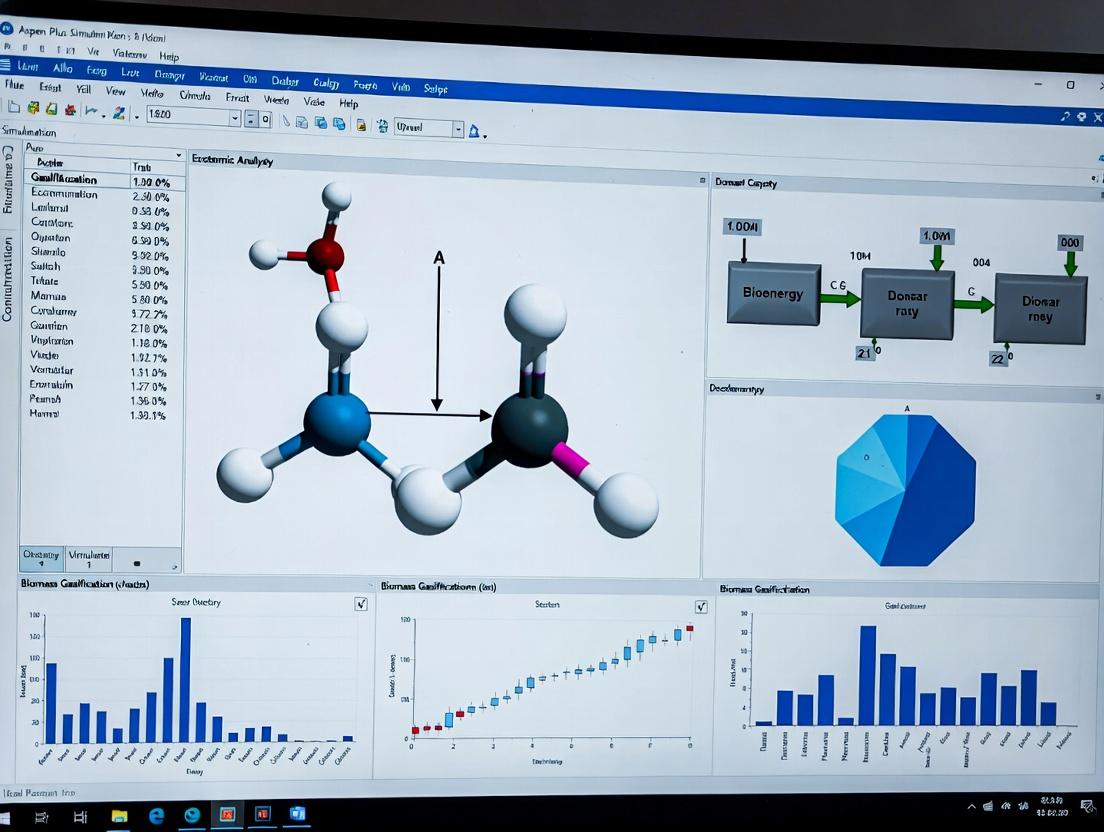

Biomass to Bio-Syngas Economics: A Comprehensive Aspen Plus Simulation Guide for Process Optimization

This article provides a detailed methodology for conducting techno-economic analysis (TEA) of biomass gasification processes using Aspen Plus simulation software.

Biomass to Bio-Syngas Economics: A Comprehensive Aspen Plus Simulation Guide for Process Optimization

Abstract

This article provides a detailed methodology for conducting techno-economic analysis (TEA) of biomass gasification processes using Aspen Plus simulation software. Aimed at researchers, scientists, and process development professionals, it covers the foundational principles of gasification modeling, step-by-step simulation setup, strategies for troubleshooting common convergence issues, and robust methods for model validation against experimental data. The guide integrates thermodynamic property methods, reactor selection (RGibbs, RStoic, RYield), and downstream purification to establish a framework for calculating key economic indicators like capital expenditure (CAPEX), operating expenditure (OPEX), and levelized cost of syngas. By bridging process simulation with financial analysis, this work serves as a practical resource for optimizing biomass conversion pathways toward commercially viable biorefineries and sustainable chemical production.

Biomass Gasification Fundamentals and Aspen Plus Modeling Prerequisites

Abstract This application note details the core principles of biomass gasification, providing essential background and experimental protocols for researchers engaged in process modeling, particularly within the context of Aspen Plus simulation for techno-economic analysis. The content is tailored for scientific professionals requiring rigorous, reproducible methodologies.

Chemistry of Biomass Gasification

Biomass gasification is a thermochemical process that converts carbonaceous materials into a combustible gas mixture (syngas: primarily CO, H₂, CH₄, CO₂) through partial oxidation at elevated temperatures (typically 700–1200°C). The process occurs through four principal, often overlapping, stages:

- Drying (Up to ~150°C): Removal of moisture.

- Pyrolysis/Devolatilization (200–500°C): Thermal decomposition in the absence of oxygen to produce char, condensable tars, and volatile gases.

- Oxidation (700–1500°C): Exothermic reaction of a portion of the char and volatiles with a limited supply of oxygen (air, pure O₂) or steam to provide the heat for the process. Key reactions include:

- C + O₂ → CO₂ (Complete combustion)

- 2C + O₂ → 2CO (Partial combustion)

- Reduction (800–1100°C): Endothermic reactions where the primary syngas is formed. Key reactions include:

- Boudouard: C + CO₂ 2CO

- Water-Gas: C + H₂O CO + H₂

- Water-Gas Shift: CO + H₂O CO₂ + H₂

- Methanation: C + 2H₂ CH₄

Reactor Types and Characteristics

The choice of gasifier significantly impacts syngas composition, tar content, and overall process efficiency, critical for downstream economic analysis.

Table 1: Comparison of Primary Biomass Gasifier Reactor Types

| Reactor Type | Operating Principle | Typical Temp. Range (°C) | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| Fixed-Bed (Downdraft) | Biomass & gas flow co-currently downward. Oxidation zone at bottom. | 700-1000 | Low particulate & moderate tar in syngas; Simple construction. | Requires uniform fuel size; Limited scale-up. |

| Fixed-Bed (Updraft) | Biomass moves down, gasification agent flows upward. Counter-current heat exchange. | 700-900 | High thermal efficiency; Handles high moisture fuel. | Syngas contains high tars; Not suitable for pyrolysis applications. |

| Fluidized-Bed (Bubbling) | Bed material (sand) fluidized by agent. High heat transfer & mixing. | 750-900 | Fuel flexibility; Good temperature uniformity; Scalable. | Syngas contains particulates; Moderate tar levels. |

| Fluidized-Bed (Circulating) | High gas velocity carries bed material, which is separated & recirculated. | 850-950 | Very high carbon conversion; Excellent mixing & heat transfer. | Complex design; Higher operating cost. |

| Entrained-Flow | Pulverized biomass & agent fed co-currently at very high velocity & temperature. | >1200 | Very high conversion; Very low tar; Large capacity. | Requires fine feed; High oxygen demand; High ash slagging. |

Key Performance Parameters (KPPs)

For Aspen Plus simulation and subsequent economic analysis, quantifying the following parameters is essential. Experimental protocols for their determination are provided.

Table 2: Key Performance Parameters for Gasification Evaluation

| Parameter | Definition | Formula/Typical Range | Impact on Economic Analysis |

|---|---|---|---|

| Cold Gas Efficiency (CGE) | Ratio of chemical energy in syngas to energy in biomass feed. | CGE = (LHV_gas * m_gas) / (LHV_biomass * m_biomass) | Directly influences fuel cost and plant revenue. Primary efficiency metric. |

| Carbon Conversion Efficiency (CCE) | Fraction of carbon in biomass converted to gas-phase carbon. | CCE = (Carbon in syngas / Carbon in biomass) * 100% | Impacts feedstock requirement and char waste stream. |

| H₂/CO Ratio | Molar ratio of hydrogen to carbon monoxide in syngas. | Varies (0.5-2.0) with feedstock, agent (air/steam/O₂). | Critical for downstream synthesis (e.g., Fischer-Tropsch, methanol). |

| Lower Heating Value (LHV) | Net energy content of syngas (excluding latent heat of water vapor). | Calculated from composition. Air gasification: 4-7 MJ/Nm³; O₂/steam: 10-15 MJ/Nm³. | Determines gas quality and energy output. |

| Tar Yield | Mass of condensable hydrocarbons produced per unit biomass. | mg/Nm³; Highly dependent on reactor & temp. | Major operational challenge; increases cleanup cost. |

Experimental Protocols for KPP Determination

Protocol 4.1: Syngas Composition Analysis via Gas Chromatography (GC) Objective: Quantify the volumetric or molar composition of dry syngas (H₂, CO, CO₂, CH₄, N₂, light hydrocarbons). Materials: See The Scientist's Toolkit below. Procedure:

- Sampling: Draw a representative, hot syngas sample from the reactor outlet using a heated sampling line (>300°C) to prevent tar condensation.

- Conditioning: Pass sample through a series of impinger bottles in an ice bath to remove moisture and heavy tars. Follow with a silica gel or molecular sieve trap for final drying.

- Filtration: Use a heated particulate filter (0.5 µm) upstream of condensers to remove fine char/ash.

- Calibration: Calibrate the GC using a certified standard gas mixture spanning expected concentrations.

- Analysis: Inject a fixed volume of the dry, clean gas into the GC. A typical configuration uses a TCD for permanent gases (H₂, CO, CO₂, CH₄, N₂) and an FID for hydrocarbons. Use appropriate columns (e.g., ShinCarbon ST, MolSieve).

- Calculation: Use retention times and peak areas from the calibration standard to calculate the concentration of each component. Normalize to 100% on a dry, N₂-free basis if using air as gasification agent.

Protocol 4.2: Gravimetric Tar Yield Measurement (Solid Phase Absorption - SPA) Objective: Determine the total gravimetric tar content in the syngas. Materials: Sampling probe, heated line, tar condensation train (impingers), dichloromethane (DCM), drying column, rotary evaporator, analytical balance. Procedure:

- Isokinetic Sampling: Extract syngas at the same velocity as the main flow using a calibrated pump and a critical orifice. Maintain line temperature at 350-400°C.

