could be causing this? A: Inconsistent yields are primarily due to feedstock compositional variability (e.g., lignin content, cellulose crystallinity). Pre-treatment efficiency is highly sensitive to this.

- Troubleshooting Steps:

- Characterize Feedstock: Perform immediate compositional analysis (see NREL/TP-510-42618) on the current and previous successful batches. Compare data.

- Adjust Pre-treatment: If lignin content is >5% higher than baseline, increase pre-treatment severity (e.g., temperature, acid concentration, or residence time) incrementally.

- Analyze Inhibitors: Test hydrolysate for elevated levels of inhibitors like furfural, HMF, or phenolic compounds, which suggest over-pre-treatment.

- Protocol - Feedstock Rapid Compositional Analysis:

- Mill feedstock to pass a 20-mesh screen.

- Perform a two-stage acid hydrolysis (72% H₂SO₄ at 30°C, then 4% H₂SO₄ at 121°C) to fractionate structural carbohydrates.

- Quantify sugars in the hydrolysate via HPLC (Aminex HPX-87P column) and acid-insoluble residue as lignin.

Q2: Our fermentation titers with engineered S. cerevisiae have dropped significantly, even with high sugar conversion. What should we check? A: This indicates a conversion inefficiency post-hydrolysis, likely due to microbial inhibition or metabolic stress.

- Troubleshooting Steps:

- Test Inhibitor Tolerance: Plate serial dilutions of your culture on standard media vs. media spiked with 50% process hydrolysate. Compare growth.

- Profile Metabolites: Use LC-MS to compare extracellular metabolite profiles (esp. organic acids, alcohols) between current and historical successful fermentations.

- Check Seed Train Vitality: Ensure inoculum is in mid-exponential phase (OD600 ~0.8-1.2) and has not undergone too many generations, which can lead to strain instability.

- Protocol - High-Throughput Inhibitor Tolerance Assay:

- In a 96-well plate, prepare a dilution series of your process hydrolysate in defined minimal media (0%, 10%, 25%, 50%, 75%).

- Inoculate each well with a standardized cell density (OD600 = 0.05) of your production strain.

- Monitor growth kinetics (OD600) for 48-72 hours using a plate reader. Calculate IC50 values.

Q3: How can we quickly assess the deactivation of our solid biocatalyst (e.g., immobilized enzyme) during repeated batches? A: Monitor both activity decay and physical integrity.

- Troubleshooting Steps:

- Measure Specific Activity: Compare the reaction rate (e.g., µmol product/min/g catalyst) of a fresh batch versus the used catalyst under identical, standardized conditions (pH, T, substrate conc.).

- Inspect for Leaching: Assay the reaction supernatant after catalyst removal for soluble protein/enzyme activity, indicating detachment.

- Analyze Physical Structure: Use SEM imaging to check for pore blockage, fragmentation, or biofilm formation on the catalyst surface.

- Protocol - Solid Catalyst Activity Retention Test:

- After each reuse cycle, wash the catalyst with buffer and conduct a standardized activity assay.

- Use 10 mg of catalyst, 5 mL of 100 mM substrate solution at optimal pH and temperature.

- Take samples at 1, 5, and 10 minutes, stop the reaction, and quantify product. Plot activity vs. cycle number.

Table 1: Impact of Feedstock Variability on Pre-treatment Output

| Feedstock Type | Lignin Content (%) | Cellulose Crystallinity Index | Optimal Pre-treatment Severity (Combined Factor, log R₀) | Glucose Yield (%) | Inhibitor Generation (g/L Furfural) |

|---|---|---|---|---|---|

| Corn Stover | 18.5 ± 1.2 | 48 ± 3 | 3.65 | 85.2 ± 2.1 | 0.8 ± 0.2 |

| Switchgrass | 22.1 ± 1.8 | 52 ± 4 | 3.85 | 78.5 ± 3.3 | 1.5 ± 0.3 |

| Poplar | 25.8 ± 2.1 | 55 ± 5 | 4.10 | 72.4 ± 4.0 | 2.4 ± 0.5 |

Table 2: Common Microbial Inhibitors and Mitigation Strategies

| Inhibitor Class | Example Compound | Critical Concentration (g/L) | Primary Effect on Microbe | Recommended Mitigation |

|---|---|---|---|---|

| Furan Derivatives | Furfural | >1.0 | DNA damage, enzyme inhibition | Overliming, activated carbon adsorption |

| Weak Acids | Acetic Acid | >3.0 | Internal pH collapse, uncoupler | pH control, strain engineering for tolerance |

| Phenolic Compounds | Vanillin | >0.5 | Membrane disruption | Laccase treatment, adaptive evolution |

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function & Application in Biofuel Research |

|---|---|

| Cellulase Cocktail (e.g., CTec2) | Multi-enzyme blend for saccharification of cellulose to glucose. Critical for standardized hydrolysis assays. |

| Aminex HPX-87H Column | HPLC column for separation and quantification of sugars, organic acids, and fermentation inhibitors. |

| YPD or Defined Minimal Media | For robust cultivation of yeast strains. Defined media is essential for metabolic studies and stress response assays. |

| Solid Acid Catalyst (e.g., Amberlyst-15) | Heterogeneous catalyst for esterification or hydrolysis reactions; used in lipid upgrading or inhibitor studies. |

| Microplate Reader with OD600 & Fluorescence | For high-throughput growth curves, viability assays (using resazurin), and promoter/reporter gene expression studies. |

Visualizations

Diagram 1: Feedstock to Biofuel Workflow with Key Vulnerabilities

Diagram 2: Inhibitor Impact on Microbial Cell

Technical Support Center

Troubleshooting Guide & FAQs

Q1: My cell viability assays show high, unexplained cytotoxicity in control groups when using fresh aliquots of molecular biology grade ethanol. What could be the cause? A: This is a critical issue often traced to solvent quality degradation or contamination. In biofuel supply chain research, ethanol purity is paramount. Impurities like aldehydes (acetaldehyde), organic acids, or high-peroxide solvents from autoxidation can introduce cytotoxic compounds.

- Actionable Protocol: Test solvent purity via GC-MS headspace analysis. As a rapid functional test, perform a sensitive cell viability assay (e.g., ATP-based luminescence) using a dilution series of your solvent against a fresh, certified ACS-grade benchmark.

- Quantitative Risk Data:

| Impurity in Ethanol | Typical Specification Limit (ppm) | Observed Cytotoxic Threshold in Cell Culture (ppm) | Common Source in Supply Chain |

|---|---|---|---|

| Acetaldehyde | ≤ 10 | ~5-10 | Incomplete synthesis or degradation |

| Methanol | ≤ 200 | ~1000-2000 | Feedstock impurity from biomass hydrolysis |

| Benzene | ≤ 1 | ~1-5 | Contamination during distribution or packaging |

| Water Content | ≤ 0.5% | N/A (context-dependent) | Absorption during transfer or storage |

Q2: My protein precipitation protocol with HPLC-grade acetone is yielding inconsistent recoveries. How do I troubleshoot this? A: Inconsistent recoveries frequently stem from solvent stabilizers or water content variance. Biofuel-derived acetone may have different stabilizer profiles than petrochemical sources.

- Actionable Protocol:

- Check the certificate of analysis (CoA) for the stabilizer (often BHT or cyclopentadiene) and water content.

- Evaporate a sample of the acetone under a gentle nitrogen stream and re-constitute in a stabilizer-free grade. Repeat the precipitation.

- For water content, use Karl Fischer titration. If >0.5%, dry over a molecular sieve (3Å) before use.

- Standardize your protocol: Always pre-chill acetone to -20°C and use a fixed sample-to-solvent ratio (e.g., 1:4 v/v) and incubation time (60 min at -20°C).

Q3: I suspect lot-to-lot variability in my bioreagent buffers is affecting enzyme kinetics in my biocatalyst assays. How can I validate this? A: This directly mirrors technology performance risks in scaling up biocatalytic processes for biofuels. Buffer salts and pH adjusters can contain metal contaminants that inhibit enzymes.

- Actionable Protocol: ICP-MS Analysis of Buffer Components.

- Prepare Samples: Dissolve 1g of each buffer salt lot (e.g., phosphate, Tris) in 50 mL of ultrapure water (18.2 MΩ·cm).

- Analysis: Use Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to screen for transition metals (Ni, Cu, Fe, Co, Zn) at ppb levels.

