Maximizing Carbon Yield in SAF Production: Advanced Thermochemical Conversion Strategies for Renewable Aviation Fuel

This article provides a comprehensive overview of current strategies to improve carbon yield during the thermochemical conversion of biomass and waste feedstocks into Sustainable Aviation Fuel (SAF).

Maximizing Carbon Yield in SAF Production: Advanced Thermochemical Conversion Strategies for Renewable Aviation Fuel

Abstract

This article provides a comprehensive overview of current strategies to improve carbon yield during the thermochemical conversion of biomass and waste feedstocks into Sustainable Aviation Fuel (SAF). Aimed at researchers and process engineers, it explores the fundamental chemistry of carbon efficiency, details advanced catalytic and process methodologies for yield optimization, addresses common technical challenges and mitigation strategies, and validates approaches through comparative analysis of leading technologies like pyrolysis, gasification, and hydrothermal liquefaction. The synthesis offers a roadmap for enhancing the economic viability and environmental impact of SAF production.

The Carbon Efficiency Imperative: Understanding Yield Fundamentals in SAF Thermochemistry

Troubleshooting Guides & FAQs

Q1: During biomass gasification for syngas production, we observe a significant drop in carbon yield as measured by carbon in useful products (CIUP). What are the primary culprits and corrective actions? A: A drop in CIUP typically indicates carbon loss to undesired byproducts like tar, soot, or excessive CO₂. Common causes and actions include:

- Cause: Suboptimal Temperature. Low temperatures favor tar formation.

- Action: Increase gasification temperature within the optimal range (typically 800-900°C for fluidized bed) and ensure uniform temperature distribution.

- Cause: Inadequate Steam-to-Biomass Ratio (S/B).

- Action: Recalculate and adjust the S/B ratio. Increasing S/B promotes the water-gas shift reaction, boosting H₂ and CO yield while reducing tar. Monitor for excessive steam that lowers thermal efficiency.

- Cause: Poor Catalyst Performance or Deactivation in catalytic gasification/reforming.

- Action: Characterize spent catalyst for coking (carbon deposition) or sintering. Implement a regeneration protocol (e.g., controlled oxidation for coke removal) or increase catalyst bed volume/changing catalyst formulation.

Q2: In Fischer-Tropsch Synthesis (FTS) for SAF, our carbon efficiency to liquid fuels (Cₗᵢᵩ) is low, with high methane selectivity. How do we troubleshoot this? A: High methane selectivity in FTS wastes carbon. Focus on catalyst and process conditions:

- Cause: Incorrect Catalyst Metal or Promoter.

- Action: For Co-based catalysts, ensure proper promotion with Re or Pt to increase reducibility and activity. For Fe-based catalysts, use Cu and K promoters. Verify dispersion and loading.

- Cause: Reaction Temperature Too High.

- Action: Lower the reaction temperature (e.g., 200-220°C for Co catalysts) to favor chain growth over methane formation, while monitoring activity loss.

- Cause: H₂/CO Syngas Ratio Too High.

- Action: Adjust the inlet H₂/CO ratio closer to the stoichiometric requirement (~2.1 for cobalt catalysts). Use a water-gas shift unit (for Fe catalysts) or syngas conditioning to tune the ratio.

Q3: When calculating overall carbon yield from biomass to SAF, how should we handle carbon in the aqueous phase (e.g., from oxygenates) in our mass balance? A: Aqueous phase products (acetic acid, acetone, glycols) represent a significant carbon pool. They must be quantified for an accurate mass balance.

- Protocol for Quantification: Use High-Performance Liquid Chromatography (HPLC) with a Refractive Index (RI) detector and an Aminex HPX-87H column. Prepare standard curves for expected oxygenates. Filter aqueous samples (0.2 µm), dilute as necessary, and inject. Integrate peak areas to determine concentrations.

- In Mass Balance: Assign this carbon to the "Carbon in Byproducts" or "Carbon in Aqueous Phase" stream. This refines your Carbon Recovery (CR) metric and identifies targets for process optimization (e.g., aqueous phase reforming to recover H₂).

Q4: Our analytical results for product distribution (gas, liquid, solid) show a carbon closure gap >5%. What are the systematic steps to resolve this? A: A closure gap >5% indicates measurement or sampling error. Follow this systematic check:

- Calibration: Re-calibrate all analytical instruments (GC, TOC analyzer, HPLC) with fresh certified standards.

- Sampling: Ensure representative sampling of all product streams. For gases, use heated lines to prevent condensation. For liquids/tars, use cold traps with appropriate solvents (e.g., isopropanol).

- Flow Measurement: Verify accuracy of gas flow meters (e.g., wet gas meter, mass flow controller) under process conditions.

- Unaccounted Products: Analyze for volatile oxygenates missed by standard GC methods (use GC-MS) and quantify soot/coke on catalyst/reactor walls via temperature-programmed oxidation (TPO).

- Repeat Experiment: Conduct a dedicated mass balance experiment with extended, stable operation time and parallel sampling.

Key Metrics & Data Presentation

Table 1: Core Carbon Yield Metrics for SAF Production Pathways

| Metric | Formula | Ideal Range | Purpose |

|---|---|---|---|

| Carbon Recovery (CR) | (Σ Carbon in all output streams / Carbon in biomass feed) x 100% | >90% | Overall process carbon accountability. |

| Carbon in Useful Products (CIUP) | (Carbon in SAF-range hydrocarbons / Carbon in biomass feed) x 100% | Maximize (Target >40%) | Primary efficiency metric for fuel production. |

| Carbon Efficiency to Liquids (Cₗᵢᵩ) | (Carbon in all liquid hydrocarbons / Carbon in biomass feed) x 100% | Maximize | Evaluates liquid fuel production stage (e.g., FTS). |

| Carbon Selectivity to C₅-C₂₀ | (Carbon in C₅-C₂₀ hydrocarbons / Total carbon in hydrocarbons) x 100% | >70% for SAF | Targets fuel range within hydrocarbon pool. |

Table 2: Typical Carbon Distribution from Biomass Gasification & FTS

| Product Stream | Carbon Percentage (Range) | Key Influencing Factors |

|---|---|---|

| Syngas (CO + CO₂ + CH₄ + C₂) | 70-85% | Gasifier type, temperature, S/B ratio, catalyst. |

| Tar & Condensables | 5-15% | Temperature, heating rate, catalyst. |

| Soot & Char | 3-10% | Temperature, biomass ash content. |

| Aqueous Phase Organics | 2-8% | Biomass composition, fast pyrolysis conditions. |

| FTS Products (from Syngas) | ||

| • C₅-C₂₀ (SAF/Jet) | 60-75% of FTS Carbon | Catalyst type (Co/Fe), temperature, pressure. |

| • C₂₁⁺ (Wax) | 15-25% of FTS Carbon | Catalyst, temperature. |

| • C₁-C₄ (Light Gas) | 10-20% of FTS Carbon | Catalyst, H₂/CO ratio, temperature. |

Experimental Protocols

Protocol 1: Determining Carbon Distribution in Gasification Products Objective: Quantify carbon in gas, tar, char, and aqueous phases from a bench-scale gasifier. Methodology:

- Setup: Operate fluidized bed gasifier at setpoint (e.g., 850°C). Use N₂ as fluidizing agent. Introduce steam at calibrated S/B ratio.

- Feed: Use precisely weighed, torrefied woody biomass (particle size 300-500 µm).

- Product Collection:

- Gas: Online Micro-GC samples every 5 min. Calibrate for H₂, CO, CO₂, CH₄, C₂H₄, C₂H₆.

- Tar/Aerosols: Two-stage ice-cooled condenser trap followed by dichloromethane (DCM) impinger bottles.

- Char: Collected via cyclone separator and weighed.

- Aqueous Phase: Collected from condensate tank; filtered (0.45 µm) for TOC analysis.

- Analysis: Calculate carbon in gas from flow rate and GC composition. Recover tar by evaporating DCM; weigh. Determine carbon in char via elemental analysis. Measure aqueous carbon via TOC analyzer.

- Calculation: Perform mass balance: Cin (biomass) = Cgas + Ctar + Cchar + C_aq. Calculate CR and CIUP (if syngas is the "useful product").

Protocol 2: Evaluating FTS Catalyst for Carbon Selectivity to SAF-Range Hydrocarbons Objective: Measure Cₗᵢᵩ and C₅-C₂₀ selectivity of a Co/Pt/Al₂O₃ catalyst. Methodology:

- Catalyst Activation: Reduce 1.0 g of catalyst pelletized to 180-250 µm in a fixed-bed reactor under pure H₂ flow (100 mL/min) at 350°C for 16 hours.

- Reaction Conditions: Switch to syngas (H₂/CO = 2.1) at 220°C, 20 bar, GHSV = 2000 h⁻¹. Stabilize for 24 hours.

- Product Collection: Use a hot (200°C) and cold (0°C) trap system to separate wax (hot), liquid hydrocarbons (cold), and aqueous phase.

- Analysis:

- Gas: Online GC-TCD/FID for permanent gases and light hydrocarbons (C₁-C₄).

- Liquids/Wax: Offline GC-MS with Simulated Distillation for hydrocarbon distribution (C₅-C₈₀).

- Aqueous Phase: Analyze for oxygenates via HPLC (as in FAQ A3).

- Calculation: Use internal standard (n-dodecane) for liquid quantification. Calculate carbon moles in each fraction. Determine Cₗᵢᵩ, C₅-C₂₀ selectivity, and methane selectivity.

