Breaking the Scale Barrier: Innovative Solutions for BECCS Scalability in Climate Mitigation

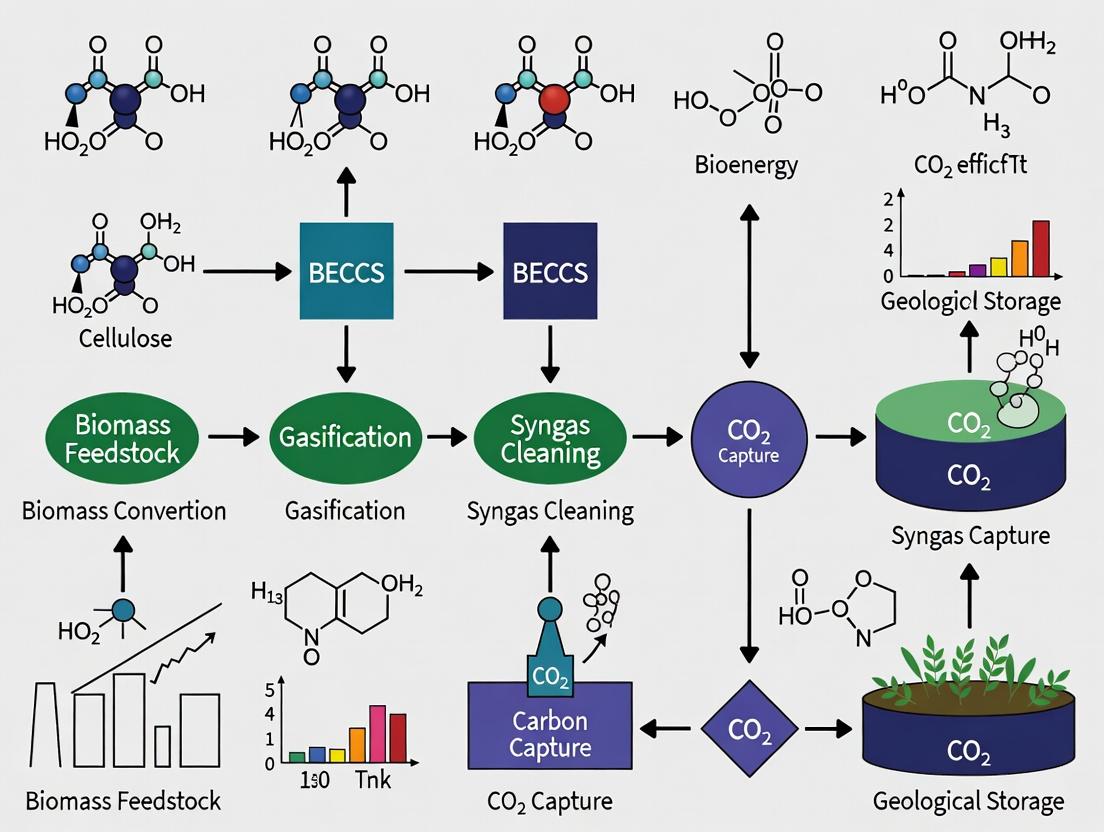

Bioenergy with Carbon Capture and Storage (BECCS) is a critical negative emissions technology in IPCC climate pathways, yet significant scalability constraints threaten its deployment at gigatonne scale.

Breaking the Scale Barrier: Innovative Solutions for BECCS Scalability in Climate Mitigation

Abstract

Bioenergy with Carbon Capture and Storage (BECCS) is a critical negative emissions technology in IPCC climate pathways, yet significant scalability constraints threaten its deployment at gigatonne scale. This article examines the foundational, methodological, and optimization challenges limiting BECCS, including biomass sustainability, supply chain logistics, high costs, and public acceptance. We analyze current technological solutions, policy frameworks, and validation methods, providing researchers and climate professionals with a comprehensive roadmap for overcoming these barriers and enabling BECCS to fulfill its potential in global decarbonization strategies.

Understanding the Core Challenges: What's Limiting BECCS at Gigatonne Scale?

Welcome to the BECCS Scalability Technical Support Center. This resource is designed for researchers and professionals investigating the scalability constraints of Bioenergy with Carbon Capture and Storage (BECCS) within integrated assessment and climate models. Find troubleshooting guides, FAQs, and experimental protocols to support your computational and empirical research.

Frequently Asked Questions & Troubleshooting

Q1: My integrated assessment model (IAM) shows unrealistic BECCS deployment levels exceeding 10 Gt CO2/yr by 2050. What constraints might I be missing? A: Many IAMs historically underestimated constraints. Ensure your model incorporates:

- Land-Use Competition: Implement dynamic feedback between bioenergy crop area, food prices, and deforestation emissions.

- Geospatial CCS Suitability: Limit storage capacity to geologically verified, proximate saline formations, not theoretical global totals.

- Infrastructure Ramp-Rates: Apply annual build-rate limits for both biomass supply chains and CO2 pipeline networks.

Q2: How do I parameterize sustainable biomass feedstock supply in my scenario? A: Move beyond a single "biomass potential" scalar. Structure your supply curve using the following categories, ensuring integration with land-use modules:

| Feedstock Category | Estimated Global Annual Potential (EJ/yr) | Key Sustainability Constraints to Model |

|---|---|---|

| Residues & Wastes | ~50-150 EJ | Competing uses (soil health, bio-materials), collection logistics cost. |

| Dedicated Energy Crops | Varies Widely (0-300+ EJ) | Direct/indirect land-use change (LUC/iLUC) emissions, water use, biodiversity impact. |

| Forest Management | ~30-60 EJ | Sustainable harvest rates, carbon debt repayment time. |

Source: Compiled from recent (2020-2024) IEA Bioenergy, IPCC AR6, and peer-reviewed literature analyses.

Q3: My techno-economic analysis (TEA) for BECCS yields negative costs, but real-world projects stall. What non-cost barriers should my research address? A: The "at scale" barrier is often socio-technical. Design experiments to quantify:

- Policy & Risk: Model impacts of inconsistent carbon pricing vs. guaranteed offtake agreements.

- Public Acceptance: Incorporate siting risk multipliers for CO2 transport and storage infrastructure.

- Supply Chain Maturity: Apply learning rates only after accounting for upfront capital mobilization risk.

Experimental Protocols for Scalability Research

Protocol 1: Quantifying the Land-Use Change (LUC) Carbon Debt of BECCS Feedstock Cultivation Objective: To empirically measure the net CO2 flux from converting native ecosystem to bioenergy cropland. Methodology:

- Site Selection: Identify paired sites: native ecosystem (control) and adjacent land recently converted (1-5 years) to candidate bioenergy crop (e.g., switchgrass, miscanthus).

- Carbon Stock Measurement:

- Above-Ground Biomass: Use allometric equations based on destructive sampling or LiDAR.

- Soil Carbon: Take core samples (0-100 cm depth) at systematic grid points. Analyze Soil Organic Carbon (SOC) via dry combustion.

- Litter & Dead Wood: Collect and weigh all non-living biomass in quadrats.

- Net Flux Calculation: Calculate carbon stock difference (converted - native). Express as CO2-equivalent debt. Monitor annually until the new system's carbon stock matches or exceeds the baseline (debt repayment time).

Protocol 2: Geospatial Mapping of BECCS "Sweet Spots" Objective: To identify high-potential, low-cost locations for BECCS deployment by overlaying key spatial datasets. Methodology:

- Data Layer Acquisition:

- Biomass feedstock production locations (from agricultural models or remote sensing).

- Geological CO2 storage capacity and proximity to infrastructure.

- Water stress indices.

- Protected area and biodiversity priority maps.

- Overlay Analysis: Use GIS software (e.g., QGIS, ArcGIS) to perform a multi-criteria suitability analysis. Assign weights to criteria (e.g., storage proximity weighted highest).

- Output: Generate a global/regional map with suitability scores. Calculate cumulative capacity from "high-suitability" areas only for input into models.

Visualizations

Title: Scalability Constraints Filter for BECCS in Models

Title: Empirical Data to Model Parameter Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in BECCS Scalability Research |

|---|---|

| Integrated Assessment Model (IAM) | Platform to simulate energy, economy, land-use, and climate interactions; tests BECCS deployment scenarios. (e.g., GCAM, MESSAGEix, REMIND) |

| Life Cycle Assessment (LCA) Database | Provides emissions factors for background processes (e.g., fertilizer manufacture, transport). (e.g., Ecoinvent, GREET) |

| Geographic Information System (GIS) | Analyzes and visualizes spatial constraints (biomass yield, storage basins, water stress). (e.g., ArcGIS, QGIS) |

| Soil Organic Carbon Analyzer | Quantifies carbon stocks in soils pre- and post-land conversion; critical for LUC debt. (e.g., Dry Combustion Analyzer) |

| Process-Based Crop Model | Projects biomass yield under future climate scenarios on marginal/degraded land. (e.g., LPJmL, Agro-IBIS) |

Technical Support Center: BECCS Feedstock & Land-Use Analysis

FAQs & Troubleshooting Guides

Q1: My geospatial analysis of marginal land for biomass cultivation shows inconsistent yield projections. What are the primary sources of error? A: Inconsistent yields often stem from soil carbon data variability or resolution mismatches. Use the harmonized global soil dataset (SoilGrids 250m) and align all spatial layers to the same projection (e.g., WGS84). Re-run your analysis using the standardized protocol below.

Q2: How do I resolve conflicts between "food-crop" and "energy-crop" land-use classifications in my LCA model?

A: This indicates a system boundary issue. Implement the dynamic iLUC (indirect Land Use Change) assessment protocol. Use the GTAP-BIO economic model outputs as baseline coefficients. See Table 1 for key reconciliation parameters.

Q3: My feedstock sustainability score (FSS) calculation for miscanthus is returning anomalous values outside the 0-1 range. How do I correct this? A: Check the normalization of your input variables. Ensure each of the seven indicators (e.g., soil erosion factor, water stress index) is normalized to a [0,1] scale before applying the weighted sum. Use the recalculator tool provided in the protocol.

