BECCS vs Direct Air Capture: A Comparative Analysis of Technological Potential and Scaling Challenges

This article provides a comprehensive comparative analysis of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC) as critical negative emission technologies (NETs).

BECCS vs Direct Air Capture: A Comparative Analysis of Technological Potential and Scaling Challenges

Abstract

This article provides a comprehensive comparative analysis of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC) as critical negative emission technologies (NETs). Targeting researchers, scientists, and policy analysts, it explores the foundational principles, current methodologies, key challenges, and relative validation of both approaches. The scope includes technological readiness, energy and land requirements, cost trajectories, integration potential, and their respective roles in achieving net-zero targets, offering a data-driven framework for evaluating their deployment potential in climate mitigation portfolios.

Understanding the Core: Foundational Principles of BECCS and Direct Air Capture

Defining Negative Emission Technologies (NETs) and the Net-Zero Imperative

Within the global effort to limit warming to 1.5°C, Net-Zero emissions is an imperative. This necessitates neutralizing residual anthropogenic emissions through the deliberate removal of CO₂ from the atmosphere, achieved via Negative Emission Technologies (NETs). This whitepaper provides a technical overview of NETs, framing the critical comparison between two leading candidates: Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture and Storage (DACS). The evaluation of their comparative potential—encompassing technical maturity, scalability, cost, and lifecycle impacts—forms the core of the referenced thesis.

Core NETs: Technical Mechanisms

Bioenergy with Carbon Capture and Storage (BECCS)

Mechanism: BECCS integrates two sequential processes: (1) the cultivation of biomass, which photosynthetically absorbs atmospheric CO₂, and (2) the conversion of this biomass to energy (e.g., via combustion, gasification, or fermentation) coupled with capture of the resulting concentrated CO₂ stream, followed by geological storage. Key Pathways: The biochemical (e.g., fermentation to bioethanol) and thermochemical (e.g, gasification) pathways are predominant.

Direct Air Capture and Storage (DACS)

Mechanism: DACS employs engineered chemical systems to adsorb or absorb CO₂ directly from ambient air (~415 ppm). Two primary approaches exist: (1) Solid Sorbent (Temperature-Swing) Systems using amine-functionalized materials, and (2) Liquid Solvent (pH-Swing) Systems using aqueous alkaline solutions or amino acids. Captured CO₂ is then released via application of heat or vacuum, purified, and compressed for storage.

Other NETs

Additional NETs include enhanced weathering, ocean alkalinity enhancement, and afforestation/reforestation, though they are not the primary focus of this comparative analysis.

Table 1: Comparative Technical and Economic Parameters for BECCS and DACS (Current Estimates)

| Parameter | BECCS (Bioethanol w/CCS) | DACS (Liquid Solvent) | DACS (Solid Sorbent) | Source/Notes |

|---|---|---|---|---|

| Technology Readiness Level (TRL) | 7-9 (Commercial in some sectors) | 6-8 (First commercial plants) | 6-8 (First commercial plants) | IEA, 2023 |

| Theoretical Global Potential (GtCO₂/yr) | ~5 - 11 | 5 - 40+ | 5 - 40+ | IPCC AR6, 2022 |

| Current Cost (USD/tCO₂ removed) | $50 - $200 | $250 - $600 | $150 - $400 | NASEM, 2022; Industry Reports 2024 |

| Energy Requirement (GJ/tCO₂) | 2 - 6 (for capture) | 5 - 12 (thermal & electrical) | 4 - 10 (primarily thermal) | Smith et al., 2023 |

| Land Use (m²/yr/tCO₂) | 1,000 - 10,000 | ~0.1 - 1 | ~0.1 - 1 | Fuss et al., 2018; Updated 2023 |

| Water Use (tH₂O/tCO₂) | 1 - 100 (for biomass) | 1 - 10 (for solvent/sorbent) | 0.5 - 5 | Recent LCAs 2023-2024 |

| Primary Challenges | Land competition, sustainability of biomass, leakage | High energy/cost, plant siting & integration | Sorbent degradation, cost, integration | Literature Synthesis |

Experimental Protocols for Core Analyses

Protocol: Life Cycle Assessment (LCA) for NETs

A standardized LCA (ISO 14040/44) is critical for comparing net removal efficiency.

- Goal & Scope Definition: Define functional unit (e.g., 1 tonne of CO₂ removed from atmosphere and durably stored). Establish system boundaries (cradle-to-grave).

- Inventory Analysis (LCI):

- BECCS: Collect data on biomass cultivation (fertilizer, fuel, land-use change), transport, conversion process efficiency, capture rate (typically 90-95%), compression, transport, and injection.

- DACS: Collect data on sorbent/solvent production, DAC plant construction, operational energy (source matters: renewable vs. grid), CO₂ desorption energy, compression, transport, and injection.

