From Biomass to Blue Skies: Integrated Biorefineries as the Engine for Sustainable Aviation Fuel Production

This article provides a comprehensive analysis of integrated biorefineries for sustainable aviation fuel (SAF) production, tailored for researchers and biotech professionals.

From Biomass to Blue Skies: Integrated Biorefineries as the Engine for Sustainable Aviation Fuel Production

Abstract

This article provides a comprehensive analysis of integrated biorefineries for sustainable aviation fuel (SAF) production, tailored for researchers and biotech professionals. It explores the foundational principles of biorefinery integration, detailing key platform pathways like Hydroprocessed Esters and Fatty Acids (HEFA), Fischer-Tropsch synthesis, and Alcohol-to-Jet (ATJ). The article examines methodological challenges in lignocellulosic biomass processing, pretreatment, and catalyst design, and offers solutions for optimizing yield, cost, and energy efficiency. A comparative validation of SAF against conventional fuels assesses lifecycle emissions, techno-economic viability, and compatibility with existing infrastructure. The synthesis underscores the critical role of integrated biorefining in achieving aviation decarbonization, highlighting future research priorities for scalability and commercial deployment.

The Biorefinery Blueprint: Core Principles and Feedstocks for Aviation Fuel Synthesis

Within a broader thesis on integrated biorefineries for sustainable aviation fuel (SAF) production, this article delineates the integrated biorefinery (IBR) model through detailed application notes and protocols. The IBR is defined as a processing facility that sustainably converts heterogeneous biomass into a spectrum of valuable products—fuels, power, and high-value chemicals—via the integration of multiple conversion technologies, maximizing resource efficiency and enabling a circular bioeconomy.

Application Note 1: Lignocellulosic Biomass Fractionation and Valorization

Objective: To detail a cascading valorization protocol for wheat straw, fractionating it into hemicellulose-derived xylitol, cellulose-rich pulp for enzymatic saccharification, and technical lignin for polymer applications, prior to funneling sugars to SAF precursors.

Quantitative Data Summary (Typical Yield Benchmarks): Table 1: Typical Mass Balance for Wheat Straw Fractionation (Per 1000 kg dry biomass)

| Component | Input Mass (kg) | Process Stream | Output Mass (kg) | Yield (%) | Primary Destination/Use |

|---|---|---|---|---|---|

| Cellulose | 380 | C6 Sugar Stream (Glucose) | 342 | 90% (of initial) | Fermentation to SAF Alcohols |

| Hemicellulose (xylan) | 280 | C5 Sugar Stream (Xylose) | 224 | 80% (of initial) | Catalytic Hydrogenation to Xylitol |

| Lignin | 180 | Technical Lignin | 144 | 80% (of initial) | Phenol-Formaldehyde Resins |

| Ash/Other | 160 | - | - | - | - |

Protocol 1.1: Two-Stage Acid-Catalyzed Organosolv Pretreatment

Materials:

- Wheat straw, milled to 2-mm particle size.

- Aqueous ethanol solution (60% v/v).

- Dilute sulfuric acid (0.1 M).

- Pressure reactor with temperature control.

- Filtration setup.

Methodology:

- Stage 1 (Hemicellulose Removal): Charge reactor with biomass and 60% ethanol containing 0.1 M H₂SO₄ (solid:liquid ratio 1:10 w/v). Heat to 160°C for 60 min with agitation.

- Filtration: Cool mixture and filter. Retain the liquid fraction (hemicellulose-rich hydrolyzate) for downstream xylose recovery and conversion to xylitol.

- Stage 2 (Delignification): Wash the solid residue with fresh 60% ethanol. Resuspend in 60% ethanol (no added acid) at a 1:8 ratio. Heat to 180°C for 90 min.

- Separation: Filter hot. The liquid fraction contains solubilized lignin. Precipitate lignin by adding 3 volumes of cold water, followed by filtration and drying. The solid residue is cellulose-rich pulp.

Protocol 1.2: Enzymatic Hydrolysis of Cellulose-Rich Pulp

Materials:

- Cellulase enzyme cocktail (e.g., CTec3, Novozymes).

- 50 mM sodium citrate buffer, pH 4.8.

- Shaking incubator.

Methodology:

- Adjust the solid loading of the washed pulp to 10% (w/v) in citrate buffer in a sealed flask.

- Add cellulase cocktail at a loading of 20 mg protein per g glucan.

- Incubate at 50°C with agitation (150 rpm) for 72 hours.

- Terminate hydrolysis by heating to 90°C for 10 min. Centrifuge to separate solids (residual lignin) from the C6 sugar-rich hydrolyzate.

Application Note 2: Catalytic Upgrading of Sugars to SAF Intermediates

Objective: To convert C6 sugars (glucose) into alcohol intermediates (e.g., isobutanol) suitable for catalytic upgrading to aliphatic alkanes (SAF range: C8-C16) via biological fermentation.

Protocol 2.1: Fermentation to Isobutanol using Engineered Saccharomyces cerevisiae

Materials:

- Engineered S. cerevisiae strain (e.g., harboring modified Ehrlich pathway).

- Defined fermentation medium (supplemented with C6 sugar hydrolyzate).

- Bioreactor with pH and dissolved oxygen control.

Methodology:

- Inoculum Prep: Grow engineered yeast overnight in rich medium (e.g., YPD). Harvest cells and inoculate into defined medium with 20 g/L glucose to an OD600 of 0.1.

- Fermentation: Scale up to a 2-L bioreactor. Feed with C6 sugar hydrolyzate to maintain sugar concentration below inhibitory levels (<50 g/L). Control pH at 5.5, temperature at 30°C, and maintain microaerobic conditions.

- Monitoring: Sample periodically to monitor sugar consumption and isobutanol production via HPLC.

- Recovery: Terminate fermentation at 96h or upon sugar depletion. Recover isobutanol via gas stripping or distillation.

Quantitative Data Summary (Typical Fermentation Metrics): Table 2: Performance Metrics for Isobutanol Production from C6 Sugars

| Metric | Value | Unit |

|---|---|---|

| Titer | 35-40 | g/L |

| Yield | 0.35-0.38 | g isobutanol / g glucose |

| Productivity | 0.4-0.45 | g/L/h |

| Carbon Efficiency | ~70 | % |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for IBR-SAF Research

| Item | Function/Application |

|---|---|

| CTec3 Cellulase Cocktail | Multi-enzyme blend for high-efficiency hydrolysis of cellulose to glucose. |

| Engineered S. cerevisiae (Isobutanol Pathway) | Robust microbial chassis for fermentative conversion of C5/C6 sugars to advanced alcohol biofuels. |

| Solid Acid Catalyst (e.g., Zeolite Beta) | Catalyzes dehydration, oligomerization, and hydrodeoxygenation reactions for alcohol-to-jet fuel upgrading. |

| Lignin-Depolymerization Catalyst (e.g., Ni/C) | Heterogeneous catalyst for reductive depolymerization of technical lignin into monophenolic compounds. |

| Anaerobic Chamber | Essential for working with strict anaerobic microorganisms used in syngas fermentation or chain elongation processes. |

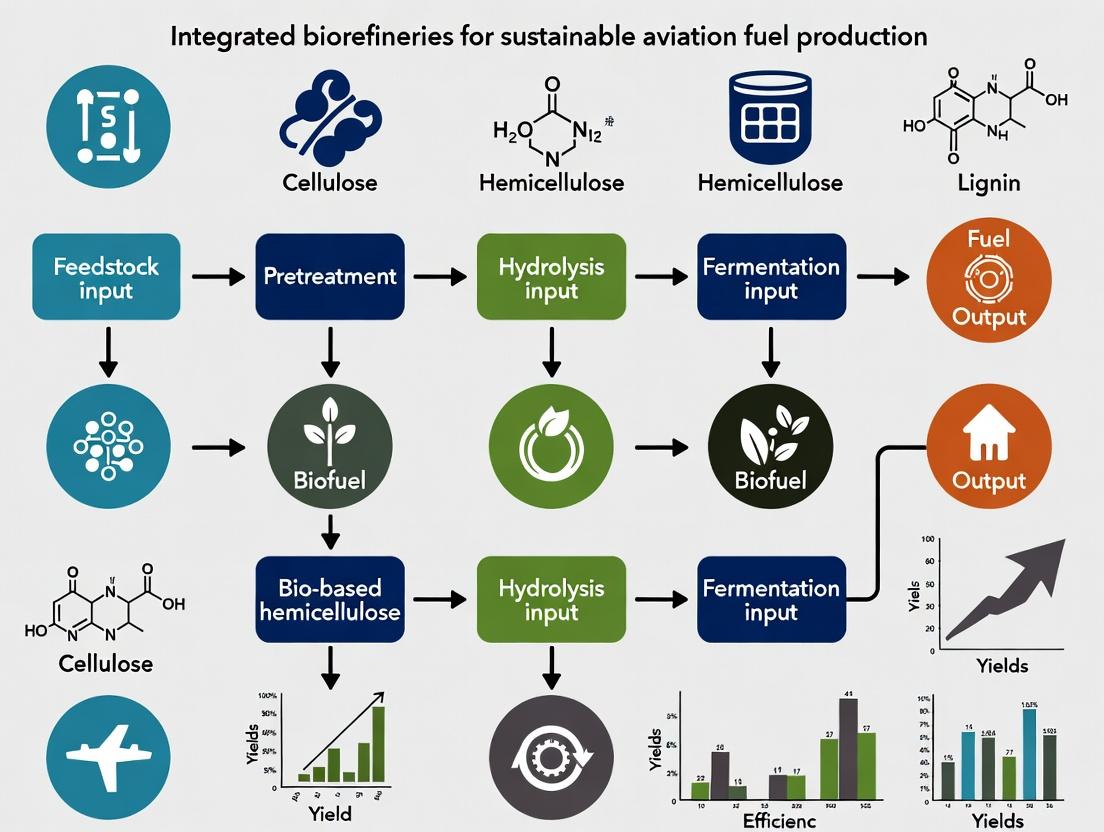

Visualization of Key Concepts and Workflows

Integrated Biorefinery Circular Bioeconomy Concept

Lignocellulose to SAF via Biochemical Route

Engineered Isobutanol Biosynthesis Pathway in Yeast

This document provides detailed application notes and experimental protocols for four leading Sustainable Aviation Fuel (SAF) production pathways: Hydroprocessed Esters and Fatty Acids (HEFA), Fischer-Tropsch (FT), Alcohol-to-Jet (ATJ), and Catalytic Hydrothermolysis (CH). Within the broader thesis on Integrated Biorefineries for Sustainable Aviation Fuel Production Research, these pathways represent core technological platforms for the conversion of diverse biomass feedstocks into hydrocarbon fuels meeting ASTM D7566 specifications. Their integration into a multi-feedstock, multi-process biorefinery model is critical for maximizing yield, optimizing resource use, and improving economic viability.