Q4: When modeling BECCS supply chains, my transport emissions are disproportionately high compared to literature values. What is the likely cause? A: You are likely using default transport distances. Integrate the facility location-allocation model (FLAM) to optimize collection radius. Pre-process feedstock density maps using a 50km grid. The optimal radius for herbaceous feedstocks is typically 80-100km.

Q5: My soil carbon sequestration measurement from experimental plots has high variance, obscuring the impact of different perennial grasses. What sampling strategy should I use? A: High variance is common. Implement a nested sampling design with core sampling at 0-30cm and 30-60cm depths, repeated at 0, 12, and 24 months. Increase your sample size to n≥15 per treatment plot. Use a fixed-volume corer to avoid compaction bias.

Experimental Protocols

Protocol EP-01: Dynamic iLUC Factor Integration for Life Cycle Assessment

- Objective: Quantify indirect land-use change emissions attributable to dedicated biomass feedstock expansion.

- Materials: Economic model output data (e.g., from GTAP-BIO), regional land transition matrices, carbon stock datasets (IPCC Tier 1 or higher).

- Method:

a. Define the biomass expansion scenario (crop type, hectare, region).

b. Input scenario into the calibrated economic equilibrium model to obtain projected land displacement by type (e.g., forest, pasture).

c. For each displaced land type

i, calculate the carbon debt:C_debt_i = (C_stock_original_i - C_stock_new_bioenergy_crop) * Area_i. d. Sum carbon debt across all displaced land typesi. e. Allocate this total carbon debt over a 30-year amortization period to derive an annual iLUC emission factor (g CO₂e/MJ). f. Add this factor to the direct lifecycle emissions of the bioenergy pathway.

Protocol EP-02: Field Measurement of Soil Organic Carbon (SOC) Sequestration under Perennial Grasses

- Objective: Accurately measure change in SOC stocks following conversion from reference land use to biomass cultivation.

- Materials: Steel soil corer (fixed volume, 5cm diameter), drying oven, elemental analyzer, GPS, sieves (2mm), polyethylene bags.

- Method:

a. Establish a sampling grid within both the treatment (energy crop) and control (reference land) plots. Mark permanent sampling points.

b. At Time

T0(pre-establishment or immediately after), collect soil cores at 0-30cm and 30-60cm depths atn=15random points per plot. c. Process samples: air-dry, sieve to 2mm, remove visible organic debris, grind. d. Determine SOC concentration via dry combustion (Elemental Analyzer). e. Calculate SOC stock:SOC_stock (Mg/ha) = SOC_conc (g/g) * Bulk_density (g/cm³) * Depth (cm) * 100. f. Repeat steps b-e atT1(e.g., 12 months) andT2(e.g., 24 months) at the same georeferenced points. g. Calculate sequestration rate:ΔSOC = (SOC_stock_Tx - SOC_stock_T0) / Time_period.

Data Tables

Table 1: Key Parameters for Reconciling Food & Feedstock Land Use in Modeling

| Parameter | Description | Typical Range/Value | Source Model |

|---|---|---|---|

| Crop Yield Elasticity | Responsiveness of yield to price change for land competition. | 0.1 - 0.3 (varies by crop/region) | GTAP-BIO, IMPACT |

| Land Transformation Matrix | Probability of land transitioning from type A to B. | Region-specific | GLM, LandSHIFT |

| Carbon Stock Reference (Forest) | Above & belowground biomass carbon. | 40 - 200 Mg C/ha (IPCC Tier 1) | IPCC Guidelines, FAO |

| iLUC Amortization Period | Years over which carbon debt is distributed. | 20 - 30 years | EU Renewable Energy Directive |

Table 2: Comparative Analysis of Lignocellulosic Feedstock Sustainability Indicators

| Feedstock | Avg. Yield (Mg DM/ha/yr) | Water Stress Index (0-1)* | Soil Erosion Factor (vs. bare soil)* | SOC Sequestration Potential (Mg C/ha/yr) | FSS Range* |

|---|---|---|---|---|---|

| Miscanthus | 10-15 (temperate) | 0.4-0.6 | 0.1-0.3 | 0.5 - 1.5 | 0.65-0.80 |

| Switchgrass | 8-12 (temperate) | 0.3-0.5 | 0.2-0.4 | 0.3 - 1.0 | 0.70-0.85 |

| Short Rotation Coppice (Willow) | 8-10 (boreal/temp) | 0.5-0.7 | 0.1-0.2 | 0.8 - 2.0 | 0.60-0.75 |

| Agricultural Residues (e.g., Corn Stover) | 2-4 (ratio to grain) | 0.1 (allocated) | 0.8-1.0 (if over-removed) | -0.2 - 0.0 | 0.40-0.60 |

*Lower is better. Positive values indicate sequestration. *Feedstock Sustainability Score (0-1, higher is better).

Diagrams

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in BECCS Feedstock Research |

|---|---|

| Fixed-Volume Soil Corer | Ensures accurate, uncompacted soil samples for bulk density and carbon content analysis. |

| Elemental Analyzer (CN/S) | Precisely measures carbon and nitrogen content in soil and plant tissue via dry combustion. |

| Geographic Information System (GIS) Software (e.g., QGIS, ArcGIS) | For spatial analysis of land use, yield maps, and resource constraints. |

| Life Cycle Assessment (LCA) Software (e.g., openLCA, GaBi) | Models the environmental impacts of bioenergy supply chains, integrating iLUC factors. |

| Dynamic Global Vegetation Model (DGVM) (e.g, LPJmL, ORCHIDEE) | Projects long-term biomass yield and carbon cycles under climate scenarios. |

| Economic Equilibrium Model (e.g., GTAP-BIO) | Assesses market-mediated indirect land-use change impacts. |

| Near-Infrared (NIR) Spectrometer | For rapid, non-destructive estimation of lignocellulosic composition (cellulose, hemicellulose, lignin). |

Technical Support Center: Troubleshooting BECCS Integration & Analysis

FAQ: Core Technical Issues

Q1: During a pilot-scale amine-based CO₂ capture experiment integrated with a biomass boiler, we observe a rapid increase in solvent viscosity and a drop in capture efficiency. What is the likely cause and solution? A: This is a classic symptom of solvent degradation due to oxidative degradation, exacerbated by the presence of oxygen and impurities (e.g., SOx, NOx) in the flue gas from biomass combustion, which is often more variable than from fossil sources.

- Troubleshooting Protocol:

- Immediate Analysis: Test solvent samples for heat stable salts (HSS) concentration and total acid number.

- Flue Gas Pre-treatment Check: Verify the efficiency of your particulate filter and wet scrubber. Measure SO₂ and O₂ levels entering the absorber column.

- Solvent Management: Implement a continuous solvent reclamation process (e.g., vacuum distillation) to remove HSS. Consider adding an antioxidant (e.g., sodium metavanadate) to the solvent formulation.

- Preventive Maintenance: Increase the pre-treatment severity. For experimental consistency, use a synthetic, standardized flue gas mixture during initial bench-scale trials to isolate the biomass-specific impurity effects.

Q2: Our techno-economic assessment (TEA) model shows extreme sensitivity to biomass moisture content, drastically altering the net energy output. How can we stabilize this input parameter experimentally? A: Biomass feedstock variability is a primary economic and energetic hurdle. You must control and measure this parameter rigorously.

- Experimental Protocol for Feedstock Standardization:

- Pre-processing: Establish a dedicated drying protocol. Pass all biomass through a rotary drum dryer set to a consistent moisture content target (e.g., 15% w.b.).

- Monitoring: Use a real-time moisture analyzer (e.g., NIR-based) on the feedstock conveyor pre-combustion.

- Data Integration: Feed real-time moisture data into your process mass and energy balance calculations. Your TEA should run scenarios with a ±5% deviation from your controlled baseline.

- Key Reagent/Material: Standardized Biomass Pellets. Use commercially available, characterized pellets (with certificate of analysis for moisture, ash, HHV) as your experimental control to benchmark your variable local feedstock against.

Q3: When calculating the Energy Penalty of a BECCS add-on, what are the critical boundary conditions for the system, and how do I avoid double-counting? A: The energy penalty must isolate the parasitic load of the CCS chain from the base energy conversion plant.

- Methodology for Consistent Calculation:

- Define Base Case: System = Biomass plant without capture. Output = Net electrical/thermal energy (Ebase).

- Define BECCS Case: System = Same plant + capture + compression units. Output = Net energy (EBECCS).

- Calculation: Energy Penalty (%) = [(Ebase - EBECCS) / E_base] * 100.

- Key Boundary: All ancillary loads for capture (solvent pumps, fans, stripper reboiler heat) and compression (compressor power) must be allocated to the BECCS case. The heat for solvent regeneration must be drawn from the plant steam cycle, reducing power output.

- Common Pitfall: Do not separately account for the energy content of the captured CO₂ itself; the penalty reflects the energy cost of capturing and compressing it.