- Tar Capture: Pass the gas through a series of 5-6 impingers submerged in an ice-salt bath (-20°C). The first 1-2 contain DCM as a solvent, the remainder are empty for condensation.

- Solvent Recovery: Combine the contents of all impingers and rinse with DCM. Filter the solution to remove soot/particulates.

- Drying: Pass the DCM-tar solution through a drying column containing anhydrous sodium sulfate.

- Evaporation: Evaporate the DCM solvent using a rotary evaporator at 40°C under reduced pressure.

- Weighing: Transfer the residual tar to a pre-weighed vial. Dry in a desiccator and weigh until constant mass is achieved.

- Calculation: Tar concentration (mg/Nm³) = (Mass of residue, mg) / (Sampled gas volume at standard conditions, Nm³).

Protocol 4.3: Calculation of Cold Gas Efficiency (CGE) & Carbon Conversion Efficiency (CCE) Objective: Compute CGE and CCE from experimental mass balances and analytical data. Prerequisites: Data from Protocol 4.1, plus measured biomass feed rate (kg/hr) and syngas flow rate (Nm³/hr). Procedure:

- Syngas LHV Calculation:

- From GC analysis, obtain the dry molar fraction (yi) of H₂, CO, CH₄, C₂H₄, etc.

- Multiply each yi by its respective volumetric LHV (e.g., H₂=10.8 MJ/Nm³, CO=12.6 MJ/Nm³, CH₄=35.8 MJ/Nm³).

- Sum the contributions: LHV_gas (MJ/Nm³) = Σ (yi * LHVi).

- CGE Calculation:

- CGE (%) = [ (Volumetric Syngas Flow, Nm³/hr) * (LHV_gas, MJ/Nm³) ] / [ (Biomass Feed Rate, kg/hr) * (LHV_biomass, MJ/kg) ] * 100.

- CCE Calculation:

- Determine molar flow of carbon in syngas: nC_gas (mol C/hr) = Syngas Flow * Σ (yi * ni), where ni = number of carbon atoms in species i (CO=1, CO₂=1, CH₄=1, C₂H₄=2).

- Determine molar flow of carbon in biomass: nC_biom (mol C/hr) = (Biomass Feed Rate / MW_carbon) * wt% Carbon in biomass (from ultimate analysis).

- CCE (%) = (nC_gas / nC_biom) * 100.

Visualization: Gasification Process Flow & Parameter Relationships

Diagram 1: Stages of Biomass Gasification

Diagram 2: KPPs Link Experiments to Economic Model

The Scientist's Toolkit

Table 3: Essential Research Reagents & Materials for Gasification Experiments

| Item | Function / Application | Specification Notes |

|---|---|---|

| Biomass Feedstock | Primary reactant. | Characterized by proximate (moisture, volatiles, fixed carbon, ash) and ultimate (C, H, N, S, O) analysis. Particle size controlled (e.g., 0.5-1.0 mm). |

| Gasifying Agent | Provides oxidant for partial combustion. | Air (for low-LHV syngas), Pure O₂ (for medium-LHV), Steam (for high H₂ content), or mixtures. Mass flow controllers required for precise blending. |

| Inert Bed Material (for FB) | Provides heat transfer medium and fluidization. | Typically silica sand (0.2-0.5 mm). Olivine or dolomite can act as tar-cracking catalysts. |

| Gas Chromatograph (GC) | Analyzes dry syngas composition. | Equipped with TCD (for H₂, CO, CO₂, CH₄, N₂) and FID (for hydrocarbons). Requires specific columns (e.g., MolSieve 5A, PoraPLOT U). |

| Calibration Gas Standard | Quantifies GC response. | Certified mixture of H₂, CO, CO₂, CH₄, C₂H₄, N₂ at known concentrations (e.g., 5-20% each balance N₂). |

| Dichloromethane (DCM) | Solvent for tar absorption and washing. | Analytical grade. Used in gravimetric tar measurement (SPA method). |

| Heated Sampling Line | Transfers representative syngas sample from reactor to analyzers/ traps without condensation. | Stainless steel or SilcoNert tubing, maintained at 300-400°C with trace heating. |

| Particulate Filter | Removes solid particulates (char, ash) from gas sample stream. | Heated sintered metal or ceramic filter (e.g., 2 µm pore size). |

Core Components of Techno-Economic Analysis (TEA) for Syngas Production

Within a broader thesis on Aspen Plus simulation for biomass gasification economic analysis, the Techno-Economic Analysis (TEA) serves as the critical framework for evaluating commercial viability. For researchers and scientists, including those in drug development leveraging syngas-derived biochemicals, TEA translates complex process simulations into actionable financial and strategic insights. This application note details the core components, protocols, and tools essential for a rigorous TEA of syngas production via biomass gasification.

Core TEA Components: Definitions & Quantitative Benchmarks

The TEA for syngas production integrates technical performance data from Aspen Plus simulations with economic parameters. The following table summarizes the key components and typical benchmark values derived from current literature and industry data.

Table 1: Core Components of TEA for Syngas Production

| Component Category | Specific Parameter | Typical Range/Value (Biomass to Syngas) | Explanation & Relevance |

|---|---|---|---|

| Technical Performance | Syngas Yield (m³/kg biomass, dry) | 1.0 - 2.5 | Primary output metric from Aspen simulation. |

| Syngas Composition (H₂+CO, vol%) | 30% - 60% | Defines quality and suitability for downstream use (e.g., Fischer-Tropsch, methanol). | |

| Cold Gas Efficiency (%) | 60% - 85% | Ratio of chemical energy in syngas to energy in feedstock. Key performance indicator. | |

| Carbon Conversion (%) | 75% - 99% | Fraction of biomass carbon converted to gas. | |

| Capital Costs (CAPEX) | Total Installed Plant Cost (TIP) | $1,000 - $3,000 per kW syngas output | Scale-dependent; includes gasifier, cleanup, auxiliary units. |

| Contingency (% of TIP) | 10% - 20% | Covers unforeseen expenses. | |

| Operating Costs (OPEX) | Feedstock Cost ($/dry tonne) | $20 - $80 | Major OPEX variable; highly location-specific. |

| Catalyst & Consumables | 2% - 5% of OPEX | For catalytic tar reforming or gas cleanup. | |

| Fixed Operating Costs | 2% - 4% of CAPEX/yr | Includes labor, maintenance, overhead. | |

| Economic Metrics | Minimum Syngas Selling Price ($/GJ) | $10 - $20 | Target price for economic viability at given ROI. |

| Net Present Value (NPV) | Project-specific ($M) | Must be >0 for profitability. Sensitive to discount rate. | |

| Internal Rate of Return (IRR, %) | 10% - 20% (hurdle rate) | Benchmark for investor attractiveness. | |

| Payback Period (years) | 5 - 12 | Time to recover initial investment. |

Experimental Protocols for TEA Data Generation

The following protocols outline the methodologies to generate data required for populating the TEA framework, linking Aspen Plus simulation to economic analysis.

Protocol 3.1: Integrated Process Simulation & Mass/Energy Balance

- Objective: To generate reliable technical performance data (yields, efficiencies, utility loads) as inputs for cost calculations.

- Methodology:

- Model Development: Build a steady-state Aspen Plus model of the entire biomass gasification and syngas cleanup train (e.g., using RGibbs for gasifier, Sep blocks for cleanup).

- Component Specification: Define all components, including non-conventional biomass (e.g., using ultimate and proximate analysis) and syngas species.

- Parameter Definition: Set operating conditions (temperature, pressure, equivalence ratio for air/steam gasification) based on experimental validation data.

- Simulation & Convergence: Run the simulation to convergence, ensuring mass and energy balances close within a 0.1% tolerance.

- Data Extraction: Record key stream data: syngas flow rate, composition, temperature, and pressure. Calculate performance metrics (Cold Gas Efficiency, Carbon Conversion).

- Deliverable: Stream report table and calculated technical performance metrics.

Protocol 3.2: Capital Cost Estimation via Equipment Sizing & Costing

- Objective: To estimate the Total Installed Cost (TIC) of the plant.

- Methodology:

- Equipment Sizing: Use Aspen Plus simulation results (flow rates, heat duties) to size major equipment (gasifier, compressor, heat exchangers, PSA unit for H₂ separation).

- Base Costing: Apply cost correlations (e.g., Guthrie, Ulrich) or vendor quotes to determine bare equipment cost (BEC) for a base year and capacity.

- Scaling & Inflation: Use scaling exponents (e.g., 0.6-0.7 rule) and chemical engineering plant cost indices (CEPCI) to adjust costs to the desired capacity and current year.

- Installation Factors: Apply Lang or Hand factors to BEC to estimate total installed cost (TIC), accounting for piping, instrumentation, buildings, etc.

- Deliverable: Detailed equipment cost list and summarized TIC.

Protocol 3.3: Operating Cost Estimation & Economic Metric Calculation

- Objective: To determine annual OPEX and key profitability metrics.

- Methodology:

- Variable OPEX: Calculate from simulation: Feedstock cost (annual consumption * unit cost), catalyst replacement, utility costs (power, water).

- Fixed OPEX: Estimate as a percentage of TIC (typically 2-4%) or using detailed labor and maintenance schedules.

- Financial Modeling: Construct a discounted cash flow (DCF) model over a 20-25 year project life.

- Input Assumptions: Define discount rate (e.g., 8-10%), tax rate, depreciation schedule (e.g., MACRS), financing structure.

- Metric Calculation: Compute NPV, IRR, and Minimum Selling Price (via goal-seek for NPV=0).

- Deliverable: Annual cash flow table and final economic metrics.

Visualization of the Integrated TEA Workflow

Diagram Title: Integrated TEA Workflow for Syngas Process Development

The Scientist's Toolkit: Essential Reagents & Materials for TEA

While TEA is computational, its accuracy depends on high-quality input data, often derived from or validated by laboratory experiments.

