From Ethanol to Thrust: The Science and Scalability of Alcohol-to-Jet (ATJ) Bio-SAF Pathways

This article provides a comprehensive analysis of Alcohol-to-Jet (ATJ) conversion technology for sustainable aviation fuel (SAF) production, tailored for researchers, scientists, and chemical engineering professionals.

From Ethanol to Thrust: The Science and Scalability of Alcohol-to-Jet (ATJ) Bio-SAF Pathways

Abstract

This article provides a comprehensive analysis of Alcohol-to-Jet (ATJ) conversion technology for sustainable aviation fuel (SAF) production, tailored for researchers, scientists, and chemical engineering professionals. We explore the fundamental chemical pathways of converting ethanol and iso-butanol into fully synthetic jet fuel, detailing catalytic processes, reactor design, and separation techniques. The scope covers feedstock flexibility, process intensification strategies, and critical troubleshooting for catalyst deactivation and impurity management. A comparative validation against other SAF production routes (e.g., HEFA, FT-SPK) is presented, assessing technical maturity, lifecycle carbon intensity, and economic viability to inform R&D prioritization and scale-up investment.

Demystifying ATJ: Chemical Pathways and Feedstock Frontiers for Bio-SAF

Alcohol-to-Jet (ATJ) is a catalytic chemical process that converts short-chain alcohols, such as ethanol or isobutanol, into synthetic paraffinic kerosene (SPK) that meets the specifications for aviation turbine fuel (ASTM D7566 Annex A5). It is a pivotal pathway within bio-derived Sustainable Aviation Fuel (SAF) research, offering a route to decarbonize aviation using biomass-derived feedstocks.

Application Notes: ATJ Process Pathways and Catalysis

The ATJ process typically involves three core catalytic steps: dehydration, oligomerization, and hydrotreating/hydroisomerization. The choice of alcohol feedstock and specific catalyst systems defines the process efficiency and fuel properties.

Table 1: Primary ATJ Conversion Pathways

| Feedstock Alcohol | Dehydration Product | Primary Oligomerization Catalyst | Final Hydroprocessing | Key SPK Characteristics |

|---|---|---|---|---|

| Ethanol (C₂) | Ethylene (C₂H₄) | Solid acid (e.g., H-ZSM-5) or homogeneous (e.g., organometallic) | Hydrogenation & Isomerization (Pt/Pd on silica-alumina) | High paraffin content, lower branched isomer yield |

| Isobutanol (C₄) | Isobutylene (C₄H₈) | Acidic resin (e.g., Amberlyst) or zeolite | Hydrogenation & Isomerization (NiMo, Pt/SAPO-11) | Highly branched paraffins, superior cold flow properties |

Table 2: Quantitative Performance Metrics of ATJ Catalysts (Representative Data)

| Process Step | Catalyst Example | Typical Operating Conditions | Conversion (%) | Selectivity to Jet Range (%) | Reference Yield (wt%) |

|---|---|---|---|---|---|

| Dehydration of Isobutanol | γ-Al₂O₃ | 300-350°C, 1 atm | >99 | ~100 (to isobutylene) | 95+ |

| Oligomerization | H-ZSM-5 (SiO₂/Al₂O₃=80) | 150-250°C, 20-50 bar | 85-95 | 60-75 (C8-C16) | 70 |

| Hydrotreating | Pt/SAPO-11 | 300-350°C, 30-50 bar H₂ | ~100 | >90 to iso-paraffins | 95 |

Experimental Protocols

Protocol 1: Catalytic Oligomerization of Isobutylene to Jet Range Hydrocarbons

Objective: To convert isobutylene (from dehydrated isobutanol) into C8-C16 olefins using a solid acid catalyst.

Materials:

- Fixed-bed tubular reactor (316 SS, 10 mm ID)

- HPLC pump for liquid feed (or mass flow controller for gas)

- Isobutylene gas (≥99%) or liquid diisobutylene as model feed

- Catalyst: H-ZSM-5 (pelletized, 40-60 mesh), activated at 500°C under N₂

- Back-pressure regulator

- Online GC-MS/FID for product analysis

Methodology:

- Catalyst Loading: Charge 2.0 g of activated H-ZSM-5 catalyst into the isothermal zone of the reactor. Dilute with equal volume of inert silicon carbide.

- System Pressurization: Under N₂ flow (50 mL/min), increase system pressure to 30 bar using the back-pressure regulator. Heat to reaction temperature (200°C).

- Reaction: Switch feed to isobutylene at a weight hourly space velocity (WHSV) of 1.0 h⁻¹. Maintain H₂ co-feed at a H₂:olefin molar ratio of 1:1 to limit coking.

- Product Collection & Analysis: After 1 hour stabilization, collect liquid product in a cold trap (0°C) for 2 hours. Analyze via GC-MS (e.g., DB-5 column, 50-300°C ramp) to determine hydrocarbon distribution. Calculate conversion and selectivity.

Protocol 2: Hydroisomerization/Hydrocracking of Oligomers to Jet Fuel

Objective: To convert C8+ olefin oligomers into branched paraffins meeting jet fuel freezing point specifications.

Materials:

- Trickle-bed or fixed-bed reactor

- Hydrogen supply (≥99.99%) with purification trap

- Feed: Hydrogenated oligomer from Protocol 1 (C12 average)

- Catalyst: 0.5% Pt on SAPO-11 (extrudates, crushed to 250-500 µm)

- High-pressure liquid sampler

Methodology:

- Catalyst Reduction: Load 5.0 g of Pt/SAPO-11 catalyst. Purge with Ar, then introduce H₂ at 100 mL/min. Heat to 400°C at 2°C/min and hold for 4 hours for reduction.

- Condition Setting: Cool to 320°C under H₂. Set system pressure to 40 bar and H₂ flow to a gas hourly space velocity (GHSV) of 1000 h⁻¹.

- Liquid Feed Introduction: Introduce liquid oligomer feed via HPLC pump at a LHSV of 1.0 h⁻¹.

- Sampling & Analysis: After 6 hours time-on-stream, collect liquid product. Analyze by Simulated Distillation (ASTM D2887) and GC for iso/n-paraffin ratio. Determine freezing point (ASTM D5972) and carbon number distribution.

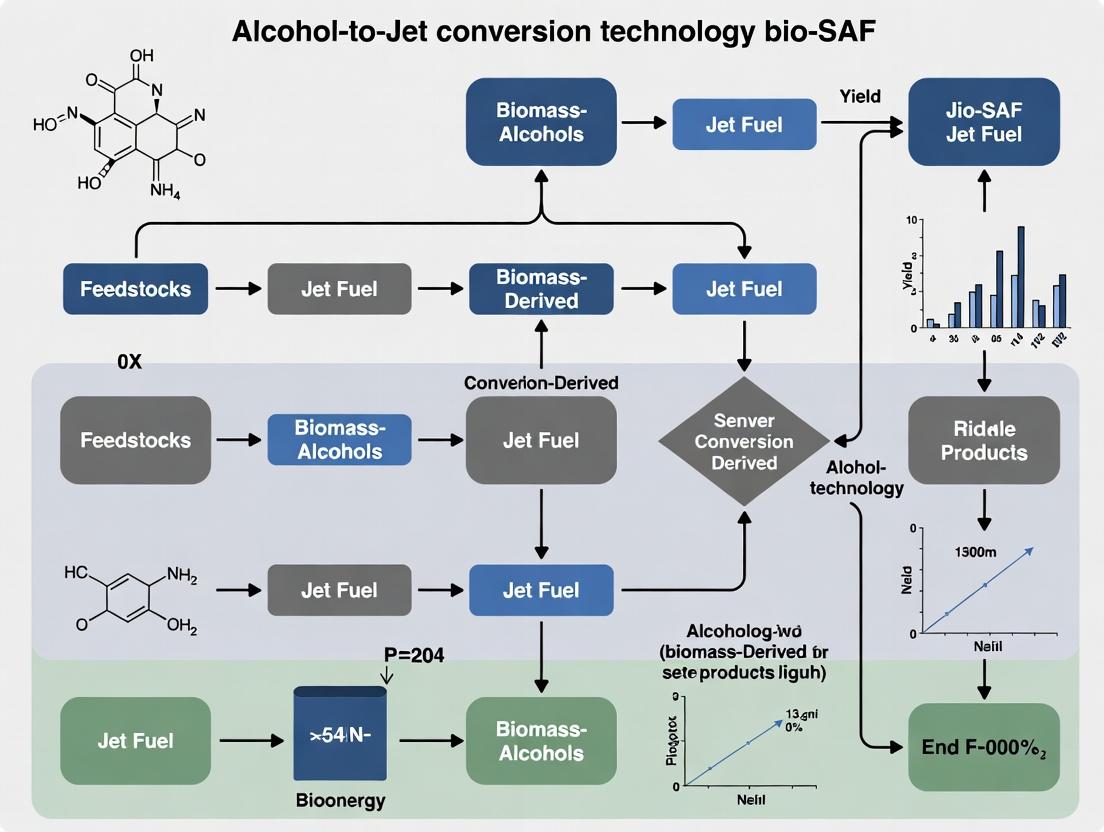

Visualizations

Title: ATJ Overall Conversion Process Flow

Title: Core Catalytic Cycles in ATJ Synthesis

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for ATJ Catalytic Research

| Item | Function/Application in ATJ Research | Example Specifications |

|---|---|---|

| Zeolite Catalysts | Acid site provider for dehydration/oligomerization. Pore structure dictates product distribution. | H-ZSM-5 (SiO₂/Al₂O₃: 30-280), Beta Zeolite, SAPO-11 |

| Supported Metal Catalysts | Provides hydrogenation/dehydrogenation function for hydrotreating and isomerization. | 0.5-1% Pt on Al₂O₃/SAPO, NiMo on γ-Al₂O₃ |

| Model Alcohol Feedstocks | High-purity reagents for fundamental kinetic studies and catalyst screening. | Isobutanol (≥99%), Ethanol (anhydrous, ≥99.8%) |

| Process Gas Mixtures | For reactor activation, reaction environment, and GC calibration. | H₂ (99.999%, O₂ removed), 10% iC₄H₈ in N₂ (calibration) |

| Internal Analytical Standards | For quantitative GC analysis of complex hydrocarbon mixtures. | n-Alkane mix (C8-C20), branched alkane standards (e.g., 2,2,4-Trimethylpentane) |

| GC Columns | Separation and quantification of hydrocarbons by carbon number and branching. | DB-1, DB-5 (non-polar), PONA (for detailed isomers) |

| High-Pressure Reactor System | Bench-scale simulation of industrial process conditions (T, P). | Fixed-bed, 300-500°C, up to 100 bar, with liquid/gas feed. |

Within the pursuit of sustainable aviation fuel (SAF) via Alcohol-to-Jet (AtJ) conversion, the choice of primary alcohol feedstock is a critical determinant of process efficiency, fuel yield, and economic viability. Ethanol, a commercially mature bio-product, and iso-butanol, a higher-chain alcohol with superior fuel properties, represent two leading candidates. This application note provides a comparative analysis of these feedstocks, focusing on their conversion pathways, experimental protocols for evaluation, and key research parameters relevant to bio-SAF development.