Visualizations

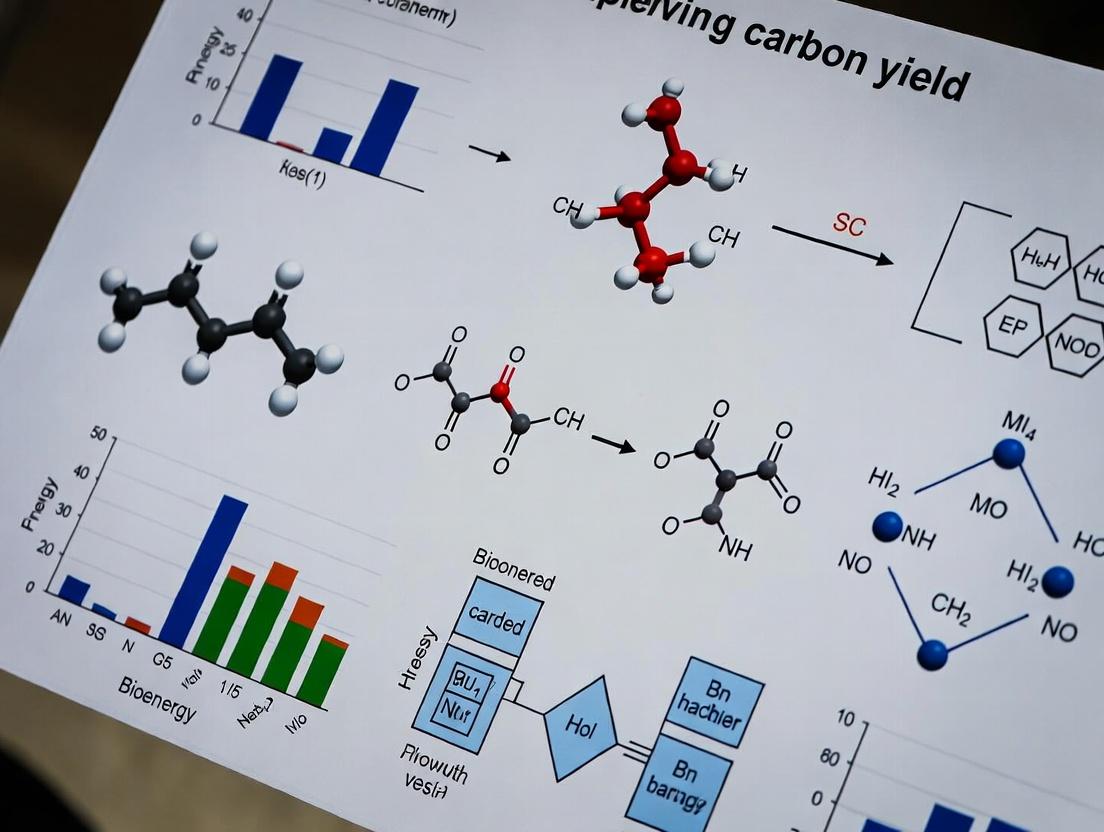

Diagram: SAF Carbon Mass Balance

Diagram: Low Yield Troubleshooting Flow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for SAF Conversion Experiments

| Item | Function & Specification |

|---|---|

| Co/Pt/γ-Al₂O₃ Catalyst Pellets | Fischer-Tropsch catalyst; 15-20% Co, 0.1% Pt promoter, high surface area (>150 m²/g) for high C₅⁺ selectivity. |

| Ni-Based Reforming Catalyst | For tar reforming and syngas conditioning; high Ni loading on MgAl₂O₄ support, resistant to sintering. |

| Certified Syngas Mixture (H₂/CO/CO₂/N₂) | For FTS reactor calibration and baseline studies; precise composition (e.g., H₂/CO=2.1, 5% CO₂, bal. N₂). |

| Dichloromethane (DCM), HPLC Grade | Solvent for efficient tar and heavy hydrocarbon collection from process streams in impinger traps. |

| Aminex HPX-87H HPLC Column | Industry-standard column for separation and quantification of aqueous phase oxygenates (acids, alcohols, glycols). |

| Internal Standards (n-Dodecane, n-Hexane) | For accurate quantification of liquid hydrocarbon yields in GC-FID analysis via internal standard method. |

| Porous Graphitic Carbon (PGC) Sorbent Tubes | For sampling and subsequent thermal desorption analysis of trace light hydrocarbons and oxygenates in gas streams. |

| Calibration Gas Cylinders (H₂, CO, CO₂, C₁-C₄) | Individual certified standards for precise calibration of online gas chromatographs (GC-TCD/FID). |

Troubleshooting Guides & FAQs

Q1: During the catalytic fast pyrolysis (CFP) of lignocellulosic biomass, we observe a rapid deactivation of the zeolite catalyst (e.g., HZSM-5) and a drop in hydrocarbon yield. What are the primary causes and mitigation strategies? A: Rapid deactivation is often due to coking (carbon deposition) from oxygenates in the pyrolysis vapor and ash deposition (especially alkali and alkaline earth metals - AAEMs).

- Troubleshooting Steps:

- Pre-treatment: Implement a biomass washing step (e.g., dilute acid or water leaching) to remove AAEMs. See Protocol 1.

- Co-feeding: Introduce a co-reactant like waste plastic or lipid fraction to dilute oxygenates and alter H/C ratio.

- Catalyst Modification: Use a catalyst with hierarchical porosity or moderate metal impregnation (e.g., Ga, Ni) to facilitate coke gasification.

- Process Adjustment: Lower reactor temperature or implement a two-stage reactor to separate pyrolysis and catalytic upgrading zones.

Q2: When hydrotreating waste cooking oil (WCO) to produce SAF, we encounter excessive hydrogen consumption and undesired methane formation. What is the likely issue? A: This indicates overly severe hydrodeoxygenation (HDO) conditions or unsuitable catalyst selection, promoting excessive decarboxylation/decarbonylation (deCOx) and cracking reactions over the desired hydrodeoxygenation pathway.

- Troubleshooting Steps:

- Optimize Conditions: Systematically lower reaction temperature (target 300-350°C) and pressure.

- Catalyst Selection: Switch from a strong acid support (e.g., Al2O3) to a neutral one (e.g., SiO2, activated carbon) and use a less cracking-active metal (e.g., Pt, Pd) instead of NiMo/CoMo for pre-cleaned WCO.

- Feedstock Pre-treatment: Filter and pre-treat WCO to remove water and food residues that can poison catalysts and cause side reactions. See Protocol 2.

Q3: The carbon yield from herbaceous biomass (e.g., switchgrass) is consistently lower than from woody biomass in our hydrothermal liquefaction (HTL) experiments. Why? A: Herbaceous biomass typically has higher ash (particularly silica and alkali) and hemicellulose content but lower lignin content than woody biomass. Ash can catalyze char formation, and hemicellulose decomposes to more aqueous-soluble products.

- Troubleshooting Steps:

- Ash Removal: Pre-treat feedstock via acid washing or fractionation to reduce ash content.

- Co-liquefaction: Blend herbaceous biomass with a high-lipid feedstock (e.g., microalgae, waste oil) to boost biocrude yield and quality.

- Additive Use: Employ homogeneous alkali catalysts (e.g., K2CO3) to suppress char formation and promote depolymerization.

Experimental Protocols

Protocol 1: Dilute Acid Leaching of Biomass for Ash Reduction

Objective: To reduce the AAEM content in lignocellulosic biomass, mitigating catalyst poisoning and undesirable reactions.

- Milling: Mill feedstock to a particle size of 20-80 mesh.

- Leaching: For every 10g of biomass, add 100 mL of 0.1M nitric acid (or oxalic acid) solution.

- Incubation: Heat the mixture to 60°C with stirring for 60 minutes.

- Filtration & Washing: Vacuum filter the slurry and wash the solids with deionized water until the filtrate is pH neutral.

- Drying: Dry the washed solids in an oven at 105°C overnight. Store in a desiccator.

Protocol 2: Pre-treatment of Waste Cooking Oil (WCO) for Hydroprocessing

Objective: To remove water, solids, and free fatty acids (FFAs) from WCO to prevent reactor issues and catalyst poisoning.

- Filtration: Filter warm (40-50°C) WCO through a 5-10 µm filter paper to remove food particulates.

- Dehydration: Heat the filtered oil to 110°C under vacuum (∼100 mbar) with stirring for 1-2 hours to remove residual water.

- (Optional) Esterification: For WCO with high FFA (>2%):

- Cool oil to ~60°C.

- Add methanol (6:1 molar ratio to FFA) and concentrated H2SO4 catalyst (1% wt. of oil).

- React at 60°C for 1 hour with stirring.

- Separate the esterified product and wash with warm water to remove catalyst.

- Final Filtration: Perform a final filtration (1-2 µm) before introducing to the hydroprocessing reactor.

Table 1: Typical Composition & Theoretical Carbon Yield of SAF Feedstocks

| Feedstock Type | Lignin (wt%) | Cellulose (wt%) | Hemicellulose (wt%) | Lipid (wt%) | Ash (wt%) | Effective H/Ceff* | Max Theoretical Carbon Yield to Hydrocarbons (%) |

|---|---|---|---|---|---|---|---|

| Softwood (Pine) | 27-30 | 40-45 | 25-30 | <1 | 0.5 | ~1.3 | 40-45 |

| Herbaceous (Switchgrass) | 17-20 | 30-35 | 25-30 | <1 | 5-6 | ~1.1 | 25-30 |

| Lipid-Based (WCO) | 0 | 0 | 0 | >95 | <0.1 | ~1.8 | 75-85 |

| Microalgae (Chlorella) | 0 | 0 | 10-20 | 20-30 | 5-10 | ~1.5 | 50-65 |

H/Ceff = (H - 2O - 3N - 2S)/C (molar). *Estimated from stoichiometry for deoxygenation pathways.

Table 2: Common Catalyst Issues & Solutions in Thermochemical Conversion

| Process | Common Catalyst | Primary Issue | Recommended Solution |

|---|---|---|---|

| Catalytic Fast Pyrolysis | HZSM-5 Zeolite | Coke deposition, pore blockage | Use hierarchical ZSM-5, co-feed lipids, regenerate frequently |

| Hydrodeoxygenation (HDO) | NiMo/Al2O3 | Excessive cracking, sulfur loss | Use Pt/SiO2 for low-sulfur feeds, tailor metal/support acidity |

| Hydrothermal Liquefaction | Na2CO3 (Homogeneous) | Corrosion, difficult recovery | Test heterogeneous bases (e.g., supported metal carbonates) |

Visualizations

SAF Production Workflow from Diverse Feedstocks

Key Deoxygenation Pathways for Lipid Feedstocks

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function/Application |

|---|---|

| HZSM-5 Zeolite (Si/Al=40) | Primary catalyst for catalytic fast pyrolysis; promotes deoxygenation & aromatization of vapors. |

| NiMo/γ-Al2O3 (Sulfided) | Standard hydrotreating catalyst for deoxygenation, denitrogenation, and desulfurization of biocrudes. |

| Pt/Al2O3 or Pt/SiO2 | Noble metal catalyst for low-temperature hydrodeoxygenation of pretreated lipid feedstocks. |

| Potassium Carbonate (K2CO3) | Homogeneous alkaline catalyst used in HTL to suppress char formation and enhance biocrude yield. |

| Tetralin (1,2,3,4-Tetrahydronaphthalene) | Common hydrogen-donor solvent in liquefaction experiments to stabilize free radicals. |

| Dilute Nitric Acid (0.1M) | Leaching agent for removing alkali and alkaline earth metals (AAEMs) from biomass feedstocks. |

| Microporous Zeolite Beads (3Å) | Desiccant for drying feedstocks and reaction gases (e.g., N2, H2) to prevent water interference. |

| Internal Standard (Dodecane, Hexadecane) | Used in GC analysis for quantitative determination of hydrocarbon yields from conversion experiments. |

Troubleshooting Guides & FAQs

FAQ 1: Yield & Product Quality Issues

Q: During woody biomass pyrolysis, my liquid bio-oil yield is consistently below 40 wt.% and the oil phase-separates. What are the primary causes and solutions?