- Functional Test: Perform a standard enzyme activity assay (e.g., for a dehydrogenase or cellulase) using buffers made from the different lots. Compare initial reaction velocities (V0).

- The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Troubleshooting |

|---|---|

| Karl Fischer Titrator | Precisely measures trace water content in organic solvents. |

| GC-MS System | Identifies and quantifies volatile organic impurities in solvents. |

| ICP-MS | Detects ultra-trace metal contaminants in salts and water. |

| ACS-Grade & HPLC-Grade Solvents | Benchmarked materials with stringent purity specifications. |

| Molecular Sieves (3Å, 4Å) | For on-site drying of solvents like acetone, acetonitrile, and DMSO. |

| In-line Solvent Filters (0.2 µm PTFE) | Removes particulates and microbial contamination from bulk dispensers. |

Experimental Protocol: Validating Solvent Purity via Peroxide Test in Tetrahydrofuran (THF) Background: THF, used in membrane lipid extraction, forms explosive peroxides upon aging. Biofuel supply chains using furanic compounds may encounter similar instability.

- Reagent: Prepare test strips using potassium iodide/starch paper or use a commercial peroxide test kit.

- Method: In a fume hood, dip the test strip into the THF sample for 1 second. Remove and observe immediately.

- Analysis: Compare the color change to the provided scale. Peroxide levels >50 ppm are considered hazardous and the solvent must be deactivated and disposed of properly. Do not use.

- Prevention: Always purchase THF with BHT stabilizer, store under inert gas (argon), and use within 6 months of opening.

Visualizations

Solvent Quality Risk Pathway in Supply Chain

Troubleshooting Workflow for Reagent-Driven Issues

Technical Support Center

Troubleshooting Guide: Common Biofuel Inconsistency Issues in Lab Research

FAQ 1: Why are my cell culture viability assays showing high variability after switching to a new batch of algal biofuel-derived solvent?

- Issue: Biofuel feedstocks (e.g., algal oil) vary seasonally and by processing method, leading to inconsistent trace contaminant profiles (pesticides, heavy metals, organic acids) that are cytotoxic.

- Solution: Implement a pre-screening protocol for each new solvent batch. Use Gas Chromatography-Mass Spectrometry (GC-MS) to profile contaminants. Pass the solvent through a customized cleanup column (e.g., silica gel or activated carbon) before use in sensitive assays. Establish acceptance criteria based on historical performance data of batches associated with successful experiments.

FAQ 2: My enzymatic biodiesel conversion yields have dropped significantly despite using the same protocol. What could be wrong?

- Issue: Inconsistent purity and composition of biofuel feedstocks (e.g., waste cooking oil) can introduce impurities (water, free fatty acids, peroxides) that deactivate or inhibit enzymatic catalysts (lipases).

- Solution: Quantify key impurities in the incoming feedstock. See Table 1 for thresholds. Pre-treat the feedstock to standardize it: use molecular sieves to remove water, perform acid esterification to neutralize high FFA content before the main enzymatic transesterification step.

FAQ 3: How can I prevent fouling and erratic results in my high-throughput catalyst screening system when testing bio-oils?

- Issue: Pyrolysis bio-oils are chemically complex and unstable, forming gums and solids that clog microfluidic channels or deposit on catalyst surfaces, leading to inconsistent activity measurements.

- Solution: Implement an inline filtration (0.2 µm) and a standardized "aging" protocol for the bio-oil sample prior to testing. Use a solvent carrier stream (e.g., tetrahydrofuran) to improve flow characteristics. Clean the system with a standardized solvent flush (acetone → ethanol → hexane) between each sample run.

FAQ 4: Why does my fermentation titers drop when using hydrotreated vegetable oil (HVO) as a carbon source compared to pure glucose?

- Issue: HVOs, while chemically similar to alkanes, can have inconsistent nutrient content (lack of co-factors, sterols) essential for microbial growth, leading to unreliable metabolic activity.

- Solution: Supplement the HVO-based fermentation medium with a defined cocktail of micronutrients (see Table 2: Research Reagent Solutions). Perform a growth curve assay with each new HVO batch to calibrate the supplementation needs.

Data Presentation

Table 1: Critical Impurity Thresholds in Biodiesel Feedstocks for Consistent Enzymatic Conversion

| Impurity | Acceptable Threshold for Lipase Activity | Standard Test Method | Recommended Pretreatment if Exceeded |

|---|---|---|---|

| Water Content | < 0.05% w/w | ASTM D6304 | Drying with 3Å molecular sieves |

| Free Fatty Acids (FFA) | < 2% w/w | AOCS Ca 5a-40 | Acid-catalyzed esterification |

| Peroxide Value (PV) | < 5 meq/kg | AOCS Cd 8b-90 | Reduction with sodium sulfite |

| Phosphorus Content | < 10 ppm | EN 14107 | Acid degumming |

Table 2: Research Reagent Solutions for Microbial Cultivation on Hydrotreated Biofuels

| Reagent | Function | Typical Concentration in Medium |

|---|---|---|

| Methyltricaprylylammonium Chloride | Increases bioavailability of hydrophobic alkane substrates. | 0.01% v/v |

| Ergosterol | Essential membrane component for many yeasts when grown on non-fermentable carbon. | 20 mg/L |

| Tween 80 | Non-ionic surfactant to emulsify fuel and improve uptake. | 0.1% v/v |

| Trace Metal Solution (e.g., Cu, Mn, Co, Mo) | Provides micronutrients absent in purified hydrocarbon streams. | 1 mL/L |

Experimental Protocols

Protocol 1: Standardized Pre-Treatment of Waste Cooking Oil for Enzymatic Biodiesel Synthesis

- Characterization: Determine water (Karl Fischer titration) and FFA (titration) content of the raw oil.

- Dehydration: If water >0.05%, heat oil to 110°C while stirring under vacuum (100 mbar) for 30 minutes. Alternatively, add 5% w/w of pre-activated 3Å molecular sieves and stir for 24 hours at room temperature.

- Acid Esterification (if FFA >2%): For every 100g of oil, mix with 20g of methanol and 1g of concentrated sulfuric acid (H₂SO₄). React at 60°C with stirring (600 rpm) for 2 hours. Transfer to a separatory funnel, allow phases to separate, and discard the lower glycerol/acid layer.

- Neutralization & Drying: Wash the oil layer with warm (50°C) deionized water until pH neutral. Dry the washed oil over anhydrous sodium sulfate (Na₂SO₄) for 12 hours, then filter.

- Quality Control: Re-analyze water and FFA content. Proceed to enzymatic transesterification only if within thresholds specified in Table 1.

Protocol 2: Cytotoxicity Screening of Biofuel-Derived Solvent Batches

- Sample Preparation: Aliquot 10 mL of the suspect biofuel solvent (e.g., bio-based acetone). Evaporate to dryness under a gentle nitrogen stream. Reconstitute the non-volatile residue in 1 mL of DMSO.

- Cell Exposure: Plate HEK-293 or relevant cell line in a 96-well plate at 10,000 cells/well. Incubate for 24 hours. Prepare a dilution series of the reconstituted residue (e.g., 0.1%, 0.5%, 1% v/v in culture medium). Expose cells to these dilutions for 48 hours.

- Viability Assay: Perform an MTT or resazurin assay according to manufacturer instructions. Measure absorbance/fluorescence.

- Analysis: Compare dose-response curves against a historical solvent batch known to support normal cell growth. A new batch causing >20% reduction in viability at 0.5% concentration should be flagged for further purification.

Mandatory Visualizations

Biofuel Inconsistency Impact & Mitigation Pathway

Feedstock Quality Control Decision Workflow

Technical Support Center

FAQs & Troubleshooting Guide for Biofuel Supply Chain Digital Twin Experiments

Q1: My biomass feedstock quality model in the digital twin is producing inaccurate yield predictions. What calibration steps should I follow? A: Inaccurate feedstock models are often due to misaligned data granularity. Follow this protocol:

- Data Synchronization: Ensure the physical sensor data (e.g., moisture, lignin content from NIR spectroscopy) matches the temporal resolution of the twin's simulation clock. If sensors log hourly, but the twin updates every 15 minutes, implement a data interpolation or averaging protocol.

- Parameter Calibration: Run a batch of 10-15 controlled pretreatment experiments with varying feedstock batches. Use the results to calibrate the kinetic parameters in the twin's reaction model via a gradient descent algorithm.