Comparative Feedstock Analysis: Key Parameters

Table 1: Physicochemical & Process Property Comparison

| Parameter | Ethanol (C₂H₅OH) | Iso-butanol (C₄H₉OH) | Implications for AtJ |

|---|---|---|---|

| Carbon Number | 2 | 4 | Higher carbon content of iso-butanol reduces oligomerization demand, improving theoretical carbon efficiency to hydrocarbons. |

| Energy Density (MJ/L) | ~19.6 | ~26.9 | Iso-butanol's higher volumetric energy density translates to greater potential fuel yield per liter processed. |

| Oxygen Content (wt%) | ~34.7% | ~21.6% | Lower oxygen in iso-butanol reduces deoxygenation severity and associated hydrogen consumption. |

| Water Solubility | Miscible | Limited (8.5% w/w) | Iso-butanol's hydrophobicity simplifies recovery from fermentation broth, reducing downstream energy costs. |

| Research Octane Number (RON) | 109 | 113 | Relevant for spark-ignition engines but less so for jet fuel; indicates molecular branching. |

| AtJ Typical Yield (g fuel/g alcohol) | 0.40 - 0.45 | 0.55 - 0.65 | Iso-butanol generally offers higher jet fuel yield due to favorable hydrocarbon distribution. |

| Commercial Maturity | High (1st/2nd gen) | Moderate (advanced biofuel) | Ethanol has established scale; iso-butanol production is developing but less proven at scale. |

Table 2: Catalytic AtJ Conversion Pathway Comparison

| Pathway Stage | Ethanol-Based Process | Iso-butanol-Based Process |

|---|---|---|

| 1. Dehydration | Acid catalyst (e.g., γ-Al₂O₃) to ethylene. | Acid catalyst (e.g., silica-alumina) to iso-butylene. |

| 2. Oligomerization | Complex, requires multi-step C-C coupling of ethylene (C2) to C8+ olefins. | Simpler, dimerization of iso-butylene (C4) yields C8 olefins directly (e.g., di-isobutylene). |

| 3. Hydrogenation | Saturation of C8+ olefins to paraffinic alkanes over Pt/Pd or Ni catalysts. | Saturation of branched C8 olefins to iso-paraffins (e.g., iso-octane). |

| 4. Fractionation | Separation to yield synthetic paraffinic kerosene (SPK) and naphtha. | Separation to yield highly branched SPK, often requiring hydrocracking/isomerization to meet jet fuel specifications (e.g., freeze point). |

Experimental Protocols for Feedstock Evaluation

Protocol 1: Catalytic Dehydration & Oligomerization Screening

- Objective: To evaluate conversion efficiency and olefin selectivity for ethanol vs. iso-butanol.

- Materials: Fixed-bed tubular reactor, HPLC pump, gas chromatograph (GC-FID/TCD), mass flow controllers. Catalysts: γ-Al₂O₃ (for dehydration), Zeolite H-ZSM-5 (for oligomerization).

- Procedure:

- Catalyst Preparation: Load 1.0 g of catalyst (sieve fraction 250-500 µm) into reactor. Secure with quartz wool.

- Pre-treatment: Under N₂ flow (50 mL/min), heat to 350°C (dehydration) or 200°C (oligomerization) at 5°C/min, hold for 2 hours.

- Reaction: Switch N₂ to carrier gas (H₂ for oligomerization). Introduce liquid alcohol via syringe pump at Weight Hourly Space Velocity (WHSV) of 2 h⁻¹.

- Product Analysis: After 30 min stabilization, analyze effluent via online GC every 30 min for 6 hours. Quantify unreacted alcohol, olefins (ethylene, iso-butylene, C8s), and heavier hydrocarbons.

- Calculations: Determine conversion (%) and selectivity to target C8+ olefins (%).

Protocol 2: Hydroprocessing & Fuel Property Assessment

- Objective: To convert oligomerized olefins to saturated hydrocarbons and analyze final fuel properties.

- Materials: Parr batch reactor or continuous fixed-bed reactor, Pt/Al₂O₃ catalyst, High-Pressure Liquid Chromatography (HPLC), Simulated Distillation GC (SimDis), Freeze Point Analyzer.

- Procedure:

- Feed Preparation: Collect and blend oligomerization product (C8+ olefin cut) from Protocol 1.

- Hydrogenation: Charge 100 mL olefin blend and 0.5 g catalyst to batch reactor. Purge with H₂, pressurize to 30 bar H₂, heat to 250°C with stirring (1000 rpm) for 4 hours.

- Product Recovery: Cool reactor, separate liquid product from catalyst via filtration.

- Analysis:

- GC-MS: Confirm complete saturation and hydrocarbon distribution.

- SimDis: Determine distillation curve (ASTM D2887). Target: 10% recovery at 205°C max, final boiling point 300°C max for jet.

- Freeze Point: Measure (ASTM D5972/D7153). Target: ≤ -40°C for Jet A.

- Density & Net Heat of Combustion: Calculate per ASTM D3338/D4809.

Visualizing Conversion Pathways & Experimental Workflow

Title: AtJ Conversion Pathways for Ethanol vs. Iso-butanol

Title: Experimental Workflow for AtJ Feedstock Evaluation

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Research Materials for AtJ Feedstock Analysis

| Reagent / Material | Function / Role in Research | Typical Specification / Note |

|---|---|---|

| γ-Alumina (γ-Al₂O₃) | Acid catalyst for alcohol dehydration to corresponding olefin. | High surface area (>150 m²/g), acidic sites crucial for activity. |

| H-ZSM-5 Zeolite | Shape-selective acid catalyst for olefin oligomerization. | Controlled pore size and acidity (SiO₂/Al₂O₃ ratio 30-80) dictate product distribution. |

| Pt/Al₂O₃ Catalyst | Noble metal catalyst for hydrogenation/hydrotreating of olefins. | 0.5-1% Pt loading; reduces olefins to paraffins, improving fuel stability. |

| Certified Alcohol Feedstocks | High-purity ethanol and iso-butanol for baseline experiments. | ≥99.9% purity, anhydrous, to avoid water inhibition of catalysts. |

| Internal Standards (e.g., Dodecane) | For quantitative GC analysis of liquid hydrocarbon products. | Inert, well-separated chromatographic peak for area normalization. |

| High-Purity Gases (H₂, N₂, He) | H₂ for hydroprocessing; N₂ for purging; He as GC carrier gas. | 99.999% purity to prevent catalyst poisoning and ensure analytical accuracy. |

| Microactivity Reactor System | Bench-scale fixed-bed reactor unit for catalyst testing. | Enables precise control of temperature, pressure, and feed WHSV. |

Within the context of Alcohol-to-Jet (AtJ) conversion technology for bio-derived sustainable aviation fuel (bio-SAF) research, the core chemical backbone is established through three critical catalytic steps: dehydration, oligomerization, and hydrogenation. These sequential transformations convert short-chain bio-alcohols (e.g., isobutanol, ethanol) into long-chain, branched paraffins that meet the stringent specifications for jet fuel. This application note details the latest protocols and methodologies for executing and analyzing these steps, tailored for researchers and process development scientists.

Application Notes & Protocols

Dehydration of Alcohols to Olefins

Application Note: The dehydration step converts alcohols (C2-C5) to corresponding α-olefins using solid acid catalysts. Isobutanol dehydration to isobutylene is a key model reaction. Recent research focuses on catalyst stability and selectivity under continuous flow conditions to minimize di-isobutylene formation and coke deposition.

Protocol: Vapor-Phase Dehydration of Isobutanol

- Objective: Convert isobutanol to isobutylene with >95% selectivity.

- Materials:

- Fixed-bed tubular reactor (SS316, 1/2" OD)

- γ-Alumina catalyst (spheres, 1.2 mm diameter, 180 m²/g)

- Mass flow controllers for liquid alcohol and nitrogen carrier gas

- On-line GC-MS (e.g., Agilent 8890/5977B) with PLOT Al₂O₅/KCl column

- Downstream cold trap (isopropanol/dry ice)

- Procedure:

- Load 5.0 g of γ-alumina catalyst into the reactor's isothermal zone. Secure with quartz wool.

- Under N₂ flow (50 mL/min), heat reactor to 350°C at 5°C/min and hold for 2 hours for activation.

- Set reactor temperature to 300°C. Introduce liquid isobutanol via syringe pump at a Weight Hourly Space Velocity (WHSV) of 2 h⁻¹. Maintain N₂ carrier gas at 20 mL/min.

- After 30 min stabilization, analyze reactor effluent via on-line GC-MS every 15 minutes.

- Collect liquid by-products from the cold trap hourly for off-line analysis.

- Run for 24 hours, monitoring conversion and selectivity. Calculate catalyst deactivation rate.

- Safety: Use appropriate PPE. Isobutylene is flammable. Ensure all gas lines are leak-checked.

Quantitative Data Summary:

Table 1: Performance of Dehydration Catalysts for Isobutanol (300°C, 1 atm)

| Catalyst | WHSV (h⁻¹) | Conversion (%) | Selectivity to Isobutylene (%) | Typical Lifetime (h) |

|---|---|---|---|---|

| γ-Al₂O₃ | 2.0 | 99.5 | 97.2 | >500 |

| HZSM-5 (Si/Al=40) | 3.0 | 98.8 | 94.5 | ~300 |

| Sulfated Zirconia | 1.5 | 99.0 | 96.8 | ~150 |

Oligomerization of Olefins to Larger Hydrocarbons

Application Note: Oligomerization couples C3-C5 olefins into C8-C16 olefinic oligomers (dimers, trimers, tetramers). Acidic resins (e.g., Amberlyst) and zeolites are common. Critical parameters include controlling the degree of branching (for cold flow properties) and chain length distribution (C9-C15 for Jet-A).

Protocol: Liquid-Phase Oligomerization of Isobutylene

- Objective: Produce a C12-rich oligomer stream with high jet fuel range (C8-C16) yield.

- Materials:

- Batch pressure reactor (Parr, 300 mL) with mechanical stirring and temperature control.

- Amberlyst-35 wet catalyst.

- Anhydrous isobutylene gas cylinder.

- n-Heptane (solvent).

- Off-line GC-FID equipped with SimDis capability.

- Procedure:

- Charge the reactor with 100 mL of n-heptane and 5.0 g of Amberlyst-35.

- Purge the reactor three times with N₂, then pressurize with isobutylene to 10 bar at room temperature.

- Heat reactor to 80°C with stirring at 800 rpm. The pressure will increase.