- A: Low yield and phase separation often indicate excessive moisture in feedstock, overly rapid heating/cooling rates, or suboptimal vapor condensation. Ensure feedstock moisture is <10%. Implement a staged condensation system (e.g., 1st electrostatic precipitator at ~200°C, 2nd condenser at 0-4°C) to recover different fractions and minimize thermal stress on vapors. Check for excessive carrier gas flow which shortens vapor residence time.

Q: In Gasification-Fischer-Tropsch (G-FT), my syngas H₂:CO ratio is unstable, leading to poor FT catalyst performance and low C5+ yield. How can I stabilize it?

- A: An unstable H₂:CO ratio typically stems from fluctuations in the gasifier's operating parameters (temperature, steam-to-biomass ratio) or feedstock composition. Implement real-time syngas monitoring (NDIR sensors) and link it to a feed-forward control loop for the steam injection system. Consistently shred and dry feedstock to <15% moisture and <2mm particle size. Include a guard bed (e.g., ZnO, activated carbon) upstream of the FT reactor to remove catalyst poisons (H₂S, tars).

Q: In HTL, my biocrude has unacceptably high nitrogen content (>5 wt.%) when using proteinaceous feedstocks like microalgae. How can I reduce N in the oil?

- A: High nitrogen originates from protein conversion. Employ pre-processing steps such as acidic washing of the feedstock to remove proteins. During HTL, consider a two-stage approach: a low-temperature step (~150-200°C) for hydrolysis, followed by separation of water-soluble nitrogen compounds, then processing the solid residue to biocrude at ~350°C. Alternatively, use a homogeneous catalyst (e.g., Na₂CO₃) or post-hydrotreating to denitrogenate the biocrude.

FAQ 2: Reactor & Operational Failures

Q: My fluidized bed pyrolysis reactor is experiencing bed agglomeration and defluidization. What should I do?

- A: Agglomeration is caused by low melting point ashes (high K, Na content). Pre-treat biomass by water leaching/washing to remove alkali metals. Lower the reactor temperature below the ash melting point (if possible without sacrificing yield) or switch to a higher melting point bed material like olivine or dolomite instead of silica sand.

Q: The FT reactor shows a rapid pressure drop increase across the fixed catalyst bed. What is the most likely cause and remedy?

- A: This indicates catalyst bed fouling or plugging, often from heavy wax accumulation or carbon coking. For wax, implement periodic in-situ warm-up cycles to melt and drain waxes. For coke, schedule regular in-situ oxidative regeneration (dilute O₂ in N₂ at controlled temperature) based on pressure drop thresholds. Ensure effective upstream gas cleaning to remove particulates.

Q: HTL batch reactor seals frequently fail or corrode. What are the best practices for containment?

- A: HTL's high-pressure, aqueous, and often acidic/alkaline conditions are severe. Use reactors lined with Hastelloy C-276 or Inconel 625. Implement a routine seal inspection and replacement schedule. Always use properly torqued, premium-grade seal fittings (e.g., Swagelok). Include a pressure relief valve and perform routine hydrostatic testing of the vessel.

FAQ 3: Analytics & Data Validation

- Q: How do I accurately measure and report carbon yield to Sustainable Aviation Fuel (SAF) precursors?

- A: Use carbon balance closure as the primary metric. Quantify carbon in all output streams: gas (via GC), liquid (CHNS/O analysis, GC-MS), and solid (CHNS/O analysis). Calculate Carbon Yield to desired product = (Mass of Carbon in Product Stream / Mass of Carbon in Feedstock) × 100. Consistently use methods from standards like ASTM D5291 for CHNS analysis. Closure within 95-105% is typically acceptable.

Yield Comparison Data

Table 1: Typical Carbon Yield Ranges to Intermediate Products from Lignocellulosic Biomass

| Pathway | Primary Intermediate Product | Typical Carbon Yield (wt.%) | Key Influencing Parameters |

|---|---|---|---|

| Fast Pyrolysis | Bio-Oil | 45 - 75 | Temperature (~500°C), Vapor Residence Time (<2s), Rapid Quenching, Dry Feedstock (<10% H₂O) |

| Gasification-FT | FT Synthetic Crude (Waxes) | 25 - 50* | Gasifier Type, H₂:CO Ratio (~2.0), FT Catalyst (Co-based), Pressure (20-40 bar) |

| Hydrothermal Liquefaction | Biocrude | 35 - 60 | Temperature (250-350°C), Pressure (100-200 bar), Retention Time (10-60 min), Catalyst (Na₂CO₃) |

Note: This is a holistic carbon yield from biomass to FT syncrude. Yield is highly dependent on gasifier efficiency and FT selectivity.

Experimental Protocols

Protocol 1: Bench-Scale Fast Pyrolysis for Bio-Oil Yield Maximization

- Feedstock Prep: Mill and sieve biomass to 0.5-1.0 mm. Dry at 105°C for 24h.

- Reactor Setup: Use a fluidized bed reactor (Inconel, 2" diameter) with silica sand bed. Set induction heater to 500°C. Connect a staged condensation train: cyclone, electrostatic precipitator (200°C), and two condensers in series (0°C).

- Procedure: Purge system with N₂ (1 L/min). Feed biomass at 100 g/hr using a calibrated auger feeder. Maintain vapor residence time at ~1.5s. Collect liquids from each condenser stage separately. Collect non-condensable gas in a Tedlar bag for GC analysis.

- Yield Calc: Weigh all liquid and solid (char) products. Analyze gas composition. Perform carbon balance.

Protocol 2: Syngas Conditioning & FT Synthesis for C5+ Yield

- Syngas Generation: Generate syngas via a dual-fluidized bed gasifier using steam.

- Cleaning & Conditioning: Pass syngas through a hot ceramic filter (>400°C), then a scrubber for acid gas removal. Precisively adjust H₂:CO ratio to 2.0 using a membrane H₂ separation unit or water-gas shift reactor.

- FT Synthesis: Load a Co/Al₂O₃ catalyst (mesh 60-80) into a fixed-bed tubular reactor. Reduce catalyst under H₂ at 350°C, 1 bar for 10h. Pressurize to 25 bar with syngas. Set temperature to 220°C. Collect waxes in a hot trap (~150°C) and lighter liquids in a cold trap (0°C).

Protocol 3: Catalytic HTL for Low-Nitrogen Biocrude

- Feedstock Slurry: Blend dried, powdered microalgae (or other feedstock) with deionized water to 20 wt.% solids. Add 5 wt.% Na₂CO₃ (catalyst) relative to dry biomass.

- Reactor Loading: Charge 100 mL of slurry into a 300 mL Parr batch reactor (Hastelloy C-276).

- Reaction: Purge with N₂. Pressurize to 50 bar with N₂. Heat to 350°C at ~10°C/min and hold for 30 minutes under vigorous stirring.

- Product Separation: Cool rapidly. Recover gas and measure volume. Filter slurry to separate aqueous phase and solid residues. Extract the filter cake and aqueous phase with dichloromethane (DCM) to recover biocrude. Rotavaporate DCM.

Visualizations

Title: Fast Pyrolysis & Staged Condensation Workflow

Title: Gasification-FT Process Block Diagram

Title: Hydrothermal Liquefaction & Separation Process

The Scientist's Toolkit: Key Research Reagent Solutions

| Item/Chemical | Function/Application in SAF Pathway Research |

|---|---|

| Co/Al₂O₃ Catalyst (FT) | Cobalt on alumina support; the predominant catalyst for Fischer-Tropsch synthesis of long-chain hydrocarbons (waxes) from syngas, favored for high C5+ selectivity. |

| Na₂CO₃ (HTL Catalyst) | Alkali homogenous catalyst used in Hydrothermal Liquefaction to promote deoxygenation reactions, improve biocrude yield, and reduce char formation. |

| Olivine Bed Material | (Mg,Fe)₂SiO₄; a high-melting-point, naturally occurring mineral used as a fluidized bed material in gasifiers/pyrolyzers. It exhibits catalytic activity for tar cracking. |

| Dichloromethane (DCM) | Organic solvent used for quantitative extraction of biocrude from the aqueous and solid product streams following HTL or pyrolysis oil collection. |

| Silica Sand (60-80 Mesh) | Standard inert bed material for fluidized bed pyrolysis reactors to ensure good heat transfer and uniform temperature. |

| Internal Standard (for GC) | e.g., Dodecane, Fluorobenzene. Added in known quantities to liquid bio-oil/biocrude samples before GC analysis to enable accurate quantitative determination of components. |

| Reduction Gas (5% H₂ in Ar) | Standard safe mixture for the in-situ activation (reduction) of metal catalysts (e.g., Co, Ni) prior to FT or hydrotreating experiments. |

| Swagelok VCR Gasket | Metal gasket face seal fittings essential for creating reliable, high-integrity, leak-free connections in high-pressure and high-temperature experimental rigs. |

Troubleshooting Guides & FAQs

FAQ 1: Why is my observed carbon yield in bio-char significantly lower than theoretical predictions?

- Answer: Low char yield is frequently caused by excessive secondary vapor-phase cracking reactions or overly aggressive primary devolatilization. Ensure your reactor heating rate is calibrated and matches your target (e.g., fast pyrolysis vs. slow pyrolysis). Excessive carrier gas flow rate can also strip away primary vapors, preventing condensation into bio-oil (liquid carbon) and promoting gas-phase losses. Check Table 1 for typical carbon distribution benchmarks.

FAQ 2: How can I minimize carbon loss to non-condensable gases (e.g., CO, CO₂) during pyrolysis?

- Answer: High yields of CO and CO₂ often indicate dominant dehydration and decarboxylation pathways. To mitigate:

- Catalyst Selection: Use carefully selected catalysts (e.g., zeolites, basic oxides) to suppress decarboxylation. See the "Research Reagent Solutions" table.

- Process Parameters: Lower pyrolysis temperature and reduce vapor residence time can limit secondary cracking of primary vapors into permanent gases.