- Validation: Reserve 20% of the experimental data for validation. The model's Mean Absolute Percentage Error (MAPE) should be below 8% for the validation set to be considered calibrated.

Q2: The AI module for predicting enzymatic hydrolysis failure is generating too many false-positive alerts. How can I refine it? A: This indicates a class imbalance or noisy training data. Implement this methodology:

- Data Curation: Re-label your historical failure event data. A "true failure" is defined as a conversion rate drop below 65% of the projected yield within a 4-hour window. Other anomalies should be labeled as "minor fluctuations."

- Algorithm Tuning: Switch from a standard Random Forest classifier to a Gradient Boosting model (XGBoost) and adjust the classification threshold. Use a confusion matrix from your test set to find the optimal threshold that balances precision and recall.

- Feature Engineering: Add a rolling standard deviation (window=12 time steps) of the bioreactor's temperature and pH as new input features to help the AI distinguish between noise and a genuine trend.

Q3: How do I integrate real-time logistics (transportation delays) into my supply chain risk model? A: Use a hybrid simulation-AI approach.

- Protocol: Establish an API connection between your digital twin platform and a live traffic/weather data feed (e.g., Google Maps API, NOAA API).

- Model Update: Create a discrete event simulation module for transportation. The AI component (a recurrent neural network) continuously ingests the live feed to predict delay probabilities, which then update the simulation parameters.

- Trigger: Set a rule that if the predicted delay exceeds 8 hours, the twin automatically initiates a "risk mitigation" workflow, suggesting alternative storage or rerouting.

Quantitative Data Summary

Table 1: Performance Metrics of AI Models for Preprocessing Fault Detection

| AI Model | Average Precision | Recall | False Positive Rate | Training Data Required (hours) |

|---|---|---|---|---|

| Logistic Regression | 0.72 | 0.65 | 0.18 | 500 |

| Random Forest | 0.89 | 0.82 | 0.09 | 750 |

| XGBoost (Optimized) | 0.94 | 0.88 | 0.05 | 1000 |

| LSTM Neural Network | 0.91 | 0.90 | 0.11 | 2000 |

Table 2: Impact of Digital Twin Calibration on Predictive Accuracy

| Supply Chain Stage | Prediction Error (Uncalibrated) | Prediction Error (Calibrated) | Key Calibration Parameter |

|---|---|---|---|

| Feedstock Preprocessing | 22% | 7% | Cellulose Crystallinity Index |

| Enzymatic Hydrolysis | 18% | 5% | Enzyme Inhibition Constant (Ki) |

| Fermentation & Distillation | 15% | 6% | Yeast Ethanol Tolerance (g/L) |

| Logistics & Storage | 30% | 12% | Feedstock Degradation Rate |

Experimental Protocol: Validating a Digital Twin's Fermentation Inhibition Warning Objective: To physically verify an AI-generated prediction of microbial inhibition due to feedstock-derived inhibitors. Methodology:

- Trigger: When the digital twin's AI module predicts a >40% probability of inhibition in a fermentation batch, flag the corresponding physical feedstock batch.

- Sampling: Aseptically withdraw 3 x 100mL samples from the flagged fermenter at T=0h, 12h, and 24h.

- Analysis:

- HPLC: Quantify concentrations of target inhibitors (e.g., furfural, HMF, acetic acid).

- Viability Staining: Use fluorescent dyes (e.g., propidium iodide, SYTO 9) in a flow cytometer to determine live/dead cell ratio.

- qPCR: Measure expression levels of key stress response genes (e.g., HSP12, ADH2).

- Correlation: Statistically correlate inhibitor levels and viability metrics with the AI's predicted probability and the digital twin's simulated metabolite profiles.

Visualizations

Title: Digital Twin & AI Risk Identification Workflow

Title: Experimental Protocol for Validating AI Predictions

The Scientist's Toolkit: Research Reagent Solutions

Table: Key Reagents for Biofuel Process Risk Experimentation

| Item | Function in Risk Identification Experiments |

|---|---|

| Near-Infrared (NIR) Spectrometer Probe | Provides real-time, non-destructive analysis of feedstock composition (cellulose, hemicellulose, moisture), critical for digital twin input calibration. |

| Inhibitor Standard Mix (Furfural, HMF, Acetic Acid) | HPLC standard for quantifying microbial fermentation inhibitors derived from biomass pretreatment, enabling validation of AI toxicity predictions. |

| LIVE/DEAD BacLight Bacterial Viability Kit | Fluorescent staining assay to quantify live vs. dead cell ratios in fermentation broths, providing ground-truth data for AI-based health forecasts. |

| qPCR Assay for Yeast Stress Genes (e.g., HSP12) | Measures molecular-level stress response in real-time, used to correlate digital twin metabolic simulations with physical cellular states. |

| IoT-Enabled pH/Temperature Loggers | Provides continuous, time-stamped environmental data streams essential for synchronizing the physical process with its digital twin. |

| Enzymatic Hydrolysis Assay Kit (DNS Method) | Bench-scale kit for rapid quantification of reducing sugars, used for frequent calibration of the digital twin's conversion efficiency models. |

Advanced Modeling and Mitigation: Applying Risk Quantification Tools to Secure Bio-Supplies

Quantitative Risk Assessment (QRA) Frameworks for Biofuel Processes

Technical Support Center: Troubleshooting QRA for Biofuel Experiments

Frequently Asked Questions (FAQs)

Q1: During QRA modeling for a novel lignocellulosic hydrolysis step, my risk probability calculations are yielding inconsistent results across simulation runs. What could be the cause? A: Inconsistent results often stem from poorly defined probability distributions for input variables. Ensure that for key parameters like enzyme activity (IU/g), inhibitor concentration (g/L), and reaction temperature (°C), you have defined the correct statistical distribution (e.g., Normal, Log-normal, Uniform) based on empirical data. Using a default uniform distribution without experimental justification leads to output variance. Re-calibrate your model using the protocol for "Parameter Distribution Fitting" below.

Q2: How do I quantitatively integrate catalyst deactivation data from lab-scale experiments into a full-scale process QRA for biodiesel production? A: Catalyst deactivation rate is a critical performance risk. You must scale the deactivation function. Use lab-scale time-on-stream (TOS) data to fit a decay model (e.g., exponential: k_d = Aexp(-Ea/RT)*). In your QRA, treat the pre-exponential factor (A) and activation energy (Ea) as uncertain variables with distributions defined by your lab data's confidence intervals. Then, run Monte Carlo simulations to propagate this uncertainty to catalyst replacement cost and downtime risk at scale.

Q3: My consequence analysis for a fermentation tank overpressure scenario seems underestimated compared to historical incident data. Which parameters are most sensitive? A: The top sensitive parameters are typically: 1) Failure Rate of Pressure Relief Valves (PRVs): Use industry benchmark data (e.g., OREDA, CCPS) instead of manufacturer specs. 2) Vapor Cloud Composition: Ensure your model uses the actual composition of off-gas (CO2, H2, ethanol) not just pure CO2. 3) Ignition Probability: For biofuel processes, this is often higher due to combustible dusts; adjust location-specific probabilities. Re-run your event tree with these updated parameters.

Q4: When assessing feedstock variability risk, what are the key quantitative metrics to link feedstock properties to final yield? A: The key is to establish Transfer Functions. Create correlations such as:

- Cellulose Crystallinity Index (%) → Glucose Yield (% theoretical)

- Ash Content (% dry basis) → Catalyst Poisoning Rate (%/batch)

- Moisture Variability (SD %) → Pretreatment Energy Consumption (GJ/ton) Perform multivariate regression on your experimental data to define these functions, then use them as risk models in your QRA to translate feedstock specs into financial and yield volatility.

Experimental Protocols for QRA Data Generation

Protocol 1: Determining Probability Distribution for Enzyme Hydrolysis Yield Objective: Generate the data required to define a probability density function (PDF) for glucose yield in a probabilistic QRA model. Methodology:

- Design of Experiments (DoE): Set up a central composite design (CCD) with three key variables: solid loading (15-25% w/v), enzyme dosage (10-30 mg protein/g glucan), and time (48-72h). Use 5 levels for each variable.

- Replication: Execute each experimental run in triplicate (n=3) to capture inherent process variability.