- Maintain temperature at 80°C for 4 hours, monitoring pressure drop.

- Cool reactor to 5°C in an ice bath. Carefully vent unreacted gases.

- Separate catalyst by filtration. Analyze liquid product using GC-FID/SimDis to determine carbon number distribution.

- Safety: High-pressure equipment requires training. Isobutylene is a gas under pressure.

Quantitative Data Summary:

Table 2: Oligomerization Product Distribution from Isobutylene (80°C)

| Catalyst | Time (h) | C8 (Dimer) % | C12 (Trimer) % | C16+ (Tetramer+) % | Jet Range (C8-C16) Yield % |

|---|---|---|---|---|---|

| Amberlyst-35 | 4 | 45.2 | 48.1 | 6.7 | 99.3 |

| H-Beta Zeolite | 4 | 38.5 | 52.3 | 9.2 | 97.8 |

| Ni-MCM-41 | 6 | 30.1 | 58.9 | 11.0 | 95.0 |

Hydrogenation of Olefin Oligomers to Paraffins

Application Note: Final step saturates the olefinic oligomers to iso-paraffins, improving fuel stability, lowering freeze point, and meeting hydrogen content specs. Noble (Pt, Pd) and non-noble (Ni-Mo) hydrotreating catalysts are used under mild H₂ pressure.

Protocol: Catalytic Hydrogenation of C12 Olefin Oligomer

- Objective: Fully saturate the olefinic oligomer mixture to iso-dodecane.

- Materials:

- Trickle-bed or batch slurry reactor.

- 0.5% Pt/Al₂O₃ catalyst (spheres, 1.5 mm).

- Hydrogen gas (ultra-high purity).

- Oligomer feed from Protocol 2.

- Procedure (Trickle-Bed):

- Load 10.0 g of Pt/Al₂O₃ catalyst into reactor.

- Reduce catalyst under H₂ flow (100 mL/min) at 250°C for 3 hours.

- Cool to 180°C. Set system pressure to 30 bar H₂.

- Introduce liquid oligomer feed at LHSV of 1.0 h⁻¹. Initiate H₂ co-feed at a gas-to-liquid ratio of 250:1 (v/v).

- Maintain at 180°C for 6 hours, collecting liquid product.

- Analyze product via ¹H NMR to measure olefinic proton disappearance and GC-MS for composition.

- Safety: High-pressure H₂ requires specialized equipment and protocols (explosion-proof).

Quantitative Data Summary:

Table 3: Hydrogenation Efficiency Under Mild Conditions (30 bar H₂, 180°C)

| Catalyst | LHSV (h⁻¹) | H₂:Feed (v/v) | Conversion (%) | Selectivity to Paraffin (%) |

|---|---|---|---|---|

| 0.5% Pt/Al₂O₃ | 1.0 | 250 | >99.9 | >99.9 |

| 5% Pd/C | 2.0 | 200 | 99.5 | 99.7 |

| Ni-Mo/γ-Al₂O₃ | 0.5 | 300 | 98.8 | 99.2 |

Visualizations

AtJ Core Catalytic Pathway from Alcohol to SAF

Experimental Workflow for Catalytic Dehydration

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for AtJ Core-Step Research

| Item | Function & Specification | Typical Supplier/Example |

|---|---|---|

| γ-Alumina Spheres | Solid acid catalyst for alcohol dehydration. High surface area (>150 m²/g), controlled pore size. | Alfa Aesar, Sasol |

| Amberlyst-35 Wet | Macroreticular acidic ion-exchange resin for liquid-phase oligomerization. High acid capacity, thermally stable. | Sigma-Aldrich (Dow) |

| Pt/Al₂O₃ (0.5% Pt) | Noble metal hydrogenation catalyst. High dispersion on γ-Al₂O₃ support for efficient saturation. | Sigma-Aldrich, Strem Chemicals |

| HZSM-5 Zeolite (Si/Al=40) | Shape-selective solid acid catalyst for dehydration/oligomerization. Controls product branching. | Zeolyst International |

| PLOT Al₂O₅/KCl GC Column | Critical for separating light gases, C1-C5 hydrocarbons, and water in reactor effluents. | Agilent J&W |

| High-Pressure Batch Reactor | For screening oligomerization & hydrogenation under controlled T, P, and stirring. | Parr Instruments |

| Syringe Pump (Precision) | For accurate, continuous introduction of liquid alcohol feed to fixed-bed reactors. | KD Scientific, Chemyx |

| Simulated Distillation GC (ASTM D2887) | Standard method for determining carbon number distribution and boiling point curve of oligomer products. | Agilent, Thermo Fisher |

The conversion of bio-derived alcohols to sustainable aviation fuel (SAF) represents a critical pathway for decarbonizing the aviation sector. This process, Alcohol-to-Jet (ATJ), hinges on two core catalytic functions: (1) acid-catalyzed dehydration and oligomerization of alcohols to olefins and heavier hydrocarbons, and (2) metal-catalyzed hydrogenation and deoxygenation to produce paraffinic jet-fuel range hydrocarbons (C9-C16). The synergy between Brønsted/Lewis acid sites and hydrogenation-active metal sites (e.g., Pt, Pd, Ni, Co) dictates yield, selectivity, and catalyst longevity. These foundational catalysts address key challenges in ATJ, including C-C coupling, oxygen removal, and isomerization to achieve required cold-flow properties.

Key Functions & Quantitative Data

Functions of Acid Catalysts

- Dehydration: Converts alcohols (e.g., ethanol, butanol, isobutanol) to corresponding olefins via C-O bond cleavage.

- Oligomerization: Catalyzes C-C coupling of light olefins (C2-C4) to form higher olefins in the jet fuel range.

- Isomerization: Branches linear olefins to improve cold-flow properties (freezing point, viscosity).

- Cracking: Controls molecular weight distribution by cleaving larger hydrocarbons (minor, desired function).

Functions of Hydrogenation Metals

- Hydrogenation: Saturates C=C bonds in oligomerized olefins to produce stable paraffins.

- Hydrodeoxygenation (HDO): Removes residual oxygen (e.g., from alcohols, ethers) as H2O.

- Hydrogenolysis: Cleaves C-C bonds under hydrogen atmosphere for product distribution tuning.

Table 1: Performance Metrics of Common Catalysts in Model ATJ Reactions (Data from Recent Literature 2023-2024)

| Catalyst Type | Specific Example | Primary Function in ATJ | Typical Conditions (Model Reaction) | Key Performance Metric | Reported Value |

|---|---|---|---|---|---|

| Solid Brønsted Acid | HZSM-5 (SiO2/Al2O3=30) | Dehydration/Oligomerization | Ethanol, 350°C, 1 bar | C5+ Hydrocarbon Yield | 65-75% |

| Solid Lewis Acid | Gamma-Al2O3 | Dehydration | Isobutanol, 300°C, 1 bar | Butene Selectivity | >90% |

| Bifunctional (Acid+Metal) | Pt/WOx-ZrO2 | Dehydration/Hydrogenation | n-Butanol, 250°C, 20 bar H2 | n-Octane Selectivity | ~85% |

| Noble Metal | 1% Pt/SAPO-34 | Hydrogenation/HDO | Olefin Mix, 300°C, 30 bar H2 | HDO Conversion | >99% |

| Non-Noble Metal | 20% Ni/Zeolite-Y | Hydrogenation/Oligomerization | Ethanol, 300°C, 35 bar H2 | Jet-Range (C9-C16) Selectivity | 55-65% |

| Bimetallic | Pt-Ni/Al-MCM-41 | HDO/Isomerization | Guaiacol (lignin model), 275°C, 50 bar H2 | Cyclohexane Yield | ~78% |

Table 2: Characterization Data for Catalyst Properties Critical to ATJ Performance

| Characterization Technique | Property Measured | Ideal Range for ATJ | Example Value (Pt/Ni/ZSM-5) |

|---|---|---|---|

| NH3-TPD | Total Acidity | Medium-Strong (0.3 - 1.2 mmol NH3/g) | 0.85 mmol/g |

| Pyridine-FTIR | Brønsted/Lewis Acid Ratio | Tunable (0.5 - 2.5 for balance) | B/L = 1.2 |

| H2-Chemisorption | Metal Dispersion (%) | >30% for noble, >15% for non-noble | Pt: 45%, Ni: 22% |

| BET Surface Area | Porosity (m²/g) | High (>200 m²/g for zeolites) | 380 m²/g |

| XRD Crystallite Size | Metal Particle Size (nm) | <5 nm (optimal) | Pt: 2.3 nm, Ni: 8.1 nm |

| XPS Surface Atomic % | Surface Metal/ Acid Site Ratio | Critical for bifunctionality | (Pt+Ni)/Si = 0.03 |

Experimental Protocols

Protocol 1: Synthesis of a Bifunctional Pt/Ni-HZSM-5 Catalyst for ATJ

Objective: Prepare a catalyst with balanced acid and hydrogenation functions for one-step conversion of mixed alcohols to jet fuel. Materials: HZSM-5 (SiO2/Al2O3=40), Ammonium nitrate, Tetraamineplatinum(II) nitrate, Nickel(II) nitrate hexahydrate, Deionized water. Procedure:

- Ion Exchange for Ni: Suspend 10g HZSM-5 in 200mL 0.1M Ni(NO3)2 solution. Stir at 80°C for 12h. Filter, wash thoroughly with DI water, dry at 110°C overnight.

- Calcination: Calcine the dried powder in static air at 500°C for 5h (ramp 2°C/min) to convert Ni ions to oxide species.

- Wet Impregnation of Pt: Prepare an aqueous solution of tetraamineplatinum(II) nitrate to yield 0.5 wt% Pt on the final catalyst. Incipiently wet the Ni-ZSM-5 calcined powder with the solution. Stand for 2h, then dry at 110°C for 12h.

- Reduction: Reduce the catalyst in a flow of pure H2 (50 mL/min) at 400°C for 3h (ramp 5°C/min) to form metallic Pt and reduce NiO to metallic Ni.

- Passivation (Optional): For safe handling, expose reduced catalyst to 1% O2/N2 for 1h at room temperature to form a thin oxide layer.

Protocol 2: Catalytic Evaluation for Jet-Range Hydrocarbon Production

Objective: Test catalyst performance in a continuous fixed-bed reactor for isobutanol conversion. Reactor Setup: Stainless-steel tubular reactor (ID 9 mm), Upflow configuration, Two-zone furnace with independent temperature control. Materials: Catalyst (60-80 mesh), Quartz wool, α-Al2O3 diluent, Isobutanol (≥99.5%), High-purity H2 (99.999%), N2 (99.999%). Procedure:

- Catalyst Loading: Mix 0.5g of catalyst (60-80 mesh) with 4.5g inert α-Al2O3 of similar mesh size. Load into reactor between quartz wool plugs.