Table 1: Key SAF Production Pathways - Comparative Metrics

| Pathway | Primary Feedstock | Core Process | Typical Carbon Efficiency | TRL (2024) | ASTM Standard | Key Advantage | Key Challenge |

|---|---|---|---|---|---|---|---|

| HEFA | Triglycerides (Oils, Fats) | Deoxygenation, Hydro-isomerization | 70-85% | 9 (Commercial) | D7566 Annex A2 | Commercial readiness, Simple process | Feedstock competition & cost |

| FT | Syngas (from biomass/gasification) | Catalytic polymerization | 35-50% (Biomass to Liquid) | 8 (First Commercial) | D7566 Annex A1 | Feedstock flexibility (e.g., MSW), High-quality fuel | High capital cost, Complex gas cleaning |

| ATJ | C2-C5 Alcohols (e.g., Ethanol, Isobutanol) | Dehydration, Oligomerization, Hydrogenation | 70-80% (Alcohol to Jet) | 7-8 (Demo/Commercial) | D7566 Annex A5 & A6 | Leverages existing bioethanol infrastructure | Alcohol purity requirements, Yield loss |

| Catalytic Hydrothermolysis (CH) | Triglycerides, Fatty Acids | High-pressure thermal hydrolysis, Hydrotreatment | 75-85% | 7-8 (Demo) | D7566 Annex A4 | Handles high FFA feedstocks (e.g., algae, tall oil) | High-pressure operation, Catalyst stability |

Table 2: Representative Product Distribution & Fuel Properties

| Parameter | HEFA-SPK | FT-SPK | ATJ-SPK (Isobutanol) | CH-SPK (CHJ) |

|---|---|---|---|---|

| Aromatics (% vol) | <0.5% | 0% | 0% (Synthetic) | 8-20% (Inherent) |

| Naphtha Co-Product | 5-15% | 10-25% | Minimal | 10-20% |

| Freeze Point (°C) | < -47 | < -60 | < -60 | < -40 |

| Energy Density (MJ/kg) | ~44 | ~44 | ~44 | ~44 |

| Blend Limit (with Jet A) | Up to 50% | Up to 50% | Up to 50% | Up to 50% |

Experimental Protocols & Detailed Methodologies

Protocol 3.1: HEFA Hydroprocessing Bench-Scale Experiment

Objective: Convert refined soybean oil to HEFA-SPK (Synthetic Paraffinic Kerosene). Materials: Fixed-bed tubular reactor (Hastelloy, 300mm L x 25mm ID), back-pressure regulator, HPLC pumps, H₂ mass flow controller, thermocouple, PID controller. Reagents: Refined soybean oil (food-grade), Sulfided NiMo/Al₂O₃ catalyst (1.5mm extrudates), Di-methyl disulfide (sulfiding agent), Hydrogen (99.99%), Nitrogen (99.99%). Procedure:

- Catalyst Loading & Activation: Load 50cc catalyst into reactor center, flanked by quartz wool. Purge system with N₂ at 200 sccm for 1 hour. Heat to 320°C under N₂ (2°C/min). Switch to 5% H₂S/H₂ mix at 30 bar, hold for 4 hours to sulfide catalyst. Cool to 150°C under H₂.

- Reaction: Set reactor to target conditions: 350-400°C, 40-80 bar H₂ pressure, LHSV 1.0 h⁻¹, H₂/Oil ratio 1000 Nl/l. Feed pre-heated oil (100°C) via HPLC pump. Allow 24 hours to reach steady-state.

- Product Collection & Separation: Collect liquid effluent in a high-pressure separator cooled to 5°C. Separate aqueous (light) and organic (heavy) phases. Degas organic phase and fractionate via simulated distillation (ASTM D2887) to isolate C9-C16 fraction (SPK).

- Analysis: Analyze SPK for composition (GC-MS), freeze point (ASTM D5972), density (ASTM D4052), and hydrogen content via elemental analysis.

Protocol 3.2: Biomass-to-Jet via FT Synthesis (Microreactor Screening)

Objective: Evaluate cobalt-based catalyst performance for Fischer-Tropsch Synthesis (FTS) to produce long-chain hydrocarbons. Materials: Stainless-steel micro-reactor (10mm ID), online micro-GC, gas blending system, mass flow controllers, condensers, hot trap (150°C), cold trap (0°C). Reagents: Co/Re/γ-Al₂O₃ catalyst (100-150 µm sieve fraction), Syngas mix (H₂/CO/Ar = 60/30/10), Calibration gas standards for H₂, CO, CO₂, CH₄, C2-C6. Procedure:

- Catalyst Reduction: Load 500mg catalyst diluted with SiC. Heat to 350°C (5°C/min) under H₂ at 20 bar, 50 sccm for 16 hours.

- FTS Reaction: Cool to 220°C, switch to syngas feed at 20 bar, GHSV 4000 h⁻¹. Maintain for 72+ hours. Condensable products collected in sequential hot/cold traps. Non-condensables analyzed online via micro-GC every 30 min.

- Product Workup: Weigh liquid (wax/oil) and aqueous products from traps daily. Combine and analyze via comprehensive GC×GC for hydrocarbon distribution.

- Data Processing: Calculate CO conversion, C5+ selectivity, and chain growth probability (α) using Anderson-Schulz-Flory distribution model from GC data.

Protocol 3.3: Alcohol-to-Jet (ATJ) from Isobutanol: Three-Step Conversion

Objective: Convert bio-derived isobutanol to ATJ-SPK via dehydration, oligomerization, and hydrogenation. Step A – Dehydration to Isobutylene: Feed >99.5% isobutanol over γ-alumina catalyst (250-300°C, 1-5 bar, LHSV 2 h⁻¹). Collect gaseous product, dry over molecular sieve. Confirm >95% isobutylene yield via GC-FID. Step B – Oligomerization: React dried isobutylene over acidic resin catalyst (e.g., Amberlyst-70) in a packed-bed reactor at 70-90°C, 20 bar. Control residence time to target C8 (dimer) and C12 (trimer) olefins. Recycle lighter fractions. Step C – Hydrogenation: Hydrogenate oligomerized liquid over Pd/Al₂O₃ catalyst at 180-220°C, 30-60 bar H₂, LHSV 1.5 h⁻¹. Product is a mixture of branched paraffins (iso-paraffins). Distill to recover C9-C16 cut as ATJ-SPK. Key Analysis: Measure olefin content pre-hydrogenation (ASTM D1159) and final SPK aromatics via supercritical fluid chromatography (ASTM D8474).

Protocol 3.4: Catalytic Hydrothermolysis (CH) Continuous Flow Test

Objective: Convert high-acid lipid feedstocks (e.g., crude algae oil) to hydrocarbons. Materials: High-pressure continuous stirred tank or plug flow reactor (Titanium or Hastelloy), preheater, high-pressure slurry pump, water HPLC pump, high-pressure liquid-gas separator. Reagents: Crude algae oil (FFA ~20%), Water (deionized), Homogeneous catalyst (e.g., K₂CO₃, 1-5 wt%), Hydrogen, Pd/C catalyst (for downstream hydrotreatment). Procedure:

- Reaction Mixture Preparation: Create an emulsion of algae oil, water (10-30% wt), and catalyst. Homogenize at 5000 rpm for 5 minutes.

- CH Reaction: Feed emulsion via slurry pump to reactor set at 400-450°C, 200-250 bar. Maintain residence time of 15-30 minutes. Effluent passes through a series of separators to remove gases (CO₂, light HCs) and aqueous phase.

- Hydrotreatment: The separated organic bio-crude phase is pumped to a fixed-bed hydrotreater (NiMo, 350°C, 100 bar) for deoxygenation and stabilization. Final product is fractionated to yield CH-SPK (CHJ).

Visualizations: Process Pathways & Workflows

Diagram 1: HEFA Process Block Flow

Diagram 2: Biomass-to-Jet FT Pathway

Diagram 3: ATJ Three-Step Conversion Workflow

Diagram 4: Catalytic Hydrothermolysis Process

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Research Materials & Reagents for SAF Pathway Experiments

| Item / Reagent | Primary Function / Application | Key Characteristics & Notes |

|---|---|---|

| Sulfided NiMo/Al₂O₃ Catalyst | Hydrodeoxygenation (HEFA, CH hydrotreatment) | Pre-sulfided form for immediate activity. Deoxygenates triglycerides/FFAs to n-paraffins. |

| Co/Re/γ-Al₂O₃ Catalyst | Fischer-Tropsch Synthesis | Cobalt active for long-chain paraffins. Rhenium promoter enhances reducibility & activity. |

| γ-Alumina (Acidic) | Dehydration in ATJ pathway | Converts alcohols (ethanol, isobutanol) to corresponding olefins. Requires thermal stability. |

| Amberlyst-70 (Solid Acid Resin) | Oligomerization in ATJ | Acidic catalyst for olefin dimerization/trimerization. Stable at moderate temperatures (<120°C). |

| Pd/Al₂O₃ Catalyst | Hydrogenation (ATJ, finishing) | Selectively hydrogenates olefins to paraffins. Critical for meeting jet fuel specifications. |

| Potassium Carbonate (K₂CO₃) | Homogeneous catalyst for CH | Promotes hydrolysis & reactions in aqueous phase. Must be recovered or neutralized. |

| Model Compound Feeds | Process mechanism studies | Methyl Oleate (HEFA), Syngas Calibration Mix (FT), Isobutanol >99.5% (ATJ). |

| High-Pressure Syngas Mix | FT microreactor studies | Certified H₂/CO/CO₂/Ar/N₂ blends at specific ratios. Requires high-pressure cylinders & regulators. |

| Certified Hydrocarbon Standards | GC-MS/FID calibration | For quantifying paraffins, iso-paraffins, olefins, aromatics in final SPK products. |

| Porous Silica-Alumina (e.g., Siralox) | Isomerization catalyst testing | Provides mild acidity for branching n-paraffins to improve freeze point of HEFA/FT-SPK. |

Application Notes: Feedstock Characterization & Pre-Treatment

The viability of an integrated biorefinery for Sustainable Aviation Fuel (SAF) production hinges on the efficient conversion of diverse, non-food feedstocks. Each feedstock class presents unique biochemical challenges that necessitate tailored pre-treatment and conversion protocols to maximize yield of intermediates suitable for hydroprocessing into SAF.