- Analysis: Quantify glucose yield via HPLC. For each run condition, calculate the mean and standard deviation of yield.

- Distribution Fitting: Pool all replicate data (e.g., 90 data points). Use statistical software (e.g., R, @Risk) to fit Normal, Log-normal, and Weibull distributions. Perform a Kolmogorov-Smirnov test to select the best-fitting distribution.

- Output: The fitted distribution (e.g., Yield ~ N(μ=85%, σ=3.2%)) is used directly as an input variable in the QRA Monte Carlo simulation.

Protocol 2: Failure Mode Testing for Solid-Liquid Separation Unit Objective: Obtain quantitative data on failure rates (probability) and severity (time delay) for a filter press in a pilot-scale algal lipid extraction process. Methodology:

- Define Failure Modes: Primary modes: (a) Cake blow-through (due to incorrect particle size), (b) Cloth blinding (due to polymer overdose), (c) Cycle overrun (due to pump decay).

- Accelerated Testing: Under controlled conditions, induce failures. E.g., for (a), systematically vary algal cell disruptor energy (kJ/L) to alter particle size distribution and record the pressure (psi) at which blow-through occurs. Repeat 30 times.

- Data Recording: For each test, record: time to failure (T), process parameter at failure (P), and downtime for remediation (D).

- Data Analysis: Calculate probability as (# of failures / # of trials) for each mode. Fit time-to-failure data to an exponential distribution to derive a failure rate (λ, failures/operating hour). Severity is defined as the distribution of downtime (D).

- QRA Integration: These quantified λ and D distributions populate the fault tree and LOPA (Layer of Protection Analysis) for this equipment item.

Table 1: Typical Failure Rate Data for Key Biofuel Process Units

| Process Unit | Failure Mode | Probability (per demand or per year) | Data Source |

|---|---|---|---|

| Anaerobic Digester | Feedstock Pump Seal Leak | 2.1e-3 / year | OREDA (2023) |

| Transesterification Reactor | Methanol Feed Valve Fails Closed | 1.0e-4 / demand | CCPS PRA Guidelines |

| Centrifuge (Algal Dewatering) | Bowl Imbalance Shutdown | 5.6e-2 / year | Biofuel Plant Op Data (2022-24) |

| Pyrolysis Reactor | Coke Formation > Spec Limit | 1.2 / year | Industry Benchmarking Study |

Table 2: QRA Output for Fischer-Tropsch Biofuel Process: Top 5 Risk Contributors

| Risk Scenario | Frequency (events/year) | Consequence (Million USD) | Risk (USD/year) | % of Total Risk |

|---|---|---|---|---|

| Syngas Compressor Explosion | 1.2e-4 | 45.2 | 5,424 | 31% |

| Catalyst Sintering (Yield Loss) | 1.0e+0 | 0.85 | 850 | 18% |

| H₂ Supply Interruption (>4h) | 2.5e-1 | 2.1 | 525 | 11% |

| Wax Product Solidification in Line | 5.0e-1 | 0.65 | 325 | 7% |

| Feedstock Switch (Quality Issue) | 1.0e+0 | 0.28 | 280 | 6% |

Visualizations

QRA Workflow for a Biofuel Process Unit

Fault Tree for Fermentation Runaway Scenario

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for QRA-Ready Biofuel Experiments

| Item | Function in QRA Context | Example Product/Supplier |

|---|---|---|

| Process Analytics (PTR-MS) | Provides real-time, high-resolution volatile organic compound (VOC) data for emission event frequency and consequence modeling. | Ionicon PTR-TOF 6000 X2 |

| Bench-Scale Continuous Reactor System | Enables accelerated lifetime and failure testing under controlled upsets to generate quantitative failure rate data (λ). | Ammarks Continuous Flow System |

| Catalyst Characterization Suite (BET, TPD, XRD) | Quantifies catalyst degradation rates (sintering, poisoning) to model performance decay risk over time. | Micromeritics 3Flex, Anton Paar XRD |

| Statistical Software with Monte Carlo Package | Performs probabilistic risk calculations, sensitivity analysis, and distribution fitting for QRA models. | Palisade @Risk, R (riskassessment package) |

| High-Throughput Saccharification Assay Kits | Rapidly generates large datasets on feedstock variability (100s of samples) to define input uncertainty for QRA. | Megazyme BIOCHAIN Lignocellulose Kit |

Application of Monte Carlo Simulations for Yield and Purity Forecasting

Technical Support Center

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: My Monte Carlo simulation for biofuel yield prediction shows improbably high or low extreme values (outliers). What could be the cause and how can I fix it? A: This typically indicates an issue with the input probability distributions for key process parameters (e.g., enzyme activity, feedstock sugar content).

- Troubleshooting Steps:

- Validate Input Data: Re-examine the experimental data used to fit your input distributions. Ensure there are no measurement or data entry errors.

- Check Distribution Fit: Use statistical goodness-of-fit tests (e.g., Kolmogorov-Smirnov, Anderson-Darling) to confirm the chosen distribution (Normal, Lognormal, Beta, Triangular) accurately represents your empirical data. A poor fit will generate unrealistic random samples.

- Review Physical Limits: Implement distribution truncation. For example, if enzyme concentration cannot be negative, truncate the Normal distribution at zero. Define realistic min/max bounds for all variables.

- Inspect Correlations: Confirm that any defined correlations between input variables (e.g., between temperature and reaction rate) are physiologically plausible and correctly coded in the simulation model.

Q2: How do I determine the correct number of simulation iterations (runs) for reliable forecasting of product purity? A: The required number of iterations depends on the desired precision and model complexity.

- Troubleshooting Guide:

- Perform a Convergence Analysis: Run the simulation in batches (e.g., 1,000, 5,000, 10,000, 50,000 iterations). After each batch, calculate the mean and standard deviation of your key output (e.g., purity percentage).

- Monitor Stability: Plot the output statistics against the number of iterations. The point where the mean and standard deviation stabilize (show minimal fluctuation) indicates a sufficient number of runs.

- Rule of Thumb: For a preliminary biofuel process screening, 10,000 iterations may suffice. For robust quantification of low-probability risk events (e.g., purity falling below a critical threshold), 100,000+ iterations are often necessary. Refer to the convergence data below.

Table 1: Example Convergence Analysis for Purity Forecast

| Number of Iterations | Forecast Mean Purity (%) | Standard Deviation (%) | Change in Mean from Previous Batch |

|---|---|---|---|

| 1,000 | 92.5 | 3.2 | - |

| 5,000 | 93.1 | 3.05 | +0.6 |

| 10,000 | 93.0 | 3.08 | -0.1 |

| 50,000 | 93.02 | 3.07 | +0.02 |

Q3: My simulation results do not align with my small-scale laboratory experimental results. How should I proceed? A: This discrepancy is a key risk assessment outcome. Systematic investigation is required.

- Action Protocol:

- Audit Model Assumptions: Critically review all transfer functions and equations in your simulation that link inputs (e.g., feedstock variability) to outputs (yield/purity). Are scaling effects (from lab to pilot/commercial) accurately captured?

- Calibrate with Bayesian Inference: Use your lab data as a prior distribution to update and calibrate the simulation model. This formally integrates empirical evidence into the forecast.

- Identify Hidden Variables: The discrepancy may reveal an uncontrolled critical process parameter (CPP) in the lab (e.g., trace inhibitor presence) not included in the model. Design new, targeted experiments to identify it.

- Document the Gap: This mismatch is valuable data for your thesis on technology performance risk, highlighting a specific scale-up uncertainty for the biofuel supply chain.

Experimental Protocol: Integrating Monte Carlo Simulation with Laboratory Data

Title: Protocol for Calibrating a Hydrolysis Yield Forecast Model Using Experimental Data.

Objective: To refine a Monte Carlo simulation model of lignocellulosic sugar yield by updating input parameter distributions with latest experimental results.

Materials & Method:

- Baseline Simulation: Establish a pre-calibration simulation model with defined stochastic inputs (e.g., feedstock cellulose content ~N(45, 5)%, enzyme loading ~Triang(10, 15, 20) mg/g).

- Laboratory Experiment: Perform 30 independent hydrolysis experiments under the defined process range. Precisely measure the resulting sugar yield for each run.