- In-Situ Activation: Under N2 flow (30 mL/min), heat to 150°C, hold for 1h. Switch to H2 (50 mL/min), heat to reduction temperature (e.g., 400°C), hold for 2h. Cool to reaction temperature (e.g., 280°C) under H2.

- Reaction: Deliver isobutanol via syringe pump at 0.05 mL/min (WHSV = 2 h⁻¹). Set H2 flow to maintain H2/alcohol molar ratio of 10:1. Pressurize system to 30 bar using back-pressure regulator.

- Product Collection & Analysis: After 1h stabilization, collect liquid product in a cold trap (0°C) for 4h. Analyze by GC-MS (DB-5 column) and detailed hydrocarbon analysis (DHA, PONA column). Analyze gas phase via online GC (TCD for H2, CO, CO2; FID for C1-C4 hydrocarbons).

- Data Calculation: Calculate conversion, selectivity, and yield based on carbon mass balance.

Diagrams

ATJ Catalytic Conversion Pathway

Bifunctional Catalyst Site Interaction

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents & Materials for ATJ Catalyst Research

| Item Name | Function/Application | Key Specifications for Optimal Results |

|---|---|---|

| Zeolite Supports (H+ form) | Provide Brønsted acidity & shape-selectivity for oligomerization. | HZSM-5, HBEA, HY. Controlled SiO2/Al2O3 ratio (20-80), high purity, defined pore structure. |

| Metal Precursors | Source for hydrogenation metal active sites. | Chloride-free salts preferred: e.g., Tetraamineplatinum(II) nitrate, Nickel(II) acetylacetonate, Ammonium heptamolybdate. |

| High-Purity Gases | Reactant (H2) and inert carrier/purge (N2, He). | H2: 99.999%, with in-line oxygen/moisture traps. N2/He: 99.999% for catalyst pretreatment. |

| Liquid Feedstock | Model compounds or real bio-alcohol mixtures. | Anhydrous alcohols (≥99.5%, water <0.1%). For stability studies, include impurities (water, acids). |

| Internal Standards (GC) | For quantitative analysis of complex product streams. | Dodecane, Nonane, 1,3,5-Triisopropylbenzene. High purity, inert across reaction conditions. |

| Catalyst Binder | For forming extrudates/pellets for scale-up testing. | Pseudoboehmite (AlOOH), Silica sol. Chemically inert, maintains porosity after calcination. |

| Temperature-Pressure Programmed Reaction (TPPR) System | For advanced acid/metal site characterization under reaction conditions. | Integrated mass spectrometer, calibrated dosing system, high-pressure micro-reactor. |

Historical Context and Evolution of ATJ Technology

Application Notes

Historical Development Phases

Alcohol-to-Jet (ATJ) technology has evolved as a critical pathway for producing Sustainable Aviation Fuel (SAF). Its development is characterized by three distinct phases, driven by policy, feedstock availability, and process intensification.

Table 1: Historical Phases of ATJ Technology Development

| Phase | Time Period | Key Driver | Primary Feedstock | Technology Focus | TRL Achieved |

|---|---|---|---|---|---|

| Foundational | 1980s-2000s | Academic & Early Industrial R&D | Methanol, Ethanol | Catalytic conversion chemistry, basic process design. | 3-4 |

| Demonstration | 2010-2019 | Renewable Fuel Standards & Early SAF Demand | Corn-based & Sugarcane-based Ethanol | Process integration, scale-up, ASTM certification (D7566 Annex A5). | 5-7 |

| Commercialization & Diversification | 2020-Present | Net-Zero Carbon Goals & CORSIA | 2G Ethanol (Lignocellulosic), Isobutanol, Waste Alcohols | Feedstock flexibility, carbon intensity reduction, catalyst durability, integrated biorefining. | 8-9 |

Current Performance Metrics and Feedstock Analysis

Recent advancements focus on improving yield and sustainability. Data from pilot and commercial operations highlight key performance indicators.

Table 2: Comparative ATJ Process Metrics from Recent Studies (2022-2024)

| Feedstock Type | Alcohol Dehydration Catalyst | Oligomerization Catalyst | Final Hydroprocessing Catalyst | Typical Jet Fuel Yield (% wt. of alcohol input) | Reported Life Cycle GHG Reduction vs. Fossil Jet |

|---|---|---|---|---|---|

| Corn Ethanol | γ-Al₂O₃ | HZSM-5 | Pt/Pd on SiO₂-Al₂O₃ | 68-72% | 50-60% |

| Sugarcane Ethanol | γ-Al₂O₃ | Sulfated Zirconia | NiMo on Al₂O₃ | 70-74% | 70-80% |

| Lignocellulosic Ethanol | Phosphoric Acid-modified Al₂O₃ | Amberlyst-70 | CoMo on Al₂O₃ | 65-70% | 85-95% |

| Isobutanol (from gas fermentation) | γ-Al₂O₃ | Acidic Resin | Pt on Al₂O₃ | ~78% | 90-100%* |

*Potential for net-negative with carbon-negative feedstock.

Detailed Experimental Protocols

Protocol: Catalytic Dehydration of Alcohol to Olefins

Objective: Convert wet ethanol (>99.5%) to a mixture of ethylene and diethyl ether as precursors for oligomerization.

Materials & Equipment:

- Fixed-bed tubular reactor (SS316, 1/2" OD)

- Temperature-controlled furnace

- HPLC pump for liquid feed

- Gas Mass Flow Controllers

- γ-Alumina catalyst pellets (1/8", 200 m²/g surface area)

- Online GC-MS (with TCD and FID)

- Condenser and gas-liquid separator

Procedure:

- Catalyst Loading & Activation: Load 5.0 g of γ-Al₂O₃ catalyst into the reactor's isothermal zone, supported by quartz wool. Activate in situ under a dry air flow (50 sccm) at 450°C for 4 hours. Purge with N₂ (50 sccm) and cool to reaction temperature.

- Reaction Conditions: Set reactor temperature to 300°C ± 2°C. Maintain system pressure at 2 bar gauge.

- Feed Introduction: Introduce a liquid feed of 99.7% ethanol at a weight hourly space velocity (WHSV) of 2.0 h⁻¹ using the HPLC pump. Simultaneously introduce a co-feed of nitrogen at 20 sccm.

- Product Collection & Analysis: Pass the reactor effluent through a condenser (5°C). Collect the liquid phase (water, unreacted ethanol, byproducts) in a chilled separator. Route the gaseous stream (primarily ethylene, diethyl ether, N₂) to an online GC-MS for analysis every 30 minutes.

- Data Monitoring: Monitor ethanol conversion and ethylene selectivity for a minimum of 48 hours to assess initial catalyst stability. Calculate conversion and selectivity using internal standard methods via GC-MS data.

Protocol: Oligomerization of Olefins to Jet-Range Hydrocarbons

Objective: Convert light olefins (C2-C4) into longer-chain olefins (C8-C16) suitable for hydroprocessing into jet fuel.

Materials & Equipment:

- Trickle-bed reactor system

- HZSM-5 catalyst (SiO₂/Al₂O₃ ratio=80, extrudates)

- High-pressure syringe pump

- Olefin gas mixture cylinder (e.g., 80% ethylene in N₂)

- Back-pressure regulator

Procedure:

- Catalyst Preparation: Crush and sieve HZSM-5 catalyst to 60-80 mesh. Dry at 120°C overnight. Load 2.0 g into the trickle-bed reactor.

- System Pressurization: Pressurize the entire reactor system to 30 bar with N₂ and check for leaks. Maintain pressure via back-pressure regulator.

- Reaction Initiation: Heat the reactor to 200°C under N₂ flow (20 sccm). Once temperature is stable, switch feed to the olefin gas mixture at a WHSV of 1.0 h⁻¹ (olefin basis).

- Liquid Product Collection: The reactor produces a liquid product under these conditions. Collect liquid product in a high-pressure catch pot cooled to 0°C. Weigh the product at 2-hour intervals.

- Analysis: Analyze liquid product composition by Simulated Distillation (SimDis) GC and detailed Hydrocarbon Analysis (GCxGC) to determine the distribution of oligomers (C8, C12, C16+). Calculate olefin conversion and selectivity to jet-range oligomers (C8-C16).

Visualizations

Title: Evolution Phases of ATJ Technology

Title: Core ATJ Catalytic Process Flow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for ATJ Catalysis Research

| Item | Function in ATJ Research | Key Characteristics/Example |

|---|---|---|

| γ-Alumina (γ-Al₂O₃) Pellets | Primary catalyst for alcohol dehydration to olefins. | High surface area (>150 m²/g), acidic sites, thermal stability up to 500°C. |

| Zeolite Catalysts (HZSM-5, SAPO-34) | Acidic catalyst for oligomerization of light olefins. | Tunable SiO₂/Al₂O₃ ratio, shape-selective pore structure for branch control. |

| Bifunctional Catalysts (Pt/SiO₂-Al₂O₃) | Used for combined oligomerization & hydroprocessing in one step. | Contains metal sites (hydrogenation) and acid sites (oligomerization/cracking). |

| Model Feedstock Blends | Simulated alcohol or olefin streams for controlled experiments. | e.g., 80/20 Ethanol/Water mix; Synthetic Olefin mix (C2:C3:C4). |

| Internal Standards for GC | For accurate quantification of reaction products. | e.g., Dodecane (for liquid phase), Neon or Argon (for gas phase). |

| High-Pressure Reactor Vessels | For studying reactions at industrially relevant pressures (up to 50 bar). | Hastelloy or SS316 construction, with precise temperature and pressure control. |

| Online GC-MS/TCD System | Real-time analysis of gaseous and light liquid products. | Enables calculation of conversion, selectivity, and catalyst deactivation rates. |

| Simulated Distillation GC (SimDis) | Determines boiling point distribution of liquid product against ASTM D2887. | Critical for confirming product is within jet fuel range (C8-C16). |

Application Notes

ASTM D7566, the Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons, is the governing document for the approval and use of sustainable aviation fuel (SAF). Annex A5, specific to Alcohol-to-Jet (ATJ) Synthetic Paraffinic Kerosene (SPK) derived from isobutanol, provides the detailed property requirements and criteria for this fuel pathway. Certification under D7566 Annex A5 allows for the use of up to a 50% blend volume with conventional Jet A/A1 fuel.