- Impact Assessment (LCIA): Calculate net CO₂ removal: Gross Removal – Lifecycle Emissions. Assess other impacts (eutrophication, acidification, energy demand).

- Interpretation: Conduct sensitivity analysis on key parameters (biomass yield, energy source, capture rate).

Protocol: Sorbent/Solvent Performance Testing (DACS)

This protocol evaluates candidate materials for DACS.

- Material Synthesis: Prepare solid sorbent (e.g., amine-grafted silica) or liquid solvent (e.g., 5M KOH or amino acid solution).

- Adsorption/Aborption Test:

- Use a controlled atmospheric chamber or gas flow system with 410-420 ppm CO₂ in air.

- For solids, use a fixed-bed reactor. Monitor breakthrough curve via NDIR CO₂ analyzer.

- For liquids, use a bubble column or packed tower. Measure CO₂ uptake via pH change, titration, or weight gain.

- Record conditions: temperature (20-30°C), relative humidity (40-80%), gas flow rate.

- Desorption/Regeneration Test:

- Apply temperature swing (80-120°C for solids, 80-100°C for liquids) or pressure/vacuum swing.

- Measure CO₂ purity and concentration in output stream.

- Record energy input (J/g CO₂) precisely via calorimetry.

- Cycling Stability Test: Repeat adsorption-desorption cycles (1000+ cycles). Measure capacity degradation over time.

Protocol: BECCS System Integration Pilot

A protocol for pilot-scale evaluation of integrated BECCS.

- Feedstock Preparation: Use a standardized biomass (e.g., Miscanthus, forestry residues). Characterize moisture, ash, and energy content.

- Conversion & Capture:

- For biochemical route: Ferment biomass to ethanol, recover CO₂ from fermentation off-gas (nearly pure), purify and compress.

- For thermochemical route: Gasify biomass, condition syngas, use amine scrubbing (e.g., 30 wt% MEA) to capture CO₂ from shifted syngas (~20-40% CO₂ concentration).

- Measurement & Monitoring: Continuously measure:

- Inputs: Biomass mass flow, energy inputs.

- Outputs: Bioenergy product (e.g., ethanol, electricity), captured CO₂ mass flow and purity.

- Key Metrics: Capture rate (%), net energy balance, net carbon balance via real-time carbon accounting.

Research Reagent Solutions Toolkit

Table 2: Essential Research Materials for NETs Experiments

| Item / Reagent | Function / Application | Example / Specification |

|---|---|---|

| Amine-functionalized Sorbent | Solid adsorbent for DAC; selectively binds CO₂ from air. | PEI-impregnated mesoporous silica (e.g., SBA-15); Class 3 aminosilica. |

| Aqueous Alkaline Solvent | Liquid absorbent for DAC; chemically reacts with CO₂. | Potassium hydroxide (KOH, 3-5M) or sodium hydroxide (NaOH) solutions. |

| Calcium Oxide (CaO) | Sorbent for high-temperature loops or mineralization studies. | High-purity (>95%) for enhanced weathering or calcium looping experiments. |

| Monoethanolamine (MEA) Solution | Benchmark solvent for post-combustion CO₂ capture (relevant to BECCS). | 30 wt% aqueous MEA for absorption column tests. |

| NDIR CO₂ Analyzer | Critical for real-time, precise measurement of CO₂ concentration in gas streams. | Must have low-range capability (0-2000 ppm) and high-range (0-100%) for different process points. |

| Gas Chromatograph (GC) | For analyzing gas composition (e.g., syngas from gasification, purity of captured CO₂). | Equipped with TCD and FID detectors, Hayesep and Molsieve columns. |

| pH/Conductivity Meter | For monitoring liquid solvent state during absorption/desorption cycles. | High-precision, temperature-compensated probe for corrosive solutions. |

| TGA-DSC (Thermogravimetric Analyzer) | For measuring sorbent CO₂ capacity, regeneration energy, and cycling stability. | Controlled atmosphere (N₂, air, CO₂), temperature ramp capabilities. |

| Certified Gas Standards | For calibrating analyzers and creating synthetic atmospheres. | 410 ppm CO₂ in air (for DAC simulation), 10-30% CO₂ in N₂ (for BECCS simulation). |

| LCA Software & Databases | For performing lifecycle inventory and impact assessment. | SimaPro, GaBi, or openLCA with updated databases (Ecoinvent, USLCI). |

Within the comparative assessment of negative emissions technologies (NETs), Bioenergy with Carbon Capture and Storage (BECCS) presents a unique dual-function engine. It integrates the natural, short-term carbon cycle of biomass growth with engineered, permanent carbon sequestration. This positions BECCS distinctly from Direct Air Capture (DAC), which interacts directly with the well-mixed, dilute atmospheric CO₂ reservoir. The thesis of a comparative potential research must evaluate BECCS not merely as a carbon removal tool, but as a biomass-carbon cycle engine where biomass acts as the concentrating agent, fundamentally altering the thermodynamic and economic boundaries compared to DAC.