- Feedstock Pre-treatment: Employ demineralization (acid washing) to remove alkali and alkaline earth metals (AAEMs) that catalyze gas-forming reactions.

FAQ 3: My hydroprocessing for SAF production yields excessive coke and reactor plugging. What's wrong?

- Answer: Coke formation during hydroprocessing (HDO, hydro cracking) typically stems from polymerization and condensation of reactive oxygenates (like phenols) or olefins. This is a major carbon loss from the liquid fuel pool.

- Catalyst Deactivation: Ensure your catalyst (e.g., Pt/SAPO-11, NiMo/Al₂O₃) is properly sulfided and active. Inactive catalysts promote coke.

- Hydrogen Partial Pressure: Insufficient H₂ pressure fails to stabilize reactive intermediates. Verify your H₂ flow and system pressure.

- Oil Quality: Highly acidic, high-oxygen-content bio-oil will coke rapidly. Consider two-stage upgrading or improved upstream deoxygenation.

FAQ 4: How do I accurately measure and track carbon distribution between output streams?

- Answer: A closed carbon balance is critical. Use the following protocol:

- Quantify all outputs: Precisely weigh solid char. Trap liquids in a cold trap (dry ice/isopropanol) and weigh. Use an online micro-GC or TCD analyzer for permanent gases (CO, CO₂, CH₄, C₂'s). Aqueous phase is collected separately and analyzed for TOC (Total Organic Carbon).

- Use an internal standard: For complex liquid/vapor, use an inert tracer gas (e.g., Ar) in the carrier stream to calculate flow rates.

- Account for tars: Material balance closures >95% are challenging; "missing" carbon is often heavy tars deposited in transfer lines. Use heated lines and periodic solvent washing to recover.

Data Presentation

Table 1: Typical Carbon Distribution from Lignocellulosic Biomass Fast Pyrolysis (Pine, 500°C)

| Product Stream | % Carbon Yield (Range) | Primary Influencing Factors |

|---|---|---|

| Bio-Char | 15 - 25% | Temperature, Heating Rate, Particle Size |

| Bio-Oil (Org. Phase) | 35 - 50% | Vapor Residence Time, Condensation Efficiency |

| Aqueous Phase | 10 - 20% | Feedstock Moisture, Reaction Severity |

| Non-Condensable Gases | 12 - 25% | Temperature, Catalytic Effects (AAEMs) |

| Balance (Tars/Losses) | 5 - 10% | System Configuration, Line Temperature |

Table 2: Carbon Loss Mitigation Strategies in Catalytic Fast Pyrolysis for SAF Precursors

| Loss Mechanism | Target Product | Strategy | Effect on Carbon Distribution |

|---|---|---|---|

| Excessive Decarboxylation | Aromatics | Use ZSM-5 (Si/Al=40) | ↓ CO₂, ↑ Aromatic C in Oil |

| Char Formation | Deoxygenated Vapors | Use Fluidized Bed + Sand | ↓ Solid C, ↑ Vapor C |

| Coking on Catalyst | Hydroprocessed SAF | Use CoMo/Al₂O₃ with High H₂ Pressure | ↓ Solid Coke C, ↑ Liquid Alkane C |

| Water-Soluble Organics | Hydrocarbon Liquids | Apply Mild Hydrotreatment (150°C) | ↓ Aqueous Phase C, ↑ Oil Phase C |

Experimental Protocols

Protocol 1: Determining Carbon Yield in Aqueous Phase via TOC Analysis

- Collection: Condense pyrolysis vapors using an electrostatic precipitator (ESP) at 80°C for bio-oil, followed by a dry-ice cooled condenser for aqueous phase.

- Separation: Separate the aqueous layer from the organic bio-oil using a separation funnel. Filter through a 0.45 µm PTFE filter.

- Analysis: Analyze the filtered aqueous sample using a Total Organic Carbon (TOC) analyzer. Use a non-purgeable organic carbon (NPOC) method by acidifying the sample to pH <3 and sparging to remove inorganic carbon.

- Calculation: Calculate carbon yield:

%C_aq = (Mass of Carbon in Aqueous Phase / Mass of Carbon in Feedstock) * 100.

Protocol 2: Assessing Vapor-Phase Cracking Using a Two-Stage Fixed Bed Reactor

- Setup: Configure two tubular reactors in series. The first is for primary pyrolysis (500°C, sand bed). The second is a vapor-phase upgrading reactor (variable temp: 400-600°C, optionally with catalyst).

- Procedure: Load biomass (∼1g) in the first reactor. Under inert flow, rapidly insert the first reactor into the furnace. Primary vapors are carried into the second reactor.

- Variation: Run experiments with (a) an empty second reactor, and (b) a catalyst-packed second reactor (e.g., HZSM-5).

- Measurement: Collect and weigh all products (char, liquid in two stages, water). Analyze gas yield via online GC. The difference in carbon distribution quantifies vapor-phase cracking severity.

Mandatory Visualization

Title: Carbon Flow & Loss Pathways in Biomass Pyrolysis

Title: Experimental Setup for Carbon Balance Closure

The Scientist's Toolkit

Research Reagent Solutions for SAF Thermochemical Conversion

| Item | Function in Experiment | Key Consideration for Carbon Yield |

|---|---|---|

| HZSM-5 Zeolite (Si/Al=30-40) | Catalytic vapor upgrading; promotes deoxygenation via dehydration, increases aromatic hydrocarbons in oil. | High selectivity can reduce carbon loss to water and coke if optimized. |

| Pt/TiO₂ Catalyst | Hydrodeoxygenation (HDO) of bio-oil; selectively cleaves C-O bonds while minimizing C-C loss to gases. | Minimizes decarboxylation/decarbonylation, preserving liquid carbon yield. |

| Fluidized Bed Quartz Sand | Inert heat carrier in pyrolysis; provides rapid, uniform heating for high liquid yield. | Reduces secondary char formation by minimizing vapor-char interactions. |

| Diatomaceous Earth (Celite) | Filtration aid for separating aqueous phase from pyrolytic sugars/oil. | Accurate separation is critical for measuring aqueous vs. organic carbon. |

| Deionized Water + 0.1M HCl | Feedstock demineralization pre-treatment; removes AAEMs (K, Na) via acid washing. | Significantly reduces catalytic cracking to gases, increasing organic vapor yield. |

| Internal Standard Gas (e.g., 1% Ar in N₂) | Carrier gas with tracer for precise volumetric gas flow measurement. | Essential for calculating absolute gas yields and closing carbon balance. |

| TOC Calibration Standard (Potassium Hydrogen Phthalate) | Calibrating the TOC analyzer for aqueous phase organic carbon quantitation. | Directly measures carbon loss to the aqueous stream. |

Troubleshooting Guides & FAQs

FAQ 1: Why is my hydroprocessed biocrude yield lower than expected despite high initial biocrude quality?

- Answer: Low final yield is often not a function of initial biocrude quality alone but of its specific composition and the hydroprocessing conditions. High oxygenate content (e.g., >20 wt%) or high concentrations of reactive oxygenates like carboxylic acids and ketones can lead to excessive coke formation and gas production during hydrodeoxygenation (HDO). Ensure your biocrude analysis includes detailed speciation of oxygenates. Troubleshoot by:

- Verify Catalyst Activity: Test catalyst with a model compound. Deactivated catalyst due to feed impurities (e.g., alkali metals, sulfur) is common.

- Optimize H₂ Pressure & Temperature: Insufficient H₂ partial pressure can favor polymerization over deoxygenation. Increase pressure incrementally (e.g., from 80 to 120 bar) while monitoring coke formation.

- Analyze Off-Gases: High CO/CO₂ yields indicate decarboxylation/decarbonylation pathways, which reduce liquid carbon yield compared to HDO pathways.

FAQ 2: My syngas has acceptable H₂/CO ratio (>2), but Fischer-Tropsch (F-T) hydrocarbon yield is poor. What's wrong?

- Answer: The H₂/CO ratio is necessary but not sufficient. Trace contaminants in syngas are primary culprits.

- Tar/Aerosols: Can coat and deactivate F-T catalysts. Check your gas cleaning (cyclones, scrubbers, ESPs) efficiency.

- Sulfur/Nitrogen Compounds: Even ppb levels of H₂S or NH₃ can poison cobalt-based F-T catalysts. Implement and verify guard bed (e.g., ZnO) performance.

- Alkali Metals: Vapor-phase alkali can alter catalyst selectivity. Use a quartz wool filter or a cool-down trap.

- Experimental Protocol Check: Perform gas chromatography (GC) analysis of syngas before it enters the F-T reactor to confirm composition. Calibrate your GC with standard gas mixtures containing expected impurities.

FAQ 3: How can I minimize aging and instability of bio-oil before upgrading, which affects downstream yield?

- Answer: Bio-oil polymerization and viscosity increase are caused by reactive aldehydes (e.g., hydroxyacetaldehyde) and ketones. Follow this stabilization protocol:

- Immediate Post-Production: Cool bio-oil to 4°C or below within minutes of collection.

- Solvent Addition: Dilute with a stabilizing solvent (e.g., methanol, ethanol) at 10-20 wt% immediately. This inhibits oligomerization.

- Storage: Store in sealed, inert (N₂-purged) containers at -20°C for long-term stability. Avoid exposure to air or temperature fluctuations.

- Pre-Upgrading Step: Consider mild catalytic stabilization (e.g., low-temperature esterification over acidic catalysts) to convert reactive carbonyls before major upgrading.

FAQ 4: During catalytic fast pyrolysis (CFP), I observe high water and gas yields, reducing biocrude yield. How to adjust?

- Answer: This indicates excessive cracking. You need to balance deoxygenation and C-C bond preservation.

- Catalyst Selection & State: Switch from a pure microporous zeolite (e.g., HZSM-5) to a mesoporous catalyst (e.g., Ga-doped MCM-41) or a metal oxide (e.g., CeO₂) to reduce over-cracking. Ensure catalyst is properly regenerated (calcined in air at 550°C) to remove coke before each run.

- Process Conditions: Reduce reactor temperature in 10°C increments (e.g., from 600°C to 550°C). Adjust catalyst-to-biomass ratio. Decreasing the ratio typically reduces over-cracking.

- Vapor Residence Time: Shorten residence time to <2 seconds to minimize secondary cracking of primary vapors.