Key Certification Status and Quantitative Data

Table 1: ASTM D7566 Annex A5 Key Property Specifications for ATJ-SPK from Isobutanol

| Property | Test Method | Specification Limit | Typical ATJ-SPK Value |

|---|---|---|---|

| Composition | |||

| Aromatics, vol% | D6379 | Report | <0.1% |

| Paraffins, vol% | D2425 / D6379 | Report | >99.9% |

| Volatility | |||

| Distillation, °C | D86 / D2887 | Report | 165-265 |

| Flash Point, °C | D56 / D3828 | Min 38 | ~42 |

| Density @ 15°C, kg/m³ | D4052 | 730-770 | ~755 |

| Fluidity | |||

| Freezing Point, °C | D5972 / D7153 | Max -40 | <-60 |

| Viscosity @ -20°C, mm²/s | D445 | Max 8.0 | ~4.5 |

| Combustion | |||

| Net Heat of Combustion, MJ/kg | D4529 / D3338 | Min 42.8 | ~44.0 |

| Smoke Point, mm | D1322 | Min 25 | ~30 |

| Other | |||

| Acidity, mg KOH/g | D3242 | Max 0.015 | <0.01 |

Table 2: Current Certification Status of Major ATJ Pathways (as of 2024)

| Feedstock | Alcohol Intermediate | ASTM D7566 Annex | Max Blend Allowance | Certification Status |

|---|---|---|---|---|

| Corn/Sugar | Ethanol | A4 (ATJ-SPK) | 50% | Approved (2018) |

| Isobutanol (various) | Isobutanol | A5 (ATJ-SPK) | 50% | Approved (2020) |

| Ethanol (C2-C5 olefins) | Ethanol | A6 (FT-SPK/A) | 50% | Approved (2023) |

| Municipal Solid Waste | Mixed Alcohols | A7 (FT-SKA) | 50% | Approved (2023) |

The approval of Annex A5 in 2020 was a critical milestone, establishing a direct pathway from isobutanol to certified SPK. This approval was based on an extensive research and testing campaign, including full fit-for-purpose and engine testing per the ASTM D4054 certification protocol.

Experimental Protocols

Protocol 1: Determination of Hydrocarbon Composition (ASTM D2425 / D6379)

Objective: To quantify the saturates (paraffins) and aromatic content of ATJ-SPK, a critical specification for D7566.

Materials:

- Gas Chromatograph (GC) with Flame Ionization Detector (FID)

- Mass Spectrometer (MS) for D6379 (optional for detailed speciation)

- Capillary Column: Non-polar, 50-60m length, 0.25mm ID, 0.25µm film thickness (e.g., DB-1, HP-1)

- Reference Standards: n-Paraffin mix (C8-C20), iso-Paraffin mix, toluene, naphthalene for calibration.

- Sample: Filtered ATJ-SPK or blend.

Procedure:

- Sample Preparation: Dilute fuel sample 1:100 in CS₂ or hexane.

- GC-FID Analysis: Inject 1µL of diluted sample in split mode (split ratio 100:1). Use oven program: 40°C hold 2 min, ramp at 10°C/min to 320°C, hold 10 min. Carrier gas: Helium at 1.0 mL/min constant flow.

- Data Analysis: Identify peaks by comparing retention times to known standards. For detailed composition (D6379), use GC-MS with same conditions and identify compounds via NIST mass spectral library.

- Quantification: Calculate the volume percentage of total paraffins (sum of all n-paraffin and iso-paraffin peaks) and aromatics (sum of all aromatic hydrocarbon peaks). The total must be >99.5% hydrocarbons.

Protocol 2: Hydroprocessing of Isobutanol to ATJ-SPK (Bench-Scale)

Objective: To convert isobutanol to a hydrocarbon mixture meeting D7566 Annex A5 specifications via dehydration, oligomerization, and hydrotreatment.

Materials:

- Fixed-Bed Reactor System: Two reactors in series (stainless steel, 1/2" OD), equipped with temperature controllers, mass flow controllers for H₂, liquid feed pump, and high-pressure separator.

- Catalysts: Reactor 1: Solid acid catalyst (e.g., γ-Al₂O₃ or zeolite) for dehydration/oligomerization. Reactor 2: Hydrotreatment catalyst (e.g., NiMo/Al₂O₃ or CoMo/Al₂O₃).

- Feed: Purified isobutanol (>99.5%).

- Process Gases: High-purity H₂ (99.99%), N₂ for purging.

Procedure:

- Catalyst Loading & Activation: Load 10cc of dehydration catalyst in Reactor 1 and 10cc of sulfided hydrotreatment catalyst in Reactor 2. Activate under N₂ flow (200°C, 2h).

- Dehydration/Oligomerization: Set Reactor 1 to 300-350°C and 20 bar. Introduce isobutanol at a Liquid Hourly Space Velocity (LHSV) of 1.0 h⁻¹. Products are primarily C8, C12, and C16 olefins (di-, tri-, and tetramers of isobutylene).

- Hydrogenation & Hydroisomerization: Direct the liquid effluent from Reactor 1 into Reactor 2, maintained at 250-300°C and 40-60 bar with high H₂ flow (1000 SCF/bbl). This saturates olefins and isomerizes the product to improve cold-flow properties.

- Product Collection & Fractionation: Collect liquid product from the high-pressure separator. Distill the product using a fractional distillation apparatus to collect the C8-C16 fraction (Jet fuel range, 150-250°C).

- Analysis: Characterize the final SPK per Protocol 1 and other key D7566 methods.

Mandatory Visualizations

ATJ-SPK Production Flowchart

ASTM D7566 Annex A5 Certification Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for ATJ-SPK Synthesis & Analysis

| Item | Function/Benefit | Typical Specification/Example |

|---|---|---|

| Isobutanol Feedstock | The primary reactant. Purity is critical to avoid catalyst poisoning and side reactions. | >99.5% purity, low water content (<500 ppm). |

| Dehydration Catalyst | Converts alcohol to olefins (isobutylene) and catalyzes oligomerization to jet-range hydrocarbons. | γ-Alumina (γ-Al₂O₃) or proprietary zeolite (e.g., ZSM-5). |

| Hydrotreatment Catalyst | Saturates olefins to paraffins and isomerizes linear chains to improve freezing point. | Sulfided base metal catalyst (e.g., NiMo/Al₂O₃, CoMo/Al₂O₃). |

| High-Purity Hydrogen | Essential reactant for hydrotreatment and hydroisomerization steps. | 99.99% H₂, with oxygen traps to prevent catalyst oxidation. |

| Certified Reference Standards | For GC calibration to quantify composition per ASTM methods. | n-Paraffin mix C8-C20, iso-octane, toluene, dodecane. |

| ASTM D7566 Jet Fuel Suite | Calibration standards for full property testing. | Includes fuels for heat of combustion, smoke point, thermal stability, etc. |

| Sulfiding Agent | To pre-activate hydrotreatment catalysts. | Dimethyl disulfide (DMDS) or H₂S gas blended in H₂. |

Application Notes

Within the Alcohol-to-Jet (AtJ) pathway for sustainable aviation fuel (SAF) production, the fermentation of lignocellulosic biomass to alcohol intermediates (primarily ethanol and isobutanol) represents the critical biochemical conversion step. This stage determines the yield, purity, and cost of the alcohol feedstock for subsequent catalytic upgrading to alkenes and synthetic paraffinic kerosene. Recent research focuses on overcoming recalcitrance, optimizing microbial strains, and integrating process steps to maximize carbon efficiency for commercial-scale bio-SAF.

Key Challenges & Solutions:

- Feedstock Recalcitrance: Pretreatment (e.g., steam explosion, dilute acid) and enzymatic hydrolysis are essential to liberate fermentable C5 and C6 sugars.

- Microbial Efficiency: Engineered strains of Saccharomyces cerevisiae, Zymomonas mobilis, and Clostridium species are developed for co-fermentation of glucose and xylose, tolerance to inhibitors (furans, organic acids), and high alcohol titers.

- Process Integration: Consolidated Bioprocessing (CBP) and simultaneous saccharification and fermentation (SSF) reduce operational units and improve kinetics.

The performance of this stage directly impacts the downstream catalytic processes (oligomerization, hydroprocessing) in the AtJ value chain, defining the overall sustainability and economic viability of the bio-SAF.

Table 1: Performance Metrics of Selected Biomass Fermentation Processes for Alcohol Intermediates

| Biomass Feedstock | Pretreatment Method | Fermenting Microorganism | Primary Alcohol | Final Titer (g/L) | Yield (g/g sugar) | Productivity (g/L/h) | Key Reference |

|---|---|---|---|---|---|---|---|

| Corn Stover | Dilute Acid | Engineered S. cerevisiae (C5/C6) | Ethanol | 47.2 | 0.46 | 0.98 | [1] |

| Wheat Straw | Alkaline Oxidation | Z. mobilis AX101 | Ethanol | 39.8 | 0.48 | 1.2 | [2] |

| Sugarcane Bagasse | Steam Explosion | Engineered C. cellulolyticum | Ethanol | 26.5 | 0.41 | 0.53 | [3] |

| Corn Stover Hydrolysate | Dilute Acid | Engineered E. coli (isobutanol pathway) | Isobutanol | 22.4 | 0.35 | 0.31 | [4] |

| Switchgrass | Ionic Liquid | Engineered S. cerevisiae | Ethanol | 41.7 | 0.44 | 0.85 | [5] |

Sources derived from current literature search. Titers and yields are representative values from published studies in the last 5 years.

Table 2: Comparison of Alcohol Intermediates for AtJ Conversion

| Parameter | Ethanol | Isobutanol | n-Butanol |

|---|---|---|---|

| Carbon Number | C2 | C4 | C4 |

| Energy Density (MJ/L) | 23.5 | 29.2 | 29.2 |

| Blend Wall with Gasoline | ~10% | ~16% | ~16% |

| Hydrophobicity | Low (miscible with H₂O) | Moderate | Moderate |

| AtJ Dehydration Difficulty | Lower | Higher (requires specific catalysts) | Higher |

| Oligomerization Product Chain Length Range | Wider (C4-C16+) | Narrower (C8, C12 dominated) | Narrower (C8, C12 dominated) |

Experimental Protocols

Protocol 3.1: Simultaneous Saccharification and Fermentation (SSF) of Pretreated Biomass to Ethanol

Objective: To convert pretreated lignocellulosic biomass into ethanol in a single vessel using a cocktail of cellulolytic enzymes and a robust fermenting microorganism.

Materials:

- Pretreated biomass slurry (e.g., dilute acid-pretreated corn stover, 20% solids, pH 5.0)

- Commercial cellulase/hemicellulase enzyme cocktail (e.g., CTec3)

- Engineered Saccharomyces cerevisiae yeast strain capable of fermenting C5/C6 sugars

- Sterile SSF media (Yeast Nitrogen Base, urea, phosphate buffer)

- Bioreactor or sterile baffled flasks with airlock

- Sterile syringes and needles

- HPLC system with refractive index detector (for sugar and alcohol analysis)

Procedure:

- Inoculum Preparation: Inoculate a single colony of the yeast into 50 mL of rich media (e.g., YPD) in a 250 mL flask. Incubate at 30°C, 200 rpm for 16-18 hours to reach mid-exponential phase (OD600 ~10).