The Core Technical Principle: The Two-Stage Engine

The BECCS process functions as a two-stage engine:

- Biomass-Driven Concentration (Biological Stage): Photosynthesis captures diffuse atmospheric CO₂ (~420 ppm) and concentrates carbon into solid or liquid biomass feedstock.

- Point-Source Capture & Sequestration (Engineering Stage): The biomass is processed (combusted, gasified, fermented), releasing a high-concentration CO₂ stream (>10%) suitable for efficient capture and subsequent geological storage.

This contrasts with DAC, which must energetically process the entire atmospheric volume to isolate CO₂, facing a significantly lower initial partial pressure.

Quantitative System Performance Data

Table 1: Comparative Performance Metrics of BECCS Pathways vs. Baseline DAC

| Metric | Biomass Combustion + Post-Combustion Capture | Biomass Gasification + Pre-Combustion Capture | Biochemical Conversion (e.g., Ethanol) + Capture | Solid Sorbent DAC (for reference) |

|---|---|---|---|---|

| CO₂ Concentration in Flue Gas | 8-15% | ~40% (in syngas, pre-shift) | ~99% (fermentation off-gas) | 0.04% (ambient air) |

| Typical Capture Efficiency | 85-95% | >95% | >99% | 75-90% |

| Net Removal Efficiency (Lifecycle)* | 70-90% | 75-95% | 60-85%* | 85-95% |

| Energy Penalty (% of plant output) | 15-25% | 10-20% | 5-15% | 200-400% (of thermal eq.) |

| Estimated Cost per tonne CO₂ removed (current) | $100-$200 | $80-$180 | $120-$250 | $250-$600 |

| Key Technology Readiness Level (TRL) | 7-9 (commercial) | 6-8 (demonstration) | 6-8 (demonstration) | 5-7 (pilot/demo) |

*Net Removal Efficiency accounts for supply chain emissions. For biochemical pathways, it is highly sensitive to feedstock and process design.

Experimental Protocol: Quantifying Carbon Balance in a BECCS Value Chain

Title: Protocol for Lifecycle Carbon Balance Analysis of a Dedicated Energy Crop BECCS System.

Objective: To empirically determine the net carbon removal of a BECCS system using Miscanthus via combustion with amine-based capture.

Methodology:

- Field Trial & Carbon Uptake Measurement:

- Establish a 1-hectare plot of Miscanthus x giganteus.

- Annually, at harvest, measure above-ground biomass dry matter yield via destructive sampling in five 4m² subplots.

- Determine carbon content (default ~48%) using a CHNS elemental analyzer (e.g., EuroVector EA3000). Calculate total carbon captured: C_biomass = Biomass Yield × Carbon Fraction.

Supply Chain Emission Audit (Inputs):

- Quantify all fossil fuel inputs for cultivation (diesel), harvesting, and transport (distance to conversion facility).

- Quantify fertilizer (N, P, K) application; model N₂O emissions using IPCC Tier 1 or Tier 2 methodology.

- Convert all inputs to CO₂-equivalent emissions (C_supply_chain) using relevant emission factors.

Conversion & Capture Efficiency Experiment:

- Process a representative biomass sample in a pilot-scale fluidized bed combustor coupled with a 0.1 MWth amine scrubbing unit (e.g., 30 wt% MEA solution).

- Continuously monitor inlet and outlet flue gas CO₂ concentrations (using NDIR analyzer) for >100 operational hours.

- Calculate capture efficiency (ηcapture) = (CO₂in - CO₂out) / CO₂in.

- Measure parasitic energy load of the capture process.

Carbon Storage Assurance:

- Model the fate of captured, compressed CO₂ using geological simulation software (e.g., TOUGH2) for a target saline aquifer.

- Assume a conservative storage permanence of >99% over 1,000 years based on engineered and natural trapping mechanisms.

Net Carbon Calculation:

- Net CO₂ Removed = (C_biomass - C_supply_chain) × η_capture × η_storage.

- Express result in tonnes CO₂e per hectare per year.