Table 1: Impact of Intermediate Quality on Final Fuel Carbon Yield

| Intermediate | Key Quality Parameter | Typical Range | High-Quality Threshold | Correlation with Final Fuel Carbon Yield | Primary Upgrading Challenge |

|---|---|---|---|---|---|

| Bio-Oil (from FP) | Total Acid Number (TAN) | 50-100 mg KOH/g | < 60 mg KOH/g | Negative (High TAN -> corrosion, instability) | Aging, high oxygen (∼40 wt%) |

| Water Content | 15-30 wt% | < 25 wt% | Negative (High water -> energy penalty) | Phase separation, heating value | |

| Syngas (from Gasification) | H₂/CO Molar Ratio | 0.5-2.0 | > 1.8 (for F-T) | Positive (up to optimal) | Tar content (>1 g/Nm³ is problematic) |

| Tar Concentration | 1-100 g/Nm³ | < 0.1 g/Nm³ | Strong Negative | Catalyst poisoning, fouling | |

| Biocrude (from HTL) | O Content | 5-20 wt% | < 10 wt% | Strong Negative | H₂ consumption during HDO |

| N Content | 0.5-5 wt% | < 2 wt% | Negative | Denitrogenation requires severe conditions |

Table 2: Recommended Analytical Methods for Intermediate Characterization

| Intermediate | Critical Analysis | Standard Method | Target Frequency | Purpose for Yield Optimization |

|---|---|---|---|---|

| Bio-Oil | Karl Fischer Titration | ASTM E203 | Every batch | High water lowers effective C yield. |

| GC/MS after Silylation | NREL TP-5100-62554 | Every 5th batch | Speciation of reactive oxygenates. | |

| Syngas | Online Micro-GC | ASTM D1946 | Continuous/Per run | Real-time H₂/CO ratio for process control. |

| Tar Protocol (GC-MS) | Tar Protocol (CEN/TS 15439) | Weekly/After cleanup | Quantify catalyst poisons. | |

| Biocrude | Elemental (CHNS/O) | ASTM D5291 | Every batch | Directly calculates O, N content for HDO. |

| Simulated Distillation | ASTM D7169 | Every 10th batch | Predicts final fuel fraction distribution. |

Experimental Protocols

Protocol 1: Hydrodeoxygenation (HDO) of Biocrude for Yield Maximization

- Objective: To upgrade biocrude to hydrocarbon fuel with maximum carbon yield.

- Materials: Fixed-bed reactor system (Hastelloy), mass flow controllers, HPLC pump, liquid/gas separators, sulfided NiMo/Al₂O₃ catalyst (100-200 µm), high-pressure H₂.

- Method:

- Catalyst Loading & Activation: Load 5.0 g catalyst in reactor center. Activate under 50 bar H₂ at 350°C for 4 hours (ramp: 5°C/min).

- Feed Preparation: Dilute 10 wt% biocrude in a hydrocarbon solvent (e.g., dodecane) to reduce viscosity and coking.

- Reaction: Set pressure to 100 bar H₂ and temperature to 350-400°C. Introduce feed at LHSV of 0.5 h⁻¹. Run for 6-8 hours to achieve steady state.

- Product Collection & Analysis: Collect liquid product in a cold trap. Weigh separately. Analyze by GC-MS (SIMDIS) and CHNS. Collect off-gas in a Tedlar bag for GC-TCD analysis (CO, CO₂, C1-C4).

- Yield Calculation: Carbon Yield (%) = (Carbon in liquid hydrocarbons / Carbon in fed biocrude) * 100.

Protocol 2: Syngas Cleaning & Conditioning for Fischer-Tropsch Synthesis

- Objective: To remove contaminants from syngas to protect F-T catalyst and maximize C5+ yield.

- Materials: Syngas generator, tar cracker (800°C), cyclone, water scrubber, packed-bed guard bed (ZnO), chiller/condenser, particulate filter (0.5 µm).

- Method:

- Primary Cleaning: Pass syngas through a hot ceramic filter (>500°C) followed by a cyclone to remove particulates.

- Tar Reduction: Direct gas through a catalytic tar reformer (e.g., dolomite bed at 800-900°C).

- Cooling & Scrubbing: Cool gas to 40°C in a quench tower. Use a venturi water scrubber to remove heavy tars and aerosols.

- Fine Cleaning: Pass through a chiller (5°C) to condense water and light tars, then through a ZnO guard bed (200°C) to remove H₂S to <10 ppb.

- Verification: Sample cleaned syngas before F-T reactor using impinger trains (Sparging in acetone/methanol) for gravimetric tar analysis and online GC for sulfur species.

Diagrams

Title: Bio-Oil Pathway from Pyrolysis to Final Fuel

Title: Syngas Cleaning Workflow for F-T Synthesis

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function/Application | Key Consideration for Yield |

|---|---|---|

| Sulfided NiMo/Al₂O₃ Catalyst | Standard catalyst for hydrodeoxygenation (HDO) of biocrude. Promotes C-O bond cleavage without excessive C-C cracking. | Must be pre-sulfided. Activity declines with high N/alkali in feed. |

| HZSM-5 Zeolite (Si/Al=40) | Acidic catalyst for catalytic fast pyrolysis (CFP). Promotes deoxygenation via dehydration/decarbonylation. | High acidity favors gas yield; often modified with metals (Ga, Zn) to improve aromatics yield. |

| Dodecane (≥99%) | High-bo-point, inert solvent for diluting viscous biocrude feeds for HDO. Reduces coking in transfer lines & reactors. | Ensures uniform feed and accurate pumping, critical for yield calculations. |

| ZnO Sorbent Pellets | Guard bed material for removing H₂S from syngas to ppb levels, protecting precious F-T catalysts (Co, Ru). | Breakthrough capacity is key. Must be replaced/renewed before H₂S slips into reactor. |

| Methanol with Stabilizers | Solvent for immediate bio-oil dilution/quenching. Inhibits polymerization, preserving quality for subsequent upgrading. | Must be added immediately upon collection to lock in quality and maximize recoverable carbon. |

| Internal Standards (e.g., Dodecane-d26, Fluoranthene-d10) | For quantitative GC-MS analysis of bio-oil/biocrude. Allows accurate yield calculation of specific compound families. | Critical for mass balance closure and identifying carbon loss pathways. |

Catalytic and Process Engineering Strategies to Maximize Carbon Retention

Advanced Catalyst Design for Selective Deoxygenation and C-C Coupling (Zeolites, Transition Metals, Supported Catalysts)

Technical Support Center: Troubleshooting & FAQs

FAQ 1: Why is my catalyst rapidly deactivating during the deoxygenation of lignin model compounds?

- Issue: Rapid coke deposition leading to pore blockage and active site coverage.

- Solution: Implement a mild pre-treatment (e.g., 350°C under H₂ flow for 1 hour) to reduce surface carbon. For zeolite-supported metals, consider post-synthesis dealumination to reduce strong Brønsted acid sites that catalyze coking. Introduce a co-fed gas (e.g., 5 vol% H₂ in Ar) to hydrogenate coke precursors.

- Supporting Protocol: Temperature-Programmed Oxidation (TPO) for Coke Analysis: After reaction, cool catalyst to 50°C under inert flow. Switch to 5% O₂/He (30 mL/min). Heat to 800°C at 10°C/min while monitoring CO₂ signal via MS. Peaks below 400°C indicate filamentous carbon; above 500°C indicate graphitic carbon.

FAQ 2: How can I improve C-C coupling selectivity and minimize over-hydrogenation to alkanes on my transition metal catalyst?

- Issue: Excessive hydrogenation activity of noble metals (Pt, Pd) or sulfided Ni/Co catalysts leads to low yields of desirable olefinic or aromatic coupling products.

- Solution: Modify metal nanoparticles via alloying (e.g., Pt-Sn, Pd-Fe) to dilute surface ensembles. Use reducible oxide supports (TiO₂, Nb₂O₅) to create metal-support interfaces that stabilize reaction intermediates. For zeolites, fine-tune the balance between metal (deoxygenation) and acid (coupling) sites by controlling ion-exchange levels.

- Supporting Protocol: Controlled Metal Deposition on Zeolite: For 2 wt% Pd on H-ZSM-5, use incipient wetness impregnation. Dissolve Pd(NO₃)₂·2H₂O in deionized water equal to 95% of zeolite pore volume. Add dropwise to zeolite under stirring. Age for 2 hours, dry at 110°C for 12h, calcine in static air at 350°C for 3h (ramp 2°C/min).

FAQ 3: My supported metal catalyst shows inconsistent performance between batches. What are the key variables to control?

- Issue: Inconsistent metal nanoparticle size, oxidation state, or dispersion due to variations in synthesis or activation.

- Solution: Standardize the reduction procedure. Use in-situ reduction immediately prior to reaction. Employ a consistent reducing agent (e.g., 10% H₂/Ar) and a calibrated temperature ramp (e.g., 5°C/min to target, hold for 2 hours). Characterize each batch with CO chemisorption and TEM for metal dispersion and particle size distribution.

- Supporting Protocol: Standardized Catalyst Reduction: Load 100 mg catalyst in quartz reactor. Purge with Ar (50 mL/min) at RT for 30 min. Switch to 10% H₂/Ar (50 mL/min). Heat to reduction temperature (e.g., 500°C for Ni, 300°C for Pt) at 5°C/min. Hold for 2 hours. Cool in H₂/Ar to reaction temperature.

FAQ 4: How do I select the optimal zeolite topology and acidity for C-C coupling of oxygenates?

- Issue: Uncontrolled oligomerization or cracking leads to low carbon yield to jet-fuel range (C8-C16) hydrocarbons.

- Solution: For coupling of furanics (e.g., furfural), use 3D large-pore zeolites (e.g., FAU) to accommodate dimerization. For phenolic coupling, 10- or 12-membered ring channels (MFI, BEA) are effective. Control acidity via Si/Al ratio: higher Si/Al (e.g., >40) reduces strong acid sites, favoring coupling over fragmentation.

Table 1: Performance of Representative Catalyst Systems in SAF Precursor Production

| Catalyst System | Reaction (Model Feed) | Temp. (°C) | Pressure (bar) | Carbon Yield to C8+ (%) | Major Deactivation Cause | Ref. Year* |

|---|---|---|---|---|---|---|

| Pt/Nb₂O₅ | Guaiacol HDO | 300 | 20 (H₂) | 42 | Nb₂O₅ Phase Change | 2023 |

| Ni/HZSM-5 (Si/Al=40) | Furfural-Acetone Coupling | 120 | 1 (N₂) | 68 | Coke on Acid Sites | 2024 |

| Pd/Fe₂O₃ | Vanillin C-C Coupling | 250 | 10 (H₂) | 55 | Sintering | 2023 |

| Co/SiO₂ | Butanol Guerbet | 200 | 30 (H₂) | 75 | Metal Leaching | 2024 |

*Data based on recent literature search.