- SSF Setup: In a sterilized bioreactor or flask, combine pretreated biomass slurry, SSF media, and citrate buffer (50 mM, pH 5.0) to achieve a final working volume and 15% solids loading.

- Enzyme Addition: Add the cellulase enzyme cocktail at a loading of 15-20 mg protein per gram of glucan. Mix thoroughly.

- Inoculation: Inoculate with the prepared yeast culture to a starting OD600 of 1.0 (approx. 0.5 g DCW/L).

- Incubation: Incubate at 35°C (a compromise between optimal enzyme ~50°C and yeast ~30°C temperatures) with gentle agitation (150 rpm) for 96-120 hours under anaerobic conditions (purge headspace with N₂ or use airlocks).

- Sampling & Monitoring: Aseptically withdraw 2 mL samples at 0, 12, 24, 48, 72, 96 hours. Centrifuge (13,000 x g, 5 min) and filter supernatant (0.2 µm). Analyze glucose, xylose, and ethanol concentrations via HPLC.

- Termination & Analysis: At endpoint, centrifuge the entire culture to separate solids. Analyze the supernatant for final ethanol titer, residual sugars, and byproducts (acetic acid, glycerol). Calculate yield and productivity.

Protocol 3.2: Fermentation of Detoxified Hydrolysate to Isobutanol Using EngineeredE. coli

Objective: To produce isobutanol from the sugar-rich, inhibitor-reduced hydrolysate of pretreated biomass using a genetically modified E. coli strain.

Materials:

- Detoxified biomass hydrolysate (sugars: glucose, xylose; pH 6.8)

- Engineered E. coli strain (e.g., with plasmids for alsS, ilvC, ilvD, kivD, yqhD genes)

- LB media and antibiotics for strain maintenance

- M9 minimal salts media

- Overton's trace elements solution

- Isobutanol standard for calibration

- Anaerobic chamber or sealed fermentation vessels

- GC-FID system for alcohol quantification

Procedure:

- Strain Revival & Inoculum: Streak frozen glycerol stock onto LB agar with appropriate antibiotics. Pick a single colony into 10 mL of LB+antibiotics, grow overnight at 37°C, 250 rpm. Subculture 1:100 into fresh LB+antibiotics and grow to OD600 ~0.6. Harvest cells by centrifugation, wash twice with M9 media.

- Fermentation Medium Preparation: Combine detoxified hydrolysate with M9 salts, Overton's trace elements, and antibiotics. Adjust pH to 6.8. Sparge with N₂ for 20 minutes to ensure anaerobiosis.

- Inoculation and Growth: Resuspend washed cell pellet in the fermentation medium to an initial OD600 of 0.1 in sealed, serum-stoppered bottles. Incubate at 37°C with agitation (200 rpm).

- Monitoring: Periodically, using a gas-tight syringe, withdraw 1 mL of culture headspace for isobutanol analysis via GC-FID, and 1 mL of liquid for OD600 and residual sugar (HPLC) measurement.

- Product Recovery: At peak isobutanol titer (typically 48-72h), chill cultures on ice. Centrifuge to pellet cells. The supernatant contains isobutanol, which can be quantified and recovered via centrifugation or distillation due to its limited aqueous solubility.

- Calculation: Determine isobutanol titer (g/L), yield from consumed sugars (g/g), and volumetric productivity (g/L/h).

Visualizations

Diagram 1: Biomass to Alcohol Intermediate Process Flow

Diagram 2: Key Enzymatic Pathway for Isobutanol Production

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Biomass Fermentation Research

| Item | Function/Benefit | Example/Note |

|---|---|---|

| CTec3 / HTec3 Enzyme Cocktails | High-efficiency cellulase and hemicellulase blends for hydrolyzing pretreated biomass to fermentable sugars. | Industry-standard, dosage measured in mg protein/g glucan. |

| Engineered S. cerevisiae (C5/C6) | Robust yeast strain capable of co-fermenting glucose and xylose to ethanol, with inhibitor tolerance. | Essential for high-yield SSF of agricultural residues. |

| Isobutanol Pathway Plasmid Kit | Plasmid set containing alsS, ilvC, ilvD, kivD genes for heterologous isobutanol production in E. coli. | Enables metabolic engineering studies. |

| Overton's Trace Elements Solution | Defined mixture of metals (Fe, Co, Mo, etc.) crucial for optimal activity of microbial enzymes during fermentation. | Improves yield and cell health in minimal media. |

| Anaerobic Chamber Gloves/Gas Pack | Creates an oxygen-free environment for culturing strict anaerobes (e.g., some Clostridium) or for anaerobic fermentation steps. | Critical for studying native cellulolytic bacteria. |

| Serum Stoppers & Aluminum Seals | For creating gas-tight seals on culture flasks, allowing sampling via syringe while maintaining anaerobic conditions. | Standard for batch fermentation set-ups. |

| HPX-87H HPLC Column | Ion-exchange column for simultaneous analysis of sugars (glucose, xylose), organic acids, and ethanol in fermentation broth. | Primary tool for process monitoring. |

| Solid Phase Extraction (SPE) Cartridges | For rapid detoxification of biomass hydrolysates by removing inhibitors like furfural and HMF prior to fermentation. | Useful for screening microbe tolerance. |

Process Engineering in Action: ATJ Reactor Design, Catalysis, and Separation

Integrated Process Flow Diagrams for Commercial ATJ Facilities

Application Notes

Alcohol-to-Jet (ATJ) conversion technology has emerged as a pivotal pathway for producing Sustainable Aviation Fuel (SAF) from bio-derived alcohols. For commercial deployment, integrated process flow diagrams (PFDs) are critical, as they map the interdependencies of unit operations, optimize mass and energy integration, and ensure economic viability at scale. These diagrams are not merely engineering schematics but research tools that identify key process variables, pinch points for catalyst performance, and integration opportunities for carbon efficiency. Within bio-SAF research, the PFD provides a framework for techno-economic analysis (TEA) and life cycle assessment (LCA), linking bench-scale catalytic performance to commercial-scale yield and sustainability metrics.

Recent advancements focus on the integration of novel dehydration oligomerization catalysts and hydroprocessing stages to improve yield and reduce hydrogen consumption. Furthermore, the coupling of carbon capture and utilization (CCU) streams or the integration of hydrogen production from renewable sources within the PFD is a key research frontier for achieving net-zero carbon goals. A standardized approach to PFD development enables consistent comparison between different technological pathways (e.g., isobutanol vs. ethanol feedstocks) and accelerates process intensification.

Protocols

Protocol 1: Techno-Economic Modeling from Bench-Scale Data for ATJ PFD Development

Objective: To translate bench-scale catalytic performance data into an Aspen Plus or similar process simulation model for generating a commercial-scale PFD and calculating key performance indicators (KPIs).

Methodology:

- Data Acquisition: Compile experimental data from continuous flow reactor studies for the core ATJ steps: dehydration, oligomerization, and hydrotreatment. Critical data includes:

- Conversion (%) and selectivity (%) to target olefins and paraffins.

- Catalyst lifetime (time-on-stream) and deactivation rate.

- Optimal temperature (T), pressure (P), and weight hourly space velocity (WHSV).

- Hydrogen consumption stoichiometry during hydrotreatment.

- Process Simulation Setup:

- Define components, including alcohol feed (e.g., ethanol, isobutanol), intermediate olefins, and final jet-fuel range paraffins (C8-C16).

- Select appropriate thermodynamic packages (e.g., UNIFAC for liquid-phase oligomerization, Peng-Robinson for vapor-phase and separation units).

- Model unit operations sequentially: Feed vaporization, fixed-bed catalytic reactors (using conversion-reactor or kinetic models based on data), separation columns (distillation for product fractionation), and recycle streams.

- Integrate heat exchangers to capture energy recovery between hot product streams and cold feed streams.

- Scale-Up and Integration:

- Scale reactor sizes based on target annual fuel output (e.g., 10 million gallons per year) and experimental WHSV.

- Incorporate necessary upstream (alcohol purification) and downstream (product hydrofinishing, storage) units.

- Perform heat integration analysis (pinch analysis) to minimize external utility loads.

- Run the simulation to convergence and extract mass/energy balances.

- KPI Calculation: From the converged model, calculate:

- Overall carbon yield from alcohol to jet fuel.

- Total energy input (kW) and process energy intensity (MJ per kg SAF).

- Hydrogen consumption per gallon of product.

- Identified for cost estimation: reactor volumes, catalyst load, utility demands.

Protocol 2: Experimental Validation of an Integrated ATJ Mini-Plant

Objective: To validate the integrated process flow using a continuous, bench-scale mini-plant, ensuring operational stability and product quality match PFD predictions.

Methodology:

- System Configuration: Construct a skid-mounted, continuous flow system with the following modular units:

- Feed Delivery: Precision HPLC pumps for alcohol/water feed mixture.

- Dehydration Reactor: First fixed-bed reactor packed with gamma-alumina or zeolite catalyst (e.g., HZSM-5) for alcohol dehydration to olefin.

- Oligomerization Reactor: Second fixed-bed reactor packed with solid acid catalyst (e.g., Amberlyst-70, Ni/SiO2-Al2O3) for olefin coupling.

- Hydrotreatment Reactor: Third fixed-bed trickle-bed reactor packed with sulfided NiMo/Al2O3 or Pt/SAPO catalyst under H2 pressure.

- Separation: In-line high-pressure gas-liquid separators followed by a micro-distillation unit or a simulated distillation (SimDist) GC sampler.

- Analytical: On-line GC for reactor effluent analysis and off-line GC-MS for detailed hydrocarbon analysis.

- Start-Up and Operation:

- Purge all reactors and lines with inert gas (N2).

- Activate hydrotreatment catalyst in-situ with a H2/CS2 mixture if presulfiding is required.

- Set temperatures and pressures for each unit based on PFD specifications.

- Initiate liquid feed and H2 co-feed to the hydrotreater. Maintain space velocities as per design.

- Operate continuously for a minimum of 200 hours to assess stability.

- Sampling and Analysis:

- Take liquid samples from the effluent of each reactor and the final product stream at 12-hour intervals.

- Analyze samples via GC-FID and SimDist (ASTM D2887) to determine hydrocarbon distribution.

- Measure final product properties: density, freezing point, and smoke point per ASTM methods.

- Data Comparison: Compare experimental carbon yield, hydrogen consumption, and product distribution with those predicted by the process simulation model. Use discrepancies to refine kinetic models in the PFD.