Table 1: Key Characteristics of Primary SAF Feedstocks

| Feedstock Category | Example Sources | Avg. Lipid/Carbohydrate Content | Key Pre-Treatment Challenge | Target SAF Intermediate |

|---|---|---|---|---|

| Lignocellulosic Biomass | Corn stover, switchgrass, miscanthus | 60-75% carbohydrates (cellulose/hemicellulose), 15-25% lignin | Recalcitrance; lignin barrier to hydrolysis | Fermentable C5/C6 sugars for Alcohol-to-Jet (ATJ) |

| Waste Oils & Fats | Used cooking oil (UCO), animal tallow, grease trap waste | >95% triglycerides, Free Fatty Acids (FFAs) | Heterogeneity; high FFA content deactivates base catalysts | Hydroprocessed Esters and Fatty Acids (HEFA) |

| Oil-Rich Microalgae | Nannochloropsis sp., Chlorella vulgaris | 20-50% triglycerides (strain & condition dependent) | Energy-intensive dewatering; robust cell walls | HEFA feedstock; potential for co-product extraction |

Table 2: Comparative Pre-Treatment Efficiency Data (Recent Bench-Scale Studies)

| Pre-Treatment Method (Feedstock) | Conditions | Sugar/Lipid Recovery Yield | Energy Input (MJ/kg feedstock) | Inhibitor Formation (e.g., furfural, HMF) |

|---|---|---|---|---|

| Dilute Acid Hydrolysis (Switchgrass) | 1% H₂SO₄, 160°C, 10 min | 85% hemicellulose sugars | 2.8 | High (requires detoxification) |

| Steam Explosion (Wheat straw) | 1.5 MPa, 200°C, 5 min | 75% cellulose accessible | 3.1 | Moderate |

| Enzymatic Saccharification (AFEX-pretreated biomass) | Cellulase cocktail, 50°C, 72h | >90% glucan conversion | 0.5 (enzyme production) | Negligible |

| In-situ Transesterification (Wet algae, 80% moisture) | H₂SO₄/MeOH, 90°C, 2h | >95% direct FAME yield | 4.5* | N/A |

| Two-Stage FFA/TAG Processing (High-FFA UCO) | 1. Esterification (H₂SO₄/MeOH), 2. Base Transesterification | >98% FAME yield | 1.2 | N/A |

*Includes dewatering energy.

Experimental Protocols

Protocol 2.1: Two-Stage Saccharification of Lignocellulosic Biomass for C5/C6 Sugar Recovery

Objective: To hydrolyze cellulose and hemicellulose from pre-treated biomass into monomeric sugars for subsequent fermentation to ATJ alcohols (e.g., isobutanol, ethanol).

Materials:

- Pre-treated lignocellulosic biomass (e.g., steam-exploded corn stover), milled to ≤2 mm.

- Commercial cellulase enzyme cocktail (e.g., Cellic CTec3).

- Hemicellulase enzyme supplement.

- Sodium citrate buffer (50 mM, pH 4.8).

- Sterile deionized water.

- Shaking incubator or bioreactor with temperature control.

- HPLC system with refractive index (RI) detector and suitable column (e.g., Bio-Rad Aminex HPX-87H).

Procedure:

- Slurry Preparation: In a sterile flask or bioreactor, prepare a 10% (w/v) solids loading of pre-treated biomass in sodium citrate buffer.

- Hemicellulose Hydrolysis: Adjust pH to 4.8 using NaOH or HCl. Add hemicellulase at 10 mg protein/g biomass. Incubate at 50°C with mild agitation (150 rpm) for 24 hours.

- Cellulose Hydrolysis: Add cellulase cocktail at a loading of 20 mg protein/g cellulose (theoretical). Maintain conditions at 50°C, pH 4.8.

- Monitoring: Sample periodically (e.g., 0, 6, 24, 48, 72h). Centrifuge samples (10,000 x g, 5 min) and filter supernatant (0.2 µm syringe filter).

- Analysis: Quantify glucose, xylose, arabinose, and inhibitor (furfural, HMF) concentrations via HPLC. Calculate hydrolysis yield.

- Detoxification (if required): Pass hydrolysate through an anion-exchange resin column or treat with activated charcoal to reduce inhibitor levels before fermentation.

Protocol 2.2: Hydroprocessing of Algal Lipid Extract to Renewable Diesel/SAF Blendstock

Objective: To catalytically deoxygenate and isomerize algal lipids (triglycerides) into a branched hydrocarbon mixture meeting the boiling point range of jet fuel.

Materials:

- Algal lipid extract (FAMEs or triglycerides).

- Bifunctional catalyst (e.g., Pt/SAPO-11, NiMo/γ-Al₂O₃).

- High-pressure Parr reactor (300 mL+).

- Hydrogen gas (≥99.99% purity).

- n-Hexane (HPLC grade).

- Gas Chromatograph with Flame Ionization Detector (GC-FID) and Simulated Distillation (SIMDIS) column.

Procedure:

- Reactor Loading: Charge the reactor with 50 g of algal lipid and 2.5 g of catalyst (5% w/w). Seal the reactor.

- Purging & Pressurization: Purge the reactor three times with H₂ to remove air. Pressurize with H₂ to 30 bar at room temperature.

- Reaction: Heat the reactor to the target temperature (e.g., 350°C for deoxygenation, 300°C for isomerization) with continuous stirring (750 rpm). Maintain H₂ pressure at 50 bar via constant supply. Run the reaction for 4 hours.

- Quenching & Separation: Cool the reactor rapidly in an ice bath. Carefully vent gases. Transfer the liquid product to a separation funnel. Rinse the reactor with n-hexane.

- Catalyst Removal: Filter the product-hexane mixture through a 0.45 µm PTFE filter to remove catalyst particles.

- Solvent Removal: Evaporate hexane under reduced pressure using a rotary evaporator.

- Product Analysis:

- GC-FID: Analyze for hydrocarbon distribution (n-paraffins, iso-paraffins, cyclics).

- GC-SIMDIS: Determine the boiling point curve and calculate yield in the jet fuel range (150-300°C).

- Calculations: Determine yield of liquid hydrocarbon product and selectivity to C8-C16 isomers.

Visualizations

Title: Integrated Biorefinery Feedstock Conversion Pathways to SAF

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents & Materials for SAF Feedstock Research

| Item | Function & Specification | Example Application |

|---|---|---|

| CTec3 / HTec3 Enzyme Cocktails | Multi-component cellulase/hemicellulase blends for efficient saccharification of pre-treated biomass. | Protocol 2.1: Hydrolysis of cellulose to glucose. |

| Pt/SAPO-11 or NiMo/γ-Al₂O₃ Catalyst | Bifunctional catalyst providing metal sites (for hydrogenation/deoxygenation) and acid sites (for isomerization/cracking). | Protocol 2.2: Hydroprocessing of lipids to iso-paraffins. |

| Aminex HPX-87H HPLC Column | Ion-exchange column optimized for separation and quantification of sugars, acids, and fermentation inhibitors. | Analyzing hydrolysate composition (Protocol 2.1). |

| SIMDIS Capillary GC Column (e.g., DB-2887) | Specialized column for simulating petroleum distillation curves per ASTM D2887. | Determining jet fuel range yield from hydroprocessed oil (Protocol 2.2). |

| Lipid Extraction Solvent System (Chloroform:Methanol, 2:1 v/v) | Standard biphasic Folch method for total lipid extraction from wet algal biomass. | Quantitative recovery of algal triglycerides prior to hydroprocessing. |

| Anion Exchange Resin (e.g., Amberlite IRA-96) | Weakly basic resin for removal of inhibitory organic acids and phenolics from biomass hydrolysates. | Detoxification step prior to microbial fermentation in ATJ pathway. |

| High-Pressure Parr Reactor System (450°C, 200 bar rating) | Bench-scale batch reactor with precise temperature, pressure, and stirring control for catalytic reactions. | Conducting hydroprocessing (HDCJ, HEFA) experiments (Protocol 2.2). |

This application note details protocols for the enzymatic deconstruction of lignocellulosic biomass and subsequent conversion by engineered microbes, within the context of an integrated biorefinery for Sustainable Aviation Fuel (SAF) production. The focus is on generating hydrolysate streams optimized for oleaginous yeast or bacteria to synthesize lipid intermediates for hydroprocessing into drop-in SAF.

The integration of enzymatic hydrolysis and microbial conversion is critical for efficient sugar platform biorefineries. Pretreated lignocellulose (e.g., agricultural residues, energy crops) is hydrolyzed by tailor-made enzyme cocktails to release fermentable monosaccharides. Engineered microbial workhorses are then employed to convert these sugars, and potentially inhibitory compounds, into target molecules like fatty acids or isoprenoids. Key challenges include achieving high sugar yields at low enzyme loadings and engineering robust microbial strains tolerant to hydrolysate inhibitors.

Table 1: Performance Metrics of Commercial Enzyme Cocktails on Alkaline-Pretreated Corn Stover

| Enzyme Cocktail | Total Protein Loading (mg/g glucan) | Glucose Yield (%) | Xylose Yield (%) | Time to 90% Yield (h) | Optimal pH | Optimal Temp (°C) |

|---|---|---|---|---|---|---|

| Cellic CTec3 | 15 | 96.5 | 85.2 | 48 | 4.8-5.0 | 50 |

| Accellerase 1500 | 25 | 92.1 | 78.7 | 72 | 4.8-5.0 | 50 |

| Novozymes Cellic HTec3 | 20 (with CTec3) | [N/A - boosts xylose] | >90 | 72 | 5.0 | 50 |

Table 2: Engineered Microbial Strains for SAF Precursor Production

| Microbial Host | Primary Engineering Target | Key Product | Max Titer Reported (g/L) | Yield (g/g sugar) | Key Tolerance Feature |

|---|---|---|---|---|---|

| Yarrowia lipolytica | DGAT1 overexpression, ACL deletion | Triacylglycerides (TAG) | 90 | 0.22 | Acetate, phenolic tolerance |

| Rhodosporidium toruloides | Nitrogen starvation optimization | Microbial Oil | 65 | 0.28 | Native lignan degradation |

| Escherichia coli | Reverse beta-oxidation pathway, fadE knockout | Free Fatty Acids | 8.5 | 0.12 | Requires detoxified hydrolysate |

| Pseudomonas putida | Aryl-alcohol dehydrogenase expression | cis,cis-Muconic Acid (SAF precursor) | 50 | 0.35 | Native solvent/aromatic tolerance |

Experimental Protocols

Protocol 2.1: High-Solids Enzymatic Hydrolysis of Pretreated Biomass

Objective: To hydrolyze pretreated lignocellulosic biomass at high dry matter content to generate a concentrated sugar hydrolysate for fermentation.

Materials (Research Reagent Solutions):

- Substrate: Alkali-pretreated and washed corn stover (20% w/w total solids).

- Enzyme Cocktail: Cellic CTec3/HTec3 mix (9:1 ratio).

- Buffer: 1.0 M Sodium citrate buffer, pH 4.8.

- Antimicrobial: 0.005% (w/v) Sodium azide.

- Reaction Vessel: 250 mL baffled Erlenmeyer flask or bioreactor with tumbling/mixing capability.

Procedure:

- Weigh 60g of pretreated biomass (12g dry weight equivalent) into the reaction vessel.