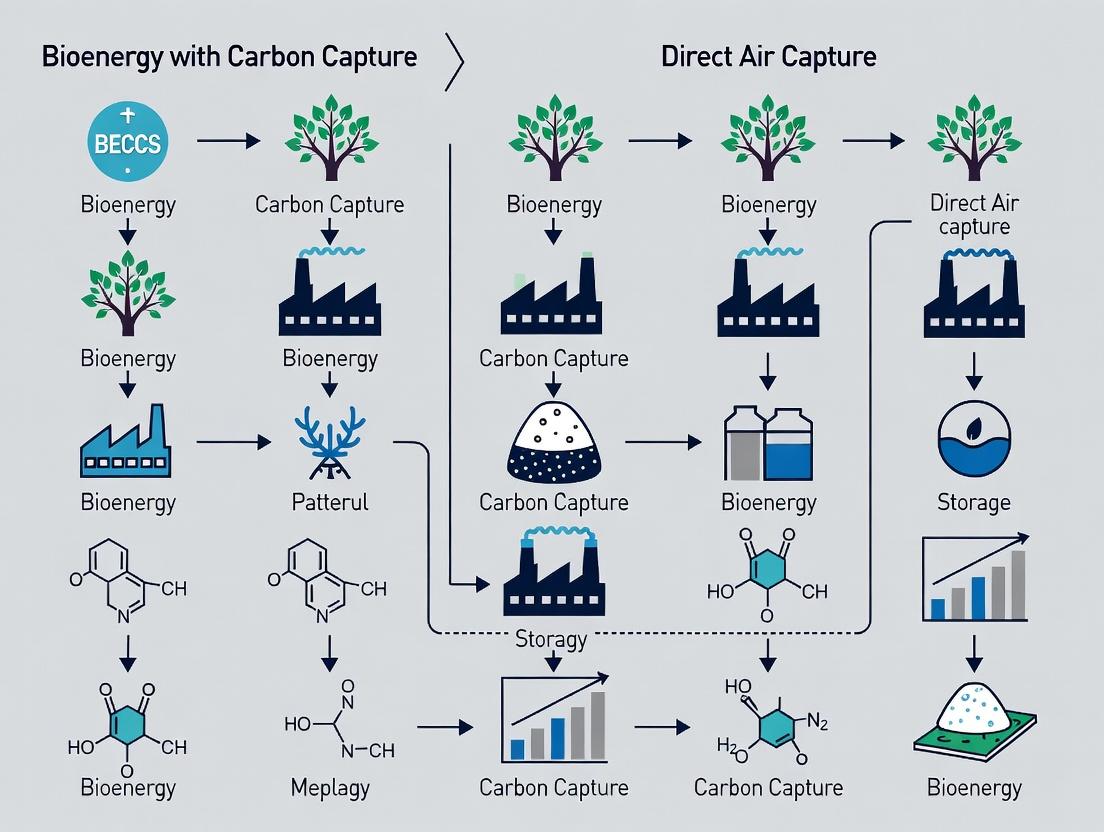

Visualization of System Pathways

Diagram 1: BECCS vs. DAC: Fundamental Carbon Pathways

Diagram 2: Detailed BECCS Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for BECCS Laboratory-Scale Research

| Research Reagent / Material | Primary Function in BECCS Research | Technical Notes |

|---|---|---|

| Amine-Based Solvents (e.g., MEA, MDEA, PZ) | Liquid absorbent for post-combustion CO₂ capture from flue gas. | 30 wt% MEA is a benchmark. Research focuses on novel blends/ionic liquids for lower regeneration energy & degradation resistance. |

| Solid Sorbents (e.g., Zeolite 13X, MOFs, Amine-Functionalized Silica) | Solid adsorbent for pressure/temperature swing adsorption (PSA/TSA) processes. | Key parameters: CO₂ capacity, selectivity (over N₂, H₂O), isotherm shape, and cycling stability under realistic conditions. |

| Gas Calibration Standards | Calibration of NDIR, GC, or MS for precise CO₂, CH₄, N₂O, CO, O₂ measurement. | Critical for mass balance closure. Requires certified standards at concentrations matching flue gas (e.g., 10% CO₂ in N₂) and ambient air. |

| Stable Isotope Tracers (¹³CO₂) | Tracing carbon flow through biological (plant uptake) and engineered (capture) systems. | Used in chamber studies to validate photosynthetic incorporation and in capture experiments to track solvent carbon inventory. |

| Lignocellulosic Biomass Reference Materials | Standardized feedstock for comparative conversion and capture experiments. | NIST or other standard reference materials ensure reproducibility in gasification kinetics, ash behavior, and slagging studies. |

| Bench-Scale Fluidized Bed Reactor | Simulating biomass combustion/gasification under controlled conditions. | Enables study of reaction kinetics, ash chemistry, and the production of a representative syngas/flue gas for capture experiments. |

| High-Pressure/Temperature Autoclave | Simulating geological reservoir conditions for CO₂-brine-rock interaction studies. | Used to assess mineral trapping rates and caprock integrity for storage assurance research. |

This whitepaper provides an in-depth technical guide to Direct Air Capture (DAC), a critical negative emissions technology. The analysis is framed within a broader comparative research thesis examining the potential of DAC versus Bioenergy with Carbon Capture and Storage (BECCS). While BECCS leverages the photosynthetic efficiency of biomass, DAC offers a land-sparing, high-purity CO₂ stream suitable for diverse utilization or sequestration pathways. This document details the core principles, current technological state, and experimental protocols for researchers.