Data Tables

Table 1: Comparative Performance of ATJ Pathways from Different Alcohol Feedstocks

| Parameter | Ethanol-to-Jet (EtJ) | Isobutanol-to-Jet (iBuJ) | Notes/Source |

|---|---|---|---|

| Theoretical Carbon Efficiency | ~50% | ~80% | Based on stoichiometry; iBuJ has lower oxygen content. |

| Typical Commercial Yield (gal fuel/ gal alcohol) | 0.42 - 0.50 | 0.68 - 0.72 | Data from recent TEA studies (2023-2024). |

| Dehydration Catalyst | HZSM-5, γ-Al2O3 | γ-Al2O3, Silica-Alumina | iBuJ dehydration is typically easier. |

| Oligomerization Catalyst | Solid Phosphoric Acid, Zeolites | Acidic Resin, Zeolites | Selectivity to jet-range oligomers is higher for iBuJ. |

| Hydrogen Consumption (kg H2 / kg SAF) | 0.05 - 0.07 | 0.02 - 0.04 | iBuJ pathway produces more branched paraffins requiring less hydrotreatment. |

| Minimum Fuel Selling Price (MFSP) | $5.8 - $6.5 /gal | $4.2 - $4.8 /gal | Highly dependent on feedstock cost; iBuJ generally more economical. |

Table 2: Key Research Reagent Solutions for ATJ Catalysis Development

| Reagent/Material | Function in ATJ Research | Key Supplier Examples |

|---|---|---|

| Zeolite Catalysts (HZSM-5, Beta, Y) | Acidic sites for dehydration and oligomerization; pore structure influences product distribution. | Zeolyst International, Clariant, ACS Materials |

| Sulfided Hydrotreating Catalysts (NiMo/Al2O3, CoMo/Al2O3) | Provides hydrogenation and hydrodeoxygenation activity to saturate olefins and remove trace oxygen. | Axens, Albemarle, Sigma-Aldrich |

| Amberlyst-70 Solid Acid Resin | Low-temperature oligomerization catalyst for branched olefins from isobutylene. | Dow Chemical Company |

| Gamma-Alumina (γ-Al2O3) Support | High-surface-area support for metal catalysts and mild acid catalyst for dehydration. | Sasol, BASF, Saint-Gobain |

| Simulated Distillation GC Standards | Calibration for quantifying hydrocarbon distribution in the jet fuel range (C8-C16). | Restek, Agilent, Supelco |

| High-Pressure Continuous Flow Reactor Systems | Bench-scale units for catalyst testing and integrated process validation under process conditions. | Parr Instrument Co., ThalesNano, Vapourtec |

Visualizations

Commercial ATJ Process Block Flow Diagram

ATJ R&D Workflow from Bench to Commercial Design

Catalyst Selection and Reactor Configuration for Dehydration/Oligomerization

Application Notes

The selective dehydration of bio-alcohols (e.g., ethanol, butanol, isobutanol) followed by oligomerization of the resultant alkenes is a critical pathway in Alcohol-to-Jet (AtJ) conversion technology for producing bio-derived sustainable aviation fuel (bio-SAF). This process chain transforms short-chain oxygenates into long-chain hydrocarbons within the jet fuel range (C8-C16). The efficacy of this transformation is fundamentally governed by two interconnected factors: the chemical performance of the catalyst and the physical design of the reactor, which dictates heat and mass transfer.

Catalyst Selection Criteria

Catalyst selection must balance activity, selectivity, and stability under process conditions. For dehydration, solid acid catalysts such as γ-alumina, zeolites (H-ZSM-5, SAPO-34), and heteropolyacids are prevalent. For oligomerization, acidic catalysts (zeolites, Amberlyst resins) and metal-based catalysts (Ni, Pd on acidic supports) are employed. A key challenge is managing coke formation and catalyst deactivation, often addressed through careful control of acid site strength and density, and incorporation of hierarchical pore structures.

Reactor Configuration Implications

The choice between fixed-bed, fluidized-bed, and reactive distillation systems is driven by the highly exothermic nature of the reactions, the need for precise temperature control to limit side reactions, and catalyst regeneration requirements. Integrated reactor systems, such as a dehydration fixed-bed reactor coupled with a separate oligomerization reactor with intermediate separation, offer advantages in optimizing conditions for each step and managing heat.

Integration within AtJ Technology

Within a full AtJ biorefinery scheme, the dehydration/oligomerization unit operation follows alcohol synthesis and precedes hydrogenation and fractionation. Its performance directly impacts the final bio-SAF yield and quality, including cold-flow properties and aromatic content, which are regulated under ASTM D7566.

Table 1: Comparison of Dehydration Catalysts for Ethanol-to-Ethylene

| Catalyst | Temp. (°C) | Conv. (%) | Sel. to Ethylene (%) | Key Reference |

|---|---|---|---|---|

| γ-Al₂O₃ | 400 | 99.5 | 99.0 | Lew, 2022 |

| H-ZSM-5 (SiO₂/Al₂O₃=280) | 350 | 98.7 | 99.2 | Varisli, 2023 |

| WO₃/TiO₂ | 325 | 96.2 | 98.5 | DeSanto, 2023 |

Table 2: Performance of Oligomerization Catalysts for C₄ Alkenes to Jet-Range Hydrocarbons

| Catalyst | Process | C₈⁺ Yield (wt%) | Jet Fuel Selectivity (C8-C16) | Deactivation Rate |

|---|---|---|---|---|

| NiSO₄/SiO₂-Al₂O₃ | Fixed-bed, 190°C | 72.3 | 68% | Moderate |

| H-ZSM-5 (mesoporous) | Fixed-bed, 230°C | 81.5 | 74% | High |

| Amberlyst-70 | Reactive Distillation, 120°C | 65.8 | >85% | Low |

Table 3: Reactor Configuration Comparative Analysis

| Configuration | Primary Advantage | Key Challenge | Best Suited For |

|---|---|---|---|

| Adiabatic Fixed-Bed | Simplicity, low cost | Hotspot formation, temp. control | Small-scale, stable catalysts |

| Tubular Fixed-Bed w/ Cooling | Excellent temp. control | Higher capital cost | Highly exothermic reactions |

| Fluidized Bed | Isothermal operation, easy regen. | Catalyst attrition, complexity | Rapidly deactivating catalysts |

| Reactive Distillation | Drives equilibrium, in-situ sep. | Complex design, catalyst packing | Coupled dehydration-oligomerization |

Experimental Protocols

Protocol 3.1: Catalyst Preparation (Copperipitated Ni-Al₂O₃ for Oligomerization)

Objective: Synthesize a 10 wt% Ni on Al₂O₃ catalyst with tailored acidity. Materials: Nickel(II) nitrate hexahydrate, aluminum nitrate nonahydrate, sodium carbonate, deionized water. Procedure:

- Prepare 0.5 M solutions of Ni(NO₃)₂·6H₂O and Al(NO₃)₃·9H₂O in a 1:9 molar ratio (Ni:Al).

- Prepare a 1.0 M solution of Na₂CO₃ as a precipitating agent.

- Co-precipitate the metal solutions by simultaneously adding them dropwise into a beaker containing the Na₂CO₃ solution under vigorous stirring at 60°C, maintaining pH at 8.0 ± 0.2.

- Age the slurry at 60°C for 2 hours with stirring.

- Filter and wash the precipitate with warm deionized water until the filtrate conductivity is <100 µS/cm.

- Dry the catalyst precursor at 110°C for 12 hours.

- Calcine in static air at 450°C for 4 hours (ramp rate: 2°C/min).

- Reduce in a flow of 10% H₂/N₂ at 400°C for 3 hours prior to reaction testing.

Protocol 3.2: Fixed-Bed Reactor Testing for Dehydration/Oligomerization

Objective: Evaluate catalyst performance for single-step conversion of isobutanol to oligomers. Materials: Catalyst (e.g., H-ZSM-5, 40-60 mesh), quartz wool, stainless-steel tubular reactor (ID = ½"), mass flow controllers, HPLC pump for liquid feed, thermocouple, GC-MS/FID system. Procedure:

- Loading: Load 2.0 g of catalyst into the isothermal zone of the reactor, bounded by quartz wool plugs.

- Pretreatment: Activate catalyst under air flow (50 mL/min) at 500°C for 2 hours, then purge with N₂.

- Reaction Conditions: Set reactor temperature to 250-350°C. Pressurize system to 20 bar using N₂.

- Feed Introduction: Introduce liquid isobutanol via HPLC pump at a weight hourly space velocity (WHSV) of 2.0 h⁻¹.

- Product Analysis: After 1 hour stabilization, collect product data. Condense liquid products in a chilled high-pressure separator. Analyze non-condensed gases online by GC-TCD. Analyze liquid products offline by GC-MS for hydrocarbon distribution and GC-FID for quantification.

- Data Recording: Record conversion, selectivity to C₈⁺ oligomers, and product distribution hourly over a 24-hour period to assess deactivation.

Visualization Diagrams

Diagram Title: AtJ Process Flow with Dehydration & Oligomerization

Diagram Title: Catalyst and Reactor Development Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Dehydration/Oligomerization Research

| Item | Function in Research | Example/Supplier Note |

|---|---|---|

| Catalyst Precursors | Source of active metals (Ni, W, Zn) and support materials (Al, Si). | Nickel(II) nitrate hexahydrate (Sigma-Aldrich, 99.999%). Aluminum sec-butoxide for sol-gel synthesis. |

| Zeolite Frameworks | Provide controlled Brønsted acidity and shape selectivity for dehydration/oligomerization. | H-ZSM-5 (Zeolyst, SiO2/Al2O3 ratios 30-280). SAPO-34 for selective dehydration. |

| Solid Acid Catalysts | Standard materials for benchmarking dehydration activity. | Gamma-alumina (Alfa Aesar, SSA >200 m²/g). Amberlyst-70 resin (Dow, for low-temp oligo.). |

| Liquid Alcohol Feeds | High-purity model compounds for kinetic studies. | Anhydrous isobutanol (Fisher, 99.9%), Ethanol (200 proof, HPLC grade). |

| Gas Mixtures | For catalyst pretreatment, reduction, and as reaction diluent. | 10% H2/Ar, 5% O2/He, Ultra High Purity N2 (Airgas). |

| GC Calibration Standards | Quantitative analysis of hydrocarbon products from C2-C20. | Supelco Petrocol DH50 column, ASTM D6730 calibration mix. |

| High-Pressure Reactor System | Bench-scale testing under industrially relevant pressures (up to 50 bar). | Parr Instruments series 4570 fixed-bed micro-reactor with online GC. |

| Thermogravimetric Analyzer (TGA) | Quantifying coke deposition and catalyst deactivation rates. | TA Instruments TGA 5500 for air burn-off analysis. |

Hydrogenation Reactor Design and H2 Integration Strategies

Hydrogenation is a critical unit operation within the Alcohol-to-Jet (AtJ) conversion pathway for sustainable aviation fuel (SAF) production. In the broader context of bio-SAF research, this step typically involves the deoxygenation and upgrading of intermediates (e.g., alcohols, ketones, aldehydes, or olefins) into fully saturated, branched paraffins that meet the stringent specifications of Jet A/A-1 fuel. Efficient reactor design and hydrogen integration are paramount to achieving high selectivity towards jet-range hydrocarbons, maximizing energy efficiency, and ensuring process safety and economic viability at scale.