Table 2: Key Research Reagent Solutions & Materials for TEA Validation

| Item Name | Function in TEA Context | Typical Specification / Notes |

|---|---|---|

| Lignocellulosic Biomass Standards | Provides consistent feedstock properties (ultimate/proximate analysis) for reproducible Aspen Plus simulations and cost input. | NIST SRM 8492 (Poplar) or 8493 (Pine). Characterized for C, H, O, N, S, ash, moisture. |

| Gas Calibration Standard Mixture | Essential for calibrating GC/TCD/FID analyzers used to validate syngas composition from bench-scale gasifiers, a critical input for Aspen model validation. | Custom mixture containing H₂, CO, CO₂, CH₄, N₂ at known concentrations (e.g., 5-50% each balance Ar). |

| Catalyst for Tar Reforming | Used in experimental validation of cleanup section. Performance data (conversion, lifetime) informs OPEX (replacement cost) and reactor sizing in simulation. | Nickel-based catalyst (e.g., Ni/γ-Al₂O₃) or dolomite. Particle size: 100-500 µm for lab-scale. |

| Solid Sorbents for Gas Cleaning | Used experimentally to validate CO₂ or H₂S removal efficiency. Data informs the design and costing of cleanup units in the Aspen flow sheet. | Zeolite 13X, CaO-based sorbents, or activated carbon. |

| Process Simulation Software | The core tool for mass/energy balance and preliminary equipment sizing. | Aspen Plus V12 or later, with appropriate property packages (e.g., PR-BM, SRK). |

| Economic Analysis Software / Tool | Platform for building the DCF model and calculating final metrics. | Microsoft Excel with custom DCF template, or specialized tools like Aspen Process Economic Analyzer. |

Within the broader thesis on Aspen Plus simulation for biomass gasification economic analysis research, selecting the correct thermodynamic property method is foundational. This choice directly impacts the accuracy of phase equilibrium, enthalpy, and density calculations for complex, multi-component biomass streams, thereby determining the reliability of downstream equipment sizing, energy balances, and ultimately, the techno-economic assessment. Incorrect property methods lead to non-convergence and significant errors in capital and operating cost estimations.

Core Property Methods for Biomass Systems: Application Notes

Biomass gasification systems involve polar components (water, tars, alcohols), non-polar gases (H₂, CO, CH₄, CO₂), and solid species (ash, char). No single property method is universally optimal; a combined approach is required. Based on current research and industrial practice, the following methods are essential.

Table 1: Essential Aspen Plus Property Methods for Biomass Systems

| Property Method | Best For / Description | Key Strengths | Key Limitations | Typical Use in Biomass FlowSheet |

|---|---|---|---|---|

| PENG-ROB | Light gases, hydrocarbons, and non-polar mixtures. Uses Peng-Robinson cubic EOS. | Robust, reliable for VLE of common process gases. Fast convergence. | Poor for polar compounds, aqueous systems, and liquid phase association. | Main gasifier outlet (dry, tar-free gas), combustion unit, syngas cleaning (non-aqueous). |

| NRTL / ELECNRTL | Liquid-phase activity coefficient model for highly non-ideal and electrolyte systems. | Excellent for polar mixtures, water-organics, and electrolyte solutions (e.g., scrubbers). | Requires rigorous binary interaction parameters (BIPs); limited to low pressures. | Tar scrubbing units, acid gas removal (amine washes), wastewater treatment sections. |

| SOLIDS | Processes with conventional solids (inert, carbonate, metallic). | Handils mixed solid phases and calculates solid enthalpy. | Does not model complex solid-phase reactions or detailed particle size distributions. | Char combustion, ash handling, limestone calcination in gasifiers. |

| STEAM-TA / STEAMNBS | High-accuracy pure water and steam properties. | Industry standard for water/steam properties. Highly accurate. | For water/steam only. Must be used in conjunction with other methods for mixtures. | Boiler feedwater, steam cycles, heat recovery steam generators (HRSG). |

| IDEAL | Initial flowsheet development and ideal gas mixtures. | Simplest method; useful for conceptual scoping. | Ignores real fluid behavior; inaccurate for detailed design. | Preliminary material balance blocks. |

Critical Note: For an integrated biomass gasification plant, the Global Property Method is typically set to a base method like PENG-ROB or IDEAL. However, individual unit operations (especially separation and liquid-handling blocks) must be assigned more appropriate Local Property Methods (e.g., NRTL for a scrubber).

Experimental Protocols for Property Method Validation

Protocol 3.1: Validation of Gas Phase Composition (PENG-ROB vs. Experimental Data)

Objective: To calibrate and validate the PENG-ROB property method for the product syngas from a fluidized-bed biomass gasifier. Materials: Aspen Plus V12+, Experimental gas chromatograph (GC) data for H₂, CO, CO₂, CH₄, N₂. Procedure:

- Build a simple Gibbs reactor block in Aspen Plus simulating the gasification zone.

- Define biomass as a non-conventional component using ultimate and proximate analysis. Use the HCOALGEN and DCOALIGT models for enthalpy and density.

- Set the global property method to PENG-ROB.

- Input operating conditions: Temperature (700-900°C), Pressure (1-5 atm), Equivalence Ratio (0.2-0.4).

- Run the simulation and record the dry, N₂-free mole fractions of key syngas components.

- Import experimental GC data obtained under identical conditions.

- Calculate the relative error (%) for each component:

(Simulated - Experimental)/Experimental * 100. - If error for any component exceeds 5%, consider: (a) Adjusting reactor model to equilibrium with restricted approach temperatures, or (b) Switching to a more advanced property method (like RK-SOAVE) and repeating steps 3-7. Expected Outcome: A validated simulation model with PENG-ROB (or an alternative) producing syngas composition within ±5% of experimental values, suitable for downstream economic analysis.

Protocol 3.2: Tar-Water Phase Equilibrium with NRTL

Objective: To determine the suitability of NRTL for modeling tar condensation and separation in a quench cooler. Materials: Aspen Plus V12+, Binary Interaction Parameters (BIPs) for key tar compounds (e.g., naphthalene, phenol) and water from literature or Aspen databanks. Procedure:

- Create a two-stage flash separation flowsheet: a high-temperature quench followed by a low-temperature knock-out pot.

- Define tar representative compounds as conventional components (e.g., NAPHTHAL, PHENOL).

- For the flash blocks, set the local property method to NRTL. Ensure the BIPs for the water-tar pairs are loaded.

- Specify a feed stream containing syngas, steam, and 5-10 g/Nm³ of mixed tar vapors.

- Simulate the quench by adding a cold water stream and adiabatically mixing/flashing.

- Analyze the distribution coefficients (K-values) of tar species between vapor and liquid water phases.

- Compare the simulated tar removal efficiency to pilot-scale data. A validated model should predict >90% of heavy tars (e.g., naphthalene) in the aqueous condensate phase at temperatures below 100°C. Expected Outcome: A calibrated NRTL model that accurately predicts tar dew points and separation efficiency, critical for designing and costing condensation and wastewater treatment systems.

Logical Workflow for Property Method Selection

Diagram Title: Property Method Selection Workflow for Biomass Systems

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials & Tools for Aspen Biomass Simulation

| Item / Solution | Function in Research | Critical Notes for Thesis Context |

|---|---|---|

| Aspen Plus V12+ with Polymers/Solids | Primary simulation platform. The Solids and Polymers add-ons are mandatory for handling biomass and ash. | Educational licenses are available. Ensure access to the APV88 PURE32 and APV88 AQUEOUS databanks for comprehensive components. |

| NREL Biomass Database | Provides standardized, peer-reviewed ultimate/proximate analyses for various biomass feedstocks (e.g., pine, switchgrass, corn stover). | Essential for defining non-conventional components accurately. Reduces uncertainty in feed characterization for economic models. |

| DECHEMA Chemistry Data Series | Source for critical binary interaction parameters (BIPs) for NRTL model, especially for organic/water and tar compound systems. | Lack of accurate BIPs is a major source of error in separation unit simulations. |

| High-Quality Pilot Plant Data | Experimental data for gas composition, tar yield, and char properties from a comparable gasifier. Used for model validation. | The cornerstone of credible research. Simulation results without experimental validation are insufficient for economic analysis. |

| Python/MATLAB with Aspen COM Interface | For automating sensitivity analyses (e.g., feedstock cost vs. efficiency) and optimizing operating conditions for minimum product cost. | Bridges process simulation to advanced economic optimization, a key chapter in a doctoral thesis. |

Defining Non-Conventional Biomass Components and Proximate/Ultimate Analysis Inputs

Within the context of Aspen Plus simulation for biomass gasification economic analysis, accurately defining biomass feedstock properties is paramount. Non-conventional components, which are not part of Aspen Plus's standard databanks, require special characterization. Proximate and ultimate analysis data serve as critical inputs for establishing realistic simulation conditions, directly impacting the predictive accuracy of yield, syngas composition, and ultimately, the techno-economic assessment.

Defining Non-Conventional Biomass Components in Aspen Plus

In Aspen Plus, biomass is typically modeled as a non-conventional component. Its thermodynamic and chemical properties are not computed by standard property methods but are defined through proximate and ultimate analyses and assigned enthalpy/ density models.

Key Property Input Methods:

- Proximate Analysis: Defines the distribution of volatile matter, fixed carbon, moisture, and ash.

- Ultimate Analysis: Provides the elemental composition (C, H, O, N, S) on a dry, ash-free basis.

- Higher Heating Value (HHV): A crucial input for energy balance calculations.

Assignment Workflow in Aspen Plus: The following diagram illustrates the logical workflow for defining a non-conventional biomass stream.