Table 2: Common Characterization Techniques for Catalyst Diagnosis

| Technique | Information Gained | Typical Problem Identified |

|---|---|---|

| NH₃-TPD | Acid site strength & density | Excessive strong acid sites causing cracking |

| H₂-TPR | Metal oxide reducibility, alloy formation | Incomplete reduction, strong metal-support interaction |

| XRD | Crystallinity, phase identification, particle size (Scherrer) | Unwanted phase formation, sintering |

| XPS | Surface composition, metal oxidation state | Surface poisoning, unintended oxidation state |

Experimental Protocols

Protocol: Vapor-Phase Deoxygenation and Coupling of Phenolic Compounds.

- Catalyst Preparation: Synthesize 5 wt% Ni on mesoporous ZSM-5 via wet impregnation using nickel(II) nitrate hexahydrate. Dry at 110°C overnight. Calcine at 550°C for 4 h (ramp 1°C/min).

- Reactor Setup: Load 0.5 g catalyst (60-80 mesh) in a fixed-bed, down-flow, stainless-steel tubular reactor (ID 9 mm). Pack with quartz wool.

- In-situ Activation: Reduce catalyst under 50 sccm H₂ flow at 500°C for 2 h (ramp 5°C/min).

- Reaction: Cool to reaction temperature (280°C). Switch feed to a mixture of m-cresol (10 wt% in dodecane) delivered via syringe pump at 0.1 mL/min and H₂ at 50 sccm (30 bar total pressure).

- Product Analysis: Analyze effluent after 6 h time-on-stream using an online GC-FID equipped with a DB-5 column. Use external standards for quantification.

Diagrams

Experimental Workflow for Catalyst Optimization

Reaction Pathway on a Bifunctional Catalyst

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Catalyst Synthesis & Testing

| Reagent / Material | Function in Experiment | Key Consideration for SAF Research |

|---|---|---|

| Zeolite H-Beta (Si/Al=25) | Acidic support for C-C coupling; provides shape selectivity. | 3D 12-ring pores ideal for intermediate-sized coupling products. |

| Nickel(II) nitrate hexahydrate | Precursor for Ni metal nanoparticles (deoxygenation/hydrogenation). | High activity but prone to sintering; requires careful reduction. |

| Niobium(V) oxide (Nb₂O₅) | Reducible oxide support; creates metal-support interfaces for selective C-O scission. | Enhances yield to aromatics over cycloalkanes. |

| Ammonium ZSM-5 (Si/Al=40) | Starting material for creating tailored acid supports via calcination (to H-form) and ion-exchange. | High Si/Al ratio offers moderate acidity, limiting coking. |

| Tetraamminepalladium(II) nitrate | Precursor for highly dispersed Pd nanoparticles. | Excellent for hydrogenation but can over-hydrogenate; often alloyed. |

| 1-Butanol & m-Cresol | Model oxygenated compounds for Guerbet coupling and HDO studies, respectively. | Representative of fermentation and lignin pyrolysis streams. |

| 10% H₂/Ar Gas Cylinder | Standard reducing agent for in-situ catalyst activation. | Consistent reduction profile is critical for reproducibility. |

Technical Support Center: Troubleshooting & FAQs

Q1: We are observing rapid catalyst deactivation during in-situ IH² runs, leading to a sharp decline in carbon yield to Sustainable Aviation Fuel (SAF) range hydrocarbons. What are the primary causes and mitigation strategies?

A1: Rapid deactivation is often due to coke formation and/or sintering of the active metal sites (e.g., Co, Mo, Ni) under the combined high-temperature pyrolysis and hydrotreating conditions.

Primary Causes:

- Insufficient Hydrogen Partial Pressure: Leads to polymerization of reactive intermediates, forming hard coke.

- Excessive Pyrolysis Vapor Contact Time with Catalyst before H₂ introduction promotes coking.

- Feedstock Inorganics (K, Na) and particulates physically blocking pores.

- Localized Hot Spots in the reactor causing thermal sintering.

Mitigation Protocols:

- Pre-Treatment: Implement strict feedstock washing/drying to reduce ash.

- Hydrogen Management: Immediately mix pyrolysis vapors with high-purity H₂. Monitor and maintain H₂ partial pressure >20 bar.

- Catalyst Design: Use structured catalysts (e.g., monoliths) or those with hierarchical porosity to reduce pore-plugging. Consider doping with Sn or Pt to promote coke gasification.

- Process Control: Ensure rapid vapor transport from the pyrolysis zone to the catalytic bed. Implement temperature zoning with precise control (±5°C).

Q2: How can we optimize the H₂-to-biomass feed ratio to maximize carbon yield without wasteful hydrogen consumption?

A2: Optimization requires balancing hydrodeoxygenation (HDO) needs against saturation reactions. The optimal ratio is feedstock-dependent but can be determined experimentally.

Protocol: H₂-to-Biomass Ratio Optimization

- Set Constants: Fix biomass feed rate (e.g., 100 g/hr), catalyst, temperature (pyrolysis: 500°C, catalytic zone: 400°C), and pressure (30 bar).

- Variable: Systematically vary H₂ flow rate from 5 to 15 standard liters per minute (SLPM).

- Measure: For each condition, after 1-hour steady-state, collect liquid product and analyze for:

- Carbon Yield (%): (Carbon in C5-C24 hydrocarbons / Carbon in dry biomass feedstock) * 100.

- Oxygen Content (wt%): Via elemental analysis.

- H₂ Consumption: Via mass flow meter differential.

- Target: Identify the "knee of the curve" where increased H₂ gives diminishing returns on deoxygenation and carbon yield.

Table 1: Representative Data from H₂ Optimization Study (Softwood, Zeolite-Supported CoMo Catalyst)

| H₂ Flow (SLPM) | H₂/Biomass (wt/wt) | Carbon Yield to SAF (% ) | Product O (wt%) | H₂ Consumed (mol/kg biomass) |

|---|---|---|---|---|

| 5 | 0.06 | 22.5 | 8.7 | 14.2 |

| 8 | 0.10 | 28.1 | 3.2 | 18.5 |

| 11 | 0.14 | 28.4 | 2.8 | 22.9 |

| 15 | 0.19 | 27.8 | 2.5 | 29.7 |

Q3: What are the critical analytical techniques for characterizing IH² products and diagnosing process issues?

A3: A multi-technique approach is essential for understanding carbon distribution and functionality.

- Gas Chromatography (GC-FID/SCD): Quantifies hydrocarbon distribution (C5-C24) and sulfur species.

- 2D GC (GCxGC-TOFMS): Unravels complex mixtures for detailed hydrocarbon speciation.

- Elemental Analyzer (CHNS/O): Determines bulk C, H, N, S, O content to calculate effective hydrogen index and oxygen rejection.

- Thermogravimetric Analysis (TGA): Assesses catalyst coke content post-run.

- X-ray Diffraction (XRD) & Temperature-Programmed Reduction (TPR): Characterizes catalyst structure and reducibility before/after testing.

Q4: Our product distribution is skewed towards light hydrocarbons (C5-C10) rather than desired SAF range (C8-C16). How can we shift the carbon chain length?

A4: This indicates excessive cracking. Strategies focus on tuning catalyst acidity and process severity.

- Catalyst Modification: Reduce strong Brønsted acid sites on the support (e.g., by desilication of zeolites, using milder alumina). Favor metals with high hydrogenation function (e.g., Pt, Pd) to stabilize intermediates before cracking.

- Process Adjustment:

- Lower Catalytic Zone Temperature: Decrease from 400°C to 350-375°C to reduce cracking.

- Reduce Contact Time: Increase gas hourly space velocity (GHSV) by 20-30% to limit secondary reactions.

- Experimental Protocol: Cracking Mitigation Test

- Prepare two catalysts: Standard acidic zeolite (ZSM-5) and a moderated acidity version (desilicated ZSM-5 or SAPO-34).

- Run identical IH² conditions: 500°C pyrolysis, 30 bar, H₂/Biomass = 0.10.

- For each catalyst, run at two catalytic zone temps: 400°C and 375°C.

- Analyze liquid product via simulated distillation (SimDist) to generate carbon number distributions.

Table 2: Carbon Number Distribution as Function of Catalyst & Temperature

| Catalyst | Cat. Temp (°C) | C5-C10 Yield (wt%) | C8-C16 (SAF) Yield (wt%) | C17+ Yield (wt%) |

|---|---|---|---|---|

| ZSM-5 | 400 | 45.2 | 38.5 | 16.3 |

| ZSM-5 | 375 | 38.7 | 43.8 | 17.5 |

| SAPO-34 | 400 | 31.4 | 52.1 | 16.5 |

| SAPO-34 | 375 | 28.9 | 54.6 | 16.5 |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for IH² SAF Yield Experiments

| Item | Function & Rationale |

|---|---|

| Lignocellulosic Model Compounds (Cellulose, Xylan, Lignin) | Isolate feedstock component effects on carbon yield and catalyst deactivation. |

| Deoxygenation Catalyst Precursors (Ammonium heptamolybdate, Cobalt nitrate, Nickel nitrate) | For synthesizing standard hydrotreating catalysts (e.g., CoMo/γ-Al₂O₃). |

| Shape-Selective Supports (HZSM-5, HY, γ-Al₂O₃, SiO₂-Al₂O₃) | To study the critical role of pore architecture and acidity on carbon yield distribution. |

| High-Pressure Hydrogen (99.999%) | Essential reactant for HDO and coke suppression. Impurities (CO, H₂S) must be minimized. |

| Internal Standards for GC (Dodecane-d26, Fluoranthene) | For accurate quantitative analysis of complex hydrocarbon product streams. |

| Temperature-Resistant Quartz Wool/Reactors | To separate pyrolysis and catalytic zones in fixed-bed reactors for in-situ studies. |

| Certified Reference Materials for SimDist | To calibrate instrument for accurate boiling point and carbon number distribution. |

Experimental Workflow & Reaction Pathway Diagrams

IH² Experimental Process Workflow for SAF Production

Key Catalytic Pathways from Biomass to SAF in IH²

Technical Support Center

Troubleshooting Guides

Issue 1: Low Carbon Yield in Fixed-Bed Pyrolysis Reactor

- Problem: The solid biochar yield is consistently below theoretical predictions.