Visualization: BECCS Process Integration & Energy Penalty Logic

Title: BECCS Process Flow & Energy Penalty Calculation Logic

The Scientist's Toolkit: Key Research Reagent Solutions

| Item / Reagent | Function in BECCS Scalability Research |

|---|---|

| 30 wt% Monoethanolamine (MEA) Solution | Benchmark solvent for CO₂ capture experiments. Used to establish baseline kinetics, loading capacity, and degradation rates. |

| Sodium Metavanadate | Antioxidant additive to amine solvents to mitigate oxidative degradation, a key factor in operational costs. |

| Certified Biomass Reference Materials | Pellets with standardized proximate/ultimate analysis. Critical for controlled experiments isolating process variables from feedstock variability. |

| Synthetic Flue Gas Mixtures | Cylinders with precise CO₂/N₂/O₂/SO2 blends. Allows study of capture performance without complex combustion set-ups. |

| Ion Chromatography (IC) System | For quantifying heat stable salts (formate, acetate, nitrate) in degraded solvent samples, informing reclamation needs. |

| Process Mass Spectrometer | For real-time analysis of gas streams (CO2, O2, SO2), essential for calculating instantaneous capture rates and solvent performance. |

Quantitative Data Summary: BECCS Techno-Economic Benchmarks

Table 1: Representative Capital & Operational Cost Ranges for BECCS Pathways (Post-2020 Literature)

| BECCS Configuration | Capital Cost ($/kW) | Energy Penalty Range | Levelized Cost of CO₂ Removed ($/tCO₂) |

|---|---|---|---|

| Post-Combustion (Amine) on Biomass Boiler | 2,800 - 4,500 | 20% - 30% | 120 - 250 |

| Biomass Integrated Gasification CCUS (BIGCC) | 4,500 - 7,000 | 15% - 25% | 150 - 300 |

| Bioethanol Fermentation with Capture | 500 - 1,200 (add-on) | 8% - 15% | 50 - 120 |

Table 2: Impact of Key Parameters on Economic Viability

| Parameter | Favorable Direction | Effect on Cost of CO₂ Removed | Experimental Control Method |

|---|---|---|---|

| Biomass Feedstock Cost ($/GJ) | Decrease | Decrease | Use waste residues; pre-process to reduce moisture. |

| Plant Capacity Factor (%) | Increase | Decrease | Design for flexible feedstock; robust solvent management. |

| Capture Efficiency (%) | Increase (beyond ~90%) | Can Increase | Optimize between energy penalty and marginal capture gain. |

| Solvent Degradation Rate | Decrease | Decrease | Use inhibitors, improved pre-treatment, reclamation. |

Technical Support Center: BECCS Experimental Systems

Troubleshooting Guides & FAQs

Q1: During our pilot-scale bioenergy carbon capture experiment, we are observing inconsistent CO₂ purity levels (>95% target) in the output stream fed to the simulated transport line. What are the primary contaminants and how can we stabilize the process?

A: Inconsistent purity is often due to water vapor carryover or residual flue gas components (N₂, O₂). Implement a three-step protocol:

- Verify Desiccant Bed Saturation: Replace or regenerate the adsorbent (e.g., 3Å molecular sieves) in the pre-compression drying unit. Standard protocol: Heat to 200°C under a vacuum of <0.1 bar for 4 hours.

- Analyze Feed Gas Composition: Use real-time Gas Chromatography (GC) with TCD detector at the absorber outlet. See Table 1 for common contaminants.

- Calibrate Solvent Regeneration: For amine-based capture, ensure the stripper reboiler temperature is maintained at 120°C ±2°C. Temperature deviation directly impacts residual water and solvent vapor in the product stream.

Q2: Our lab is modeling pipeline transport of dense-phase CO₂. We are encountering anomalous pressure drop simulations when introducing impurities based on real capture unit data. What is the acceptable impurity threshold for pipeline specifications?

A: Your simulation aligns with a key infrastructure gap. Impurities drastically alter the phase envelope and hydraulic behavior. Current industry specifications are summarized in Table 2. For BECCS-specific streams, focus on H₂O and NOx limits to prevent corrosion. The recommended experimental protocol is to use a high-pressure view cell to visually observe phase changes in your CO₂/impurity mixture at simulated pipeline conditions (90-150 bar, 10-40°C).

Q3: When planning a column experiment for mineral trapping in saline aquifers, what core parameters should we replicate, and what are common failure points in permeability?

A: Key parameters are reservoir temperature (35-80°C), pressure (>100 bar), and brine salinity (1-5 mol/kg NaCl). Common failure points include:

- Secondary Mineral Clogging: Rapid precipitation of carbonates (e.g., calcite) near the injection point can clog pore throats.

- Protocol: Conduct a batch reactor experiment first to kinetically constrain the primary reactive minerals (e.g., forsterite, anorthite) in your core sample. Use XRD analysis pre- and post-experiment.

- Solution: Model and experiment with lower CO₂ injection rates or pulsed injection to allow dissolution fronts to propagate without clogging.

Data Presentation

Table 1: Common CO₂ Stream Contaminants from BECCS Processes

| Contaminant | Typical Source in BECCS | Impact on Transport & Storage | Target Purity Threshold |

|---|---|---|---|

| Water (H₂O) | Flue gas, solvent carryover | Corrosion, hydrate formation | <500 ppm |

| Nitrogen (N₂) | Incomplete separation | Increases compression work, alters phase behavior | <4 mol% |

| Oxygen (O₂) | Incomplete separation | Accelerates pipeline corrosion | <1000 ppm |

| SOₓ & NOₓ | Biomass combustion | Forms acids with H₂O, causes corrosion & injectivity issues | <100 ppm total |

Table 2: Current CO₂ Transport Pipeline Impurity Specifications

| Specification Source | Max H₂O | Max N₂ | Max O₂ | Max Total Inerts (N₂+O₂+Ar) | Key Rationale |

|---|---|---|---|---|---|

| DIN/EN 12213 | 500 ppm | 4 mol% | 1000 ppm | 4 mol% | Prevent 2-phase flow, corrosion |

| ISO 27913:2016 | 500 ppm | 4 mol% | 1000 ppm | 4 mol% | Safety & material integrity |

| US Enhanced Oil Recovery (Typical) | 600 ppm | 4 mol% | 10 ppm | 4-5 mol% | Optimize miscibility & flow |

Experimental Protocols

Protocol 1: Determining the Corrosivity of Impure CO₂ Streams under Pipeline Conditions

- Objective: Measure corrosion rate of pipeline-grade steel (X65) in dense-phase CO₂ with controlled impurities.

- Materials: High-pressure autoclave, X65 steel coupons, HPLC pumps for H₂O injection, mass flow controllers for gases.

- Method:

- Polish and weigh six 1cm² X65 coupons.

- Load coupons into autoclave. Purge system with pure CO₂ for 5 minutes.

- Pressurize to 100 bar with CO₂ mixture (e.g., 97% CO₂, 2.5% N₂, 0.5% O₂).

- Inject deionized water to achieve 500 ppmv H₂O saturation.

- Heat to 40°C and maintain for 168 hours (1 week).

- Depressurize, retrieve coupons, clean per ASTM G1-03, and reweigh.

- Calculate mass loss and corrosion rate (mm/year) for each coupon. Compare to pure CO₂ control.

Protocol 2: Core Flooding Experiment for Saline Aquifer Injectivity Assessment

- Objective: Quantify changes in permeability of a sandstone core during supercritical CO₂ injection in the presence of synthetic brine.

- Materials: Hydrostatic core holder, syringe pumps (for brine & CO₂), confining pressure system, back-pressure regulator, synthetic brine (1M NaCl), Berea sandstone core.

- Method:

- Saturate a 1" diameter, 3" long core with synthetic brine under vacuum for 24 hours.

- Load core into holder, apply confining pressure (250 bar).

- Establish brine flow at 0.5 ml/min, measure initial permeability (Darcy's Law).

- Heat system to 60°C.

- Initiate supercritical CO₂ injection (at 150 bar) at 0.2 ml/min in a drainage cycle for 10 pore volumes (PVs).

- Switch to brine injection (imbibition) for 5 PVs.

- Repeat steps 5 & 6 for three cycles.

- Measure brine permeability after each cycle. Perform post-experiment µ-CT imaging to map pore structure changes.

Diagrams

Title: BECCS CO₂ Purity Troubleshooting Workflow

Title: Core Flood Test Protocol for Injectivity

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in BECCS Transport/Storage Research |

|---|---|

| 3Å Molecular Sieves | Desiccant for removing water vapor from CO₂ streams to prevent corrosion and hydrate formation. |

| X65 Steel Coupons | Standard pipeline material samples for corrosion testing under impure CO₂ conditions. |

| High-Pressure View Cell | Visual observation chamber for studying phase behavior of CO₂/impurity mixtures at pipeline conditions. |

| Berea Sandstone Core | Well-characterized, porous sedimentary rock used as a model substrate for saline aquifer injection experiments. |

| Synthetic Brine (1-5M NaCl) | Aqueous solution replicating the ionic strength and composition of deep saline formation waters. |

| Amino Solvent (e.g., 30 wt% MEA) | Benchmark chemical absorbent for CO₂ capture; used to study solvent carryover impacts. |

| Back-Pressure Regulator (BPR) | Critical device for maintaining precise, stable pressure during core flooding or flow loop experiments. |

Technical Support Center: BECCS Scalability Constraints Research

This support center provides troubleshooting guidance for common experimental, modeling, and analytical challenges encountered in BECCS (Bioenergy with Carbon Capture and Storage) scalability research, with a focus on intersecting geopolitical and social constraints.

FAQs & Troubleshooting Guides

Q1: Our integrated assessment model (IAM) shows high BECCS deployment, but stakeholder feedback indicates severe local opposition. How do we reconcile this data disparity? A: This is a classic "top-down vs. bottom-up" perception gap.

- Troubleshooting Step 1: Audit your IAM's socio-political parameters. Most default IAMs use simplified cost curves and do not adequately parameterize social license to operate (SLO) or justice constraints.

- Step 2: Implement a geospatial cross-reference. Layer your model's projected deployment map with GIS data on:

- Protected areas & land rights: Indigenous territories, community-managed lands.

- Historical fossil fuel dependence: Regions with high employment in extractive industries may show resistance or support based on just transition concerns.

- Water stress indices: BECCS feedstock cultivation can exacerbate local water scarcity.

Q2: How can we quantitatively assess "policy uncertainty" as a constraint in our techno-economic analysis (TEA)? A: Policy uncertainty is a risk multiplier affecting investment and innovation. Integrate it via sensitivity analysis and Monte Carlo simulations.

- Protocol: Policy Risk Factor Integration

- Identify Key Policy Levers: Carbon price, renewable fuel credits, CCS tax credits, land-use zoning laws.

- Assign Probability Distributions: For each lever, define a range (e.g., carbon price from $20 to $150/ton CO₂) and a likelihood distribution based on historical policy volatility analysis.