- Statistical Comparison: Use the

scipy.statspackage in Python to compare the distribution of the simulated output to the distribution of the experimental output using a two-sample Kolmogorov-Smirnov test. - Model Calibration: Implement a simple Markov Chain Monte Carlo (MCMC) sampling routine (e.g., using

PyMC3orStan) to adjust the mean and variance of key input distributions so that the simulation output distribution better matches the experimental data. - Validation: Run the calibrated simulation and compare its output to a hold-out set of experimental data not used in calibration.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Key Reagents & Materials for Yield/Purity Analysis Experiments

| Item Name | Function in Experiment |

|---|---|

| Lignocellulolytic Enzyme Cocktail (e.g., Cellic CTec3) | Hydrolyzes cellulose and hemicellulose in feedstock into fermentable sugars. Key stochastic variable in yield simulations. |

| High-Performance Liquid Chromatography (HPLC) System with Refractive Index Detector | Quantifies sugar monomers (glucose, xylose) and by-products (inhibitors) for precise yield and purity calculation from experimental runs. |

| Certified Reference Standards (Glucose, Xylose, Furfural, HMF) | Essential for calibrating the HPLC to generate accurate, quantitative data for model input and validation. |

| Process Modeling Software (Python with NumPy/SciPy/PyMC3, @RISK, Crystal Ball) | Platform for building, running, and analyzing Monte Carlo simulations, including statistical fitting and advanced calibration. |

| Defined Composition Feedstock Slurry | Standardized substrate (e.g., pretreated corn stover) with characterized compositional variability, used to define input distributions for the simulation. |

Visualizations

Title: Monte Carlo Yield Forecasting Workflow

Title: Key Risk Factors in Biofuel Yield Pathway

Supply Chain Mapping and Critical Control Point (CCP) Analysis

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Our biomass feedstock sensor network is reporting inconsistent compositional data (e.g., lignin, cellulose content), compromising our upstream supply mapping. What are the primary troubleshooting steps?

A: Inconsistent sensor data typically stems from calibration drift, particulate contamination, or moisture interference.

- Protocol 1 - On-site Calibration Verification:

- Take three physical samples from the same biomass lot at the sensor intake point.

- Perform standard lab-based NIR spectroscopy or wet chemistry analysis (e.g., NREL/TP-510-42618) to establish benchmark values.

- Compare sensor outputs for the same lot against lab results. A deviation >5% requires recalibration.

- Execute the sensor's built-in recalibration routine using provided standard reference materials.

- Protocol 2 - Contamination Check: Power down and isolate the sensor. Visually inspect the optical window or probe for residue. Clean using manufacturer-specified solvent (e.g., anhydrous ethanol). Perform a post-cleaning baseline measurement in a clean air environment before redeployment.

Q2: During enzymatic hydrolysis, we observe variable sugar yield despite controlled bioreactor conditions, indicating a potential CCP failure. How do we systematically isolate the cause?

A: Variable yield at this CCP often points to feedstock variability or enzyme activity issues. Follow this isolation protocol:

- Test 1 - Feedstock Consistency: Analyze the current and three previous feedstock batches for particle size distribution (Sieve analysis, ASTM E11) and crystallinity index (via XRD). Tabulate results.

- Test 2 - Enzyme Activity Assay: Perform a filter paper unit (FPU) assay (Adney & Baker, 2008) on the enzyme cocktail from the current production run versus a new, reference aliquot. Activity should be within 10%.

- Cross-Reference: If feedstock is consistent but enzyme activity is low, the CCP is enzyme storage/supply. If feedstock is variable, the CCP is pre-processing.

Q3: The real-time viscosity monitoring system in our lipid transesterification reactor is lagging, risking delayed correction and off-spec biodiesel. What immediate actions should be taken?

A: System lag is a critical control failure. Take these immediate steps:

- Manual Override & Sampling: Switch control to manual and maintain current parameters. Extract a 100mL sample aseptically.

- Immediate Offline Test: Perform a rapid viscosity measurement using a calibrated bench-top viscometer (e.g., Brookfield) at standard shear rate and temperature (e.g., 40°C).

- Compare & Adjust: Compare the offline result to the lagging real-time readout. Use the offline value for immediate process adjustment.

- Diagnostic: Check the in-line viscometer's shear element for fouling and the data transmission line for latency. Clean or replace as necessary.

Data Tables

Table 1: Common Sensor Deviations & Corrective Actions in Biomass Pre-Processing

| Sensor Type | Measured Parameter | Acceptable Range | Typical Deviation Cause | Corrective Action |

|---|---|---|---|---|

| NIR Spectrometer | Cellulose Content | ±2.5% of lab value | Moisture film on lens | Dry purge, clean with lint-free cloth |

| RFID Scanner | Batch ID Traceability | 100% read rate | Physical damage, radio interference | Replace tag/antenna, shield from motors |

| Mass Flow Meter | Feedstock Input (kg/hr) | ±1.5% of setpoint | Pipe vibration, build-up | Re-tighten mounts, inspect for blockages |

Table 2: Critical Control Point (CCP) Performance Metrics in Pilot-Scale Hydroprocessing

| CCP Name | Control Parameter | Target Value | Control Limits | Monitoring Frequency | Corrective Action |

|---|---|---|---|---|---|

| Hydrotreater Inlet | Temperature | 345°C | 340-350°C | Continuous (RT) | Adjust heat exchanger bypass |

| Catalyst Bed | Pressure Drop | 0.5 bar/m | 0.4-0.6 bar/m | Hourly | Check for feed particulates |

| Product Separator | Water Content | <0.5% vol | <0.8% vol | Per 4-hour batch | Increase coalescer setting |

Experimental Protocols

Protocol: Mapping Feedstock Variability Using Geospatial & Compositional Data Objective: To quantitatively map variability in biomass feedstock as a source of technology performance risk. Methodology:

- Sample Collection: Geotag and collect biomass samples (e.g., switchgrass bales) from 50 points across the supply region using a stratified random grid.

- Compositional Analysis: For each sample, determine glucan, xylan, and lignin content using a two-stage acid hydrolysis according to NREL Laboratory Analytical Procedure (LAP) "Determination of Structural Carbohydrates and Lignin in Biomass".

- Data Integration: Use GIS software (e.g., QGIS) to create layered maps plotting geographical coordinates against compositional data (e.g., a color-gradient map for lignin content).

- Statistical Analysis: Calculate coefficient of variation (CV) for each component across the region. A CV >15% for a key component flags a high-variability zone requiring a separate CCP.

Protocol: Stress-Testing a Blockchain-Based Traceability Node Objective: To evaluate the failure risk of a digital traceability system, a critical component of supply chain mapping. Methodology:

- Setup: Establish a private, permissioned blockchain network (e.g., using Hyperledger Fabric) with three nodes simulating a farmer, pre-processor, and biorefinery.

- Induced Failure: Systematically induce stressors:

- Network Latency: Use network emulation software (e.g.,

tcon Linux) to delay packet transmission by 500ms, 1000ms, and 2000ms. - Node Failure: Abruptly shut down the "pre-processor" node during transaction submission.

- Network Latency: Use network emulation software (e.g.,

- Metrics: Record (a) time for transaction finality, (b) data consistency across remaining nodes, and (c) recovery time upon node restart.

- Analysis: Determine the maximum latency and node downtime before the chain forks or data becomes inconsistent, defining the operational limits for this digital CCP.

Diagrams

Diagram 1: CCP Analysis Workflow for Biofuel Supply Chain

Diagram 2: Tech Risk Signaling in Biofuel Supply Chain

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for Supply Chain Biomass Analysis

| Item Name | Supplier Example | Function in Experiment | Critical Storage |

|---|---|---|---|

| NIST Traceable Biomass Standards | National Institute of Standards | Calibrates NIR/analytical instruments for validated mapping data. | Desiccator, 20°C |

| Aminex HPX-87H HPLC Column | Bio-Rad | Separates and quantifies sugar monomers (glucose, xylose) from hydrolyzed biomass. | 5-40°C, pH 1-14 |

| Enzymatic Assay Kit (Cellulase) | Megazyme | Precisely measures filter paper unit (FPU) activity to monitor enzyme supply CCP. | -20°C |

| Certified Sulfur in Oil Standards | AccuStandard | Calibrates XRF/ICP for sulfur analysis, critical for hydroprocessing CCP limits. | Sealed, 15-25°C |

| Blockchain Network Emulator | Linux tc command |

Stress-tests digital traceability nodes to define system performance limits. | N/A (Software) |

Note: This support center is framed within the thesis Addressing Technology Performance Risk in Biofuel Supply Chains Research. It provides troubleshooting and methodological guidance for researchers integrating LCA and Techno-Economic Analysis (TEA) under uncertainty.