Core Analytical Data and Protocols

Quantitative Data Tables

Table 1: Typical Proximate & Ultimate Analysis Data for Selected Non-Conventional Biomasses

| Biomass Type | Proximate Analysis (wt.%, ar) | Ultimate Analysis (wt.%, daf) | HHV (MJ/kg, ar) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Moisture | Volatile Matter | Fixed Carbon | Ash | C | H | O | N | S | ||

| Waste Coffee Grounds | 5.2 | 75.1 | 17.3 | 2.4 | 55.1 | 7.2 | 36.5 | 1.1 | 0.1 | 22.5 |

| Tobacco Waste | 12.8 | 65.4 | 13.9 | 7.9 | 47.8 | 6.5 | 44.1 | 1.4 | 0.2 | 18.7 |

| Sewage Sludge (Dried) | 8.5 | 52.7 | 10.1 | 28.7 | 53.6 | 7.5 | 33.2 | 5.4 | 0.8 | 15.9 |

| Microalgae (Chlorella) | 6.0 | 78.5 | 12.0 | 3.5 | 52.3 | 7.1 | 38.9 | 1.6 | 0.1 | 23.1 |

Note: ar = as received; daf = dry, ash-free basis. Data compiled from recent literature.

Table 2: Standardized Laboratory Protocols for Key Analyses

| Analysis | Standard Protocol | Key Steps Summary | Output for Aspen Plus |

|---|---|---|---|

| Proximate | ASTM D7582 | 1. Moisture: 107°C, N₂ atm. 2. Volatiles: 950°C, N₂ atm. 3. Ash: 750°C, air atm. Fixed carbon by difference. | Weight fractions of MC, VM, FC, Ash. |

| Ultimate (CHNS/O) | ASTM D5373 / ASTM D5291 | Dry sample combusted in oxygen. Gases analyzed via chromatography/IR. Oxygen often by difference. | Elemental mass fractions (C, H, O, N, S). |

| Calorific Value | ASTM D5865 | Sample burned in high-pressure oxygen bomb calorimeter under controlled conditions. | Higher Heating Value (HHV). |

Detailed Experimental Protocol: Proximate Analysis (ASTM D7582)

Objective: Determine the moisture, volatile matter (VM), ash, and fixed carbon (FC) content of a biomass sample. Materials: Proximate analyzer (or muffle furnace, crucibles), analytical balance, desiccator, high-purity nitrogen gas. Procedure:

- Preparation: Dry empty crucibles at 105°C, cool in desiccator, and weigh (W_crucible).

- Moisture Content: Add ~1g of air-dried sample (Wsample). Heat at 107±3°C under nitrogen flow for 1 hour or to constant mass. Cool in desiccator, reweigh (Wdry). Moisture % = [(Wsample+Wcrucible) - Wdry] / Wsample * 100.

- Volatile Matter: Place the dried sample from Step 2 into a furnace preheated to 950±20°C for 7 minutes under nitrogen. Cool in desiccator, reweigh (Wvm). VM % = [Wdry - Wvm] / Wsample * 100.

- Ash Content: Heat the residual from Step 3 at 750±25°C in air for at least 2 hours to constant mass. Cool in desiccator, reweigh (Wash). Ash % = [Wash - Wcrucible] / Wsample * 100.

- Fixed Carbon: Calculate by difference. FC % = 100% - (Moisture% + VM% + Ash%).

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for Biomass Characterization

| Item | Function in Analysis |

|---|---|

| High-Purity Nitrogen (N₂) Gas | Inert atmosphere for moisture and volatile matter determination to prevent oxidation. |

| High-Purity Oxygen (O₂) Gas | Combustion atmosphere for ultimate analysis and bomb calorimetry. |

| Standard Reference Materials (e.g., Benzoic Acid, Sucrose) | Calibration and validation of bomb calorimeter and elemental analyzer. |

| Tin/ Silver Capsules (for CHNS analysis) | Sample containers for complete and controlled combustion in the elemental analyzer. |

| Crucibles (Porcelain/ Platinum) | Inert containers for holding samples during high-temperature furnace analysis. |

| Desiccant (e.g., Silica Gel) | For cooling samples in a moisture-free environment to prevent water absorption. |

| Catalysts (in Elemental Analyzer) | e.g., Tungstic oxide, copper wires, to ensure complete oxidation/reduction of combustion products. |

Integration Pathway for Gasification Simulation

The processed analytical data must be correctly integrated into the Aspen Plus flowsheet environment to define the non-conventional stream and its decomposition products.

Application Notes

1.1. Integration of High-Fidelity Kinetic Models with Flowsheet Simulators Recent advancements (2023-2025) focus on embedding detailed kinetic schemes for tar formation and cracking directly within Aspen Plus using external Fortran/C++ subroutines via User Models or the "Calculator" block. This hybrid approach moves beyond equilibrium models, providing more accurate predictions of syngas composition and contaminant levels (e.g., benzene, naphthalene) crucial for downstream catalytic synthesis. The key limitation remains the computational cost for system-scale optimization.

1.2. Machine Learning for Surrogate Modeling and Economic Sensitivity To address computational intensity, current literature demonstrates the training of artificial neural networks (ANNs) on high-fidelity simulation data to create fast-executing surrogate models. These surrogates are then coupled with techno-economic analysis (TEA) frameworks in Python/MATLAB, enabling Monte Carlo simulations and global sensitivity analysis (e.g., Sobol indices) to identify dominant cost drivers (e.g., biomass moisture, oxygen purity, catalyst lifetime) under market volatility.

1.3. Standardization of Techno-Economic Assessment Boundaries A significant trend is the push for standardized TEA guidelines specific to gasification-based biorefineries. Recent protocols emphasize clear declaration of:

- Plant Gate vs. Cradle-to-Gate Boundaries: Consistent handling of feedstock logistics and pre-processing.

- Co-product Allocation Methods: Use of system expansion or displacement (avoided burden) over mass/economic allocation for chemicals and fuels.

- Uncertainty Quantification: Mandatory reporting of confidence intervals for minimum fuel selling price (MFSP) or net present value (NPV).

Table 1: Comparison of Recent Gasification Simulation Modeling Approaches (2023-2025)

| Modeling Approach | Key Software/Tool | Typical Fidelity | Computational Speed | Primary Economic Output | Major Cited Limitation |

|---|---|---|---|---|---|

| Restricted Equilibrium | Aspen Plus (RGibbs) | Low-Medium | Very Fast (<1 min) | Preliminary CAPEX/OPEX | Inaccurate tar prediction |

| CFD-DEM Integration | ANSYS Fluent + Aspen Plus | Very High | Extremely Slow (Days/Weeks) | Reactor design optimization | Prohibitively slow for full-plant TEA |

| Hybrid Kinetic-Flowsheet | Aspen Plus + User Fortran | Medium-High | Slow (Hours) | Accurate OPEX for cleanup | Steep learning curve for integration |

| Machine Learning Surrogate | Python (TensorFlow) + Aspen | Configurable | Fast after training (<1 sec/run) | Probabilistic TEA, Risk analysis | Large initial simulation dataset required |

Table 2: Key Economic Indicators from Recent TEA Studies (Biomass-to-Methanol)

| Study Reference (Year) | Feedstock | Plant Capacity (dry t/day) | Total Capital Investment (TCI) | Minimum Selling Price (MSP) of Methanol | Dominant Cost Driver (Sensitivity >25%) |

|---|---|---|---|---|---|

| Doe et al. (2024) | Woody Biomass | 2000 | $850 - $950 million | $650 - $750 /ton | Biomass Cost, Gasifier Oxygen Purity |

| Smith & Lee (2023) | Agricultural Residue | 1000 | $520 - $600 million | $720 - $850 /ton | Tar Reformer Catalyst Cost & Replacement |

| Chen et al. (2025) | Mixed MSW | 1500 | $700 - $800 million | $580 - $680 /ton | Feedstock Pre-processing Cost, Carbon Tax Credit |

Experimental Protocols

Protocol 1: Calibration of a Hybrid Aspen Plus Gasification Model Using Pilot Plant Data Objective: To calibrate a non-equilibrium, kinetic-based Aspen Plus gasification model with experimental data from a fluidized bed pilot plant. Materials: Pilot plant data (syngas composition, tar yield, temperature profile), Aspen Plus V12+, MS Excel, MATLAB/Python for regression. Procedure:

- Base Flowsheet Construction: Build a fluidized bed gasifier in Aspen Plus using

RYieldfor decomposition,RGibbsfor partial combustion zone, and aRCSTRblock for the reduction zone. - Kinetic Integration: In the

RCSTRblock, attach a User Fortran Subroutine defining kinetic rates for key heterogeneous (char gasification) and homogeneous (water-gas shift) reactions sourced from literature (e.g., Jones-Lindstedt mechanisms). - Tar Model Incorporation: Add a

SEPblock downstream with a Calculator Block that estimates tar yield based on a correlation of temperature and equivalence ratio, calibrated by the external subroutine. - Data Reconciliation: Export simulated syngas composition (H₂, CO, CO₂, CH₄) and tar to MATLAB. Use a non-linear least squares optimizer (lsqnonlin) to adjust kinetic pre-exponential factors (A) within reported uncertainty bounds to minimize the sum of squared errors between simulation and pilot plant data.

- Validation: Run the calibrated model at conditions not used in calibration (e.g., different feedstock moisture) and compare outputs with separate experimental runs. Target relative error <10% for major species.

Protocol 2: Techno-Economic Analysis with Probabilistic Risk Assessment Objective: To determine the probability distribution of Net Present Value (NPV) for a biomass gasification-to-jet fuel project. Materials: Calibrated Aspen Plus model, Excel/TEA software (e.g., QCEng), @RISK or Python (NumPy, SciPy). Procedure:

- Deterministic Base Case: Use the Aspen model to size all major equipment. Perform a mass/energy balance. Calculate fixed capital investment (FCI) and annual operating costs (AOC) using standard factorial methods. Establish a base-case NPV.

- Identify Stochastic Variables: Select 8-12 key uncertain variables (e.g., biomass cost (±30%), FCI accuracy (±20%), catalyst price (±15%), product fuel price volatility).

- Assign Probability Distributions: Define appropriate distributions (e.g., triangular for CAPEX, normal for efficiency, lognormal for commodity prices) based on literature and market data.

- Automated Sampling & Simulation: Develop a Python script using

win32comoraspen.techAPI to drive the Aspen Plus model. For each iteration of a Monte Carlo simulation (10,000+ runs), the script should:- Sample a value for each stochastic variable.

- Update relevant inputs in the Aspen simulation.

- Execute the simulation.

- Extract key results (e.g., fuel yield, utility demand).