- Diagnosis: This is commonly linked to excessive process severity. High temperatures and long residence times favor secondary cracking of vapors, converting condensables into non-condensable gases.

- Solution:

- Verify Thermocouple Calibration: Ensure temperature readings are accurate.

- Reduce Reactor Setpoint Temperature: Lower in increments of 25°C.

- Decrease Solid Residence Time: If possible, adjust the sample boat insertion rate or gas flow.

- Check Pressure: Ensure the system is at atmospheric pressure and not under inadvertent vacuum.

- Validation: Perform a mass balance closure check after each adjustment. Yield should stabilize or increase.

Issue 2: Excessive Pressure Fluctuations in a Hydrothermal Liquefaction (HTL) Batch Reactor

- Problem: Unsafe or inconsistent pressure readings during operation.

- Diagnosis: Potential causes are overfilling (insufficient headspace), leaking seals, or a faulty pressure transducer.

- Solution:

- Immediate Shutdown: Follow safe depressurization protocols.

- Inspect Seal Integrity: Replace all O-rings or gaskets.

- Verify Fill Volume: Do not exceed 2/3 of the reactor's volume with feedstock slurry.

- Test Pressure Transducer: Compare with a calibrated gauge.

- Prevention: Implement a pre-run checklist including seal inspection and volume verification.

Issue 3: Irreproducible Yields Under "Identical" Conditions

- Problem: Significant yield variation between experimental repeats.

- Diagnosis: Inconsistent feedstock properties (particle size, moisture) or unrepeatable heating rates are likely culprits.

- Solution:

- Standardize Feedstock: Implement sieve fractions for particle size and use a consistent drying protocol.

- Profile Heating Rate: Use reactor log data to plot actual temperature vs. time. A slow initial ramp due to reactor thermal mass can be a key variable.

- Document Ambient Conditions: Note lab temperature and humidity.

- Validation: Run a control experiment with a standard feedstock (e.g., cellulose) to benchmark reactor performance.

Frequently Asked Questions (FAQs)

Q1: Which single parameter has the most dominant effect on carbon yield to biochar? A1: Temperature is typically the most dominant parameter. Carbon yield in pyrolysis decreases exponentially with increasing temperature due to enhanced devolatilization. For maximum solid yield, lower temperatures (typically 300-400°C) coupled with slow heating rates and longer vapor residence times are favorable.

Q2: How do I optimize for liquid yield (bio-oil) versus solid yield (biochar)? A2: These products are in competition. For high bio-oil yield, use moderate temperatures (~500°C), very high heating rates (fast pyrolysis), and very short vapor residence times (<2 seconds) to quench vapors and prevent secondary cracking. This inherently reduces biochar yield.

Q3: What is the role of pressure in catalytic hydrothermolysis for SAF? A3: Elevated pressure (often 10-25 MPa) serves two critical functions: it keeps water in a liquid or supercritical state at high temperatures, and it suppresses the formation of coke (undesirable solid carbon) on catalysts, thereby improving the yield and quality of renewable intermediate oils for SAF.

Q4: How is "residence time" defined and controlled for different reactor types? A4:

- Batch Reactor: Residence time equals the total process time at the target condition. Controlled by holding time.

- Fixed-Bed Reactor: For solids, it is the time the biomass sits in the hot zone. For vapors, it is approximated by

(reactor void volume) / (gas flow rate at conditions). Controlled by gas flow rate. - Fluidized Bed Reactor: Vapor residence time is controlled similarly to fixed-bed. Solid residence time is managed by the solid feed rate and bed dynamics.

Table 1: Impact of Key Parameters on Product Yield Distribution in Biomass Pyrolysis

| Parameter | Typical Range Studied | Effect on Biochar Yield | Effect on Bio-Oil Yield | Effect on Gas Yield | Primary Mechanism |

|---|---|---|---|---|---|

| Temperature | 300-700°C | Strong decrease | Increase to an optimum (~500°C), then decrease | Steady increase | Enhanced primary decomposition & secondary vapor cracking at higher T. |

| Pressure | 0.1-5 MPa (inert) | Slight increase | Slight decrease | Variable | Physical suppression of volatile release. |

| Vapor Residence Time | 0.5-5 s (fast pyrolysis) | Minor effect | Strong decrease (longer time) | Strong increase (longer time) | Vapor-phase cracking reactions. |

| Heating Rate | 1-1000°C/s | Decrease with higher rate | Increase with higher rate | Variable | Rapid heating minimizes char-forming secondary reactions in solid. |

Table 2: Target Parameters for Maximizing Carbon Yield to Biochar (for sequestration)

| Parameter | Optimal Range | Rationale |

|---|---|---|

| Final Temperature | 300 - 400°C | Minimizes hemicellulose and cellulose devolatilization. |

| Heating Rate | Slow (1-10°C/s) | Allows time for metatestable solid intermediates to form, favoring char. |

| Pressure | Slightly above atmospheric (0.2-0.5 MPa) | Mildly suppresses volatile loss. |

| Solid Residence Time | Long (10-60 min) | Ensures complete carbonization at low temperature. |

| Vapor Residence Time | Long (>5 s) | Allows vapors to interact with hot char, promoting deposition (can increase char yield). |

Experimental Protocols

Protocol 1: Determining the Temperature-Yield Relationship in a Tubular Furnace Reactor

- Material Preparation: Mill and sieve feedstock to 250-500 µm. Dry at 105°C for 12 hours.

- Reactor Setup: Calibrate furnace temperature profile. Set carrier gas (N₂) flow to 500 mL/min.

- Experimental Run: For each temperature setpoint (e.g., 300, 400, 500, 600°C), load 1.000 g of biomass into a sample boat. Insert the boat into the cold zone. Purge for 5 minutes. Rapidly introduce the boat to the hot zone. Start timer for a 10-minute residence.

- Product Collection: After 10 minutes, remove boat to a cold zone. Condensable vapors are collected in a series of cold traps. Non-condensable gases are vented or sampled.

- Quantification: Weigh the mass of remaining char. Determine bio-oil mass by weighing traps before and after. Gas yield by difference. Perform triplicate runs.

Protocol 2: Investigating Heating Rate Effect Using a Thermogravimetric Analyzer (TGA)

- Calibration: Calibrate TGA balance and temperature using standard reference materials.

- Baseline Run: Perform an empty crucible run under the intended gas flow (N₂, 50 mL/min) and temperature program to establish a baseline.

- Sample Run: Precisely load 5-10 mg of dried, powdered biomass. Initiate temperature program: ramp from ambient to 105°C at 50°C/min, hold for 5 min (drying), then ramp to final temperature (e.g., 700°C) at the target heating rate (e.g., 10, 50, 100°C/min). Hold isothermally for 2 min.

- Data Analysis: Plot mass loss (TG) and derivative mass loss (DTG) curves. Correlate the final mass with the applied heating rate.

Visualizations

Title: Parameter Impact Pathways for Carbon Yield

Title: Experimental Workflow for Parameter Optimization

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Thermochemical Conversion Research |

|---|---|

| Lignocellulosic Model Compounds (Cellulose, Xylan, Lignin) | Used to deconvolute complex biomass reactions and study individual polymer behavior under different parameters. |

| Catalysts (e.g., Zeolites (ZSM-5), Alkali Carbonates (K₂CO₃)) | ZSM-5 catalyzes vapor upgrading for bio-oil. Alkali salts catalyze biomass decomposition, often lowering char yield. |

| Quenching Medium (e.g., Dichloromethane (DCM), Ice-water Traps) | Rapidly condense bio-oil vapors to halt secondary reactions, critical for accurate liquid yield measurement. |

| Inert Gas (High-Purity N₂ or Ar) | Creates an oxygen-free environment to prevent combustion, ensuring pyrolysis rather than burning. |

| Standard Reference Biomass (e.g., NIST Poplar, Pine) | Provides a consistent, well-characterized material for cross-laboratory comparison and reactor benchmarking. |

| Thermocouple & Data Logger | Precisely monitors real-time temperature and heating rate profiles within the reaction zone. |

| Pressure Transducer | Accurately measures and logs system pressure, crucial for HTL and pressurized pyrolysis experiments. |

| Micro-GC/TGA-MS | Online analytical tools for real-time gas composition analysis and kinetic studies of mass loss. |

Technical Support & Troubleshooting Center

Frequently Asked Questions (FAQs)

Q1: Our experiment shows a sharp decline in liquid yield after 2 hours of reaction time. What could be the cause? A: This is often due to the depletion of active hydrogen from the H₂ donor solvent. Once the donor is exhausted, free radical condensation reactions dominate, leading to repolymerization and coke formation. Monitor donor solvent concentration or consider semi-batch replenishment.

Q2: We are observing inconsistent coke reduction results when switching between different H₂ donor solvents (e.g., tetralin vs. isopropanol). Why? A: Different donors have varying hydrogen-donating capacities and mechanisms (e.g., radical vs. ionic hydrogen transfer). Tetralin is a superior radical hydrogen donor, while isopropanol may require a specific catalyst for effective dehydrogenation. Ensure your catalyst (if used) is compatible with the donor's mechanism.

Q3: How do we differentiate between "coke" and "char" in our product analysis? A: Operationally, "coke" typically refers to carbonaceous deposits formed on catalyst surfaces or reactor walls via secondary reactions of vapors. "Char" is the solid residue from the primary pyrolysis of the feedstock. Thermogravimetric Analysis (TGA) in an oxygen atmosphere can help distinguish based on combustion profiles.

Q4: What is the most common analytical technique for quantifying the effectiveness of H₂ donor solvents in-situ? A: Real-time gas analysis using Mass Spectrometry (MS) or Micro-GC to track hydrogen gas (H₂) evolution and light hydrocarbon gases (e.g., CH₄) is highly effective. A decrease in H₂ yield often correlates with improved hydrogen transfer from the donor to the bio-oil intermediates.

Q5: Our catalyst deactivates rapidly despite using a hydrogen donor solvent. What troubleshooting steps should we take? A: This suggests pore blockage or poisoning. First, perform Temperature Programmed Oxidation (TPO) on the spent catalyst to quantify coke. Compare with a non-donor run. If coke is reduced but deactivation persists, analyze for inorganic poisons (e.g., S, K, Na) from the feedstock via ICP-MS. Consider a guard bed or feedstock pre-treatment.

Experimental Protocols

Protocol 1: Assessing H₂ Donor Solvent Efficiency in Batch Reactor Objective: To quantify coke suppression and liquid yield improvement using a candidate H₂ donor solvent.