- Run Monte Carlo Simulations: Run your TEA model (e.g., in @RISK or Python) over 10,000+ iterations, each time drawing a random value for each policy lever from its defined distribution.

- Output Analysis: The result is a probability distribution of your output metric (e.g., Levelized Cost of Carbon Removal). The variance (width) of this distribution quantifies the impact of policy uncertainty.

Q3: Our life cycle assessment (LCA) yields net-negative emissions, but a justice-focused review criticized it for omitting localized air pollution impacts. What is the standard protocol for integrating environmental justice (EJ) into BECCS LCA? A: Traditional LCA uses globalized impact categories (e.g., GWP). EJ requires spatially explicit (high-resolution) inventory and impact assessment.

- Protocol: Spatially-Explicit LCA for EJ Assessment

- Inventory with Location Data: For every unit process in your BECCS supply chain (fertilizer production, feedstock transport, combustion, etc.), record the precise geographic location or proxy (e.g., county, grid region).

- Use High-Resolution Impact Models: Employ tools like the US EPA's TRACI 2.1 or ReCiPe at the regionalized level. Link emission locations to localized midpoint impact factors (e.g., particulate matter formation potential per kg of PM2.5 emitted in that specific airshed).

- Cross-Reference with Demographic Data: Overlay resulting impact "hotspots" with demographic data (using tools like EJSCREEN) to identify if burdens fall disproportionately on disadvantaged communities.

- Report Disaggregated Results: Present results not just as a single global "human health" score, but as maps or tables showing burden distribution.

Quantitative Data Summary

Table 1: Public Perception of BECCS from Recent Global Surveys (2022-2024)

| Region / Study Sample | Awareness Level | General Support | Top Concern | Highest Support Condition |

|---|---|---|---|---|

| EU Citizens (n=10,000) | Low (15%) | Conditional (45%) | Land-use competition with food | If using waste biomass & domestic storage |

| US General Public (n=2,500) | Very Low (8%) | Conditional (38%) | Cost to taxpayers | If paired with strong industrial emission reductions |

| Brazilian Agri-Community (n=800) | Medium (41%) | Opposed (62%) | Land tenure & displacement | Not supported as a primary climate solution |

| Global Climate Policymakers (n=350) | High (92%) | Supportive (78%) | Scalability & infrastructure delays | With international certification & leakage monitoring |

Table 2: Impact of Policy Uncertainty on Key BECCS Financial Metrics (Sensitivity Analysis)

| Policy Variable | Baseline Value | Uncertainty Range (±) | Impact on NPV (Median ± StDev) | Impact on Cost of CDR (Median ± StDev) |

|---|---|---|---|---|

| Carbon Price | $100/t CO₂ | 60% | +$45M ± $120M | -$15 ± $40 /t CO₂ |

| CCS Tax Credit (45Q) | $85/t CO₂ | 40% | +$30M ± $85M | -$10 ± $28 /t CO₂ |

| Biomass Sustainability Mandate | None | Binary (Pass/Fail) | -$15M to -$180M | +$5 to +$60 /t CO₂ |

| Cross-Border CO₂ Transport Agreement | No | Binary (Yes/No) | +$2M ± $75M | -$1 ± $25 /t CO₂ |

Mandatory Visualizations

Title: Geopolitical & Social Constraints Impact on BECCS Scalability

Title: Modeling Policy & Social Uncertainty in BECCS

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials & Tools for BECCS Constraints Research

| Item | Function in Research | Example / Specification |

|---|---|---|

| Integrated Assessment Model (IAM) | Projects global/regional BECCS deployment under climate pathways. Often lacks social detail. | MESSAGEix-GLOBIOM, GCAM (with custom land-use modules). |

| Spatially-Explicit LCA Database | Provides regionalized lifecycle inventory data for EJ analysis. | ecoinvent v3+ (with regionalized datasets), USDA CLUZ for land use. |

| Geographic Information System (GIS) | Layers bioresource potential, infrastructure, and socio-economic data for siting analysis. | QGIS, ArcGIS with EJSCREEN or CES 3.0 data layers. |

| Stakeholder Engagement Platform | Facilitates deliberative mapping, surveys, and workshops to gauge perception. | Pol.is, ThoughtExchange for large-scale opinion clustering. |

| Monte Carlo Simulation Add-in | Integrates with Excel or Python to model variable uncertainty. | @RISK, Python (NumPy/SciPy) for custom probabilistic modeling. |

| Policy Database | Tracks historical and current climate/energy/land policies for volatility analysis. | IEA Policies Database, Climate Change Laws of the World. |

Building Scalable Systems: Methodologies and Technologies for Expansion

Technical Support Center: Troubleshooting & FAQs

This support center is designed to assist researchers working on advanced BECCS (Bioenergy with Carbon Capture and Storage) feedstocks, within the context of overcoming scalability constraints. The following Q&As address common experimental and process challenges.

FAQ: Algae Cultivation & Processing

Q1: Our photobioreactor (PBR) algae cultures are experiencing a rapid drop in pH, followed by culture crash. What is the cause and solution? A: This is typically caused by excessive CO2 injection or heterotrophic bacterial overgrowth consuming organic acids.

- Troubleshooting Steps:

- Monitor & Adjust: Install a real-time pH probe and link it to a solenoid valve on your CO2 supply line. Setpoint should be pH 7.5-8.5 for most strains.

- Sterility Check: Aseptically inoculate a fresh BG-11 (or equivalent) agar plate from the crashed culture. Bacterial colonies indicate contamination. Re-initiate culture from a verified axenic stock.

- Protocol Enhancement: Implement a routine medium exchange (10-25% daily) in continuous systems to remove extracellular metabolites.

Q2: Lipid extraction yield from our harvested algal biomass is consistently below theoretical values. How can we optimize? A: Low yields often stem from inefficient cell wall disruption or solvent choice.

- Troubleshooting Steps:

- Pre-treatment: Implement a mechanical disruption step prior to solvent addition. Test and compare:

- Bead milling: (Protocol: Resuspend biomass paste in solvent, use 0.5mm glass beads, homogenize at 4°C for 5x 1min cycles with 1min cooling).

- Ultrasonication: (Protocol: Use a probe sonicator at 60% amplitude, 5s pulse on/10s pulse off, for 5 minutes on ice).

- Solvent System: Switch from a single solvent (e.g., hexane) to a binary system (e.g., Hexane:Ethanol 2:1 v/v) to better access polar lipids.

- Pre-treatment: Implement a mechanical disruption step prior to solvent addition. Test and compare:

FAQ: Waste Biomass Pre-processing

Q3: During enzymatic hydrolysis of agricultural waste (e.g., corn stover), we observe poor sugar conversion despite high enzyme loading. What's wrong? A: This indicates likely inhibition from pre-treatment by-products (furfurals, phenolics, acetic acid) or insufficient pre-treatment severity.

- Troubleshooting Steps:

- Analyze Pre-treatment Liquor: Use HPLC to quantify inhibitors. If levels are high (>1g/L furfurals, >5g/L acetic acid), employ a detoxification step (e.g., overliming with Ca(OH)2 to pH 10, then adjust back to 5.0).

- Assess Biomass Composition: Perform an NDF/ADF analysis or TAPPI standard test. If lignin content remains >25%, increase pre-treatment severity (e.g., increase temperature by 10°C or retention time by 5 minutes).

- Enzyme Absorption Test: Follow NREL LAP TP-510-42628 to measure cellulose accessibility.

Q4: Our gasification of municipal solid waste (MSW) syngas has high tar content, fouling downstream equipment. How to mitigate? A: Tar formation is a function of temperature, gasifier design, and feedstock uniformity.

- Troubleshooting Steps:

- Increase Temperature: Ensure gasification zone operates stably above 800°C. Tars crack efficiently above 950°C.

- Feedstock Preparation: Improve feedstock sorting and shredding to achieve a more homogeneous particle size (<2cm).

- In-bed Catalysis: Mix 5-10% wt. of dolomite (CaMg(CO3)2) or olivine sand with the feedstock bed to catalytically crack tars.

FAQ: Integrated System Modeling & LCA

Q5: Our integrated land-use model shows paradoxical carbon debt when switching from fallow land to energy grass cultivation. How is this possible? A: This "carbon debt" arises from modeled soil organic carbon (SOC) loss upon land-use change and initial cultivation emissions.

- Troubleshooting Steps:

- Validate SOC Model Parameters: Calibrate your CENTURY or RothC model with local soil data. Default parameters may overestimate loss.

- Include Full Carbon Flux: Ensure your model accounts for:

- Below-ground biomass (root) carbon accumulation.

- Annual carbon sequestration rate of the mature crop.

- Compare scenarios in the table below.

Q6: Life Cycle Assessment (LCA) results for our algae-BECCS pathway show higher fossil energy demand than the system produces. What are the key sensitivities? A: This indicates an energy-intensive process is dominating. Conduct a sensitivity analysis.

- Troubleshooting Steps:

- Isolate High-Impact Processes: Model energy demand for each stage: PBR mixing/CO2 injection, harvesting (centrifugation), drying, and lipid extraction.

- Target Reduction: Replace centrifugation with low-energy flocculation (e.g., using chitosan). Utilize waste heat for drying. Data from a typical analysis is summarized in the table below.