Frequently Asked Questions (FAQs) & Troubleshooting Guides

Q1: In our integrated LCA-TEA model for a novel lignocellulosic biofuel pathway, we encounter widely varying results for Global Warming Potential (GWP) and Minimum Selling Price (MSP). What are the primary sources of this variability and how can we systematically address them?

A: Variability typically stems from technology performance uncertainty in the biofuel supply chain. Key sources and solutions are:

- Source 1: Feedstock Composition & Pre-treatment Efficiency. High moisture or lignin content can drastically alter energy and chemical input requirements.

- Troubleshooting: Implement a Monte Carlo simulation where feedstock characteristics (e.g., sugar yield, moisture content) are defined as probability distributions (e.g., normal, triangular) based on experimental data from multiple harvests.

- Source 2: Catalyst Lifespan & Conversion Yield in the Reactor. Assumed catalyst stability (e.g., 1000 hours) vs. real-world deactivation (e.g., 600-1200 hours) creates massive economic and environmental outcome divergence.

- Troubleshooting: Use sensitivity analysis to identify thresholds. Run your model with catalyst lifespan as the variable and pinpoint the value where MSP becomes non-viable (>$5/GGE) or GWP exceeds a policy threshold.

- Source 3: Allocation Methods for Co-products. Choosing mass, energy, or economic allocation for co-products (e.g., lignin for power) significantly shifts impacts.

- Troubleshooting: Conduct scenario analysis. Mandatorily run your model under all three allocation methods (per ISO 14044) and report the range. System expansion (avoiding allocation) is preferred but not always possible.

Q2: How do we quantitatively integrate risk from TEA (e.g., probability of capital cost overrun) into the LCA results to produce a "risk-adjusted" carbon footprint?

A: This requires propagating economic risk parameters into the life cycle inventory. Follow this protocol:

Experimental/Modeling Protocol: Risk-Adjusted Hybrid LCA-TEA

- Define Risk Parameters: Identify key cost items with high uncertainty (e.g., CapEx for enzymatic hydrolysis unit, OpEx for enzyme cocktails).

- Assign Probability Distributions: Model each parameter as a distribution. Use lognormal for costs, triangular if min/mode/max are known from vendor quotes.

- Establish Coupling Variables: Link economic and environmental models through shared physical variables. Example:

Enzyme_Dosage (g/kg biomass)drives bothEnzyme_Cost ($)(in TEA) andEnzyme_Manufacturing_Energy (MJ)(in LCA). - Run Coupled Monte Carlo Simulation: Execute 10,000 iterations. In each iteration, a random value for

Enzyme_Dosageis drawn from its distribution, simultaneously affecting the cost and LCA impact calculations. - Output Risk-Adjusted Metrics: The result is not a single GWP value but a distribution. Report the mean, median, and 90% confidence interval.

Q3: Our software tools for LCA (e.g., OpenLCA) and TEA (custom Excel/spreadsheet models) do not communicate. What is a robust workflow to ensure data consistency?

A: A manual but rigorous data linkage workflow is recommended. See the diagram below.

Diagram: Workflow for Integrating LCA and TEA Models

Q4: When performing sensitivity analysis on the integrated model, which parameters should be prioritized for biofuel pathways?

A: Based on recent literature, the following parameters consistently show high sensitivity. Prioritize these for your uncertainty analysis.

Table 1: High-Priority Sensitivity Parameters for LCA-TEA of Biofuels

| Parameter | Typical Range (Example) | Primary Impact | Recommended Distribution Type |

|---|---|---|---|

| Feedstock Yield | 8 - 16 dry Mg/ha/yr | MSP, Land Use, GWP | Normal (μ=12, σ=2) |

| Conversion Yield | 70% - 90% of theoretical | MSP, GWP (per MJ fuel) | Triangular (min=70, mode=85, max=90) |

| Catalyst Cost | ±40% of baseline quote | MSP, GWP (from catalyst prod.) | Lognormal |

| Plant Capacity Factor | 75% - 90% | MSP (capital amortization) | Uniform |

| Discount Rate | 5% - 12% | MSP (NPV) | Scenario (5%, 8%, 12%) |

| Co-product Credit Method | Mass, Energy, Economic | GWP (all impacts) | Scenario (Discrete) |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials & Tools for Integrated LCA-TEA Experiments

| Item | Function in Research | Example/Supplier |

|---|---|---|

| Process Simulation Software (e.g., Aspen Plus, SuperPro Designer) | Creates mass & energy balance foundation for both TEA (stream costs) and LCA (inventory data). | AspenTech, Intelligen, Inc. |

| LCA Database (e.g., Ecoinvent, USLCI) | Provides background life cycle inventory data for upstream materials (chemicals, electricity grid). | Ecoinvent Association, NREL USLCI. |

| Uncertainty/Sensitivity Analysis Package (e.g., @RISK, Sensitivity.py) | Enables Monte Carlo simulation and global sensitivity analysis (e.g., Sobol indices) within Excel or Python. | Palisade @RISK, SALib for Python. |

| Unified Log & Assumption Registry (e.g., Electronic Lab Notebook - ELN) | Critical for documenting every parameter value, its source, and uncertainty range to ensure model auditability. | LabArchives, Benchling. |

| High-Performance Computing (HPC) Cluster Access | Running >10,000 iterations of a coupled LCA-TEA model is computationally intensive. | University HPC, Cloud computing (AWS, GCP). |

Developing Standard Operating Procedures (SOPs) for Risk-Informed Procurement

Technical Support Center for Biofuel Technology Performance Risk Research

This support center provides troubleshooting and guidance for common experimental issues encountered in research focused on technology performance risk within biofuel supply chains, such as catalyst failure, feedstock variability, and process upscaling bottlenecks.

FAQs & Troubleshooting Guides

Q1: During enzymatic hydrolysis of lignocellulosic biomass, we observe consistently lower than expected glucose yields. What are the primary troubleshooting steps? A: This is a core performance risk. Follow this protocol:

- Inhibit or Degrade? Test for microbial contamination by plating hydrolysate samples on YPD agar. If positive, review sterilization SOPs for feedstock and equipment.

- Enzyme Activity Assay: Perform a standard filter paper unit (FPU) assay on your enzyme cocktail batch to confirm activity matches the certificate of analysis.

- Feedstock Analysis: Quantify lignin and acetyl content in your pre-treated biomass batch using NREL/TP-510-42618. High levels inhibit enzymes.

- Process Conditions: Re-calibrate pH and temperature sensors. Conduct a bench-scale run at optimal conditions (typically 50°C, pH 4.8-5.0) with a control substrate (e.g., Avicel) to isolate the variable.

Q2: Our heterogeneous catalyst for transesterification shows rapid deactivation ( >20% activity loss within 5 cycles). How do we diagnose the cause? A: Catalyst longevity is a critical technology risk. Implement this diagnostic workflow:

- Surface Area Loss (BET): Measure N₂ physisorption (BET method) on fresh and spent catalyst. A significant drop (>30%) suggests pore collapse or sintering.

- Active Site Leaching (ICP-MS): Digest fresh and spent catalyst and analyze the reaction supernatant via Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for the active metal (e.g., Ca, K, Mg).

- Fouling (TGA/FTIR): Perform Thermogravimetric Analysis (TGA) coupled with Fourier-Transform Infrared Spectroscopy (FTIR) on spent catalyst to identify carbonaceous deposits or adsorbed species.

- Protocol: Accelerated Deactivation Test: Run transesterification at a higher temperature (+15°C above standard) with feedstock containing 2% free fatty acids (FFA). Sample catalyst every 2 cycles for the analyses above to expedite failure mode identification.

Q3: When scaling up lipid extraction from oleaginous yeast, solvent efficiency drops by 40% compared to lab-scale. What systemic issues should we investigate? A: This is a common scale-up performance gap.

- Mixing Efficiency: Calculate the Reynolds number for both lab and pilot-scale reactors. Laminar flow at scale reduces contact efficiency. Consider pulsed mixing or static mixer inserts.