- Materials: Lignocellulosic biomass (e.g., pine, switchgrass, ground to 250-500 µm), H₂ donor solvent (e.g., tetralin, formic acid), non-donor reference solvent (e.g., n-dodecane), 100-mL stainless steel batch reactor.

- Procedure: a. Load reactor with a 1:10 mass ratio of biomass to solvent. b. Purge reactor three times with inert gas (N₂ or Ar) at 20 bar. c. Pressurize to initial cold pressure of 10 bar with N₂. d. Heat to target temperature (e.g., 350-450°C) at a ramp rate of 10°C/min, with constant stirring (500 rpm). e. Hold at target temperature for 60 minutes. f. Cool rapidly to room temperature using an internal coil or ice bath. g. Collect gas in a graduated bag for volume and composition analysis (GC). h. Separate contents: Filter solids (char + coke). Rinse reactor walls with toluene to collect reactor-derived coke. i. Recover liquid product by rotary evaporation to separate volatile solvent from the bio-oil product.

- Analysis: Calculate yields (mass % on biomass basis):

- Liquid Yield = (Mass of bio-oil / Mass of dry biomass) * 100

- Solid Residue = (Mass of filtered, dried solids / Mass of dry biomass) * 100

- Gas Yield = By difference or directly from gas mass.

Protocol 2: Quantifying Active Hydrogen Content via Deuterium Tracing Objective: To track the transfer of hydrogen from donor solvent to bio-oil products.

- Materials: Deuterated H₂ donor (e.g., d₈-tetralin, d₆-isopropanol), biomass, batch reactor, GC-MS.

- Procedure: a. Perform reaction as in Protocol 1 using the deuterated donor. b. Recover the liquid bio-oil product. c. Derivatize bio-oil samples (e.g., silylation) for GC-MS analysis.

- Analysis: Use GC-MS to identify the incorporation of deuterium (D) into specific bio-oil compounds (e.g., phenols, alkanes). The mass shift in molecular ion peaks confirms direct hydrogen transfer from donor to stabilization of pyrolysis fragments.

Table 1: Performance of Common H₂ Donor Solvents in Biomass Liquefaction

| H₂ Donor Solvent | Mechanism | Typical Temp. Range (°C) | Coke Reduction (vs. Inert) | Typical Liquid Yield Increase | Notes |

|---|---|---|---|---|---|

| Tetralin | Radical H-transfer | 350-450 | 40-60% | 10-15 wt% | Gold standard, forms naphthalene. |

| Formic Acid | Catalytic Decomp. (H₂+CO₂) | 250-350 | 20-40% | 8-12 wt% | In-situ H₂ generation, acidic medium. |

| Isopropanol | Catalytic Dehydrogenation | 300-400 | 15-35% | 5-10 wt% | Requires metal catalyst (e.g., Cu). |

| Water (Subcritical) | Ionic/Radical | 250-374 | 10-30% | Variable | Low cost, promotes ionic pathways. |

Table 2: Troubleshooting Common Experimental Issues

| Problem | Potential Cause | Diagnostic Test | Corrective Action |

|---|---|---|---|

| Low Liquid Yield | Donor depletion, Excessive gasification | Analyze gas for H₂/CO₂ ratio; Check donor conc. post-run. | Reduce residence time; Use excess donor or semi-batch mode. |

| High Coke on Catalyst | Pore blockage, Insufficient H-transfer | TPO of spent catalyst; BET surface area. | Use smaller catalyst particle; Increase donor/catalyst ratio. |

| Poor Oil/Water Separation (with aqueous donors) | Formation of stable emulsions | Measure pH; Microscopy of emulsion. | Adjust pH; Use demulsifiers; Centrifuge product. |

| Irreproducible Results | Inconsistent heating or mixing | Calibrate thermocouple; Check stirrer speed. | Standardize heating rate; Ensure turbulent mixing. |

Visualizations

Title: Hydrogen Donor Solvent Role in Coke vs. Oil Pathways

Title: Batch Reactor Setup for H₂ Donor Solvent Testing

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in H₂ Management Research |

|---|---|

| Tetralin (1,2,3,4-Tetrahydronaphthalene) | Benchmark radical hydrogen donor solvent. Donates H-atoms to cap free radicals, preventing repolymerization. |

| d₈-Tetralin (Deuterated) | Isotopically labeled tracer to quantitatively track hydrogen transfer pathways via GC-MS analysis. |

| Formic Acid (HCOOH) | Provides in-situ hydrogen via decarboxylation (to H₂ + CO₂) under heat, often with lower severity than external H₂ gas. |

| Disproportionation Catalyst (e.g., Cu/C, Pd/Al₂O₃) | Facilitates the dehydrogenation of hydrogen-donor carriers (e.g., isopropanol to acetone) for reversible hydrogen transfer cycles. |

| N-Dodecane | Inert, high-boiling point hydrocarbon solvent used as a non-donor baseline in comparative experiments. |

| Silylation Reagent (e.g., BSTFA) | Derivatizes bio-oil hydroxyl/carboxyl groups for accurate GC-MS analysis and deuterium tracking. |

| Temperature Programmed Oxidation (TPO) System | Quantifies and characterizes the amount and reactivity of coke deposited on catalyst surfaces. |

Novel Reactor Designs (e.g., Bubbling Fluidized Bed, Dual Bed) for Enhanced Heat/Mass Transfer and Yield

Troubleshooting Guides & FAQs

FAQ 1: Why is my Bubbling Fluidized Bed (BFB) reactor experiencing poor fluidization or channeling, leading to low carbon yield?

Answer: Poor fluidization often stems from incorrect particle size distribution, insufficient gas velocity, or moisture in the feedstock. For SAF production, this causes uneven heating and reduces the efficiency of volatile matter release and char formation, lowering carbon yield. Ensure your biomass feedstock is dried (<10% moisture) and sieved to a narrow size range (e.g., 300-600 µm). Verify your superficial gas velocity is above the minimum fluidization velocity (Umf) but within the bubbling regime. Calculate Umf experimentally using a pressure drop vs. velocity curve.

FAQ 2: In a Dual Bed (or Double Loop) reactor system, how do I manage solid circulation rates to optimize char yield?

Answer: The solid circulation rate is critical for separating pyrolysis (in the first bed) from char gasification/combustion (in the second bed). Low circulation reduces heat transfer to the pyrolysis zone, lowering yield. High circulation may over-gasify the char. Control is achieved by adjusting the aeration rate in the loop-seal and the pressure balance between reactors. Monitor temperatures in both beds; the pyrolysis bed should be stable at 450-600°C for high bio-oil and char yield. Use an online solids flow meter or tracer studies to calibrate.

FAQ 3: What causes excessive tar formation and reactor fouling in my fluidized bed during biomass pyrolysis for SAF precursors?

Answer: Excessive tars indicate suboptimal temperature or vapor residence time. While some tars are precursors for aromatic hydrocarbons in SAF, too much leads to condensation and clogging. In a BFB, ensure the freeboard temperature is maintained (typically >500°C) to crack heavy tars. In a Dual Bed system, ensure rapid removal and quenching of vapors from the pyrolysis zone. Consider in-bed or downstream catalytic cracking (e.g., using zeolites in the bed) to convert tars to useful gases or lighter aromatics, protecting downstream equipment.

FAQ 4: How can I diagnose and fix poor heat transfer in the dense phase of my fluidized bed?

Answer: Poor heat transfer manifests as axial or radial temperature gradients. Causes include inadequate bed material (e.g., low heat capacity sand), wrong particle size, or low fluidization quality. Use a high heat capacity bed material like alumina or olivine. For electrically heated reactors, check the placement and insulation of heaters. Incorporate internal heat exchangers (immersed tubes) for direct heating, which is common in industrial designs. Regularly measure temperature at multiple points using shielded thermocouples.

Experimental Protocol: Determining Minimum Fluidization Velocity (U_mf) for a Novel Biomass-Sand Mixture

Objective: To empirically determine U_mf for a biomass-sand mixture used in a BFB reactor for pyrolysis.

- Setup: Assemble a cold-flow BFB model (clear acrylic column). Attach a calibrated air supply with a flow meter and a differential pressure transducer across the bed.

- Material Preparation: Mix dried, sieved biomass (e.g., pine, 500 µm) with silica sand (300 µm) at your intended operational ratio (e.g., 1:10 by mass).

- Procedure:

- Load a fixed mass of the mixture into the column.

- Gradually increase the air flow rate in small increments, allowing the system to stabilize at each step.

- Record the pressure drop (ΔP) and corresponding superficial gas velocity (U).

- Gradually decrease the flow rate, recording the same data.

- Analysis: Plot ΔP vs. U. The U_mf is identified as the velocity at the point where the decreasing velocity curve (defluidization) diverges from the linear, packed-bed trendline. This method minimizes hysteresis.

- Application: Set operational velocity typically at 2-5 times U_mf for a bubbling regime.

Experimental Protocol: Char Yield Optimization in a Micro-Dual Bed Reactor System

Objective: To maximize solid carbon yield (char) from biomass fast pyrolysis by separating and controlling reaction zones.

- Reactor System: Utilize a connected dual reactor setup: first reactor (Pyrolyzer) is a BFB; second reactor (Char Heater) is a riser or transported bed.

- Bed Material: Use catalyst (e.g., HZSM-5) or sand in the Pyrolyzer. Use sand in the Char Heater.

- Procedure:

- Heat both reactors under inert flow (N₂). Set Pyrolyzer to 500°C. Set Char Heater to a lower temperature (350-450°C) to minimize secondary char gasification.

- Initiate solid circulation between reactors using a loop-seal with controlled N₂ aeration.

- Feed biomass (100 g/hr) into the Pyrolyzer. Vapors and aerosols are rapidly quenched and collected.

- Char is transported with bed material to the Char Heater, where it is mildly heated to strip any remaining volatiles without significant gasification.

- Char is separated via a cyclone and collected. Circulation rate is varied by adjusting loop-seal aeration.

- Data Collection: Measure yields of char, bio-oil, and gas at different Pyrolyzer temperatures, Char Heater temperatures, and solid circulation rates.

- Optimization: The target is to find the condition where char yield is maximized while bio-oil quality (low oxygen content) is maintained for downstream SAF upgrading.

Data Presentation

Table 1: Comparative Performance of Reactor Designs for Biomass Pyrolysis (SAF Pathway)

| Reactor Design | Typical Temp. Range (°C) | Vapor Residence Time | Solid Residence Time | Typical Char Yield (wt.%) | Key Advantage for SAF | Key Challenge |

|---|---|---|---|---|---|---|