Data Presentation

Table 1: Comparative Carbon Budget for Land-Use Change Scenarios (Modeled over 30 years)

| Scenario | Initial SOC Loss (t CO2e/ha) | Annual Crop Sequestration (t CO2e/ha/yr) | Net Carbon Payback Time (years) | Net Cumulative Sequestration at Year 30 (t CO2e/ha) |

|---|---|---|---|---|

| Fallow Land (Baseline) | 0 | 0.2 | N/A | 6 |

| Switchgrass Cultivation | 15 | 3.5 | 4.5 | 90 |

| Miscanthus x giganteus | 18 | 6.0 | 3.2 | 162 |

| Short Rotation Coppice Willow | 10 | 2.8 | 3.8 | 74 |

Table 2: Energy Demand Sensitivity Analysis for Algae-to-Biofuel Pathways (per 1 kg biomass)

| Process Stage | Baseline (MJ/kg) | With Optimization (MJ/kg) | Key Intervention |

|---|---|---|---|

| Cultivation (Mixing, CO2) | 8.5 | 5.0 | Optimized bubble column PBR design |

| Harvesting (Centrifugation) | 12.0 | 1.5 | Switch to chitosan flocculation + belt filtration |

| Dewatering/Drying | 25.0 | 8.0 | Utilize waste heat from adjacent process |

| Lipid Extraction (Hexane) | 4.0 | 3.5 | Switch to wet extraction using ethanol |

| Total | 49.5 | 18.0 |

Experimental Protocols

Protocol 1: Standardized Biochemical Methane Potential (BMP) Assay for Waste Biomass

Purpose: To determine the ultimate anaerobic biodegradability and methane yield of a feedstock.

- Inoculum & Substrate Preparation: Collect anaerobic digester sludge as inoculum. Sieve (<1mm). Prepare substrate to a particle size of <0.5mm. Determine total solids (TS) and volatile solids (VS) of both.

- Bottle Setup: Use 500 mL serum bottles. Add inoculum (200 mL, 2 g VS/L). Add substrate at an inoculum-to-substrate VS ratio of 2:1. Include control bottles with inoculum only (blank) and cellulose (positive control). Adjust pH to 7.0 ± 0.2.

- Anaerobic Incubation: Flush headspace with N2:CO2 (70:30) for 2 min. Seal with butyl rubber stoppers and aluminum crimps. Incubate at 35°C ± 2°C with mild agitation (100 rpm) for 30-60 days.

- Gas Measurement: Measure biogas pressure daily using a manometer. Sample gas via syringe for CH4 composition analysis via GC-TCD. Calculate cumulative CH4 production at STP, subtract blank values, and report as mL CH4 per g VS of substrate added.

Protocol 2: High-Throughput Screening of Algal Strains for Growth under Flue Gas Conditions

Purpose: To identify strains tolerant to simulated industrial flue gas (high CO2, NOx, SOx traces).

- Simulated Flue Gas Medium: Prepare modified BG-11 medium. Sparge with a custom gas mix (15% CO2, 85% N2, with 100 ppm NO and 50 ppm SO2 added) for 30 min to lower pH to ~6.0. Filter sterilize.

- Inoculation & Cultivation: In a 96-well deep-well plate, add 1.8 mL of medium per well. Inoculate each well with 200 μL of a log-phase culture of different algal strains (n=3 per strain). Seal plate with a breathable membrane.

- Growth Conditions & Monitoring: Place plate in a multivariable plate shaker-incubator set to 25°C, 120 rpm, with continuous light at 150 μmol photons m⁻² s⁻¹. Monitor growth daily via optical density at 750 nm (OD750) for 7-10 days.

- Endpoint Analysis: On final day, measure pH, filter biomass for dry weight, and analyze lipid content via Nile Red fluorescence assay.

Diagrams

Algal Lipid Synthesis & Carbon Flux

Waste Biomass to BECCS Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Chitosan (from shrimp shells, >75% deacetylated) | A natural, cationic biopolymer used for low-energy flocculation and harvesting of microalgae by neutralizing negative cell surface charges. |

| Dolomite (CaMg(CO3)2, 100 mesh powder) | A low-cost, in-bed catalyst for fluidized bed gasifiers; promotes tar cracking and reforms methane, improving syngas quality. |

| Cellic CTec3 (Novozymes) | A commercial enzyme cocktail containing advanced cellulases, β-glucosidases, and hemicellulases for efficient hydrolysis of pre-treated lignocellulosic biomass. |

| Nile Red (9-Diethylamino-5H-benzo[α]phenoxazine-5-one) | A lipophilic fluorescent dye used for rapid, in-situ quantification of neutral lipids within algal cells via fluorescence spectrometry/microscopy. |

| ANKOM RF Gas Production System | An automated system for high-throughput biochemical methane potential (BMP) testing, using pressure sensors to continuously monitor biogas from multiple samples. |

| LI-COR LI-6800 Portable Photosynthesis System | Measures photosynthetic parameters (e.g., net CO2 assimilation, stomatal conductance) in plants/grasses under field conditions for growth model validation. |

| BG-11 Medium (Modified, without nitrogen) | A standard freshwater nutrient medium used for cyanobacteria and microalgae cultivation; nitrogen-free formulation induces lipid accumulation for biofuel studies. |

| RothC-26.3 Model Software | A widely-used model for simulating turnover of organic carbon in non-waterlogged soils, essential for predicting SOC changes in land-use scenarios. |

Technical Support Center

Troubleshooting Guides & FAQs

FAQ Category 1: Novel Solvents (e.g., Biphasic, Ionic Liquids, Deep Eutectic Solvents)

Q1: Our amino acid-based solvent system is showing a dramatic increase in viscosity after several absorption-desorption cycles, reducing mass transfer. What is the cause and solution? A: This is a common issue due to oxidative degradation of the organic base (e.g., DMAPA) and polymerization reactions, forming heat-stable salts (HSS) and oligomers.

- Diagnosis: Run ion chromatography on the degraded solvent. Look for peaks corresponding to formate, acetate, and oxalate. A color change to yellow/brown is also indicative.

- Solution:

- Prevention: Maintain oxygen concentration in flue gas below 50 ppm. Use an oxygen scavenger (e.g., sodium sulfite) in the wash system.

- Reclamation: Implement a side-stream reclamation process. Pass 5-10% of the solvent stream through an ion-exchange resin bed (e.g., strong acid cation resin) to remove HSS. Monitor pH and total alkalinity weekly.

- Solvent Make-up: Plan for a 2-5% solvent replacement rate per 1000 hours of operation to maintain performance.

Q2: We are experiencing phase instability in our water-lean, biphasic solvent. The system fails to separate into two distinct phases upon heating. A: Phase separation temperature is sensitive to water content and CO₂ loading.

- Diagnosis: Measure the water content (Karl Fischer titration) and CO₂ loading (BaCl₂ precipitation method) of the rich solvent.

- Solution: Adjust the water content. For a typical DEMEA/1-Propanol system, the optimal range is 15-25 wt% water. If water content is too low, add deionized water in 1% increments. If the CO₂ loading is too high (>1.2 mol CO₂ /mol amine), extend the desorption time or increase the reboiler temperature by 5-10°C to achieve more complete regeneration.

FAQ Category 2: Novel Sorbents (e.g., MOFs, Amine-Functionalized Silicas, Polymer/Sorbent Hybrids)

Q3: The CO₂ adsorption capacity of our amine-impregnated silica sorbent has dropped by over 40% after 50 temperature-swing cycles. A: This indicates amine leaching or degradation.

- Diagnosis: Run Thermogravimetric Analysis (TGA) on fresh and used sorbent. A shift in the amine decomposition peak or a change in weight loss profile confirms degradation. Collect condensate from the desorption step and test for amine presence via FTIR.

- Solution:

- Synthesis Protocol Adjustment: Switch from impregnation to grafting (e.g., use (3-aminopropyl)triethoxysilane). This forms covalent bonds, reducing leaching.

- Operational Adjustment: Ensure the desorption step uses dry, inert gas (e.g., N₂) instead of steam if the sorbent is not hydrothermally stable. Keep desorption temperature below the amine's decomposition point (typically <120°C for PEI).

- Sorbent Enhancement: Use a porous polymer scaffold (e.g., PVAm) as a support instead of silica for improved moisture stability.

Q4: Our MOF-303 column is showing excessive pressure drop during fluidized bed testing. A: This is likely due to attrition and formation of fine particles.

- Diagnosis: Sieve the used sorbent. An increase in sub-100 micron fraction confirms attrition.

- Solution:

- Pelletization: Form the MOF powder into binderless pellets or extrudes using a specialized press (> 50 MPa pressure). This improves mechanical strength.

- Coating: Apply a thin, hydrophobic polymer coating (e.g., polydimethylsiloxane) via chemical vapor deposition to toughen the outer surface without blocking pores.

- Process Control: Reduce gas velocity and implement a more gradual cycling frequency to minimize particle-on-particle impact.

FAQ Category 3: Oxy-Combustion for BECCS

Q5: Our pilot oxy-combustion boiler is experiencing erratic flame stability and increased NOx readings. A: This is caused by impurities (Ar, N₂) buildup in the recycled flue gas (RFG) loop and incorrect O₂ injection.

- Diagnosis: Continuously monitor the composition of the RFG. An inert (Ar+N₂) concentration above 35% is problematic. Check the O₂ injection lance position and swirl configuration.

- Solution:

- Purge Control: Increase the continuous purge rate from the RFG loop from ~1% to 2-3% of total flow to control inerts. Condense and compress the purged stream for storage.

- O₂ Staging: Implement staged oxygen injection. Use 70% of O₂ in the primary burner and 30% through secondary lances to create a more stable, distributed combustion zone.

- Flame Monitoring: Install a high-speed UV/IR flame detector and link it to an automated O₂ flow controller for real-time adjustment.

Q6: We are detecting significant SO₃ formation and acid dew point corrosion in the flue gas condensing heat exchanger of our oxy-combustion system. A: In oxy-combustion, SO₂ is more readily oxidized to SO₃ due to higher local oxygen partial pressures and the catalytic effect of Fe₂O₃ on boiler tubes.

- Diagnosis: Measure SO₃ concentration using controlled condensation method (ASTM D3226-11).

- Solution:

- Sorbent Injection: Inject powdered magnesium hydroxide (Mg(OH)₂) upstream of the heat exchanger. It reacts with SO₃ to form stable MgSO₄.

- Material Upgrade: Line the condensing heat exchanger with corrosion-resistant alloys (e.g., Inconel 625 or high-silicon stainless steel).

- Temperature Management: Keep the heat exchanger tube wall temperature above the acid dew point (which can be >150°C in oxy-firing) until after the SO₃ has been removed.