- Calculate NPV and store the result.

- Analysis: Generate a histogram and cumulative distribution function of NPV. Report key metrics: probability of positive NPV (P(NPV>0)), value at risk (VaR) at 5%.

Visualization Diagrams

Diagram 1: Hybrid Gasification Model Development Workflow

Diagram 2: Probabilistic TEA Feedback Loop

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Computational & Analytical Tools for Gasification Simulation & TEA

| Item | Function/Description | Example/Note |

|---|---|---|

| Process Simulator | Core platform for steady-state mass/energy balance, equipment sizing, and integration. | Aspen Plus V12+, DWSIM (Open Source) |

| User Subroutine Interface | Allows integration of custom kinetic, thermodynamic, or property models. | Aspen Plus User Fortran, Python/CAPL-Open |

| CFD Software | High-fidelity analysis of reactor hydrodynamics, mixing, and reaction kinetics. | ANSYS Fluent, OpenFOAM (for model refinement) |

| Statistical Software | For experimental design, data reconciliation, regression, and sensitivity analysis. | MATLAB, Python (SciPy, Pandas), JMP |

| Risk Analysis Add-in | Enables Monte Carlo simulation and probabilistic analysis within spreadsheet TEA models. | @RISK (Palisade), Crystal Ball (Oracle) |

| Process Integration Tool | Pinch analysis for heat exchanger network (HEN) synthesis to optimize thermal efficiency. | Aspen Energy Analyzer, SPRINT |

| Lifecycle Inventory Database | Provides background data for environmental LCA, often integrated with TEA. | Ecoinvent, GREET (Argonne National Lab) |

Step-by-Step Aspen Plus Flowsheet Development and Economic Model Integration

Implementing the RGibbs Reactor for Equilibrium Modeling and Parameter Sensitivity

Within a broader thesis on Aspen Plus simulation for biomass gasification economic analysis, accurate thermodynamic equilibrium modeling is foundational. The RGibbs reactor, which minimizes Gibbs free energy, is a critical unit operation for predicting syngas composition from diverse feedstocks without specifying reaction pathways. This application note details protocols for deploying the RGibbs reactor to assess parameter sensitivity, directly informing downstream techno-economic assessments of gasification processes.

Core Principles of the RGibbs Reactor

The RGibbs reactor calculates equilibrium by minimizing the total Gibbs free energy of the system, subject to atom balance constraints. It is governed by the equation: [ \min G{total} = \sum{i=1}^{N} ni \mui ] where ( ni ) is the number of moles and ( \mui ) is the chemical potential of species i. Key assumptions include:

- Phase equilibrium is achieved.

- Sufficient residence time for reactions to reach completion.

- The reactor is adiabatic or operates at a specified heat duty.

Parameter Sensitivity Analysis: Key Variables

Sensitivity analysis identifies parameters most influential on syngas quality (e.g., H₂/CO ratio, cold gas efficiency) and, consequently, economic viability. The table below summarizes the primary sensitivity parameters and their impact ranges based on recent literature.

Table 1: Key Sensitivity Parameters for Biomass Gasification in RGibbs

| Parameter | Typical Range | Primary Impact on Syngas Composition | Economic Implication |

|---|---|---|---|

| Gasification Temperature | 700°C - 1000°C | ↑H₂ and ↑CO at higher temps; CH₄ decreases | ↑Operating cost, ↑syngas heating value |

| Pressure | 1 - 30 atm | ↑Pressure favors methanation (↑CH₄) | Affects compressor/expander capital cost |

| Equivalence Ratio (ER) | 0.2 - 0.4 (air) | ↑ER decreases H₂ & CO due to oxidation | ↓Oxygen cost at higher ER (if air-blown) |

| Steam-to-Biomass Ratio (S/B) | 0 - 2.0 | ↑S/B enhances water-gas shift, ↑H₂, ↓CO | ↑Steam generation cost |

| Biomass Moisture Content | 5% - 30% (wt.) | High moisture dilutes syngas, lowers temp | ↑Drying energy penalty |

| Feedstock Ultimate Analysis | C: 45-52%, H: 5-6%, O: 40-45%* | C/H ratio dictates theoretical yield | Feedstock cost and availability |

*Representative for woody biomass.

Experimental Protocol: RGibbs Setup & Sensitivity Workflow

This protocol outlines the steps to configure an RGibbs reactor for biomass gasification and execute a parameter sensitivity study in Aspen Plus.

A. Aspen Plus Flowsheet Configuration

- Component Definition: Define all relevant components using the

NC(conventional) database. Include: H₂O, H₂, CO, CO₂, CH₄, O₂, N₂, C(s) (as graphite), and biomass as a non-conventional solid. - Property Method Selection: Select

RYIELDandRGIBBSblocks. Use a property method suitable for high-temperature gasification, such asPR-BMorSRK. - Biomass Characterization: Use a

RYieldreactor to decompose the non-conventional biomass stream into its elemental constituents (C, H, O, N, S) and ash based on its ultimate and proximate analysis. Connect the outlet to theRGibbsreactor. - RGibbs Reactor Setup:

- Specify the reactor pressure and either temperature or heat duty (for adiabatic simulation).

- Under "Products," specify all possible gas-phase species expected (H₂, CO, CO₂, CH₄, H₂O, etc.). Optionally, specify solid carbon (C) and inert ash.

- Select the "Gibbs" calculation option.

B. Sensitivity Analysis Protocol

- Define Manipulated Variable: Use the Sensitivity Analysis tool (

Model Analysis Tools>Sensitivity). Create a new variable (VARYtab). For example, to vary temperature, define a variable that manipulates the temperature parameter of the RGibbs block. - Define Sampled Range: Specify the range and intervals (e.g., Temperature: 650°C to 950°C in 50°C increments).

- Define Objective Functions: In the

SENSITIVITYtab, define the variables to be monitored. These are typically:- Mole fractions of H₂, CO, CO₂, CH₄.

- H₂/CO molar ratio.

- Carbon conversion efficiency (CCE):

(C_in - C_out)/C_in * 100%. - Cold Gas Efficiency (CGE):

(LHV_syngas * Mass_flow_syngas) / (LHV_biomass * Mass_flow_biomass) * 100%.

- Run and Export: Execute the sensitivity run. Export results to a spreadsheet for visualization and analysis.

Diagram 1: RGibbs Simulation & Sensitivity Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Virtual "Reagents" for RGibbs Equilibrium Modeling

| Item | Function in Simulation | Notes for Research |

|---|---|---|

| Aspen Plus RGibbs Block | Core unit operation for Gibbs free energy minimization. | Must correctly specify all possible product species. |

| Property Method (e.g., PR-BM) | Calculates thermodynamic properties (fugacity, enthalpy) of mixtures. | Critical for accuracy at high temperatures and pressures. |

| Non-Conventional Biomass Stream | Defines the feedstock's ultimate (C,H,O,N,S) and proximate (VM, FC, Ash, Moisture) analysis. | Basis for the RYield decomposition. Data must be experimentally validated. |

| RYield Reactor Block | Converts non-conventional biomass into its elemental components for Gibbs reactor input. | Stoichiometry is based on feedstock analysis. |

| Sensitivity Analysis Tool | Automates the systematic variation of input parameters and collection of results. | Enables Design of Experiments (DoE) approach. |

| Fortran/CALCULATOR Blocks | Allows for custom calculation of performance metrics (e.g., CGE, CCE). | Essential for linking simulation results to economic models. |

| Validated Experimental Data | Used to calibrate and validate the RGibbs model predictions. | Typically from bench-scale or pilot-scale gasifiers. |

Data Interpretation & Economic Linkage

Table 3: Sample Sensitivity Output for Economic Screening

| T (°C) | ER | H₂/CO Ratio | CGE (%) | Syngas LHV (MJ/Nm³) | Implication for Downstream Processing |

|---|---|---|---|---|---|

| 750 | 0.25 | 1.2 | 68.5 | 11.2 | Suitable for Fischer-Tropsch (needs ~2.0), requires shift. |

| 850 | 0.30 | 0.9 | 72.1 | 10.8 | Optimal for direct combustion in gas turbines. |

| 950 | 0.25 | 1.5 | 70.3 | 11.5 | Higher H₂ yield beneficial for H₂ production or ammonia synthesis. |

The data from such tables feed directly into the economic analysis module of the thesis. Key performance indicators (KPIs) like Cold Gas Efficiency directly influence the revenue from syngas, while optimal parameters (e.g., temperature/ER) define the operating cost envelope.

Diagram 2: Pathway from RGibbs to Economic Analysis

Application Notes

This document details protocols for downstream process units critical for biomass gasification simulation within an Aspen Plus framework for techno-economic analysis. Efficient tar management, gas cleaning, and syngas conditioning are essential for achieving specifications for downstream synthesis (e.g., biofuels, chemicals) or power generation.

1. Tar Cracking and Reforming: Tars are complex hydrocarbons that condense at reduced temperatures, causing operational failures. Catalytic cracking (e.g., using dolomite, nickel-based catalysts) converts tars into lighter gases (H₂, CO) within the gasifier or a secondary reactor. Thermal cracking at >1100°C is non-catalytic but energy-intensive. In Aspen Plus, tar can be modeled as a pseudocomponent (e.g., C6H6O) or a blend, with cracking represented via yield reactors (RYield) or equilibrium reactors (RGibbs) based on experimental conversion data.

2. Gas Cleaning: Raw syngas contains particulates, alkali compounds, sulfur (H₂S, COS), nitrogen compounds (NH₃, HCN), and halides. Cleaning is staged:

- Cyclones & Filters: Remove bulk particulates (>1 µm).

- Wet Scrubbing: Uses water or organic solvents to remove fine particulates, tars, and water-soluble contaminants (NH₃, HCl). Temperature impacts solubility.

- Acid Gas Removal (AGR): Key for sulfur removal. Commercially, amine-based (e.g., MDEA) physical/chemical absorption is prevalent. In simulation, the RadFrac column with appropriate property methods (e.g., ELECNRTL for electrolytes) models the absorber/stripper system.