- Add 46.8 mL of 50 mM sodium citrate buffer (pH 4.8) and 1.2 mL of sodium azide solution to inhibit microbial growth.

- Pre-mix the slurry using a spatula. Place the vessel in a temperature-controlled incubator shaker at 50°C, 150 rpm, for 1 hour for temperature and pH equilibration.

- Add enzyme cocktail to achieve a final total protein loading of 20 mg/g dry biomass (e.g., 240 mg protein for 12g dry weight). Use sterile water to bring the total reaction mass to 60g.

- Mix thoroughly. Maintain hydrolysis at 50°C with continuous agitation (e.g., in a bioreactor with helical stirring or in a shaker with tumbling).

- Sample at 0, 6, 24, 48, and 72 hours. Immediately centrifuge samples at 13,000 x g for 5 min to separate solids.

- Filter supernatant through a 0.22 µm syringe filter. Analyze filtrate for glucose, xylose, and inhibitor (furfural, HMF, phenolics) concentration via HPLC.

Protocol 2.2: Fed-Batch Fermentation of Hydrolysate by Oleaginous Yeast

Objective: To convert enzymatically derived sugars into intracellular lipids using an engineered oleaginous yeast strain.

Materials (Research Reagent Solutions):

- Microbe: Yarrowia lipolytica PO1f strain engineered with DGAT1 overexpression.

- Media: Synthetic complete (SC) medium for seed culture. Detoxified hydrolysate (see notes) supplemented with 5.0 g/L (NH4)2SO4, 1.7 g/L Yeast Nitrogen Base, and 1.0 g/L KH2PO4 as fermentation medium.

- Trace Elements: 1000x stock solution of MgSO4·7H2O, CaCl2, FeSO4·7H2O, ZnSO4·7H2O, CuSO4·5H2O.

- Bioreactor: 2L bench-top fermenter with DO and pH control.

Procedure:

- Hydrolysate Detoxification: Adjust hydrolysate pH to 10.0 with Ca(OH)2, stir for 1h, filter precipitate. Adjust pH back to 6.5 with H3PO4. Use activated charcoal (2% w/v, 60°C, 1h) for additional phenolic removal.

- Seed Culture: Inoculate a single colony into 50 mL SC medium in a 250 mL flask. Grow at 28°C, 250 rpm for 24-36 hours to late-log phase (OD600 ~15-20).

- Fermentation Setup: Charge the bioreactor with 1L of supplemented, detoxified hydrolysate medium. Sterilize in situ at 121°C for 20 min. Cool to 28°C. Add filter-sterilized trace elements.

- Inoculation & Batch Phase: Inoculate at 10% (v/v) from seed culture. Set initial conditions: 28°C, pH 6.0 (maintained with 2M NaOH/1M H2SO4), airflow 1 vvm, agitation 400 rpm to maintain DO >30%.

- Fed-Batch Phase: Upon depletion of initial carbon (marked by DO spike), initiate feeding of concentrated, sterile hydrolysate at a rate to maintain total sugar concentration <20 g/L.

- Nitrogen Limitation: Allow ammonium to deplete naturally to trigger lipid accumulation. Culture for 96-120 hours total.

- Harvest: Centrifuge cells at 8000 x g for 10 min. Wash with deionized water. Lyophilize cell pellets for lipid extraction via Folch method or direct transesterification for FAME analysis via GC-MS.

Mandatory Visualization

Diagram 1: SAF Precursor Bioproduction Workflow

Diagram 2: Metabolic Engineering for Lipid Overproduction

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions for Enzymatic Hydrolysis & Microbial Conversion

| Item | Function & Explanation |

|---|---|

| Cellic CTec3 | Advanced commercial enzyme cocktail. Contains high-activity cellulases, β-glucosidases, and hemicellulases for efficient lignocellulose deconstruction. |

| Yarrowia lipolytica PO1f Kit | A genetically tractable, generally recognized as safe (GRAS) oleaginous yeast strain, often the baseline for metabolic engineering for lipid production. |

| Folch Reagent (Chloroform:MeOH 2:1) | Standard solvent mixture for total lipid extraction from microbial biomass, separating lipids into the organic phase. |

| MTT (3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) | Cell viability assay reagent. Used to rapidly assess microbial inhibitor tolerance in hydrolysates. |

| HPLC Columns (Aminex HPX-87H, Bio-Rad) | Standard column for analysis of sugars (glucose, xylose), organic acids, and fermentation inhibitors (furfural, HMF) in hydrolysates and broths. |

| Gas Chromatography (GC) System with FAME Column | Essential for analyzing fatty acid methyl ester (FAME) profiles from microbial lipids to determine suitability for SAF synthesis. |

| CRISPR/Cas9 Toolkits for Yeast/Bacteria | For precise genome editing (knockouts, knock-ins, promoter swaps) to engineer metabolic pathways in microbial hosts. |

Application Notes: Policy & Carbon Accounting Frameworks

Thesis Context: This document details the critical policy drivers and carbon accounting methodologies that underpin the economic viability and sustainability assessment of integrated biorefineries for Sustainable Aviation Fuel (SAF) production. Compliance with and optimization against these frameworks is essential for research direction and technology deployment.

Core Policy Instruments

- CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation): A global market-based measure adopted by ICAO to stabilize net CO₂ emissions from international aviation at 2019 levels. It creates demand for SAF through the use of "CORSIA Eligible Fuels" and associated Emissions Unit Criteria.

- LCFS (Low Carbon Fuel Standard): A California (and other jurisdictions) regulation that reduces the carbon intensity (CI) of transportation fuels. It generates tradeable credits (LCFS credits) for fuels with a CI lower than the benchmark, providing a direct revenue stream for low-CI SAF.

- Net-Zero Targets: Corporate or national commitments to balance emitted greenhouse gases with removal from the atmosphere, often by 2050. These commitments drive long-term investment and offtake agreements for SAF.

Table 1: Key Quantitative Parameters of Major SAF Policy Drivers (2024-2025)

| Policy Driver | Governing Body | Current Phase/Target (2024-2025) | Credit/Cost Mechanism | SAF-Specific Relevance |

|---|---|---|---|---|

| CORSIA | International Civil Aviation Organization (ICAO) | Phase 1 (2024-2026): Voluntary. 2024 Sectoral Growth Factor (SGF) = 0.09. | Airlines purchase eligible emission units (e.g., from SAF) to offset emissions above 2019 baseline. | SAF must meet CORSIA Sustainability Criteria. Default lifecycle emissions savings: 60-100%. |

| CA-LCFS | California Air Resources Board (CARB) | CI Target for 2024: ~87.6 gCO₂e/MJ. CI Target for 2030: 72.2 gCO₂e/MJ. | Credit price: ~ $70-85/tonne CO₂e (Q1 2024). Generates ~$1.5-$2.5/gal credit for very low-CI SAF. | Direct financial incentive. Requires CARB-approved CI pathway using a certified model (e.g., GREET). |

| U.S. SAF Grand Challenge | U.S. Federal Government (Multi-Agency) | Goal: 3B gallons of SAF by 2030; 35B gallons by 2050. | Blender's Tax Credit (40B): $1.25-$1.75/gal (based on CI reduction). | Incentivizes CI reduction beyond 50%. Complementary to LCFS. |

| EU ReFuelEU Aviation | European Union | Sub-target for SAF: 6% of fuel uplift at EU airports by 2030. Minimum share for synthetic fuels (e-methanol): 1.2% by 2030. | Compliance via blending mandate. Penalties for non-compliance. | Obligates fuel suppliers. SAF must meet Renewable Energy Directive II (RED II) sustainability criteria. |

Table 2: Typical Carbon Intensity (CI) Scores for SAF Pathways (gCO₂e/MJ)

| Feedstock | Conversion Pathway | Approximate CI Score (GREET) | Notes for Integrated Biorefineries |

|---|---|---|---|

| Used Cooking Oil (UCO) | HEFA (Hydroprocessed Esters and Fatty Acids) | 15 - 35 | Low-CI benchmark. Supply-limited. |

| Corn Grain (with CCS) | Alcohol-to-Jet (ATJ) | 30 - 50 | Integration with Carbon Capture offers significant CI benefit. |

| Lignocellulosic Biomass (e.g., corn stover) | Gasification + Fischer-Tropsch (FT) | 15 - 40 | Highly dependent on feedstock logistics and gasifier efficiency. |

| Lignocellulosic Biomass | Pyrolysis + Upgrading | 25 - 50 | Co-product handling crucial for CI. Hydrogen source (green vs. grey) is key. |

| Sugars (Advanced) | ATJ / Direct Sugar to Hydrocarbon | 30 - 60 | Feedstock cultivation emissions are a major variable. |

| Petroleum Jet A-1 | Baseline | 89 - 95 | Reference value for CI reduction calculations. |

Experimental Protocols for Carbon Accounting & Fuel Analysis

Protocol 1: Lifecycle Assessment (LCA) Carbon Intensity Calculation for a Novel Integrated Biorefinery Pathway

Objective: To determine the CORSIA- and LCFS-compliant lifecycle Carbon Intensity (CI) of SAF produced from an integrated lignocellulosic biorefinery co-producing SAF and high-value biochemicals.

Methodology:

Goal & Scope Definition:

- Functional Unit: 1 Megajoule (MJ) of neat SAF (attydrous) meeting ASTM D7566 specification.

- System Boundary: Cradle-to-Wake (includes feedstock cultivation, collection, transport, biorefinery operation, fuel transport/distribution, and combustion).

- Allocation Method: Apply energy allocation (per CARB LCFS guidelines) or displacement (system expansion) for co-products (e.g., succinic acid, bio-power). Document rationale.

Lifecycle Inventory (LCI) Data Collection:

- Feedstock Production: Quantify fertilizer, pesticide, water, diesel use, and N₂O emissions per tonne of biomass delivered. Use field trial data.

- Biorefinery Process: Use pilot-scale or process simulation (Aspen Plus) data to collect mass and energy balances.

- Key inputs: Biomass, enzymes, catalysts, hydrogen (source tracked), process water, electricity (grid mix modeled).

- Key outputs: SAF, co-products, CO₂ emissions (biogenic and fossil), wastewater, waste streams.

- Fuel Combustion: Use standard emission factor for SAF combustion (e.g., ~73.8 gCO₂e/MJ, considering biogenic carbon).

CI Calculation using GREET Model:

- Utilize the latest Argonne GREET model (the CA-LCFS standard tool).

- Create a new feedstock and fuel pathway module within GREET.

- Input all LCI data into the corresponding modules (Feedstock, Fuel, Process).

- Apply selected allocation method in the co-product handling module.

- Execute the model to generate a full lifecycle CI (gCO₂e/MJ) for the SAF.

Sensitivity & Uncertainty Analysis:

- Vary key parameters (±20%): hydrogen CI, enzyme dosage, biomass yield, electricity grid CI.