Core Principles & Sorbent/Solvent Chemistries

DAC systems extract CO₂ from ambient air (~420 ppm) using cyclic chemical processes. The two dominant approaches are liquid solvent and solid sorbent systems.

Liquid Solvent (Aqueous Alkali) Systems: Employ a concentrated basic solution (e.g., KOH) to absorb CO₂, forming a carbonate. The carbonate is then precipitated (e.g., using calcium) and thermally decomposed to release a pure CO₂ stream, regenerating the solvent. Solid Sorbent (Amino-Functionalized) Systems: Utilize porous solid materials functionalized with amines. CO₂ chemisorbs at ambient conditions. The sorbent is regenerated using temperature-vacuum swing (TVS) processes, releasing concentrated CO₂.

Comparative Performance Data (2023-2024):

Table 1: Performance Metrics of Leading DAC Technologies

| Parameter | Liquid Solvent (e.g., Carbon Engineering) | Solid Sorbent (e.g., Climeworks, Global Thermostat) | Notes |

|---|---|---|---|

| Typical CO₂ Purity | >99% dry | >99% dry | Suitable for geological storage or e-fuels. |

| Energy Requirement (GJ/t CO₂) | 5-8 (Thermal, at ~900°C) | 5-10 (Electrical/Low-grade heat, at 80-120°C) | Highly dependent on heat source & design. |

| Water Consumption (t H₂O / t CO₂) | 1-5 (for cooling & solution management) | 0.5-2 (primarily for humidity management) | Liquid systems generally more water-intensive. |

| Reported Cost (USD/t CO₂) | $250 - $600 (current) | $300 - $800 (current) | Projected to fall to $100-$300 at scale. |

| Major Energy Input | High-grade heat for calcination | Low-grade heat for sorbent regeneration | Integration with renewables/waste heat is key. |

| Technology Readiness Level (TRL) | 8-9 (First commercial plants deployed) | 7-8 (Pilot/early commercial deployment) |

Experimental Protocol: CO₂ Adsorption Capacity of a Novel Solid Sorbent

This protocol details a standard laboratory-scale method for evaluating amine-functionalized mesoporous silica sorbents, a common DAC research focus.

Title: Determination of Equilibrium CO₂ Adsorption Capacity Under DAC-Relevant Conditions.

Objective: To measure the CO₂ adsorption capacity (mmol CO₂/g sorbent) of a candidate solid sorbent at 25°C, 1 atm, and 400 ppm CO₂ in N₂.

Materials & Apparatus:

- Fixed-Bed Reactor: Stainless steel or quartz tube (6 mm ID) equipped with heating jacket.

- Mass Flow Controllers (MFCs): For precise blending of 10% CO₂/N₂ and pure N₂ to simulate air.

- Gas Analyzer: Non-dispersive infrared (NDIR) CO₂ sensor for breakthrough detection.

- Data Acquisition System: To record temperature, pressure, and CO₂ concentration.

- Vacuum Pump: For sorbent pre-treatment.

- Analytical Balance.

Procedure:

- Sorbent Preparation: Precisely weigh ~100 mg of sorbent into the reactor. Secure with quartz wool plugs.

- Pre-treatment: Heat the reactor to 105°C under a continuous N₂ flow (50 mL/min) for 12 hours to remove physisorbed H₂O and CO₂. Cool to 25°C under N₂.

- Adsorption Phase: Switch the inlet gas to the simulated air mixture (400 ppm CO₂ in N₂) at a total flow of 100 mL/min. Maintain 25°C. Monitor effluent CO₂ concentration until breakthrough (C/C₀ = 0.95).

- Desorption/Regeneration: Switch back to pure N₂ flow and initiate a temperature-vacuum swing (e.g., heat to 90-100°C under mild vacuum, ~0.1 bar) for 60 minutes.

- Data Analysis: Integrate the area above the breakthrough curve. Calculate the dynamic adsorption capacity using the formula:

q = (F * ∫(C_in - C_out)dt) / m_sorbentwhere q=capacity (mmol/g), F=total molar flow rate, C=CO₂ concentration, t=time, m=mass.