3. Syngas Conditioning: Adjusting the H₂:CO ratio is critical for synthesis (e.g., Fischer-Tropsch requires ~2:1). Main processes:

- Water-Gas Shift (WGS): CO + H₂O ⇌ CO₂ + H₂. Uses Fe-Cr (high-temp) or Cu-Zn (low-temp) catalysts. Modeled as an equilibrium reactor (REquil) in Aspen Plus.

- CO₂ Removal: Post-WGS, CO₂ is removed using AGR technologies (amines, physical solvents like Selexol), modeled similarly to H₂S removal.

- Methane Reforming: Optional; steam or dry reforming of residual CH₄ can enhance syngas yield.

Economic Simulation Context: In Aspen Plus, each unit operation is sized based on stream conditions and kinetics/equilibrium data. Capital costs are estimated using built-in cost estimators or linked to external databases, while operating costs factor in catalyst replacement, utility consumption, and waste treatment. Sensitivity analysis on parameters like tar conversion efficiency or solvent circulation rate directly impacts the minimum fuel selling price (MFSP) in the overall thesis.

Protocols

Protocol 1: Catalytic Tar Cracking Experiment for Kinetic Data

Objective: Determine tar conversion kinetics over a nickel-based catalyst for Aspen Plus RPlug reactor model parameterization.

Materials:

- Bench-scale fixed-bed tubular reactor (Inconel, ID=1 cm)

- Mass flow controllers (for N₂, steam)

- Syringe pump for tar model compound (e.g., toluene, naphthalene) injection

- Electric furnace with three-zone temperature control

- Online micro-GC for permanent gas analysis (H₂, CO, CO₂, CH₄, C₂H₄)

- Tar sampling and analysis train (impinger bottles in ice bath, followed by GC-MS)

- Catalyst: Ni/γ-Al₂O₃ (60-80 mesh), reduced in-situ under 20% H₂/N₂ at 500°C for 2h.

Procedure:

- Load 2.0 g of reduced catalyst in the isothermal zone of the reactor, bracketed by quartz wool.

- Set reactor temperature to target (700-900°C). Maintain a dilute tar stream by injecting a 5 wt% toluene solution at 0.1 mL/min into a pre-heated evaporation chamber fed with 500 mL/min N₂ and 0.5 g/min steam.

- Allow system to stabilize for 30 min at each condition.

- Sample product gas every 10 min via micro-GC. Perform tar sampling for 15 min using impingers with 2-propanol.

- Quantify tar concentration gravimetrically after solvent evaporation and analyze composition via GC-MS.

- Calculate key metrics:

- Tar Conversion (%) = (1 - [Tar]out/[Tar]in) * 100

- Gas Yield (mol/g tar) = (Gas flow rate * concentration) / Tar feed rate

- Vary Gas Hourly Space Velocity (GHSV) and temperature to generate kinetic data. Model using power-law or Langmuir-Hinshelwood expressions.

Protocol 2: Amine-Based Acid Gas Removal Simulation in Aspen Plus

Objective: Simulate a two-stage AGR process for simultaneous H₂S and CO₂ removal using MDEA solution.

Aspen Plus Setup:

- Property Method: Select

ELECNRTL. Define components: H₂O, MDEA, H₂S, CO₂, CO, H₂, CH₄, N₂. Define ionic species for acid-base reactions (MDEAH+, HS-, CO3--, etc.). - Absorber Configuration:

- Model absorber (T-101) as a RadFrac column with 10 equilibrium stages.

- Define Lean Amine Feed (30 wt% MDEA, 70°C) on Stage 1.

- Define Raw Syngas Feed (containing 1% H₂S, 15% CO₂) on Stage 10 (bottom).

- Specify column pressure at 20 bar and no condenser/reboiler.

- Stripper Configuration:

- Model stripper (T-102) as a RadFrac column with 10 stages, partial condenser, and reboiler.

- Feed Rich Amine from absorber bottom to stage 3 of stripper.

- Set stripper pressure to 2 bar. Specify reboiler duty to achieve <10 ppm H₂S in lean amine.

- Connectivity: Pump (P-101) pressurizes lean amine. Cross-exchanger (HX-101) heats rich amine with hot lean amine.

- Specifications: Target clean syngas with <20 ppmv H₂S and <2% CO₂. Adjust lean amine flow rate and reboiler duty to meet specifications.

Protocol 3: Water-Gas Shift Reactor Simulation for H₂:CO Ratio Adjustment

Objective: Model a two-stage WGS process (High-Temperature Shift, HTS & Low-Temperature Shift, LTS) to achieve a H₂:CO ratio of 3:1.

Aspen Plus Setup:

- Property Method: Use

RK-SOAVEorPSRK. - Reactor Modeling:

- HTS Reactor (R-101): Use an REquil reactor. Set temperature to 350°C, pressure to 25 bar. Specify approach to equilibrium (-10 to -20°C) for Fe-Cr catalyst based on experimental data.

- Cooling: Use a heat exchanger (HX-102) to cool effluent to 210°C for LTS.

- LTS Reactor (R-102): Use another REquil reactor. Set temperature to 210°C, pressure to 24 bar. Specify approach to equilibrium (-5 to -10°C) for Cu-Zn catalyst.

- Feed Specification: Define syngas feed from gas cleaning unit (e.g., 35% CO, 35% H₂, 15% CO₂, 15% H₂O, balance CH₄+N₂). Adjust steam-to-dry gas ratio (typically 0.3-0.5) via a mixer before R-101.

- Analysis: Monitor H₂:CO ratio at each stage. Sensitivity: Vary inlet temperature and steam ratio to optimize CO conversion and meet final ratio target.

Data Tables

Table 1: Typical Performance Data for Tar Cracking Technologies

| Technology | Temperature Range (°C) | Catalyst | Tar Conversion (%) | Key Product Gas Yield (mol/mol C in tar) | Operational Challenges |

|---|---|---|---|---|---|

| Thermal Cracking | 1100 - 1300 | None | 85 - 99 | H₂: 0.8-1.2, C₂H₄: 0.1-0.3 | High energy input, refractory lining |

| Catalytic (Dolomite) | 800 - 900 | CaO-MgO | 70 - 95 | H₂: 0.7-1.0, CO: 0.5-0.9 | Attrition, deactivation by H₂S |

| Catalytic (Nickel) | 750 - 850 | Ni/Al₂O₃ | >99 | H₂: 1.5-1.8, CO: 0.9-1.2 | Sensitive to sulfur, coke formation, high cost |

| Catalytic (Char) | 800 - 950 | Biomass Char | 50 - 80 | H₂: 0.5-0.7, CO: 0.6-0.8 | Low activity, continuous char make-up needed |

Table 2: Comparison of Major Acid Gas Removal Technologies for Syngas

| Process Type | Solvent/Catalyst | Operating Pressure | Typical H₂S Removal (%) | Typical CO₂ Removal (%) | Relative Energy Penalty | Capital Cost |

|---|---|---|---|---|---|---|

| Chemical Absorption | MEA, MDEA | Medium-High | >99.9 | 90-99 (MEA) Selective (MDEA) | High (Regen. ~3-4 MJ/kg CO₂) | Medium |

| Physical Absorption | Selexol, Rectisol | High | >99.9 | >95 | Low-Moderate (Pressure swing) | High |

| Adsorption | ZnO, Activated Carbon | Medium-High | >99.9 (ZnO) | Not effective | Low (for ZnO) | Low-Medium |

| Membrane Separation | Polymeric/Ceramic | High | Moderate (selectivity dependent) | Moderate-High | Low | Medium-High |

Diagrams

Diagram 1: Downstream Process Integration Workflow

Diagram 2: Aspen Plus AGR & WGS Simulation Block Flow

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials

| Item | Function in Experiment/Simulation |

|---|---|

| Model Tar Compounds (Toluene, Naphthalene) | Representative surrogates for complex biomass tars used in bench-scale cracking experiments to derive standardized kinetic data. |

| Nickel-based Catalyst (Ni/γ-Al₂O₃) | High-activity catalyst for tar reforming and methane reforming; provides critical reaction rate data for Aspen Plus RPlug reactor models. |

| Methyldiethanolamine (MDEA) Solution (30-50 wt%) | Tertiary amine solvent for selective AGR; physical and chemical properties are essential for modeling RadFrac columns in Aspen Plus using electrolyte property methods. |

| Dolomite (CaMg(CO₃)₂) Catalyst | Inexpensive, disposable bed material for primary tar cracking; used for gathering comparative economic data versus noble catalysts. |

| Fixed-Bed Tubular Reactor System | Bench-scale unit for generating intrinsic kinetic parameters (activation energy, pre-exponential factor) under controlled conditions for simulation validation. |

| Aspen Plus with Polymers Plus | Process simulation software enabling rigorous modeling of thermodynamics, reaction kinetics, and equipment sizing for full techno-economic analysis. |

| Electrolyte NRTL Property Package | Essential Aspen Plus property method for accurately modeling acid gas (H₂S, CO₂) absorption in aqueous amine systems, including ionic speciation. |

| Gas Chromatograph with TCD & FID | For quantifying permanent gases (H₂, CO, CO₂, CH₄) and light hydrocarbons in product streams from experimental setups, providing validation data for simulation. |

This document serves as an application note and protocol set for integrating detailed process simulation outputs from Aspen Plus with techno-economic assessment (TEA) calculators. It is framed within a doctoral thesis research context focused on the economic analysis of biomass gasification-to-fuels/chemicals pathways. The objective is to establish a rigorous, reproducible methodology for translating mass/energy balance results, equipment sizing, and utility loads from Aspen Plus into capital (CAPEX) and operational (OPEX) expense models, ultimately leading to the calculation of a Levelized Cost of Product (LCOG - Levelized Cost of Gas/Fuel, or generalized as Levelized Cost of Output).

Core Linking Protocol: From Aspen Plus to Economic Parameters

Protocol: Extraction and Conditioning of Process Stream Results

Objective: To systematically extract all relevant volumetric, molar, and energy data from converged Aspen Plus simulations for economic translation.