- Perform Monte Carlo simulation (minimum 10,000 runs) to determine 95% confidence interval for the final CI value.

Protocol 2: Analytical Verification of SAF Blendstock Properties (ASTM D4054)

Objective: To ensure SAF blendstock from a novel integrated process meets critical ASTM D7566 annex specifications for blending with conventional jet fuel.

Materials & Workflow:

Title: SAF Blendstock Analytical Verification Workflow (Max 760px)

The Scientist's Toolkit: Key Research Reagent Solutions for Integrated Biorefinery & SAF Analysis

Table 3: Essential Research Materials for SAF Pathway Development

| Item / Reagent | Function in Research Context | Example / Specification Notes |

|---|---|---|

| Customized Enzymatic Cocktails | Hydrolysis of lignocellulosic biomass to fermentable sugars (C5/C6). Critical for yield and CI. | Cellulases, hemicellulases, accessory enzymes (e.g., from Novozymes, DuPont). Activity: ≥ 100 FPU/g. |

| Genetically Modified Microorganism | Fermentation of mixed sugars to alcohol or intermediate bio-oil. | Zymomonas mobilis or engineered S. cerevisiae for C5/C6 co-utilization. |

| Heterogeneous Catalyst (Deoxygenation) | Hydrodeoxygenation (HDO) of bio-oils to stable hydrocarbons. | Sulfided NiMo/Al₂O₃, Pt/Al₂O₃, or novel bimetallic catalysts. |

| Hydrogen (High-Purity, Source-Tracked) | For hydroprocessing reactions. CI of H₂ is a major LCA variable. | Use electrolyzer (green H₂) or steam methane reformer with CCS (blue H₂) for low-CI pathways. |

| Certified Reference Materials for GC | Quantification of hydrocarbons, aromatics, and impurities in final SAF. | n-Alkane standard mix (C8-C40), ASTM D7566 Annex-specific compound standards. |

| LCI Database Subscription | For background lifecycle inventory data (e.g., fertilizer production, grid electricity). | Ecoinvent, USLCI, or GREET embedded databases. Essential for rigorous CI calculation. |

| Process Modeling Software | Mass/energy balance simulation for LCI and techno-economic analysis (TEA). | Aspen Plus, SuperPro Designer, or open-source tools (e.g., DWSIM). |

Protocol 3: Catalytic Hydroprocessing of Bio-Oil to SAF-Range Hydrocarbons

Objective: To upgrade intermediate bio-oil from pyrolysis or hydrothermal liquefaction to a deoxygenated hydrocarbon mixture suitable for final hydroisomerization/distillation into SAF.

Detailed Methodology:

Reactor Setup:

- Use a fixed-bed, continuous-flow, down-flow tubular reactor (SS316, 1/2" OD).

- Pack reactor with catalyst (e.g., 5-10 mL of NiMo/γ-Al₂O₃, 60-80 mesh) diluted with inert SiC.

- Install thermocouples in a thermowell at the catalyst bed center.

- Connect to high-pressure syringe pump for bio-oil feed, H₂ mass flow controller, back-pressure regulator, and gas-liquid separator.

Catalyst Pre-treatment (Sulfidation):

- Pressurize reactor to 500 psig with H₂, flow at 100 mL/min.

- Heat to 200°C at 5°C/min.

- Switch H₂ flow to a 3% H₂S/H₂ mixture at 100 mL/min for 4 hours.

- Cool to reaction temperature under pure H₂.

Reaction Procedure:

- Set reaction temperature (300-400°C) and pressure (500-1500 psig).

- Establish H₂ flow rate (e.g., 500 L H₂/L bio-oil).

- Start bio-oil feed (e.g., 0.1-0.3 mL/min LHSV) using a pre-heated line.

- Maintain conditions for a minimum of 24 hours to assess stability.

- Collect liquid product in a chilled separator, weigh hourly to measure yield.

- Analyze gas stream by online micro-GC for light hydrocarbons (C1-C4), CO, CO₂.

Product Analysis & Deoxygenation Metrics:

- Water Content: Karl Fischer titration (ASTM D6304).

- Oxygen Content: Calculate via elemental analysis (CHNS-O) or by difference.

- Simulated Distillation: GC (ASTM D2887) to determine boiling range distribution.

- Key Metric: Target oxygen content < 1 wt.% and > 70% yield in the C8-C16 distillation cut.

Bridging the Lab to Sky: Processing, Catalysis, and Pilot-Scale Implementation

Within the research framework of integrated biorefineries for sustainable aviation fuel (SAF) production, overcoming lignocellulosic biomass recalcitrance is the primary bottleneck. Efficient pre-treatment and saccharification are critical to liberate fermentable sugars from cellulose and hemicellulose, which are subsequently converted to intermediates like alcohols and fatty acids for catalytic upgrading to SAF. This document provides application notes and detailed protocols for key methods in this field.

Application Notes: Comparative Analysis of Pre-treatment Technologies

The selection of a pre-treatment method directly impacts downstream enzymatic hydrolysis efficiency, inhibitor formation, and overall biorefinery economics. The following table summarizes the performance of leading pre-treatment technologies based on recent pilot-scale studies relevant to SAF feedstock processing.

Table 1: Comparative Performance of Biomass Pre-treatment Methods for SAF Feedstocks (e.g., Corn Stover, Switchgrass)

| Pre-treatment Method | Conditions (Typical) | Solid Recovery (%) | Glucose Yield Post-Sacch. (%) | Xylose Yield Post-Sacch. (%) | Key Inhibitors Generated | Scalability & Notes |

|---|---|---|---|---|---|---|

| Dilute Acid (H₂SO₄) | 160-180°C, 0.5-1.5% acid, 10-30 min | 55-65 | 85-92 | 75-85 | Furfural, HMF, acetic acid | High; Corrosion resistant reactors needed. |

| Steam Explosion | 180-220°C, 1-4 MPa, 5-15 min | 70-85 | 80-90 | 60-75 | Furfural, HMF, phenolic compounds | Very High; Combined physico-chemical action. |

| Alkaline (NaOH) | 60-120°C, 0.5-2% NaOH, 1-2 h | 65-80 | 70-85 | 50-65 | Minimal sugars loss; salts formation | Moderate; Effective for high-lignin feedstocks. |

| Liquid Hot Water | 180-220°C, pressure, 15 min | 70-80 | 75-88 | 70-82 | Lower inhibitors than acid | High; No chemicals, but high energy input. |

| Ionic Liquid ([C₂C₁im][OAc]) | 100-140°C, 3-6 h | 85-95 | 90-98 | 80-90 | Potential IL toxicity/cost | Low/Medium; Excellent efficacy but cost & recovery challenges. |

Experimental Protocols

Protocol 2.1: Dilute Acid Pre-treatment of Lignocellulosic Biomass

Objective: To solubilize hemicellulose and disrupt lignin structure, enhancing enzymatic accessibility to cellulose. Materials: Milled biomass (20 mesh), Dilute sulfuric acid (0.5-2% w/w), Parr reactor (or equivalent high-pressure vessel), Vacuum filtration setup, pH meter, NaOH. Procedure:

- Load: Charge 50 g (dry weight equivalent) of biomass into the reactor. Add dilute acid at a solid-to-liquid ratio of 1:10.

- React: Seal reactor, heat to target temperature (e.g., 160°C) with constant stirring. Maintain for prescribed residence time (e.g., 20 min).

- Quench & Recover: Rapidly cool reactor. Recover slurry and filter through a Büchner funnel to separate pre-treated solid from liquor.

- Wash & Neutralize: Wash solids with deionized water until filtrate is pH neutral. Adjust wash volume to record mass balance. Store solid fraction at 4°C for saccharification.

- Analysis: Analyze liquid fraction for sugar monomers (HPLC) and inhibitors (HPLC for furans). Determine solid composition (NREL/TP-510-42618).

Protocol 2.2: High-Solids Enzymatic Saccharification

Objective: To hydrolyze cellulose and residual hemicellulose in pre-treated biomass to monomeric sugars using a commercial enzyme cocktail. Materials: Pre-treated biomass, Commercial cellulase/hemicellulase cocktail (e.g., CTec3, HTec3), Sodium citrate buffer (50 mM, pH 4.8), Antibiotics (e.g., tetracycline, cycloheximide), 250 mL Erlenmeyer flasks, Shaking incubator. Procedure:

- Setup: Transfer pre-treated biomass equivalent to 10 g dry weight into a flask. Add sodium citrate buffer to achieve a final total solids loading of 15% (w/w).

- Dosing: Add enzyme cocktail at a loading of 20 mg protein per g glucan (or 0.2 mL CTec3/g dry biomass). Add antibiotics (40 µg/mL each) to prevent microbial growth.

- Hydrolyze: Incubate at 50°C with constant agitation at 150 rpm for 72-120 h.

- Sample: Withdraw 1 mL slurry periodically (e.g., 0, 3, 6, 12, 24, 48, 72 h). Centrifuge immediately (10,000 x g, 5 min).

- Analyze: Filter supernatant (0.2 µm) and analyze glucose, xylose, and cellobiose concentration via HPLC (Aminex HPX-87P column, 85°C, water mobile phase). Calculate sugar yields.

Visualizations

Title: Biomass Deconstruction Workflow for SAF

Title: Integrated Saccharification & Fermentation to SAF Precursors

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Biomass Deconstruction Research

| Item | Function & Application | Example Product/Catalog |

|---|---|---|

| Commercial Enzyme Cocktail | Multi-enzyme mixture for synergistic hydrolysis of cellulose/hemicellulose. Critical for saccharification assays. | Cellic CTec3 (Novozymes); Accelerase TRIO (DuPont) |

| Analytical Enzyme Kits | Quantification of key components in biomass and hydrolysates (e.g., lignin, sugars, inhibitors). | K-LIGNIN, K-ACHAR (Megazyme); D-Glucose Assay Kit (R-Biopharm) |

| Ionic Liquids | Highly effective pre-treatment solvents for lignin dissolution and cellulose swelling. Used in mechanistic studies. | 1-ethyl-3-methylimidazolium acetate ([C₂C₁im][OAc]) (Sigma-Aldrich) |

| HPLC Columns & Standards | Separation and quantification of sugar monomers, oligomers, and degradation products (furans, organic acids). | Aminex HPX-87H/P columns (Bio-Rad); Supleco sugar standards |

| Solid Load Simulators | High-torque, temperature-controlled bioreactors for accurate high-solids (>15%) saccharification/fermentation studies. | DASGIP Parallel Bioreactor System (Eppendorf) |

| Lignin Model Compounds | Used to study enzymatic or catalytic cleavage of lignin linkages (e.g., β-O-4) for valorization research. | Guaiacylglycerol-β-guaiacyl ether (GGGE) (TCI Chemicals) |

Application Notes & Protocols Framed within the thesis: "Integrated Biorefineries for Sustainable Aviation Fuel Production"

Catalytic Deoxygenation of Lipid Feedstocks via Hydrotreating

Application Note: Hydrotreating catalysis is critical for removing oxygen from bio-oils and lipid feedstocks (e.g., vegetable oils, algal lipids, tallow) to produce hydrocarbon intermediates (e.g., renewable diesel, n-paraffins) suitable for further upgrading to Sustainable Aviation Fuel (SAF). Deoxygenation proceeds primarily via three pathways: Hydrodeoxygenation (HDO), Decarboxylation (DCO₂), and Decarbonylation (DCO). The selectivity between these pathways determines carbon yield and hydrogen consumption, key economic factors for integrated biorefineries.