Data Presentation

Table 1: Performance Comparison of Novel Solvents for Post-Combustion Capture

| Solvent System | Absorption Rate (mol CO₂/L/min) | Regeneration Energy (GJ/t CO₂) | Cyclic Capacity (mol CO₂/kg solvent) | Degradation Rate (%/1000h) | Key Challenge |

|---|---|---|---|---|---|

| 30% MEA (Benchmark) | 0.85 | 3.9 | 2.1 | 3.5 | High energy, oxidative degradation |

| 5M PZ + AMP (Biphasic) | 1.42 | 2.4 | 4.3 | 1.8 | Solid precipitation, corrosion |

| [P66614][2-CNpyr] (IL) | 0.12 | 2.1 | 1.8 | <0.5 | High viscosity, slow kinetics, cost |

| ChCl:Urea (2:1) (DES) | 0.31 | 2.8 | 2.9 | 2.2 | High water volatility, long-term stability |

Table 2: Characteristics of Advanced Sorbents for Direct Air Capture (DAC) Integration

| Sorbent Material (Structure) | Capacity (mol CO₂/kg) @ 400 ppm | Regeneration T (°C) | Selectivity (CO₂/N₂) | Stability (Cycles) | Production Cost ($/kg) |

|---|---|---|---|---|---|

| PEI-Impregnated SBA-15 | 2.5 | 80-100 | >500 | ~1,000 | ~50 |

| Mg-MOF-74 | 5.1 | 80 | 200 | >10,000 | ~300 |

| SIFSIX-3-Ni | 3.8 | 60 | >10,000 | 5,000 | ~150 |

| Amino-Grafted Cellulose | 1.7 | 70 | 300 | ~2,500 | ~20 |

Experimental Protocols

Protocol 1: Evaluation of Solvent Oxidative Degradation

- Objective: Quantify the formation of heat-stable salts (HSS) and loss of total alkalinity in an amine solvent under accelerated oxidative conditions.

- Materials: 250 mL gas-washing bottle, heated water bath, gas flowmeters, compressed air/O₂/N₂, 500 mL of 5M test solvent (e.g., MEA, PZ), ion chromatograph.

- Method:

- Load 200 mL of fresh solvent into the gas-washing bottle. Place in a bath at 55°C.

- Sparge with a gas mixture of 98% N₂ + 2% O₂ at a rate of 100 mL/min. Maintain for 120 hours.

- At 0h, 24h, 72h, and 120h, extract a 5 mL sample.

- Analyze each sample: a) Measure total alkalinity by titrating with 0.1M HCl to pH 4.5. b) Filter and inject into IC to quantify formate, acetate, oxalate, and glycolate anions.

- Analysis: Plot total alkalinity and total HSS concentration vs. time. The slope indicates degradation rate.

Protocol 2: Determination of Sorbent Working Capacity in a Fixed Bed

- Objective: Measure the dynamic CO₂ adsorption and desorption capacity of a solid sorbent under realistic temperature-swing conditions.

- Materials: Fixed-bed reactor (10 mm ID x 200 mm length), tubular furnace, mass flow controllers, 10 g of pelletized sorbent, 1% CO₂ in N₂, pure N₂, online CO₂ analyzer (NDIR).

- Method:

- Pack sorbent into the reactor. Activate at 120°C under N₂ (50 mL/min) for 2 hours.

- Cool to adsorption temperature (25-40°C). Switch gas to 1% CO₂/N₂ at 100 mL/min. Record CO₂ breakthrough curve until outlet equals inlet concentration.

- Switch back to N₂ purge at 50 mL/min for 15 min to remove interstitial CO₂.

- Heat the furnace to the desorption temperature (80-110°C) under 50 mL/min N₂. Collect data until CO₂ concentration in effluent returns to baseline.

- Analysis: Integrate the area above the breakthrough curve (adsorption) and the area under the desorption peak. Calculate capacity in mol CO₂/kg sorbent.

Visualizations

Diagram 1: Oxy-Combustion Process for BECCS

Diagram 2: Primary Amine Solvent Degradation Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Novel Solvent & Sorbent Research

| Item & Example Product | Function in BECCS Research |

|---|---|

| Amino Silane Coupling Agent(3-Aminopropyl)triethoxysilane (APTES) | Graft amine functional groups onto silica/metal oxide supports for stable, leach-resistant solid sorbents. |

| Polymeric AminePolyethylenimine (PEI), Branched, MW ~800 | High-density amine source for impregnation into porous supports for DAC and dilute capture applications. |

| Ionic Liquid Precursor1-Butyl-3-methylimidazolium chloride ([BMIM]Cl) | Base for synthesizing task-specific ionic liquids with tunable properties for CO₂ capture. |

| Deep Eutectic Solvent ComponentsCholine Chloride & Ethylene Glycol | Form low-cost, biodegradable solvents with high CO₂ solubility and low volatility. |

| MOF Synthesis Linker2,5-Dihydroxyterephthalic acid (DOBDC) | Chelating linker used to synthesize high-capacity, magnesium-based MOFs (e.g., Mg-MOF-74). |

| Oxygen ScavengerSodium Sulfite (Na2SO3), Reagent Grade | Added to solvent wash systems to remove trace O₂ from flue gas, mitigating solvent oxidative degradation. |

| Corrosion InhibitorSodium Metavanadate (NaVO3) | Forms a protective layer on steel, protecting pilot plant piping and columns from amine solvent corrosion. |

| Analytical Sorbent for GCCarboxen-1010 PLOT Column | Used in gas chromatographs for precise separation and quantification of CO₂, N₂, O₂, and light impurities. |

Technical Support Center: Biomass Supply Chain Modeling

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: My geographic information system (GIS) model for biomass feedstock locations is yielding unrealistic transport distances. What could be the issue?

- A: This is often caused by incorrect network impedance settings. Ensure your road network layer includes accurate attributes for road type (e.g., highway, secondary, tertiary) and that you have applied appropriate speed limits or cost functions (e.g., $/km for trucks) to each segment. Verify that preprocessing facility locations are correctly geocoded. Common errors include using straight-line distance instead of network-constrained routing.

Q2: How do I calibrate the moisture content decay function in my dynamic inventory model for roadside biomass storage?

- A: Calibration requires local empirical data. Establish a controlled experiment (see Protocol 1). Key parameters to fit are the initial decay rate constant (k) and its dependence on local average precipitation and temperature. Use non-linear regression (e.g., Levenberg-Marquardt algorithm) to fit your experimental data to a first-order exponential decay model: MC(t) = MC₀ + (MC_eq - MC₀) * (1 - e^{-kt}), where *MC_eq is the equilibrium moisture content.

Q3: My mixed-integer linear programming (MILP) model for facility location becomes computationally intractable with high-resolution data. What are my options?

- A: Implement a two-stage heuristic. First, use clustering algorithms (e.g., k-means based on biomass density and coordinates) to aggregate feedstock points into "super-nodes." Solve the MILP on this aggregated network. Second, use the solution to fix the facility location variables and solve a detailed routing model on the full dataset. Also, examine and tighten the "Big M" constraints in your formulation.

Q4: What is the best way to model biomass quality degradation (e.g., carbohydrate loss) for BECCS feedstock specifications?

- A: Implement a quality-adjusted tonnage metric. Develop a degradation index (DI) based on key parameters (see Table 2). The model should minimize total cost per unit of usable carbohydrate, not per wet ton. This requires integrating experimental degradation kinetics (see Protocol 2) into your spatial-temporal inventory model.

Experimental Protocols

Protocol 1: Field-Based Measurement of Biomass Moisture Content Decay Objective: To quantify moisture loss and dry matter degradation of chipped biomass in open storage. Methodology:

- Sample Preparation: Collect representative biomass (e.g., corn stover, Miscanthus) and chip to a target particle size (e.g., 25 mm).

- Pile Construction: Establish multiple replicate piles (min. n=3) of standardized dimensions (e.g., 3m x 3m x 2m) at a field site.

- Instrumentation: Insert temperature and humidity probes at the pile's core and periphery. Install a rain gauge.

- Sampling Schedule: At days 0, 3, 7, 14, 30, and 60, collect 3 sub-samples from each pile (core, mid, surface).

- Lab Analysis: Weigh samples (wet weight), dry in an oven at 105°C for 24 hours, and re-weigh (dry weight). Calculate moisture content: MC (%) = [(Wet Wt. - Dry Wt.) / Wet Wt.] * 100.

- Advanced Analysis: For a subset, perform compositional analysis (e.g., NREL/TP-510-42618) to track glucan and xylan loss.

Protocol 2: Laboratory Simulation of Transport-Induced Biomass Degradation Objective: To model the effect of continuous vibration and airflow on biomass particle size distribution and dust generation. Methodology:

- Setup: Use a custom-designed or repurposed vibrating conveyor table. Place a standardized biomass sample (e.g., 5 kg of dried chips) in a ventilated container on the table.

- Stress Application: Subject samples to vibrational frequencies (e.g., 5-15 Hz) and durations (0-180 minutes) simulating truck transport over varying road qualities.

- Analysis: At set intervals, remove the sample. Sieve using a stacked sieve shaker (e.g., 8", 4", 2", 1", 0.5" sieves) for 10 minutes. Weigh the mass retained on each sieve.

- Data Processing: Calculate the change in mean particle size and the percentage of "fines" generated (<0.5 mm). Fit the data to a comminution model.