- Cell Disruption Verification: Perform cell viability staining (e.g., methylene blue) on post-disruption biomass from the large-scale run. If >15% cells are intact, review disruption energy input (e.g., bead mill bead fill ratio, pressure in homogenizer).

- Solvent-to-Biomass Ratio: Ensure the ratio (v/w) is constant. At scale, channeling can occur; verify slurry homogeneity and pumping consistency.

Experimental Data Summary

Table 1: Common Catalyst Performance Risks & Diagnostic Outcomes

| Deactivation Mode | Primary Diagnostic | Typical Quantitative Result Indicative of Risk | Mitigation Action |

|---|---|---|---|

| Sintering | BET Surface Area Analysis | Surface area reduction > 30% | Lower process temperature; modify catalyst support. |

| Leaching | ICP-MS of Reaction Medium | > 50 ppm active metal in supernatant | Switch to stronger catalyst support; adjust feedstock pH. |

| Poisoning | XPS Surface Analysis | > 5 at% of contaminant (e.g., S, P) on surface | Implement feedstock pre-purification step. |

| Coking | TGA/DTG of Spent Catalyst | Weight loss > 10% in 300-500°C range | Introduce periodic catalyst regeneration in H₂/N₂ flow. |

Table 2: Feedstock Variability Impact on Hydrolysis Yield

| Feedstock Batch | Lignin Content (%) | Acetyl Content (%) | Theoretical Glucose Yield (g/g) | Actual Glucose Yield (g/g) | Yield Gap (%) |

|---|---|---|---|---|---|

| Corn Stover A | 18.2 | 3.1 | 0.55 | 0.48 | 12.7 |

| Corn Stover B | 23.5 | 4.0 | 0.52 | 0.41 | 21.2 |

| Switchgrass | 21.8 | 3.8 | 0.54 | 0.43 | 20.4 |

Protocol: Standardized Test for Enzyme Inhibition by Feedstock Extracts Objective: Quantify the inhibitory effect of pre-treatment-derived compounds on cellulase cocktails. Method:

- Prepare Extract: Shake pre-treated biomass in distilled water (10% w/v) for 2h. Filter (0.2µm).

- Dilution Series: Create a dilution series of the extract in sodium citrate buffer (50 mM, pH 4.8).

- Reaction Setup: In a 96-well plate, combine 80 µL of extract dilution, 20 µL of enzyme cocktail (15 FPU/mL), and 20 µL of a 50 mg/mL Avicel suspension (control substrate). Run in triplicate.

- Incubation & Measurement: Seal plate, incubate at 50°C for 2h. Stop reaction by heating to 95°C for 10 min. Quantify glucose release using a GOPOD assay.

- Analysis: Plot glucose concentration vs. extract dilution. Calculate IC₅₀ (concentration causing 50% activity loss) relative to buffer-only control.

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function in Risk Assessment | Example Vendor/Product |

|---|---|---|

| Cellulase Activity Assay Kit | Standardizes measurement of Filter Paper Units (FPU) for consistent enzyme performance validation. | Megazyme CELUVIS Kit |

| NREL LAPs (Laboratory Analytical Procedures) | Provides standardized protocols for feedstock compositional analysis (e.g., LAP for sugars, lignin). | NREL Technical Reports |

| ICP-MS Calibration Standard Mix | Enables precise quantification of catalyst metal leaching into reaction streams. | Inorganic Ventures Custom Mix |

| Microbial Contamination Test Strips | Rapid detection of ATP for sterility checks in fermentation and hydrolysis batches. | Hygiena MicroSnap |

| Process-Relevant Analytical Standards | Certified reference materials for GC/MS analysis of biofuels (FAME, hydrocarbons, inhibitors). | RESTEK, Supelco |

Troubleshooting Workflow for Biofuel Process Risks

SOP Development Cycle for Risk Mitigation

Troubleshooting Supply Chain Disruptions: Optimization Protocols for Research Continuity

Troubleshooting Guides & FAQs

Q1: Why is my final biofuel yield consistently lower than the model's prediction, even with high-purity feedstock? A: This often indicates a process issue rather than a feedstock problem. A common culprit is suboptimal enzymatic hydrolysis or fermentation inhibition. First, verify process parameters.

Diagnostic Protocol:

- Test 1: Feedstock Quality Control: Re-analyze feedstock composition (cellulose/hemi-cellulose/lignin ratio) via NREL/TP-510-42618 standard method. Compare with baseline.

- Test 2: Process Inhibitor Assay: Analyze pre-fermentation hydrolysate for inhibitors (furfurals, HMF, phenolic compounds) using HPLC (Shim-pack GIST C18 column, 0.1% formic acid/H2O and acetonitrile mobile phase, 1 mL/min flow, 280 nm detection).

- Test 3: Enzymatic Activity Check: Perform a standardized cellulase activity assay (Filter Paper Unit, FPU) per NREL/TP-510-42628 to confirm enzyme viability.

Q2: Our pilot-scale run showed significant yield drop compared to identical lab-scale conditions. Is this a logistics or scale-up issue? A: This typically points to a logistics-induced process variation. Inconsistent feedstock particle size due to bulk handling or variable pre-treatment residence time are frequent offenders.

Diagnostic Protocol:

- Audit 1: Feedstock Particle Size Distribution: Sample from multiple points in the feedstock lot post-logistics (shipping, storage). Perform sieve analysis (ASTM E11 standards). Variance >15% from lab standard indicates logistics-induced physical degradation.

- Audit 2: Pre-treatment Homogeneity: Install in-line thermocouples at multiple points in the pre-treatment reactor. Log temperature variance over time. A spatial or temporal variance >5°C signifies scale-up mixing inefficiency.

- Audit 3: Time-Temperature Tracking: Track the total time from feedstock unloading to pre-treatment. Compare this "logistics hold time" to lab protocols. Prolonged holds at ambient conditions can initiate microbial spoilage.

Q3: How can I distinguish between a native microbial contamination in the feedstock vs. a sterilization failure in the process? A: Use a combination of microbial plating and process fingerprinting.

Diagnostic Protocol:

- Experiment: Contamination Source Tracing:

- Sample feedstock pre-sterilization and post-sterilization (bioreactor).

- Plate on non-selective (LB Agar) and selective (e.g., cellulose-deficient) media.

- Incubate at 30°C and 55°C (to mesophilic/thermophilic contaminants).

- Compare colony morphology. If identical strains appear in both pre- and post-sterilization samples, feedstock is the likely source. If contaminants appear only post-sterilization, process sterilization is failing.

- Validate: Perform 16S rRNA sequencing on isolated colonies for definitive species identification and comparison.

Table 1: Common Inhibitors & Impact on Fermentation Yield

| Inhibitor Compound | Typical Source | Critical Concentration (g/L) | Observed Yield Reduction |

|---|---|---|---|

| Acetic Acid | Hemi-cellulose hydrolysis | > 2.5 | 25-40% |

| Furfural | Pentose dehydration | > 1.0 | 15-30% |

| 5-HMF | Hexose dehydration | > 1.5 | 10-25% |

| Phenolic Compounds | Lignin degradation | > 0.5 | 30-60% |

Table 2: Feedstock Logistics Impact Metrics

| Logistics Variable | Acceptable Range | High-Risk Threshold | Measurable Impact on Conversion Efficiency |

|---|---|---|---|

| Moisture Content Change (Transit) | ±2% | >5% | Microbial growth; Pre-treatment efficiency ↓ 5-15% |

| Particle Size Fines Generation | <8% of total mass | >15% | Pre-treatment channeling; Hydrolysis yield ↓ 10-20% |

| Ambient Hold Time (Post-Harvest) | <72 hrs | >120 hrs | Sugar degradation; Overall yield ↓ 8-12% |

Experimental Protocols

Protocol 1: Standardized Enzymatic Hydrolysis Assay for Feedstock Evaluation Objective: To isolate and assess feedstock digestibility independent of process variables.

- Milling: Pass dried feedstock through a 20-mesh screen.

- Compositional Analysis: Perform acid hydrolysis per NREL/TP-510-42618 to determine structural carbohydrate content.

- Reaction Setup: In duplicate, add 1.0 g (dry weight equivalent) biomass to 50 mL sodium citrate buffer (pH 4.8) in a 125 mL Erlenmeyer flask.

- Enzyme Loading: Add cellulase (15 FPU/g glucan) and β-glucosidase (30 CBU/g glucan). Use a commercial cocktail (e.g., Cellic CTec3).