Key Quantitative Data Summary

Table 1: Performance of Common Hydrotreating Catalysts for Triglyceride Deoxygenation

| Catalyst Type | Support | Temp. (°C) | Pressure (bar H₂) | Main Pathway | C18 Yield (%) | Key Reference |

|---|---|---|---|---|---|---|

| Sulfided CoMo | Al₂O₃ | 300-350 | 20-50 | HDO | 75-85 | Kubička & Kaluža, 2010 |

| Sulfided NiMo | Al₂O₃ | 320-380 | 30-70 | HDO/DCO | 80-90 | Šimáček et al., 2011 |

| Pt | Al₂O₃ | 250-300 | 10-30 | DCO₂/DCO | 60-75 | Lestari et al., 2009 |

| Pd | C | 300 | 5-17 | DCO₂ | ~70 | Mäki-Arvela et al., 2007 |

| Ni | SiO₂ | 260-300 | 27 | DCO₂ | 65-80 | Morgan et al., 2012 |

Table 2: Typical Product Distribution from Oleic Acid Deoxygenation

| Condition | n-C18 (%) | n-C17 (%) | n-C18:C17 Ratio | Oxygen Removal (%) |

|---|---|---|---|---|

| H₂-rich, Sulfided NiMo (HDO) | 85 | 5 | 17:1 | >99 |

| H₂-lean, Pt/C (DCO₂/DCO) | 15 | 78 | ~0.2:1 | >99 |

Experimental Protocol: Batch Reactor Testing of Hydrodeoxygenation Catalysts

Objective: To evaluate the activity and selectivity of solid catalysts for the deoxygenation of model lipid compounds (e.g., oleic acid) under controlled conditions.

Materials & Equipment:

- High-pressure Parr batch reactor (e.g., 100 mL) with heating mantle and magnetic stirrer.

- Catalyst (e.g., 0.5g of pre-sulfided NiMo/γ-Al₂O₃, 150-250 µm sieved fraction).

- Substrate: 10.0 g of oleic acid (technical grade, >90%).

- Solvent: 30 mL of n-dodecane (anhydrous, >99%).

- Gas supply: H₂ (≥99.99%), N₂ (≥99.99%).

- Gas chromatograph (GC-FID) equipped with a DB-5HT or similar capillary column.

Procedure:

- Catalyst Loading: Weigh the catalyst and load it into the clean, dry reactor vessel.

- Substrate Addition: Add the oleic acid and n-dodecane solvent to the reactor.

- Reactor Sealing & Leak Test: Secure the reactor head. Purge the system three times with N₂ (pressurizing to 10 bar and venting). Conduct a final pressure leak test with N₂ at 30 bar for 15 minutes.

- H₂ Pressurization: Vent N₂. Purge three times with H₂. Pressurize with H₂ to the desired initial cold pressure (e.g., 30 bar at room temperature). Note: The final hot pressure will be higher.

- Reaction Initiation: Start vigorous stirring (e.g., 750 rpm) and begin heating to the target temperature (e.g., 350°C). Record "time zero" when the setpoint temperature is reached.

- Reaction Monitoring: Maintain temperature and pressure for the desired duration (e.g., 4 hours).

- Reactor Quenching: After the reaction time, cool the reactor rapidly in an ice-water bath to <50°C.

- Product Recovery: Slowly vent gaseous products (CO, CO₂, CH₄, H₂O, H₂) through a cold trap. Transfer the liquid reaction mixture to a vial. Rinse the reactor and catalyst with dichloromethane (3 x 10 mL) and combine with the product.

- Analysis: Filter the liquid to separate spent catalyst. Analyze the liquid product by GC-FID using an internal standard (e.g., methyl heptadecanoate) for quantitative determination of conversion and yields of n-C18, n-C17, and intermediates.

Upgrading of Lignocellulosic Derivatives via Zeolite Catalysis

Application Note: Zeolites (microporous aluminosilicates) are essential for upgrading oxygenated platform molecules (e.g., furans, light oxygenates from pyrolysis) into aromatic and olefinic hydrocarbons for SAF blending. ZSM-5 is the predominant catalyst, facilitating dehydration, oligomerization, cyclization, and deoxygenation reactions in a single step (Catalytic Fast Pyrolysis - CFP). The topology (pore size, dimensionality) and acidity (Si/Al ratio) of the zeolite are critical parameters governing product selectivity towards the desired aromatic hydrocarbon fraction (BTX) and catalyst lifetime.

Key Quantitative Data Summary

Table 3: Zeolite ZSM-5 Characteristics and Performance in Catalytic Fast Pyrolysis of Pine Wood

| Zeolite Property | Value / Type | Effect on Product Yield (Anhydrous Basis) | Reference |

|---|---|---|---|

| Si/Al Ratio | 30 | Organics: 16%, Aromatics: 14% | Carlson et al., 2011 |

| Si/Al Ratio | 60 | Organics: 18%, Aromatics: 16% | Carlson et al., 2011 |

| Crystal Size | Nano (~0.1 µm) | Higher olefin yield, slower deactivation | Mihalcik et al., 2011 |

| Crystal Size | Micro (~2 µm) | Higher aromatic yield, faster coking | Mihalcik et al., 2011 |

| Co-fed H₂ (atm) | 0 | Coke Yield: ~35% of carbon | Wang et al., 2014 |

| Co-fed H₂ (5 atm) | 5 | Coke Yield: ~15% of carbon | Wang et al., 2014 |

Table 4: Typical Aromatic Hydrocarbon Distribution from Glucose over HZSM-5

| Hydrocarbon Product | Average Carbon Yield (%) | Notes |

|---|---|---|

| Benzene | 5-10 | |

| Toluene | 15-25 | Major single product |

| Xylenes (o,m,p) | 10-20 | |

| Naphthalenes | 5-15 | Includes methylnaphthalenes |

| C9+ Aromatics | 10-20 | Heavier alkylbenzenes, indanes, etc. |

| Total Aromatics | 50-70 | Highly dependent on conditions and feed |

Experimental Protocol: Catalytic Fast Pyrolysis (CFP) in a Micropyrolyzer-GC/MS System

Objective: To rapidly screen zeolite catalysts for the conversion of biomass-derived oxygenates to aromatic hydrocarbons.

Materials & Equipment:

- Analytical pyrolyzer (e.g., CDS 5200, Pyroprobe) coupled directly to GC/MS.

- Quartz pyrolysis tubes with quartz wool.

- Catalyst: 1.0 mg of HZSM-5 (Si/Al=40, powdered, calcined at 550°C).

- Feedstock: 0.5 mg of cellulose or 1.0 µL of furfural/alcohol mixture.

- GC/MS system with appropriate column (e.g., DB-1701, HP-5ms).

- Microbalance.

Procedure:

- Sample Preparation: Weigh the precise amount of catalyst and place it in the center of a quartz tube. Place a small plug of quartz wool on one side of the catalyst bed.

- Feedstock Loading: For solid feeds (cellulose), weigh and place directly on top of the catalyst bed. For liquid feeds, inject onto the catalyst bed using a microsyringe and allow solvent to evaporate.

- Tube Loading: Insert the prepared quartz tube into the pyrolyzer filament assembly.

- System Purge: Ensure the GC carrier gas (He) flows through the pyrolyzer interface. The GC oven should be at the starting temperature for the method (e.g., 40°C).

- Pyrolysis/Catalysis: Initiate the pyrolyzer sequence. A typical method:

- Interface Temperature: 300°C (to vaporize products).

- Pyrolysis Temperature: 600°C (ramp rate: 1000°C/ms).

- Hold Time: 20 seconds.

- The vapors generated from the biomass/feed are swept directly through the in-situ catalyst bed and into the GC injector.

- Chromatographic Separation: Simultaneously start the GC/MS method. A common temperature program is: hold at 40°C for 2 min, ramp at 10°C/min to 280°C, hold for 5-10 min.

- Data Analysis: Identify compounds via MS library (NIST) and quantify major products (e.g., aromatics) using total ion chromatogram (TIC) peak areas, applying response factors if available. Report yields as carbon yield (%).

The Scientist's Toolkit: Key Research Reagent Solutions

Table 5: Essential Materials for Catalytic Upgrading Research in SAF Production

| Item / Reagent | Function / Application | Example Specifications |

|---|---|---|

| Sulfided NiMo/Al₂O₃ | Benchmark hydrotreating/deoxygenation catalyst. Promotes HDO. | ~3wt% NiO, ~15wt% MoO₃, ex-situ presulfided. |

| HZSM-5 Zeolite | Benchmark acidic, shape-selective catalyst for aromatization and cracking. | Si/Al ratio 23-40, powder (0.1-2 µm), ammonium form. |

| γ-Alumina (γ-Al₂O₃) | High-surface-area catalyst support for hydrotreating metals. | BET SA >200 m²/g, 1/16" extrudates or powder. |

| Oleic Acid | Model compound for lipid/lipid-based feedstock deoxygenation studies. | Purity >90% (technical) or >99% (analytical). |

| Furfural / 5-HMF | Model platform molecules from hemicellulose/cellulose for upgrading studies. | Purity >98%, stored under inert atmosphere. |

| n-Dodecane / Decalin | Common high-boiling, inert solvent for batch reactor catalysis. | Anhydrous, >99% purity. |

| Dimethyl Disulfide (DMDS) | Sulfiding agent for in-situ activation of hydrotreating catalysts. | Purity >98%. Highly toxic and malodorous. |

| Internal Standards (GC) | For quantitative analysis of complex product streams. | Methyl heptadecanoate, dodecane, hexadecane (>99%). |

| Quartz Wool | For holding catalyst/sample in fixed-bed and micropyrolysis reactors. | Acid washed, high purity. |

Visualization: Reaction Pathways & Experimental Workflows

Diagram 1: Lipid Deoxygenation Pathways to Hydrocarbons

Diagram 2: CFP Catalyst Screening Workflow

Diagram 3: Zeolite Upgrading of Oxygenates to Aromatics

Separation and Purification Technologies for Jet Fuel-Range Hydrocarbons

1. Introduction & Context within Integrated Biorefineries

The synthesis of Sustainable Aviation Fuel (SAF) within an integrated biorefinery involves the catalytic upgrading of bio-oils (e.g., via Fischer-Tropsch, Hydroprocessed Esters and Fatty Acids - HEFA, or Alcohol-to-Jet pathways) to produce complex hydrocarbon mixtures. The target output is a drop-in fuel meeting strict ASTM D7566 specifications, primarily within the jet fuel range (C8-C16 hydrocarbons, with a focus on C9-C15 iso-paraffins for superior cold-flow properties). The crude product from these upgrading units contains a broad spectrum of linear, branched, and cyclic hydrocarbons, as well as residual oxygenates and olefins. Therefore, advanced separation and purification technologies are critical downstream processing units to isolate the jet fuel-range fraction and ensure compliance with density, freezing point, flash point, and aromatic content standards. This document details application notes and protocols for key technologies in this domain.