Table 1: Comparative Transport Cost Factors for Biomass Feedstocks

| Feedstock Type | Average Density (kg/m³, baled) | Typical Moisture Content at Harvest (%) | Dry Matter Loss Rate in Storage (%/month) | Estimated Transport Cost ($/dry ton/km) |

|---|---|---|---|---|

| Corn Stover | 140-180 | 15-25 | 1.5 - 3.0 | 0.12 - 0.18 |

| Miscanthus | 160-200 | 50-60 | 0.5 - 1.5 | 0.14 - 0.20 |

| Willow Chips | 250-300 | 45-55 | 2.0 - 4.0 | 0.10 - 0.15 |

| Forest Residues | 220-280 | 30-50 | 2.5 - 5.0 | 0.13 - 0.19 |

Table 2: Biomass Quality Degradation Parameters for BECCS Modeling

| Quality Metric | Initial Value (Fresh) | Value after 60-day Storage | Analytical Method (NREL Standard) | Impact on Conversion Yield |

|---|---|---|---|---|

| Glucan Content | 36.5% | 33.1% | TP-510-42618 | Direct linear correlation |

| Ash Content | 5.2% | 7.8% | TP-510-42622 | Inhibits pyrolysis/process |

| Fines (<3mm) | 8% | 22% | Sieve analysis (ASABE S424.1) | Increases handling loss |

Visualizations

Title: Biomass Supply Chain Optimization Modeling Workflow

Title: Biomass Quality Degradation Experimental Protocol

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Biomass Supply Chain Research |

|---|---|

| GIS Software (e.g., QGIS, ArcGIS Pro) | For spatial analysis of feedstock availability, road network modeling, and optimal location-allocation studies. |

| Optimization Solver (e.g., Gurobi, CPLEX) | A computational engine to solve large-scale MILP and LP models for network design and routing. |

| Programmatic Environment (Python/R) | For scripting data pipelines, connecting GIS outputs to optimization models, and performing statistical analysis of degradation data. |

| Standardized Biomass Analytical Protocols (NREL LAPs) | Essential for generating consistent, comparable data on biomass composition, moisture, and ash content. |

| Controlled Climate Chambers | To simulate specific temperature and humidity conditions for accelerated shelf-life and degradation studies. |

| Particle Size Analyzer / Sieve Shaker | To quantify changes in particle size distribution due to handling, storage, and transport simulation. |

| Precision Moisture Analyzer | For rapid and accurate measurement of moisture content in biomass samples during experiments. |

Technical Support Center: Troubleshooting BECCS Policy & Market Experimentation

Frequently Asked Questions (FAQs)

Q1: In our modeled carbon pricing scenario, BECCS remains financially non-viable despite a high carbon price. What are the primary checkpoints? A1: First, verify the integration of the biomass feedstock cost curve and its volatility into your model. Second, confirm that the model includes transport and storage (T&SG) cost adders specific to your project's geography, which are often underestimated. Third, ensure the carbon price is applied as a slippage-adjusted effective price, not the nominal headline price. A common error is omitting the opportunity cost of biomass used in competing sectors.

Q2: Our Contracts for Difference (CfD) financial model shows high sensitivity to a single variable. Which parameter requires the most rigorous calibration? A2: The strike price calibration against the projected EUA (EU Allowance) price trajectory is the most critical. You must use a stochastic model for EUA prices, not a static forecast. Use a Monte Carlo simulation with at least 10,000 iterations, incorporating policy shock variables from recent EU Fit for 55 packages. The reference price mechanism (e.g., average vs. spot) in your CfD draft will drastically alter outcomes.

Q3: When simulating a certification scheme for biomass sustainability, how do we resolve data gaps in soil carbon stock change (ΔC) for indirect land-use change (iLUC) calculations? A3: Implement a tiered hybrid approach. For regions with >80% data coverage, use the IPCC Tier 2 method with country-specific emission factors. For data-poor regions, integrate a conservative Tier 1 fallback value with a 30% risk premium buffer into your life-cycle assessment (LCA). We recommend coupling this with remote sensing data (using NDVI time-series analysis) to proxy ΔC, as per the latest methodology from the Roundtable on Sustainable Biomaterials (RSB).

Q4: Our agent-based model (ABM) for market adoption of BECCS shows unrealistic cliff-edge behavior. How can we improve the transition logic? A4: This often stems from an oversimplified investment decision function. Replace binary payback-period thresholds with a probabilistic investment function incorporating: a) a gradient of risk aversion profiles across agent types, b) access to capital constraints modeled as a dynamic hurdle rate, and c) a "policy signal confidence" variable that increments only after consecutive periods of stable policy. Tune these parameters using historical data from analogous technology deployments (e.g., wind/solar CfD auctions).

Table 1: Comparative Analysis of Carbon Price Impact on BECCS LCOE

| Carbon Price Mechanism | Price Level (€/tCO₂) | Baseline BECCS LCOE (€/MWh) | Effective Support (€/MWh) | Breakeven Biomass Cost (€/GJ) |

|---|---|---|---|---|

| EU ETS (Average 2023-25) | 75 | 125 | 32 | 8.5 |

| National Carbon Tax (e.g., Sweden) | 115 | 125 | 48 | 10.1 |

| Hypothetical Sectoral Floor Price | 100 | 125 | 41 | 9.4 |

| CORSIA (Aviation Offset, 2024) | 8 | 125 | <5 | 2.1 |

Table 2: Key Parameters for CfD Strike Price Modeling

| Parameter | Description | Recommended Data Source | Typical Range for BECCS |

|---|---|---|---|

| WACC (Weighted Avg. Cost of Capital) | Project finance discount rate | Bloomberg NEF, Project Fin. Reports | 7-12% |

| Capacity Factor | Net operational efficiency | NETL Bioenergy Database | 70-85% |

| Capital Expenditure (CAPEX) | Overnight build cost per kW | IEAGHG 2023 Report, BECCS Updates | €4,500 - €6,500/kW |

| EUA Price Volatility (σ) | Annualized std. dev. of returns | ICE Futures Europe Historical Data | 35-50% |

| Construction Period Risk Premium | Added cost due to delay risk | Country-specific infrastructure indices | 1.5-3.0% adder to WACC |

Experimental Protocols

Protocol 1: Calibrating an Agent-Based Model (ABM) for BECCS Policy Adoption Objective: To simulate the rate of BECCS facility deployment under a hybrid carbon pricing and CfD regime. Methodology:

- Agent Definition: Define three agent classes: Independent Power Producers (IPPs), Industrial Emitters, and Investor Consortiums. Assign each agent attributes: risk tolerance (low/med/high), capital availability, and policy trust index (0-1).

- Policy Environment Module: Program a stochastic carbon price path using a mean-reverting model (Ornstein-Uhlenbeck process). Calibrate it to 5 years of historical EUA futures data.

- Decision Engine: For each simulation time step (quarterly), each agent calculates a Net Policy Benefit Score (NPBS).

NPBS = (CfD Top-up + Carbon Price Revenue) * Policy Trust Index - Perceived Risk Cost - Investment Trigger: An agent initiates a project if its NPBS exceeds its dynamically calculated hurdle rate for three consecutive periods.

- Validation: Run the model 1000 times. Compare the aggregate deployment curve (MW per year) against historical deployment curves for offshore wind under the UK CfD scheme, using the Kolmogorov-Smirnov test for distribution similarity (target p-value > 0.1).

Protocol 2: Life-Cycle Assessment (LCA) for Biomass Certification Objective: To quantify the net carbon removal of a BECCS value chain for certification under the ISO 14044:2006 standard. Methodology:

- System Boundary: Define a cradle-to-grave boundary: biomass cultivation, harvest, transport, pre-processing, conversion (BECCS plant), CO2 transport, and geological storage.

- Data Collection: Use primary data for transport distances and plant efficiency. For soil carbon change (ΔC) and iLUC, use the

CARBONmodel with regional GIS data on land cover change. - Allocation: Apply system expansion (avoided burden) for co-products (e.g., excess heat, bio-char). Do not use mass or energy allocation.

- Uncertainty Analysis: Perform a Monte Carlo simulation (10,000 runs) for the five most sensitive parameters: biomass yield, ΔC, conversion efficiency, methane leakage from supply chain, and forest management practice factor.

- Reporting: Report the net carbon dioxide removal (CDR) in tCO₂eq per TJ of biomass, with a 90% confidence interval. This is the key metric for issuance of removal credits.

Diagrams

Diagram 1: BECCS Policy Support Evaluation Logic

Diagram 2: BECCS Certification LCA Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Tools for BECCS Policy & Market Analysis

| Item/Category | Function/Description | Example Source/Product |

|---|---|---|

| Integrated Assessment Model (IAM) | Projects long-term energy system & carbon price pathways under different policy scenarios. | MESSAGEix-BECCS, GCAM |

| Life Cycle Inventory (LCI) Database | Provides emission factors for biomass cultivation, processing, and transport for LCA. | Ecoinvent 3.9, USDA GREET Model |

| Financial Modeling Software | Builds stochastic discounted cash flow (DCF) models for project finance under CfDs. | @RISK for Excel, Python (NumPy, pandas) |

| Agent-Based Modeling Platform | Simulates market dynamics and investment decisions of heterogeneous actors. | NetLogo, AnyLogic |

| Geospatial Analysis Tool | Analyzes biomass supply curves, transport networks, and iLUC impacts. | ArcGIS Pro, QGIS with GRASS |

| Policy Database | Tracks current and proposed carbon pricing, subsidy, and certification rules. | ICAP Carbon Pricing Database, OECD Policy Instruments |

Technical Support Center: Troubleshooting Guides & FAQs

Context: This support center is part of a thesis research project investigating scalability constraints and integrated solutions for Bioenergy with Carbon Capture and Storage (BECCS). The following addresses common technical challenges encountered when coupling BECCS with Direct Air Capture (DAC), renewable energy sources, and industrial process streams.

Frequently Asked Questions (FAQ)

Q1: Our integrated BECCS-DAC pilot is experiencing intermittent solvent degradation (e.g., in amine-based capture). What are the primary destabilizing factors and mitigation protocols?

A: Intermittency from coupled renewables and fluctuating industrial heat sources are common culprits. The primary factors are:

- Thermal Cycling: Rapid temperature swings from variable renewable heat degrade chemical solvents.

- Oxidative Degradation: Excess oxygen from biomass flue gas or air contact accelerates amine breakdown.

- Contaminant Ingress: Particulates, SOx, or NOx from industrial process integration foul the system.