Diagram 1: Solid Sorbent DAC Experimental Workflow

The Scientist's Toolkit: Key DAC Research Reagents & Materials

Table 2: Essential Research Reagents for DAC Sorbent Development

| Reagent/Material | Function & Rationale |

|---|---|

| 3-Aminopropyltriethoxysilane (APTES) | Common aminosilane used for grafting primary amines onto silica supports via silanization. Provides active sites for CO₂ chemisorption. |

| Polyethylenimine (PEI), branched | High-density amine polymer for impregnating porous supports. Increases CO₂ capacity per gram of sorbent but can affect kinetics. |

| Mesoporous Silica (e.g., SBA-15, MCM-41) | High-surface-area, tunable-pore support material. Provides structure for amine functionalization and minimizes diffusion resistance. |

| Potassium Hydroxide (KOH) pellets | Strong base for liquid solvent systems. Forms K₂CO₃ upon CO₂ absorption. Requires careful handling and corrosion-resistant equipment. |

| Calcium Oxide (CaO) | Used in liquid solvent systems to precipitate carbonate as CaCO₃, which is then calcined to release CO₂ and regenerate CaO. |

| Zeolites (e.g., 13X) | Physical adsorbents for pre-drying air or for selective CO₂ capture in hybrid systems. Useful for studying competitive H₂O adsorption. |

| Simulated Air Mixture | Certified gas cylinder containing 400-420 ppm CO₂ in N₂ or synthetic air. Essential for controlled, reproducible adsorption experiments. |

Diagram 2: Primary CO₂ Chemisorption Pathways on Amines

Comparative Context: DAC vs. BECCS in Research

Within the thesis comparing BECCS and DAC, key differentiators emerge. DAC's primary advantage is its small land footprint and location flexibility, avoiding BECCS's land-use competition. DAC provides a pure, concentrated CO₂ product, whereas BECCS yield is tied to biomass combustion flue gas (3-15% CO₂). However, DAC's significant energy penalty (see Table 1) and current high costs are major research hurdles. The optimal pathway may involve hybrid systems, using biomass-derived energy to power DAC units, potentially improving overall system efficiency and carbon yield per hectare.

Historical Context and Technological Evolution of Both Approaches

This whitepaper provides a technical examination of the historical development and technological evolution of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC). Framed within a broader thesis comparing their mitigation potential, this guide details the core engineering principles, key experiments, and material requirements essential for researchers and scientists evaluating these negative emissions technologies.

Historical Context

Bioenergy with Carbon Capture and Storage (BECCS)

The conceptual foundation of BECCS emerged in the early 1990s, combining established technologies from three separate fields: biomass energy conversion (19th century), carbon capture (originally developed for natural gas processing in the 1930s), and geological storage (pioneered in the 1970s for enhanced oil recovery). The first integrated proposal for BECCS as a climate solution was presented by the IPCC in 2005. Its evolution has been driven by the scaling of biomass power generation and adaptations of post-combustion capture systems.

Direct Air Capture (DAC)

The fundamental concept of extracting CO₂ directly from ambient air was first proposed in 1946, with serious technical exploration beginning in the 1990s by researchers like Klaus Lackner. Technological evolution diverged into two main pathways: solid sorbent (temperature-vacuum swing adsorption) and liquid solvent (aqueous hydroxide solution) systems. Significant acceleration in development occurred post-2010, driven by private-sector investment and recognition of the scale of carbon removal required.

Technological Evolution & Core Principles

BECCS Technological Pathways

BECCS integrates biomass supply chains with carbon capture units. Primary technological pathways include:

- Post-combustion capture: Amine-based solvents (e.g., MEA) scrub CO₂ from flue gases after biomass combustion.

- Oxy-fuel combustion: Biomass is burned in pure oxygen, resulting in a flue gas predominantly of CO₂ and water vapor.

- Pre-combustion gasification: Biomass is gasified to produce syngas (H₂ + CO), which is shifted to produce a CO₂ stream before combustion.

DAC Technological Pathways

DAC systems are categorized by their capture media regeneration method:

- Liquid Solvent Systems (Low-Temperature): Use aqueous alkaline solutions (e.g., KOH) to chemically absorb CO₂, requiring a high-temperature (900°C) calcination step to release pure CO₂ and regenerate the solvent.

- Solid Sorbent Systems (High-Temperature): Use amine-functionalized porous materials to adsorb CO₂, regenerated using heat (80-120°C) under vacuum.