2. Data Presentation: Comparison of Key Separation Technologies

Table 1: Quantitative Performance Comparison of Primary Separation Technologies

| Technology | Target Fraction/Compound | Typical Yield (%) | Purity/Selectivity Key Metric | Energy Intensity (Relative) | Key Advantage | Key Limitation |

|---|---|---|---|---|---|---|

| Fractional Distillation | C9-C16 Cut | 92-97 | Boiling Point Separation | High | High throughput, established scale | Poor separation of isomers, high energy |

| Adsorption (Zeolites) | n-Paraffins (for removal) | >95 | n-/iso- Selectivity >1000 | Medium | Excellent isomer separation, catalytic potential | Batch/cyclic operation, sorbent deactivation |

| Solvent Extraction | Aromatics (extraction/removal) | 85-92 | Aromatic/Aliphatic Distribution Coefficient: 2.5-4.0 | Medium-High | Can tailor solvent for specific compounds | Solvent recovery needed, potential contamination |

| Membrane Separation | Iso-/n- Paraffin Sorting | 70-85 | Separation Factor (α iso/n): 3-8 | Low | Low energy, continuous operation | Membrane fouling, lower single-pass yield |

| Crystallization (Urea Adduction) | n-Paraffins (for isolation) | 90-98 | n-Paraffin Purity >99% | Medium | Ultra-high purity for linear chains | Requires adduct decomposition, chemical waste |

3. Experimental Protocols

Protocol 3.1: Microscale Fractional Distillation for Simulated Biorefinery Output

Objective: To separate a synthetic Fischer-Tropsch wax hydroprocessing effluent into distinct hydrocarbon cuts, focusing on the jet fuel range (150-250°C).

Materials: Micro-distillation apparatus (e.g., ASTM D86 compliant micro setup), synthetic feed mixture (n-C8 to n-C20, 2-methyl alkanes), temperature probe, chilled condenser, receiving vials.

Procedure:

- Charge 50 mL of the synthetic hydrocarbon mixture into the distillation pot.

- Begin heating with a programmable controller, recording temperature at the distillation head.

- Collect fractions in pre-weighed vials at the following cut points: IBP-150°C (light ends), 150-190°C (light jet), 190-250°C (primary jet fuel range), 250-300°C (heavy fuel), and residue >300°C.

- Weigh each fraction to determine yield (wt%). Analyze each fraction by Gas Chromatography (GC-MS/FID) to determine hydrocarbon distribution.

- Critical Step: Maintain a steady distillation rate of 1-2 mL/min to ensure accurate boiling point correlation.

Protocol 3.2: Isomer Separation Using 5A Zeolite Adsorption

Objective: To selectively adsorb linear alkanes (n-paraffins) from an iso/n-alkane mixture, enriching the iso-paraffin content in the jet fuel fraction.

Materials: 5A Zeolite beads (activated at 350°C under vacuum), fixed-bed adsorption column (10 mm ID x 200 mm length), iso-octane/n-octane (50:50 v/v) model feed, helium carrier gas, Gas Chromatograph (GC) for on-line analysis.

Procedure:

- Pack the adsorption column with activated 5A zeolite. Condition the column under helium flow (20 mL/min) at 200°C for 1 hour.

- Cool the column to the adsorption temperature (180°C). Switch the inlet to a saturator containing the model feed, carried by helium at 10 mL/min.

- Monitor the column outlet via GC. The non-adsorbed iso-octane will break through first. Continue until the iso-octane concentration reaches 95% of the feed.

- Desorption/Regeneration: Switch feed back to pure helium and raise the column temperature to 300°C in a programmed manner. Collect the desorbed n-octane fraction. Calculate the separation factor (α) based on breakthrough curves.

- Data Recording: Record breakthrough time for iso-octane and n-octane. Calculate dynamic adsorption capacity for n-paraffins (mmol/g zeolite).

Protocol 3.3: Membrane-Based Pervaporation for Aromatic Content Adjustment

Objective: To use a polyimide-based membrane to reduce aromatic content in a simulated jet fuel to meet ASTM D7566 (<25% vol aromatics for some synthetic pathways).

Materials: Pervaporation test cell with active membrane area (25 cm²), polyimide dense-film membrane, synthetic jet fuel with 30% vol aromatics (e.g., n-dodecane + 1,2,4-trimethylbenzene), vacuum pump, liquid nitrogen cold trap.

Procedure:

- Mount and seal the membrane in the test cell. On the feed side, circulate the synthetic fuel at 60°C and 1 bar.

- Apply and maintain a vacuum (<5 mbar) on the permeate side. Condense the permeate vapor in a cold trap immersed in liquid nitrogen.

- Run the experiment for 6 hours, weighing the cold trap at 1-hour intervals to determine permeation flux (kg/m²·h).

- Analyze the composition of the collected permeate and the depleted feed (retentate) using GC.

- Calculate the membrane selectivity (αarom/alph) as [Yarom/Yalph] / [Xarom/X_alph], where Y and X are weight fractions in permeate and feed, respectively.

4. Visualization: Technology Selection & Integration Workflow

Title: SAF Purification Technology Selection Workflow

5. The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Research Materials for Separation & Purification Studies

| Item / Reagent Solution | Function & Explanation |

|---|---|

| Synthetic Hydrocarbon Mixtures (e.g., n-alkanes C8-C20, iso-alkanes like 2-methylheptane, aromatics like trimethylbenzene) | Used as model feeds to simulate biorefinery streams, allowing controlled study of separation performance without bio-oil complexity. |

| Molecular Sieves (Zeolites 5A, 13X, Beta) | Microporous aluminosilicates used as adsorbents. 5A selectively adsorbs linear alkanes; 13X adsorbs aromatics; Beta can be used in catalytic isomerization. |

| Polymeric Membranes (e.g., Polyimide, PDMS, Mixed Matrix Membranes) | Selective barriers for pervaporation or pervaporative separation. Polyimide selectively permeates aromatics; PDMS is organophilic. |

| Deep Eutectic Solvents (DES) (e.g., Choline Chloride:Glycerol) | Emerging, tunable green solvents for extractive desulfurization or denitrogenation of model fuels, replacing hazardous solvents. |

| Urea & Thiourea Crystals | Form inclusion compounds (adducts) with linear hydrocarbons, used in crystallization protocols for isolating n-paraffins. |

| Activated Alumina (Brockmann I) | Polar adsorbent used in column chromatography to separate hydrocarbons by polarity, e.g., to remove residual polar oxygenates. |

| Internal Standards for GC (e.g., n-Dodecane-d26, Perylene-d12) | Deuterated or non-native hydrocarbons added in known quantities to samples for accurate quantitative analysis via GC-MS/FID. |

| Certified Reference Materials for ASTM Tests (e.g., for D7215 SimDis, D2425 NMR) | Essential for calibrating analytical equipment used to validate fuel properties post-separation against industry standards. |

Application Notes

Context in Sustainable Aviation Fuel (SAF) Production

Within an integrated biorefinery for SAF production, maximizing resource efficiency is non-negotiable for economic viability and sustainability mandates. The core strategy involves the synergistic integration of three streams: thermal energy (heat), electrical power, and material by-products. This integration moves beyond simple cogeneration to create a resilient system where waste streams from one process become feedstocks for another, thereby improving the overall carbon intensity score—a critical metric for SAF certification (e.g., ASTM D7566).

Key Synergistic Strategies

- Combined Heat and Power (CHP) from Gasification/Syngas: Gasification of lignocellulosic residues (e.g., lignin, harvest residues) produces syngas. This syngas can be combusted in a turbine or engine to generate electricity for the biorefinery grid, while the exhaust heat is captured for process heating (e.g., hydrothermal liquefaction reactors, distillation columns).

- Anaerobic Digestion of Aqueous By-Products: Wastewater streams rich in organic acids, glycerol (from lipid upgrading), or other soluble carbon from fermentation can be fed to an anaerobic digester. This produces biogas (CH₄, CO₂), which fuels the CHP unit, and digestate, which can be processed into fertilizer.

- Thermal Integration of Exothermic Processes: Highly exothermic processes like Fischer-Tropsch synthesis or hydroprocessing provide a significant heat source. This heat can be cascaded to lower-temperature requirements, such as pre-heating feedstocks, supplying heat for enzyme hydrolysis, or providing building climate control.

- By-Product Valorization Pathways: Solid by-products like lignin are not merely burned for heat. They can be converted to bio-based chemicals (e.g., phenols, benzene, toluene), activated carbon for water treatment within the facility, or carbon additives. This material synergy displaces fossil-based inputs and creates additional revenue.

Table 1: Energy and Mass Balance Metrics for Integrated Biorefinery Strategies (Theoretical Yields)

| Strategy | Primary Input | Main Product(s) | Energy Output (Theoretical) | Key By-Product | Synergistic Use |

|---|---|---|---|---|---|

| Lignin Gasification CHP | Dry Lignin (1 tonne) | Electricity: ~1,800 kWh, Heat: ~6-8 GJ | ~75% total efficiency | Ash (50-100 kg) | Mineral recovery for fertilizer |

| Anaerobic Digestion | Wastewater COD (1,000 kg) | Biogas (~400 m³ @ 60% CH₄) | ~2,400 kWh thermal equivalent | Digestate (wet) | Nutrient source for algae cultivation |

| FT Process Heat Recovery | FT Reactor Heat (10 MWₜₕ) | Recovered Heat: ~6-7 MWₜₕ | Up to 70% recovery | Low-pressure steam | Feedstock pre-heating, distillation |

| Glycerol Valorization | Crude Glycerol (1 tonne) | Hydrogen (via reforming): ~100 kg | ~16.8 GJ (HHV of H₂) | CO₂ stream | Capture for bioprocess pH control |

Table 2: Impact on SAF Production Carbon Intensity (CI) Reduction

| Integration Measure | Estimated CI Reduction (gCO₂e/MJ SAF) | Key Contributing Factor |

|---|---|---|

| Implementing advanced CHP | 12 - 18 | Displacement of grid electricity & fossil steam |

| Anaerobic Digestion of wastes | 5 - 10 | Avoided methane emissions, fossil fertilizer displacement |

| Full thermal pinching & cascading | 8 - 12 | Reduced natural gas consumption for process heat |

| By-product chemical production | 3 - 15 (context dependent) | Displacement of fossil-based chemicals, credits |

Experimental Protocols

Protocol: Bench-Scale Syngas Generation and CHP Simulation

Objective: To simulate and measure the energy recovery potential from lignocellulosic biorefinery residues via gasification.