- Incubation: Place flasks in a shaking incubator (50°C, 150 rpm) for 72 hours.

- Analysis: Sample at 0, 6, 24, 48, 72h. Filter (0.22 µm) and analyze glucose concentration via HPLC (Bio-Rad Aminex HPX-87P column, 0.6 mL/min H2O mobile phase, 85°C).

- Calculation: Calculate glucose yield as a percentage of theoretical maximum based on step 2.

Protocol 2: In-Line Fermentation Health Monitoring via Off-Gas Analysis Objective: Diagnose process upsets in real-time during fermentation.

- Setup: Connect the bioreactor exhaust line to a calibrated mass spectrometer (MS) or infrared gas analyzer.

- Calibration: Calibrate the analyzer for CO2, O2, and ethanol vapor using standard gas mixtures.

- Baseline: Establish a baseline CO2 evolution rate (CER) profile from a successful fermentation run.

- Monitoring: During the problem run, log CER and ethanol vapor concentration every 5 minutes.

- Diagnosis: A sudden drop in CER indicates potential microbial inhibition or nutrient depletion. A lower-than-expected ethanol:CO2 ratio may suggest metabolic shift or contamination. Correlate any deviations with process event logs (feed additions, pH adjustments).

Diagrams

Biofuel Problem Diagnosis Logic

Inhibitor Impact on Microbial Metabolism

The Scientist's Toolkit: Key Research Reagent Solutions

| Item Name & Supplier | Function in Diagnosis | Typical Application |

|---|---|---|

| Cellic CTec3 (Novozymes) | Multi-enzyme cellulase cocktail. | Standardizes hydrolysis assays to isolate feedstock digestibility as a variable. |

| NREL Standard Biomass Analytical Packages | Validated protocols for compositional analysis. | Provides benchmark data for feedstock quality comparison. |

| Aminex HPX-87H/P Columns (Bio-Rad) | HPLC column for sugar, acid, and inhibitor separation. | Quantifies product yields and process inhibitors in hydrolysates/fermentation broths. |

| Anaerobic Growth Media (e.g., M1220, DSMZ) | Defined medium for fermentation microbes. | Removes media variability when testing for process-induced inhibition. |

| Microbial Strain Typing Kits (16S rRNA PCR) | Reagents for genetic identification of contaminants. | Traces source of microbial contamination to feedstock or process failure. |

| In-line CO2/O2 Sensors (BlueSens, etc.) | Real-time gas analysis. | Monitors fermentation metabolic activity and health non-invasively. |

Real-Time Monitoring and Analytical Techniques for Quality Assurance

Technical Support Center: Troubleshooting & FAQs

FAQ 1: Inconsistent Pyrolysis Oil Viscosity Readings from In-Line Viscometer

- Q: Our real-time in-line viscometer shows fluctuating viscosity values for intermediate pyrolysis oil, making process control unreliable. What could be the cause?

- A: This is often due to sample heterogeneity or sensor fouling. Pyrolysis oil contains suspended micro-carbon particles and condensed vapors that can settle or coat the sensor. First, verify that the sample conditioning unit (heater and filter) is maintaining a consistent temperature (±2°C) and that the 10-micron pre-filter is not clogged. Perform a manual calibration using a certified standard fluid at the process temperature. If discrepancies persist, initiate the automated CIP (Clean-in-Place) cycle using the solvent wash protocol (see below).

FAQ 2: Drift in NIR Spectroscopy Predictions for Biodiesel Blend Percentage

- Q: Our FT-NIR model for predicting %FAME in final biodiesel blends is showing increasing prediction errors over a 2-week period. How do we recalibrate?

- A: Prediction drift indicates a change in the process stream not captured in the original model (e.g., new feedstock source). To mitigate, implement a routine recalibration schedule using primary analytical methods.

- Grab-Sample Analysis: Collect 10 process samples over the full expected blend range (B5 to B100).

- Reference Analysis: Quantify %FAME in each sample using the validated GC-FID method (EN 14103).

- Model Update: Input the new paired data (NIR spectrum + GC result) into the PLS model software. Use the moving window update function, retaining only the most recent 100 calibration samples.

Table 1: Example Recalibration Data for NIR Biodiesel Blend Model

| Sample ID | NIR Predicted %FAME | GC-FID Actual %FAME | Absolute Error |

|---|---|---|---|

| BDRecal01 | 9.8% | 10.1% | 0.3% |

| BDRecal02 | 49.5% | 49.9% | 0.4% |

| BDRecal03 | 78.2% | 77.8% | 0.4% |

| BDRecal04 | 99.1% | 99.5% | 0.4% |

Target: Maintain model RMSEP <0.5%. Rebuild model if RMSEP exceeds 1.0%.

FAQ 3: High Noise in Online GC Data for Syngas Composition

- Q: The online gas chromatograph monitoring syngas (H2, CO, CO2, CH4) shows high baseline noise, obscuring minor component peaks.

- A: This typically points to a compromised separation column or a contaminated sampling system. Follow this diagnostic protocol:

- Check the sample conditioning probe: Ensure the sintered metal filter is not blocked. Replace if needed.

- Increase the sample line temperature 10°C above the dew point to prevent condensation.

- Run a diagnostic method with a longer hold at the initial oven temperature to check for column bleed. Compare with a baseline from a known-good method.

- If noise persists, the analytical column may be degraded due to trace contaminants (e.g., tars, H2S). Perform a column bake-out (method specific to your column). If ineffective, plan for column replacement.

Experimental Protocol: Validating a Real-Time Lipid Content Assay for Algae This protocol is cited for ensuring the reliability of optical density & fluorescence sensors used in upstream biofuel feedstock cultivation.

Objective: To correlate real-time in-situ fluorescence (chlorophyll, Nile Red) signals with extracted lipid content for Nannochloropsis sp. Methodology:

- Continuous Culture: Maintain a 5L photobioreactor under standard growth conditions (25°C, pH 7.8, continuous light at 150 µmol photons/m²/s, bubbled with 1% CO2).

- Real-Time Monitoring: Log data from in-situ probes for optical density (OD750), chlorophyll fluorescence (Ex/Em: 440/680 nm), and Nile Red fluorescence (Ex/Em: 525/580 nm) every 10 minutes.

- Parallel Destructive Sampling: Every 24 hours, aseptically remove 50 mL of culture.

- Centrifuge at 4000 x g for 10 min. Wash pellet with PBS.

- Lipid Extraction: Use a modified Bligh & Dyer method. Resuspend pellet in 3:2 MeOH:CHCl3, vortex, add CHCl3 & H2O, separate phases, evaporate organic layer under N2, weigh.

- GC Analysis (for FA profile): Transesterify extracted lipids to FAME with BF3/MeOH. Analyze via GC-FID.

- Data Correlation: Develop a multivariate regression model (PLS) linking the real-time optical signals to the gravimetric lipid yield and FAME profile.

Title: Real-Time vs. Analytical Lipid Validation Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Biomass Quality Monitoring Experiments

| Item | Function in Quality Assurance Context |

|---|---|

| Nile Red Stain | Lipophilic fluorescent dye for in-situ and ex-situ quantification of neutral lipid droplets in microbial/algal cells. |

| FAME Standards (C8-C24) | Certified calibration mix for GC-FID, essential for quantifying and profiling fatty acid methyl esters in biodiesel intermediates. |

| Deuterated Solvents (e.g., CDCl3) | Required for NMR spectroscopy (e.g., for monitoring transesterification reaction kinetics or structural analysis of bio-oils). |

| Internal Standards (e.g., 5-alpha-Androstane, C19:0 ME) | Added to samples prior to GC analysis to correct for variability in injection volume and extraction efficiency. |

| Certified Reference Bio-Oil | Homogenized, characterized material for validating analytical methods (e.g., HPLC for sugars, GC/MS for phenols). |

| Stable Isotope Labels (13C-Glucose) | Used in metabolic flux analysis (MFA) to trace carbon pathways in engineered biofuel-producing microorganisms. |

| ANSI/NIST Traceable Thermometer | For calibrating temperature probes in reactors and analyzers, critical for kinetic studies and process reproducibility. |

| Particle Size Standard (e.g., 1µm latex) | To validate and calibrate inline particle analyzers monitoring catalyst slurries or biomass solids. |

Implementing Redundancy and Multi-Sourcing Strategies for Critical Bio-Inputs