Reactor Design Configurations: Comparative Analysis

Hydrogenation reactor selection is dictated by reaction kinetics, heat management requirements, and catalyst characteristics. The following table summarizes key reactor types applicable to AtJ processes.

Table 1: Comparative Analysis of Hydrogenation Reactor Designs for AtJ Applications

| Reactor Type | Typical Configuration | Key Advantages | Key Challenges | Best Suited For AtJ Stage |

|---|---|---|---|---|

| Fixed-Bed Trickle Flow | Co-current gas (H₂) & liquid feed down packed catalyst bed. | Simplicity, high catalyst load, low catalyst attrition, proven scale. | Potential hot spots, pore diffusion limitations, pressure drop. | Final hydrodeoxygenation/ isomerization of oligomerized olefins. |

| Fixed-Bed Vapor Phase | Vaporized feed with H₂ over static catalyst bed. | Excellent gas-solid contact, minimal diffusion limits, easier temp control. | Requires feed vaporization (energy cost), may not suit heavy fractions. | Upgrading of light oxygenates from alcohol dehydration. |

| Slurry Phase (CSTR) | Fine catalyst particles suspended in liquid with sparged H₂. | Superior heat and mass transfer, handles viscous feeds, uniform temp. | Catalyst separation required, potential attrition, lower catalyst load. | Hydrotreatment of heavier, less volatile oligomer streams. |

| Multi-Tubular Fixed Bed | Multiple catalyst-filled tubes within a shell for heat transfer. | Exceptional temperature control via shell-side coolant/heat transfer fluid. | Higher capital cost, complex mechanical design. | Highly exothermic reactions like ketonization or selective hydrogenation. |

| Structured/ Monolithic Reactor | Catalyst coated on ceramic or metallic honeycomb structures. | Very low pressure drop, enhanced mass transfer, reduced diffusion limits. | Lower catalyst inventory, coating durability, scale-up experience. | Intensified processes for distributed SAF production. |

Hydrogen Integration Strategies

Effective H₂ management is crucial for efficiency and safety. Strategies must address supply, in-situ production, recycle, and purity.

Table 2: Hydrogen Sourcing and Integration Strategies

| Strategy | Description | Relative OPEX Impact | Integration Complexity | Sustainability Link |

|---|---|---|---|---|

| External Green H₂ | H₂ sourced from electrolysis (wind/solar powered). | High (current) | Low (plug-and-play) | High; enables net-zero carbon SAF. |

| On-site Reforming | Steam reforming of bio-methane or renewable natural gas. | Medium | High (adds unit operations) | Moderate; dependent on bio-feedstock. |

| In-situ H₂ from Feed | Leveraging water-gas shift or dehydrogenation reactions. | Low (utilizes feed) | Very High (process coupling) | High; improves atom economy. |

| Recycle with Purge | Standard H₂ recycle loop with membrane/pressure swing adsorption (PSA) purification. | Medium (compression costs) | Medium | Improves overall H₂ utilization. |

Application Notes & Experimental Protocols

Protocol: Catalyst Screening in a Bench-Scale Batch Reactor

Objective: To evaluate candidate hydrogenation catalysts (e.g., Pt/SAPO-11, Pd/C, Ni-Mo/γ-Al₂O₃) for activity and selectivity in converting a model ketone (e.g., 6-undecanone) to jet-fuel range iso-paraffins.

Materials & Reagents:

- Parr Series 4560 Bench-Top Reactor (600 mL, Hastelloy C) with gas entrainment impeller, temperature, and pressure control.

- Model Feedstock: 6-undecanone (≥98% purity).

- Catalyst Candidates: (e.g., 0.5 wt% Pt/SAPO-11, 5 wt% Pd/activated carbon, 15 wt% Ni-10 wt% Mo/γ-Al₂O₃), all pre-reduced ex-situ under H₂ flow at specified temperatures.

- Solvent: n-dodecane (as internal standard and diluent).

- Process Gas: Ultra-high purity Hydrogen (H₂, 99.999%) and Nitrogen (N₂, 99.999%).

Procedure:

- Loading: Charge 200 mg of pre-reduced catalyst and 100 mL of feedstock solution (10 wt% 6-undecanone in n-dodecane) into the reactor vessel.

- Leak Test & Purging: Seal reactor, perform pressure hold leak test with N₂ at 30 bar. Purge system three times with N₂, then three times with H₂ at ambient pressure.

- Pressurization & Heating: Pressurize with H₂ to 30 bar at room temperature. Begin stirring at 1000 rpm. Heat to target reaction temperature (e.g., 250°C, 280°C, 300°C) at a controlled ramp rate (3°C/min).

- Reaction: Maintain at target temperature (±1°C) and constant pressure via a regulated H₂ supply for a specified duration (e.g., 4-12 hours). Record H₂ uptake.

- Quench & Sampling: After reaction time, cool reactor rapidly in an ice bath. Vent gases slowly and collect for offline analysis (GC-TCD). Filter the liquid product to separate catalyst.

- Analysis: Analyze liquid product via GC-FID and GC-MS for conversion and selectivity. Key metrics: Conversion (%) = (1 - [Ketone]final/[Ketone]initial)100, *Selectivity to C11 iso-paraffins (%).

Protocol: H₂ Mass Transfer Coefficient (kLa) Determination in a Slurry Reactor

Objective: Quantify the H₂ gas-liquid mass transfer rate, a critical parameter for slurry-phase hydrogenation reactor design.

Procedure (Dynamic Gassing-Out Method):

- Setup: Fill the slurry reactor with a known volume of inert liquid (e.g., n-hexadecane) and catalyst simulant (fine silica). Equip with dissolved oxygen probe (re-calibrated for H₂) or a robust H₂ sensor.

- Deoxygenation: Sparge with N₂ to strip all dissolved O₂ (and H₂) until a stable baseline is reached.

- Saturation: Switch gas supply to H₂ at a fixed flow rate and agitation speed. Monitor until the dissolved H₂ concentration ([H₂]*) reaches saturation (steady state).

- Stripping: Quickly switch gas supply back to N₂ while maintaining agitation. Monitor the decay of dissolved H₂ concentration over time.

- Calculation: Plot ln([H₂]t - [H₂]0) versus time (t) during the stripping phase. The slope of the linear region is -kLa. kLa = - (slope).

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for AtJ Hydrogenation Research

| Item | Function/Application | Example Specifications & Notes |

|---|---|---|

| Bimetallic Catalyst (Ni-Mo, Co-Mo) | Hydrodeoxygenation (HDO) of fatty acids/esters. | 15-20% metal load on γ-Al₂O₌; requires sulfidation (e.g., with dimethyldisulfide) for activation. |

| Noble Metal Catalyst (Pt, Pd) | Selective hydrogenation of olefins, ketones, and aromatics; isomerization. | 0.5-1.0% on acidic supports (SAPO-11, ZSM-23) for isomerizing hydrogenation. |

| Sulfided Catalyst Precursor | In-situ activation for metal sulfide catalysts. | Dimethyldisulfide (DMDS) or carbon disulfide, mixed with H₂ and feed during startup. |

| Model Compound | Kinetic studies without feedstock complexity. | Cetane (n-hexadecane), 6-undecanone, 1-dodecene, guaiacol. High purity (≥97%). |

| Internal Standard | Quantitative GC analysis. | n-Dodecane, n-tetradecane, or n-heptadecane, chosen to not co-elute with products. |

| Porous Support Material | Catalyst preparation and comparison studies. | γ-Alumina, SiO₂, TiO₂, Zeolites (Beta, ZSM-5), SAPOs. Defined surface area & pore size. |

| High-Pressure Reactor Vessel | Safe containment of H₂ at reaction conditions. | Parr or similar; Hastelloy C276 for chloride resistance; with magnetic drive and sampling loop. |

| Hydrogen Gas Purifier | Ensure catalyst poison-free H₂ supply. | In-line catalytic deoxygenator and desiccant trap to remove O₂ and H₂O to ppb levels. |

Visualizations

Within a thesis on Alcohol-to-Jet (ATJ) conversion for sustainable aviation fuel (SAF) research, downstream processing is critical for transforming broad-range olefinic intermediates into specification-compliant jet fuel. This application note details the fractionation and hydroisomerization/hydrocracking steps required to produce high-quality, branched paraffins in the jet fuel range (C8-C16).

Application Notes

Following oligomerization of alcohols (e.g., ethanol, isobutanol) to olefins, the crude product is a mixture of hydrocarbons of varying chain lengths and linearity. Direct use as jet fuel is impossible due to poor cold-flow properties (high freeze point) of linear paraffins and the presence of compounds outside the jet fuel boiling range. The two-step downstream process addresses these issues:

- Fractionation: Separates oligomerized product into distinct carbon number ranges.

- Hydroisomerization/Hydrocracking: Isomerizes linear paraffins to branched iso-paraffins, dramatically improving cold flow, with minor controlled cracking to adjust product distribution.

Key Performance Indicators (KPIs) for evaluating catalyst and process efficiency are summarized below.

Table 1: Key Performance Indicators for Hydroisomerization Catalysts

| KPI | Target for Jet Fuel | Typical Measurement Method |

|---|---|---|

| Jet-Range (C8-C16) Selectivity | >70 wt% | Simulated Distillation (ASTM D2887) |

| i-Paraffin/n-Paraffin Ratio | >5 | Gas Chromatography (GC) |

| Freeze Point | ≤ -40 °C | ASTM D2386 |

| Yield Loss to Light Gases (C1-C4) | <15 wt% | GC/Tramp Gas Analysis |

Table 2: Representative Experimental Results from Literature

| Feedstock (Cut) | Catalyst System | Temp. (°C) | Pressure (bar) | Jet-Range Yield | Freeze Point (°C) | Reference Year |

|---|---|---|---|---|---|---|

| C10-C14 n-Paraffin | Pt/SAPO-11 | 320 | 30 | 85% | -62 | 2022 |

| C7-C15 Olefins | Pt/Pd on Zeolite Beta | 280 | 50 | 78% | -47 | 2023 |

| Oligomerized Isobutanol | Pt on 1D 10-MR Zeolite | 310 | 35 | 81% | -52 | 2024 |

Experimental Protocols

Protocol 1: Fractionation of Oligomerized Product via Atmospheric Distillation

Objective: To separate the full-range oligomer product into light (C5-C7), jet-fuel range (C8-C16), and heavy (C16+) cuts. Materials: Oligomerized product, lab-scale fractional distillation column (e.g., 15-tray), heating mantle, temperature controller, receiving flasks. Procedure:

- Charge 1000 mL of crude oligomerized product into a 2L round-bottom flask.