Materials & Equipment:

- Fixed-bed gasification reactor system (tubular furnace, quartz reactor).

- Gas cleaning train (cyclone, condenser, tar trap with isopropanol, filter).

- Gas analysis: Online Micro-GC (for H₂, CO, CO₂, CH₄, C₂) or calibrated GC-TCD.

- Flow meters, thermocouples, data logger.

- Feedstock: Milled and dried lignin or herbaceous residue.

- Gasifying agent: Nitrogen (for pyrolysis) or air/steam mixture.

Procedure:

- Feedstock Preparation: Mill feedstock to ~1 mm particles. Dry at 105°C for 24h. Determine proximate and ultimate analysis.

- Reactor Setup: Load 100g of feedstock into the reactor. Seal and purge with N₂ (200 mL/min) for 15 min to establish an inert atmosphere.

- Gasification: Heat the reactor at 20°C/min to the target temperature (750-900°C). Introduce the gasifying agent (e.g., air at 0.2 ER). Maintain for 60 min.

- Gas Collection & Analysis: Pass product gas through the cleaning train. Collect tar-free gas in a sampling bag at 10-min intervals. Analyze immediately via GC.

- CHP Simulation: Calculate the Lower Heating Value (LHV) of the syngas from its composition. Using a standard ICE efficiency of 35% for power and 45% for heat recovery, calculate the potential electrical and thermal energy yield per kg of feedstock.

Protocol: Anaerobic Digestion of Fermentation Process Water

Objective: To determine biogas yield and kinetics from the high-COD wastewater generated during ABE (Acetone-Butanol-Ethanol) or similar fermentation for SAF precursors.

Materials & Equipment:

- Serum bottles (500 mL) as batch reactors.

- Anaerobic sludge (inoculum) from a wastewater treatment plant.

- Automated methane potential test system (AMPTS II) or water displacement setup.

- pH meter, COD digestion vials.

- Substrate: Filtered fermentation broth post-product recovery.

Procedure:

- Inoculum & Substrate Preparation: Degas inoculum under N₂ for 5 days to reduce background activity. Characterize substrate COD, pH, and VFA content.

- Reactor Setup: In triplicate, add 300 mL inoculum and substrate at an inoculum-to-substrate ratio (ISR) of 2:1 (on VS basis) to each serum bottle. Set up controls with inoculum only and substrate only. Adjust pH to 7.0 ± 0.2.

- Anaerobic Incubation: Flush headspace with N₂:CO₂ (70:30) for 2 min. Seal with butyl rubber stoppers and crimp. Incubate at 37°C with gentle agitation (100 rpm) for 30 days.

- Biogas Monitoring: Connect bottles to the AMPTS or a water displacement system. Record daily biogas volume. Periodically sample headspace for composition analysis via GC (CH₄, CO₂).

- Data Analysis: Calculate cumulative methane yield (mL CH₄/g COD added). Model kinetics using the Gompertz equation. Compare against positive control (microcrystalline cellulose).

Visualizations

Diagram Title: Integrated Biorefinery Resource Network

Diagram Title: Anaerobic Digestion Experimental Workflow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function/Application in Integration Research | Typical Specification |

|---|---|---|

| Online Micro-Gas Chromatograph (Micro-GC) | Rapid, real-time analysis of syngas composition (H₂, CO, CO₂, CH₄, C₂) from gasification experiments. | Multi-channel with TCD, Moisieve & PLOT columns. |

| Automated Methane Potential Test System (AMPTS II) | Automated, high-throughput measurement of biogas volume and composition from anaerobic digestion assays. | Includes CO₂ absorption unit, flow cells, software. |

| Fixed-Bed Tubular Reactor System | Bench-scale simulation of thermochemical processes (gasification, pyrolysis) for residue valorization. | Quartz reactor, programmable furnace, gas feed system. |

| Gas Cleaning Train | Removes tars, particulates, and moisture from raw syngas prior to analysis or utilization. | Sequential: Cyclone, condenser, solvent trap, particulate filter. |

| COD Digestion Vials | For determining the Chemical Oxygen Demand of liquid waste streams, a key parameter for anaerobic digestion potential. | Pre-mixed, EPA-approved, range 0-1500 mg/L or higher. |

| Calorimeter (Bomb) | Measures the Higher Heating Value (HHV) of solid residues (lignin) and liquid/gas fuels. | Essential for energy balance calculations. |

| Process Simulation Software (Aspen Plus, SuperPro) | Models mass/energy integration, pinpoints synergies, and calculates key performance indicators (KPIs) like CI. | Includes extensive biorefinery component libraries. |

Application Notes: Comparative Analysis of Operational SAF Projects

The following table summarizes key quantitative data from current pilot and demonstration-scale SAF biorefineries, underscoring the technological diversity within the integrated biorefinery thesis.

Table 1: Comparative Analysis of Current Pilot and Demonstration-Scale SAF Biorefineries

| Project/Company | Location | Technology Pathway | Feedstock | Scale (Annual Capacity) | SAF Yield | Key Integration Feature | Operational Status (as of 2025) |

|---|---|---|---|---|---|---|---|

| LanzaJet Freedom Pines Fuels | Soperton, Georgia, USA | Alcohol-to-Jet (ATJ) via LanzaJet | Ethanol (from waste-based sources) | 10 million gallons | ~90% of alcohol-to-jet fraction | Integration of ethanol production from waste gases with ATJ catalysis. | Demonstration (Inaugurated Jan 2024) |

| Neste Singapore Expansion | Singapore | HEFA (Hydroprocessed Esters and Fatty Acids) | Used Cooking Oil, Animal Fat, Vegetable Oils | 1 million tons (total refinery) | ~700,000 tons of SAF (planned) | Co-processing with renewable diesel in a large-scale, integrated biorefinery. | Pilot/Demo for new processes. |

| Fulcrum BioEnergy Sierra Biorefinery | Reno, Nevada, USA | Fischer-Tropsch Synthesis (Gasification + FT) | Municipal Solid Waste (MSW) | ~11 million gallons (total fuels) | ~85% of FT product is syncrude for SAF | Integration of waste gasification, syngas cleanup, and FT synthesis. | Demonstration (Initial operations 2024) |

| Red Rock Biofuels | Lakeview, Oregon, USA | Fischer-Tropsch Synthesis | Forest residues, wood waste | ~15 million gallons (total renewable fuels) | Major fraction upgradable to SAF | Integrated woody biomass logistics, gasification, and FT fuel upgrading. | Demonstration (Construction completed, nearing commissioning) |

| Velocys Bayou Fuels | Natchez, Mississippi, USA (planned) | Fischer-Tropsch Synthesis | Woody biomass from forestry operations | 30 million gallons (total fuels) | High yield paraffinic syncrude for SAF | Planned integration with carbon capture and sequestration (BECCS). | Advanced Development/Pilot |

| SAF-1 (By Virent & Phillips 66) | Various pilot sites | Aqueous Phase Reforming & Catalytic Synthesis (BioForming) | Plant-based sugars (e.g., corn starch, sugarcane) | Pilot scale (< 100,000 gal) | High-purity bio-paraffins for jet blendstock | Integration of aqueous-phase sugar reforming with selective catalysis to targeted hydrocarbons. | Ongoing Pilot & Demo campaigns |

Experimental Protocols

Protocol 2.1: Catalytic Hydroprocessing of Bio-Oils (HEFA Pathway) for SAF Blendstock Production

Objective: To convert lipid feedstocks (e.g., hydrolyzed used cooking oil) into hydroprocessed esters and fatty acids (HEFA)-SPK meeting ASTM D7566 specifications. Materials: Hydrolyzed UCO (FFA >95%), NiMo/Al₂O₃ catalyst (sulfided), high-pressure batch reactor system, H₂ gas (≥99.99%), condensers, gas chromatograph with mass spectrometer (GC-MS), Simulated Distillation (SimDis) analyzer. Procedure:

- Feedstock Pretreatment: Filter feedstock to <10 µm. Dry at 120°C under vacuum for 2h to remove moisture.

- Catalyst Loading: Load 50g of presulfided NiMo/Al₂O₃ catalyst into the fixed-bed reactor zone. Condition with H₂ at 350°C, 30 bar, for 4h.

- Reaction: Pump feedstock at LHSV of 1.0 h⁻¹ into the reactor system under conditions: 300-350°C, 50-80 bar H₂ pressure. Maintain for 8-12h.

- Product Separation: Cool reactor effluent. Separate into gas (light ends, H₂S, H₂O), liquid organic (hydrocarbons), and aqueous phases in a high-pressure separator.

- Fractionation: Distill the liquid organic phase using a fractional distillation unit. Collect the fraction boiling between 150-250°C (approximate kerosene range).

- Analysis:

- Composition: Analyze via GC-MS for hydrocarbon distribution (n-paraffins, iso-paraffins, cycloparaffins).

- Cold Properties: Measure freezing point per ASTM D5972, viscosity per ASTM D445.

- SimDis: Confirm distillation curve per ASTM D2887.

- ASTM D7566 Annex A2 Tests: Confirm compliance for HEFA-SPK.

Protocol 2.2: Fischer-Tropsch Synthesis from Biomass-Derived Syngas

Objective: To demonstrate the conversion of cleaned syngas from biomass gasification into Fischer-Tropsch (FT) wax suitable for hydrocracking to SAF. Materials: Bench-scale fixed-bed FT reactor, Co-based FT catalyst (supported on Al₂O₃/SiO₂), simulated biomass-derived syngas (H₂/CO = 2.0 ± 0.1, with N₂ balance), mass flow controllers, hot trap (200°C), cold trap (0°C), online micro-GC. Procedure:

- Catalyst Activation: Reduce catalyst in situ under H₂ flow (2 NL/h/g-cat) at 350°C, 1 bar, for 12h.

- Syngas Conditioning: Mix H₂ and CO using mass flow controllers to achieve H₂/CO = 2.0. Include 10% N₂ as internal standard for conversion calculations.

- FT Reaction: Set reactor to 220°C, 20 bar. Introduce syngas at a Gas Hourly Space Velocity (GHSV) of 2000 h⁻¹. Start product collection.

- Product Collection: Heavy wax is collected in the hot trap. Lighter hydrocarbons and water condense in the cold trap. Non-condensable gases (C1-C4, unconverted syngas) are analyzed online.

- Online Analysis: Use micro-GC to analyze tail gas composition every 30 minutes. Calculate CO conversion: XCO = [1 - (COout/CO_in)] * 100%.