Quantitative Data Comparison

Table 1: Historical Development Milestones

| Technology | Decade | Key Milestone | Primary Developer/Proponent |

|---|---|---|---|

| BECCS | 1990s | Conceptual integration of biomass energy with CCS | IPCC, Academic Literature |

| 2000s | First pilot-scale demonstrations (e.g., Illinois) | U.S. Department of Energy | |

| 2010s | First commercial-scale plant (Drax pilot, UK) | Drax Group, Mitsubishi Heavy Industries | |

| 2020s | Focus on sustainable biomass sourcing & system efficiency | Various (Bioenergy Europe, IEA) | |

| DAC | 1990s | Fundamental research on air contactors & sorbents | Klaus Lackner, Columbia University |

| 2000s | First prototype mechanical capture units | Carbon Engineering, Climeworks | |

| 2010s | Commercial deployment of pilot plants (Switzerland, Canada) | Climeworks, Carbon Engineering | |

| 2020s | Scale-up to megaton-capacity projects (e.g., Project Bison, Stratos) | 1PointFive, Occidental Petroleum |

Table 2: Current Technical Performance Parameters (2024)

| Parameter | BECCS (Post-Combustion) | DAC (Liquid Solvent) | DAC (Solid Sorbent) |

|---|---|---|---|

| Typical Plant Capacity (tCO₂/yr) | 1,000,000+ (attached to power) | Designed for 1,000,000+ | 1,000 - 4,000 (modular units) |

| Energy Requirement (GJ/tCO₂) | 1.2 - 2.5 (for capture only) | 5.0 - 8.0 (thermal, low-T DAC) | 5.5 - 9.0 (electrical, high-T DAC) |

| Water Usage (t/tCO₂) | 1 - 3 (for capture & cooling) | 1 - 10 (vapor loss & process) | < 1.5 (primarily for cooling) |

| Estimated Current Cost (USD/tCO₂) | 80 - 200 | 250 - 600 | 500 - 1000 |

| Land Footprint (m²/tCO₂/yr) | Dominated by biomass cultivation | ~0.5 - 1.0 | ~0.1 - 0.3 |

| Technology Readiness Level (TRL) | 8-9 (Commercial demonstration) | 7-8 (First-of-a-kind commercial) | 6-7 (Early commercial deployment) |

Experimental Protocols for Key Evaluations

Protocol: Life Cycle Assessment (LCA) for BECCS

Objective: Quantify net carbon removal and environmental impacts of a BECCS value chain. Methodology:

- System Boundary Definition: Define cradle-to-grave boundary: biomass cultivation/harvest, transport, conversion, CO₂ capture, compression, transport, and permanent geological storage.

- Inventory Analysis: Collect data for all material/energy inputs and emissions (CH₄, N₂O) for each unit process. Use primary data from pilot plants or robust literature.

- Attributional Modeling: Apply allocation methods (e.g., energy-based) for co-products (e.g., electricity).

- Impact Assessment: Calculate Global Warming Potential (GWP) using IPCC factors. Net removal = (Biogenic CO₂ stored) - (Total lifecycle GHG emissions).

- Sensitivity Analysis: Test sensitivity to biomass type, supply distance, capture rate (85-95%), and grid electricity carbon intensity.

Protocol: Sorbent/Solvent Performance & Durability Testing for DAC

Objective: Measure CO₂ capture capacity, kinetics, and degradation over multiple cycles. Methodology:

- Material Characterization: Analyze fresh sorbent/solvent (e.g., amine-supported sorbent, KOH) for surface area, amine loading, and composition.

- Breakthrough Curve Analysis: a. Pack a fixed-bed reactor with sorbent. b. Expose to a simulated air stream (410 ppm CO₂, balance N₂/O₂) at defined T, P, and flow rate. c. Measure CO₂ concentration at outlet via NDIR sensor until saturation. d. Calculate dynamic capacity from integration of the breakthrough curve.

- Cyclic Stability Test: a. Perform repeated adsorption/desorption cycles (e.g., 1000+). b. Adsorption: Expose to humidified 410 ppm CO₂ at 25°C. c. Desorption: Apply temperature/vacuum swing (e.g., 80-120°C, 0.1 bar) for solid sorbents; or heat to 900°C for liquid solvent calcination. d. Monitor capacity retention and material properties (FTIR, TGA) every 100 cycles.

- Degradation Analysis: Quantify losses from oxidation, thermal degradation, or evaporation.

Visualization of Core Processes

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for BECCS & DAC Research

| Item | Function/Application | Example/Notes |

|---|---|---|

| Monoethanolamine (MEA) Solution | Benchmark solvent for post-combustion CO₂ capture in BECCS research. Used to establish baseline capture efficiency (85-90%) and energy penalty. | Typically used as 30% w/w aqueous solution. Research focuses on degradation inhibitors and novel amine blends. |

| Potassium Hydroxide (KOH) / Calcium Hydroxide (Ca(OH)₂) | Core chemicals for liquid solvent DAC. KOH captures CO₂ to form K₂CO₃; Ca(OH)₂ recovers KOH and precipitates CaCO₃ for calcination. | High purity required. Handling requires care due to strong corrosivity. Key cost and energy drivers. |

| Amine-Functionalized Solid Sorbents | Porous supports (e.g., silica, alumina, MOFs) grafted with amines (e.g., PEI) for adsorption in solid DAC systems. | Research parameters include pore size, amine loading, and stability under humid, oxidative conditions. |