- Mitigation Protocol: Implement a buffering thermal energy storage (TES) unit and a robust gas pre-treatment train.

- Experimental Method: Set up a continuous solvent testing loop. Expose a standardized amine solution (e.g., 30 wt% MEA) to controlled thermal cycles (40-120°C) and synthetic flue gas with varying O2 (5-15%). Sample hourly for 72 hours. Analyze total alkalinity loss and formate/nitrate formation via ion chromatography. Compare degradation rates with and without a sacrificial antioxidant (e.g., sodium sulfite at 0.1 wt%).

Q2: When coupling wind/solar to a DAC unit's auxiliary systems, we face grid instability and power quality issues (voltage sags, harmonics). How is this quantified and resolved?

A: This is a power electronics integration challenge. The issue is quantified by measuring the Power Quality Index (PQI) and Total Harmonic Distortion (THD) at the point of common coupling (PCC).

- Troubleshooting Guide:

- Monitor: Use a power quality analyzer at the PCC for 7 days. Log voltage, frequency, and current THD.

- Identify: Correlate THD spikes (>5% IEEE Std. 519) with the start/stop of DAC compressors or fan arrays.

- Resolve: Install an active power filter (APF) or a unified power quality conditioner (UPQC). Size the device based on the measured reactive power deficit and harmonic spectrum. A rule-of-thumb is to oversize the APF capacity by 25% relative to the peak non-linear load measured.

Q3: In a system where industrial waste heat (e.g., from cement kilns) supplements BECCS reboiler duty, how do we manage variable heat quality and its impact on capture efficiency (ɳ_capture)?

A: Variable temperature and flow of waste heat lead to unstable stripper reboiler operation, causing fluctuations in solvent regeneration and CO2 production rate.

- Experimental Protocol for Characterization:

- Setup: Install a plate heat exchanger between the waste heat stream and a secondary thermal oil loop feeding the reboiler.

- Instrumentation: Fit temperature (T1, T2), pressure (P1), and mass flow (F1) sensors on both sides of the primary exchanger.

- Method: Over a 24-hour industrial cycle, record data at 1-minute intervals. Calculate available thermal power: Qdot = F1 * Cp * (T1in - T1_out).

- Correlation: Simultaneously measure the CO2 production rate (via gas flow meter). Plot ɳcapture (kg CO2/MJth) against Qdot and T1in. This reveals the minimum stable operating threshold for your specific integration.

Q4: What are the key material compatibility concerns when using shared CO2 compression and pipeline infrastructure between BECCS and DAC outputs?

A: Impurity profiles differ. BECCS-derived CO2 may contain trace O2, SO2, and NOx, while DAC-derived CO2 has high O2 and N2. Key concerns are enhanced pipeline corrosion and non-compliance with transport standards (e.g., DNV GL RP J202).

- Pre-injection Testing Protocol:

- Blending Analysis: In a high-pressure autoclave, create blended CO2 streams mimicking different BECCS:DAC ratios (e.g., 100:0, 70:30, 50:50, 0:100).

- Material Exposure: Suspend coupons of pipeline steel (e.g., X65) in the saturated vapor phase with 100 ppmv H2O added.

- Accelerated Test: Pressurize to 100 bar, cycle temperature (25-50°C) over 500 hours.

- Analysis: Measure corrosion rate via mass loss (ASTM G1) and surface pitting depth (profilometry). Cross-reference impurity levels against established corrosion models.

Table 1: Comparative Solvent Degradation Under Integrated System Stressors

| Stressor Condition | Solvent Type | Degradation Rate (%/hr) | Key Degradants Identified | Recommended Mitigation |

|---|---|---|---|---|

| Thermal Cycling (40-120°C) | MEA (30 wt%) | 0.15 | Formate, Acetate, Oxalate | Buffered TES; Temp. ramp limit <5°C/min |

| High O2 (10%) in Flue Gas | MEA (30 wt%) | 0.25 | Formate, Nitrate, HEI | Antioxidant (Na2SO3) dosing; Improved O2 stripping |

| SO2 Contamination (10 ppm) | PZ (40 wt%) | 0.08 | Sulfate, Thiosulfate | Enhanced pre-scrubbing (Alkaline wash) |

| Stable Renewable Heat | KS-1 (AMP-based) | 0.03 | Trace Formate | None required |

Table 2: Power Quality Metrics Before/After Integration of Active Filter

| Metric (at PCC) | Coupled System (Before) | With 500 kVA APF (After) | Industry Standard (IEEE 519) |

|---|---|---|---|

| Voltage THD (%) | 8.2 | 2.1 | <5% |

| Current THD (%) | 25.5 | 3.8 | <5% |

| Voltage Sag Events (/week) | 15 | 2 | N/A |

| Power Factor (avg) | 0.78 | 0.98 | >0.95 |

Experimental Protocols

Protocol 1: Determining Minimum Stable Waste Heat Duty for BECCS Stripper Objective: To define the threshold of variable industrial waste heat supply required to maintain >90% CO2 capture efficiency.

- Apparatus: Pilot-scale stripper column (packed bed), thermal oil heating loop with controllable heater, plate heat exchanger, industrial waste heat simulator (programmable furnace), data acquisition system (DAS).

- Procedure: a. Load the stripper with rich solvent from a standardized absorption run. b. Initiate thermal oil flow. Set waste heat simulator to provide a constant 150°C, 50 kW for 1 hour (baseline). c. Gradually decrease the simulator's output temperature and flow in 5% increments every 30 minutes, recording T, P, flow throughout. d. Continuously measure the CO2 stream exiting the stripper condenser using a calibrated mass flow meter. e. Calculate capture efficiency for each step relative to the baseline rich solvent loading.

- Analysis: Plot capture efficiency vs. supplied thermal power (kW). The inflection point where efficiency drops below 90% defines the minimum stable duty.

Protocol 2: Accelerated Corrosion Testing for Blended CO2 Streams Objective: To evaluate corrosion rates of pipeline materials under blended BECCS/DAC CO2 impurities.

- Apparatus: High-pressure, high-temperature autoclave with gas mixing system, material coupon racks, gas chromatography system, precision balance.

- Procedure: a. Prepare and polish steel coupons (API X65), measure initial mass and surface profile. b. Place coupons in autoclave. Create desired gas blend (e.g., 98% CO2, 1.8% N2, 0.2% O2, 100 ppmv H2O, 10 ppmv SO2 for BECCS-dominant blend). c. Pressurize to 80 bar and heat to 40°C. Maintain for 168 hours (1 week). d. Depressurize, retrieve coupons, clean per ASTM G1, and measure final mass. e. Analyze surface pitting using optical profilometry.

- Analysis: Corrosion rate (mm/year) = (K * ΔW) / (A * T * D), where K=8.76e4, ΔW=mass loss (g), A=area (cm²), T=time (hr), D=density (g/cm³). Compare rates across blend ratios.

Diagrams

Integrated System Troubleshooting Workflow

Hybrid BECCS-DAC Material & Energy Flows

The Scientist's Toolkit: Research Reagent & Material Solutions

| Item Name | Function in Integrated System Research | Key Consideration for Scalability |

|---|---|---|

| Advanced Amine Solvents (e.g., KS-2, CANSOLV) | High-performance CO2 capture with lower degradation rates under thermal stress. | Cost vs. longevity trade-off in variable operation. |

| Sacrificial Antioxidants (Sodium Sulfite, ADA-500) | Mitigates oxidative solvent degradation in oxygen-rich flue gas or DAC contactor streams. | Consumption rate adds to operational cost; requires dosing control. |

| Corrosion Inhibitor Cocktails (e.g., filming amines) | Protects shared compression and pipeline infrastructure from blended-stream impurities. | Must not foul downstream processes or affect CO2 purity for storage. |

| Thermal Energy Storage Medium (Molten Salt, High-temp Oil) | Buffers intermittent heat supply from renewables/industry, ensuring stable stripper operation. | Energy density and temperature range must match process requirements. |

| Structured Packing Material (Mellapak 250.Y) | Provides gas-liquid contact in absorbers/ strippers with low pressure drop. | Fouling resistance is critical with real flue gases; cleaning protocols needed. |

| Gas Permeation Membranes (Polyimide-based) | Pre-treatment step to adjust CO2 concentration or remove impurities before capture. | Selectivity and flux under variable feed conditions determine system size. |

| Sorbent Materials (Solid DAC e.g., Aminosilica) | Alternative capture medium for DAC branch, often coupled with low-grade heat. | Cyclic capacity and attrition rate under rapid adsorption/desorption cycles. |

| Power Quality Analyzer (Fluke 435 Series II) | Diagnoses harmonic distortion and instability at renewable-conventional grid coupling point. | Essential for sizing mitigation equipment (APF, UPS) in pilot plants. |

Overcoming Implementation Hurdles: Troubleshooting and Process Optimization

Technical Support Center

Welcome to the BECCS Feedstock Analysis Technical Support Hub. This center addresses common experimental challenges in characterizing and pre-processing biomass feedstocks for Bioenergy with Carbon Capture and Storage (BECCS) systems, a critical area for scalability research.

Troubleshooting Guides & FAQs

Q1: Our lignocellulosic feedstock analysis shows inconsistent cellulose content between batches from the same supplier, leading to variable sugar yields. What could be the cause and how can we standardize our protocol? A: Seasonal variability (harvest time, rainfall, soil conditions) directly impacts the cellulose:lignin:hemicellulose ratio. To mitigate this, implement a standardized pre-screening protocol.

- Action: 1) Use NIR spectroscopy for rapid, non-destructive composition analysis on each batch. 2) For each new batch, run a full compositional analysis (see Protocol 1 below) to establish a baseline. 3) Blend batches to achieve a consistent compositional profile before processing.

Q2: During biomass size reduction, we experience equipment clogging and excessive energy use. The feedstock moisture content seems to vary widely. What is the optimal preprocessing step? A: High and variable moisture content is a primary cause. You must actively control moisture before comminution.