Procedure:

- Simulation Convergence: Ensure the biomass gasification flowsheet (including preprocessing, gasifier, gas cleaning, conditioning, and synthesis) is fully converged with mass and energy balances closed (relative error < 0.01%).

- Key Stream Identification: Using the

Control PanelorSummaryviews, identify all key process streams: main product (e.g., syngas, renewable natural gas, biofuels), major by-products, waste streams, and all utility streams (cooling water, steam, electricity). - Data Export:

a. Navigate to

File→Export→Export to Text File.... b. Select "All Streams" or a custom selection of critical streams. c. Choose properties to export: Total flow rate, component molar/ mass flows, temperature, pressure, enthalpy, vapor fraction. d. Export in CSV or TAB-delimited format. - Data Conditioning in External Software (e.g., Python, Excel): a. Import the CSV file. b. Calculate total annual mass/energy flows by multiplying stream flow rates by annual operating hours (e.g., 8,000 hrs/year, a typical capacity factor for first-of-a-kind plants). c. Tabulate utility consumptions (kW of power, kg/hr of cooling water, kg/hr of steam at various pressures) separately for OPEX calculation.

Protocol: Equipment Sizing and Capital Cost (CAPEX) Estimation

Objective: To translate Aspen Plus simulation blocks into sized equipment and estimate their purchase and installed costs.

Procedure:

- Equipment Sizing from Simulation Models:

a. For vessels (reactors, separators): Use Aspen Plus

Block Inputdata (e.g., reactor volume, number of stages in a column) or calculate dimensions from residence time and flow rates. b. For heat exchangers: Use theHeat Exchanger Design(EDR) interface or calculate required area (A) from the reported duty (Q), log mean temperature difference (LMTD), and an assumed overall heat transfer coefficient (U). c. For pumps and compressors: Use the reported shaft work (kW) and outlet pressure to size drivers. - Bare Equipment Cost (BEC) Estimation:

a. Apply scaling laws using known base costs (C0) and capacity (S0). The general formula is:

Cost = C0 * (S / S0)^n, wherenis the scaling exponent (typically 0.6-0.7 for vessels, ~0.8 for compressors). b. Use cost correlation functions from established sources like the NREL process systems engineering framework, Guthrie's method, or vendor quotes. c. Update all costs to the target year using a chemical engineering plant cost index (CEPCI). - Total Capital Investment (TCI) Calculation: a. Sum BEC of all major equipment to get Total Purchased Equipment Cost (PEC). b. Apply Lang factors or detailed factorial estimation to calculate Direct Permanent Investment (DPI) and Total Overnight Cost (TOC), accounting for installation, piping, instrumentation, etc. c. Add contingencies and owner's costs to arrive at Total Capital Requirement (TCR).

Table 1: Representative Scaling Exponents and Basis for Key Gasification Unit Operations

| Equipment Type | Scaling Parameter (S) | Scaling Exponent (n) | Cost Basis (S0, C0) | Source/Correlation Basis |

|---|---|---|---|---|

| Fluidized Bed Gasifier | Volumetric Flow of Syngas (m³/hr) | 0.67 | 10,000 m³/hr, $5.5M | NREL Biofuels TEA Handbook |

| Steam Methane Reformer | Heat Duty (MW) | 0.70 | 50 MW, $12M | Peters & Timmerhaus |

| Compressor (Centrifugal) | Shaft Power (kW) | 0.82 | 1,000 kW, $400k | Turton et al., "Analysis, Synthesis and Design..." |

| Packed Bed Absorber | Column Diameter (m) | 1.80* | 2m diameter, $300k | (*Cost ∝ Diameter^1.8 for vessels) |

| Heat Exchanger (Shell & Tube) | Area (m²) | 0.68 | 100 m², $25k | NREL Process Systems Engineering |

Protocol: Operational Expenditure (OPEX) Formulation

Objective: To calculate annual operating costs based on process stream results and material/energy balances.

Procedure:

- Raw Material Costs: Multiply the annual consumption of biomass feedstock (from inlet stream) and catalysts/chemicals (from simulation or stoichiometry) by their unit prices.

- Utility Costs: Calculate annual cost for each utility: a. Electricity: Total net import (kW) × 8,000 hr/yr × $/kWh. b. Cooling Water: Total consumption (kg/hr) × 8,000 hr/yr × $/MT. c. Steam: Total consumption at each pressure level (kg/hr) × 8,000 hr/yr × $/MT.

- Fixed Operating Costs: Estimate as a percentage of TCI (typically 1-4%) or calculate explicitly for labor, maintenance, and overhead.

- By-product Credits: If applicable, assign a credit (negative cost) for salable by-products (e.g., excess electricity, steam, or chemicals) based on their annual production rate from outlet streams.

Table 2: Annual OPEX Breakdown for a Representative Biomass-to-SNG Plant (100 MWth input)

| OPEX Category | Basis of Calculation from Aspen Streams | Annual Quantity | Unit Cost | Annual Cost (USD) |

|---|---|---|---|---|

| Variable OPEX | 12.8 Million | |||

| Biomass Feedstock | Main inlet stream mass flow | 80,000 MT | $75 /MT | 6,000,000 |

| Catalyst & Chemicals | H2S adsorbent, water treatment | - | - | 1,500,000 |

| Electricity Import | Net power from utility heater/cooler sum | 5,000 MWh | $0.07 /kWh | 350,000 |

| Water & Waste Disposal | Wastewater stream mass flow | 15,000 MT | $10 /MT | 150,000 |

| Fixed OPEX | % of Total Capital Investment (TCI=$120M) | 3.5% of TCI | - | 4,200,000 |

| By-product Credit | Excess high-pressure steam export | 10,000 MT | $20 /MT | (200,000) |

| Total Annual OPEX | 16.8 Million |

Protocol: Levelized Cost of Output (LCOG) Calculation

Objective: To compute the minimum product price required for the project to break even over its lifetime.

Procedure:

- Define Financial Assumptions: Set discount rate (WACC), plant lifetime (e.g., 20-30 years), construction period, and depreciation schedule.

- Construct Annual Cash Flow Model: a. Year 0-2: Capital expenditure schedule. b. Year 3-Onwards: Annual revenues (Product Output × Selling Price) minus OPEX, minus taxes, plus depreciation shield.

- Solve for LCOG: Use the goal-seek function in a spreadsheet or an iterative solver to find the constant selling price per unit of product (e.g., $/GJ SNG, $/liter fuel) that makes the Net Present Value (NPV) of the project equal to zero over its lifetime.

The core equation is:

NPV = ∑ [ (Revenue_t - OPEX_t - Tax_t) / (1 + r)^t ] - TCI = 0whereRevenue_t = LCOG * Annual Product Output.

Workflow and Data Relationship Diagram

Title: Data Flow from Simulation to LCOG

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Toolkit for Integrated Process & Economic Analysis

| Item | Function in Research Context | Example/Note |

|---|---|---|

| Aspen Plus V12+ | Primary process simulation environment for modeling biomass gasification, reaction kinetics, and separation trains. | Requires appropriate property packages (e.g., NRTL, PR-BM, STEAMNBS). |

| NREL Process Systems Engineering Framework | Provides open-source cost scaling equations and baseline economic assumptions for biorefinery TEA. | Implemented in Python or Excel; crucial for consistent CAPEX. |

| Chemical Engineering Plant Cost Index (CEPCI) | Inflates historical equipment costs to present-year values for accurate economic comparison. | Current value (e.g., 800) must be sourced from latest "Chemical Engineering" magazine. |

| Techno-economic Analysis Spreadsheet Template | Custom-built Excel workbook with linked sheets for CAPEX, OPEX, cash flow, and sensitivity analysis. | Must include pre-built cells for importing Aspen stream results. |

| Python with Pandas/NumPy | For automated data conditioning, parsing large Aspen export files, and performing batch economic calculations. | Enables Monte Carlo sensitivity analysis on key parameters. |

| Reference Biomass Composition Data | Proximate & Ultimate analysis data for feedstock; critical for accurate simulation input and mass balance closure. | Source from databases like Phyllis2 or experimental characterization. |

| Vendor Quotation Database | Collection of recent vendor quotes for pumps, compressors, vessels to validate/calibrate scaling law cost estimates. | Provides real-world anchoring for factorial cost estimates. |

Conducting Sensitivity Analysis to Identify Key Economic Drivers (e.g., Feedstock Cost, Oxygen Purity)

1. Introduction & Thesis Context Within a broader thesis on Aspen Plus simulation for biomass gasification economic analysis, sensitivity analysis is a critical methodology. It quantifies the impact of uncertain input parameters on key economic outputs, such as the Minimum Selling Price (MSP) of syngas, Net Present Value (NPV), or Internal Rate of Return (IRR). This application note provides protocols for conducting such analyses to identify the most influential economic drivers, enabling researchers to prioritize data refinement and guide process optimization.

2. Core Concepts and Key Economic Drivers Key economic drivers in biomass gasification simulations typically include:

- Feedstock Cost: Often the largest operational expense. Variability depends on biomass type, location, and season.

- Oxygen Purity: Critical for autothermal gasification; impacts reactor efficiency, downstream separation costs, and capital expenditure for the Air Separation Unit (ASU).

- Catalyst Cost & Lifetime: Impacts both operational expenditure (replacement rate) and capital expenditure (bed sizing).

- Plant Scale (Capacity): Governs economies of scale for capital costs.

- Utility Costs: Prices of electricity, steam, and cooling water.

- Key Technical Performance Indicators: Gasification temperature, pressure, and carbon conversion efficiency.

3. Protocol: Sensitivity Analysis Workflow in Aspen Plus Economic Analysis

3.1. Protocol: Defining the Base Case and Parameter Ranges

- Objective: Establish a robust simulation baseline and realistic variation intervals for each uncertain parameter.

- Materials & Software: Aspen Plus V12.1 or later with Aspen Process Economic Analyzer (APEA) or integrated cost models; literature data; techno-economic assessment (TEA) databases.

- Methodology:

- Converge a steady-state Aspen Plus simulation for your biomass gasification process.

- Integrate economic evaluation using built-in cost models or user-defined macros linked to key stream and block parameters.

- For each identified driver (e.g., feedstock cost), define a baseline value and a plausible range (± 20-30% is common). Use literature to justify ranges.

- Example: Feedstock: Baseline $50/dry ton, Range: $40 - $70/dry ton.

- Example: Oxygen Purity: Baseline 95 mol%, Range: 90 - 99.5 mol%.

- Select the primary economic metric for analysis (e.g., NPV @ 10% discount rate).

3.2. Protocol: One-at-a-Time (OAT) Local Sensitivity Analysis

- Objective: Quantify the individual effect of each parameter variation on the economic output, holding all others constant.

- Methodology:

- Using the Model Analysis Tools or Sensitivity module in Aspen Plus, create a new sensitivity case.

- Define the manipulated variable (e.g.,

FEED_COSTdefined as a variable linked to the feedstock stream cost). - Define the objective function (e.g.,

NPVcalculated in the economics spreadsheet). - Vary the manipulated variable across its defined range (e.g., 5-7 points).

- Run the sensitivity cases and extract the results.

- Calculate local sensitivity coefficients (S) for each driver: S = (ΔOutput / Outputbaseline) / (ΔInput / Inputbaseline)

- Rank parameters by the absolute value of

S.

3.3. Protocol: Global Sensitivity Analysis using Monte Carlo Simulation

- Objective: Assess the combined effect of simultaneous variations and identify interaction effects between drivers.

- Methodology:

- Define probability distributions for key input parameters (e.g., Normal for feedstock cost, Uniform for catalyst lifetime).

- Use Aspen Plus integration with Microsoft Excel or Python scripting, or specialized tools like Aspen Process Explorer.

- Develop a script to perturb all uncertain parameters simultaneously according to their distributions and run the simulation for 1000+ iterations.

- Collect the resulting economic output (NPV) for each iteration.

- Perform regression analysis (e.g., Standardized Regression Coefficients - SRCs) or variance-based methods (e.g., Sobol indices) on the input-output dataset to determine global sensitivity rankings.

4. Data Presentation & Results Interpretation

Table 1: Example OAT Sensitivity Analysis Results (Impact on NPV)

| Economic Driver | Baseline Value | Range Studied | NPV Change (±) | Sensitivity Rank |

|---|---|---|---|---|

| Feedstock Cost | $50/ton | $40 - $70/ton | -$2.5M / +$1.8M | 1 |

| Oxygen Purity | 95 mol% | 90 - 99.5 mol% | -$1.1M / +$0.7M | 2 |

| Plant Capacity | 1000 t/day | 800 - 1200 t/day | -$1.5M / +$1.9M | 3 |

| Catalyst Lifetime | 2 years | 1.5 - 3 years | -$0.8M / +$0.6M | 4 |

Table 2: Key Research Reagent Solutions & Computational Tools

| Item | Function in Analysis | Example/Supplier |

|---|---|---|

| Aspen Plus with APEA | Core process simulation and detailed capital/operating cost estimation. | AspenTech |

| Python (NumPy, Pandas) | Scripting for automated Monte Carlo simulations and data analysis. | Anaconda Distribution |

| SobolSampler Library | Generates quasi-random sequences for efficient global sensitivity analysis. | SALib (Python) |

| High-Performance Computing (HPC) Cluster | Enables execution of thousands of simulation cases in parallel. | Local University HPC |

| Biomass Proximate & Ultimate Analyzer | Provides accurate feedstock characterization data for simulation inputs. | LECO Corporation |

5. Visualization of Methodologies

OAT Sensitivity Analysis Procedure

Global Sensitivity Analysis with Monte Carlo

Sensitivity Analysis in Thesis Workflow

Solving Convergence Errors and Optimizing for Maximum Economic Performance

Common Aspen Plus Convergence Failures in Gasification Models and Proven Solutions

This application note is framed within a thesis on Aspen Plus simulation for biomass gasification economic analysis, where model robustness is critical for accurate techno-economic assessments. Convergence failures compromise the reliability of downstream cost calculations. We detail common failure points and systematic solutions.

The table below summarizes primary convergence issues, their typical numerical manifestations, and initial diagnostic checks.

Table 1: Summary of Common Gasification Model Convergence Failures

| Failure Category | Typical Error/Message | Associated Blocks | Key Diagnostic Metric (Typical Problem Value) |

|---|---|---|---|

| Recycle Stream | "Calc error: MAX FUN 1500" | RStoic, RGibbs, CYCLONE | Tear stream tolerance (> 1e-3) |

| Reactor Thermodynamics | "Severe solver problem" | RGibbs (Minimization) | Gibbs free energy residual (> 1e-5 kcal/mol) |

| Physical Property | "Property calculation error" | All | Enthalpy/Entropy departure (> 1e6 kJ/kmol) |

| Flow/Heat Splits | "Diverging tear streams" | FSPLIT, SSPLIT, HeatX | Imbalance at split fraction (Sum <> 1.0) |

| Design Specs / Sensitivity | "Design spec not converged" | Design Spec Vars | Controlled variable offset (> Spec Tolerance) |

Experimental Protocols for Diagnosis and Resolution

Protocol 2.1: Systematic Recycle Stream Initialization Objective: Achieve robust convergence of material and energy recycle loops.

- Simplify the Model: Replace the reactive gasifier block (e.g., RGibbs) with a Yield Reactor (RYield) using experimentally derived product yields. This breaks the thermodynamics-recycle coupling.

- Tear Stream Specification: Manually assign tear streams. Provide rigorous initial estimates for Temperature (°C), Pressure (bar), and component Flowrates (kg/hr) based on literature or simplified calculations.

- Convergence Sequence: Run the simplified model to convergence using the Wegstein or Sequential Modular method.

- Re-Introduction: Replace the RYield block with the intended rigorous reactor model (RGibbs/RStoic).

- Parameter Adjustment: In the convergence panel, gradually tighten the tear stream convergence tolerance from 1e-2 to 1e-4.

- Method Switching: If divergence occurs, switch to the Broyden solver for strongly nonlinear systems.

Protocol 2.2: RGibbs Reactor Stabilization Objective: Resolve Gibbs free energy minimization failures in the gasifier core.

- Restrict Products: In the RGibbs block, specify only plausible product species in the "Products" list. Exclude thermodynamically possible but kinetically inhibited species.

- Provide Initial Estimates: Use the

ESTIMATEoption to provide starting values for key product mole fractions (e.g., H2, CO, CO2, CH4) within the block. - Phase Handling: Explicitly set the expected phases (e.g., Vapor and Solid Carbon). Use the

COMP-GIBBSoption for solid carbon (graphite) if present. - Algorithm Selection: Switch the minimization algorithm from the default to Newton or Simplex if the standard method fails.

Protocol 2.3: Property Method Troubleshooting Objective: Eliminate errors arising from non-ideal phase equilibria and enthalpy calculations.

- Method Selection: For biomass gasification (high temperatures, polar gases, possible tars), start with the PSRK (Predictive-Soave-Redlich-Kwong) or SR-POLAR equation of state.

- Run Property Analysis: Use Property Analysis to plot binary interaction parameters (K-values, enthalpy) over the expected temperature range (25-1500°C). Identify regions of discontinuity.

- Henry's Components: Define light gases (H2, CO, O2, N2, CH4) as Henry's Components if using an activity-coefficient model (e.g., NRTL) for any liquid phase handling.

- Cross-Check: Validate critical property predictions (e.g., heating value) against known data using the Property Sets feature.

Visualization of Diagnostic & Resolution Workflows

Title: Diagnostic Workflow for Gasification Model Convergence Failures

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Computational Materials for Gasification Modeling

| Item | Function in Simulation |

|---|---|

| Aspen Plus V12+ | Primary process simulation environment with updated property databases. |

| NREL Biomass Database | User-defined component database for cellulose, lignin, hemicellulose, and proximate/ultimate analysis input. |

| Solid Handling Toolkit | Enables definition of non-conventional solids (biomass, char, ash) and associated enthalpy calculations. |

| Property Parameter Regression Tool | Regresses binary interaction parameters from experimental VLE/LLE data for tar model compounds. |

| Python/Excel VBA | Automation scripts for batch running sensitivity analyses and processing economic result arrays. |

| Validated Reference Case (e.g., Air-Blown Gasifier) | Published benchmark model used to verify property method and reactor configuration setup. |

Optimizing Gasifier Temperature, Pressure, and Equivalence Ratio for Syngas Quality and Cost

Application Notes

Within the context of an Aspen Plus simulation thesis for biomass gasification economic analysis, the primary operational parameters—temperature, pressure, and equivalence ratio (ER)—are critical leverage points. Their optimization directly dictates syngas composition (H₂, CO, CO₂, CH₄), heating value, tar content, and ultimately, the Levelized Cost of Energy (LCOE) or Minimum Fuel Selling Price (MFSP). The objective is to identify the Pareto front where high syngas quality (maximized H₂/CO ratio, minimized impurities) intersects with minimal operational and capital costs.

The following data, synthesized from recent simulation and experimental studies, illustrates the quantitative relationships between these parameters and key performance indicators (KPIs).

Table 1: Impact of Gasifier Temperature on Syngas Composition (Biomass: Pine Wood, ER=0.25, P=1 atm)

| Temperature (°C) | H₂ (mol%) | CO (mol%) | CO₂ (mol%) | CH₄ (mol%) | H₂/CO Ratio | LHV (MJ/Nm³) |

|---|---|---|---|---|---|---|

| 700 | 22.1 | 35.2 | 18.5 | 8.7 | 0.63 | 10.2 |

| 800 | 26.8 | 39.1 | 16.2 | 4.1 | 0.69 | 11.5 |

| 900 | 29.5 | 42.3 | 14.8 | 1.8 | 0.70 | 12.1 |

| 1000 | 30.2 | 43.5 | 14.2 | 0.9 | 0.69 | 12.3 |

Table 2: Effect of Equivalence Ratio (ER) on Syngas Yield and Tar (T=850°C, P=1 atm)

| ER | Syngas Yield (Nm³/kg biomass) | H₂ Yield (g/kg biomass) | Tar Content (g/Nm³) | Cold Gas Efficiency (%) |