| NDIR CO₂ Sensor | Critical for measuring low-concentration CO₂ in inlet/outlet streams during breakthrough experiments and process monitoring. | Requires calibration for range (0-2000 ppm) and high sensitivity at atmospheric levels (400 ppm). |

| Thermogravimetric Analyzer (TGA) | Measures sorbent weight change during adsorption/desorption cycles to determine CO₂ capacity and kinetics. | Can be coupled with a mass spectrometer (TGA-MS) to analyze degradation products. |

| Life Cycle Inventory (LCI) Database | Software and datasets (e.g., Ecoinvent, GREET) for modeling environmental impacts of full technology systems. | Essential for calculating net carbon removal and avoiding burden shifting in comparative research. |

Key Players and Current State of Global Demonstration Projects

Within the broader research thesis comparing the potential of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC), demonstration projects serve as critical, real-world laboratories. These initiatives, led by a consortium of public entities, private corporations, and research institutes, validate technological viability, inform scale-up protocols, and generate essential techno-economic data. This guide provides a technical dissection of the current global landscape, key methodologies, and research tools essential for professionals evaluating these carbon dioxide removal (CDR) pathways.

Live search data identifies the following leading entities and their flagship demonstration projects as of early 2025.

Table 1: Key Players in BECCS Demonstration

| Organization/Consortium | Project Name & Location | Core Technology Focus | Scale (tCO₂/yr) | Operational Phase |

|---|---|---|---|---|

| Drax / Bioenergy Energy Carbon Capture and Storage (BECCS) | BECCS Pilot, North Yorkshire, UK | Post-combustion capture (amine-based) on biomass power flue gas | 12,000 (target for full-scale) | Pilot operational; Full-scale FEED* |

| Stockholm Exergi | BECCS at Värtan, Stockholm, Sweden | Capture of biogenic CO₂ from CHP plant | Up to 800,000 (planned) | Final Investment Decision 2024 |

| Illinois Sustainable Technology Center (ISTC) | BECCS Field Demo, Illinois, USA | Biomass gasification + CCS | N/A (Research-scale) | R&D / Field Testing |

FEED: Front-End Engineering Design. *CHP: Combined Heat and Power.

Table 2: Key Players in DAC Demonstration

| Organization | Project Name & Location | Core Technology Focus | Scale (tCO₂/yr) | Operational Phase |

|---|---|---|---|---|

| Climeworks / Carbfix | Orca & Mammoth, Hellisheidi, Iceland | Solid Sorbent DAC + subsurface mineralization | 4,000 (Orca); 36,000 (Mammoth target) | Orca operational; Mammoth commissioning |

| Carbon Engineering / 1PointFive | STRATOS, Texas, USA | Liquid Solvent DAC (KOH/CaO loop) | 500,000 (planned) | Under construction |

| Global Thermostat | Multiple Pilot Sites, USA | Solid Sorbent DAC (amine-functionalized monoliths) | 1,000 - 10,000 (pilot range) | Pilot Deployment |

| Heirloom / CarbonCure | Heirloom DAC, Louisiana, USA | Accelerated weathering of calcium oxide | 1,000 (initial module) | Initial module operational |

Experimental Protocols for Technology Validation

Key experiments cited from these projects focus on core process validation and integration.

Protocol 3.1: Solid Sorbent DAC Adsorption-Desorption Cycling Test (Laboratory Scale)

- Objective: To determine the cyclic capacity, kinetics, and degradation profile of a novel amine-impregnated sorbent.

- Materials: Fixed-bed reactor, moisture-controlled flue gas simulator (400 ppm CO₂ in N₂), steam generator, gas analyzers (NDIR for CO₂), thermogravimetric analyzer (TGA).

- Procedure:

- Conditioning: 10g of sorbent is loaded into the fixed-bed reactor and pre-heated to 40°C under N₂ flow.

- Adsorption: A simulated air stream (400 ppm CO₂, 60% RH) is passed through the bed at 2 L/min for 60 minutes. Outlet CO₂ concentration is continuously logged.

- Desorption: The bed is heated to 100-120°C under a low-flow N₂ purge or exposed to low-pressure steam for 30 minutes. Desorbed CO₂ is captured and quantified.

- Cycling: Steps 2-3 are repeated for >1000 cycles.

- Analysis: Sorbent samples are extracted at cycle intervals for TGA (to measure amine loss) and porosity analysis (BET).

Protocol 3.2: BECCS Integration and Stack Emission Lifecycle Analysis (Pilot Plant)

- Objective: To measure net carbon negativity and characterize non-CO₂ emissions from a biomass-fired boiler with integrated capture.

- Materials: Pilot-scale biomass gasifier or boiler, post-combustion capture unit (e.g., amine scrubber), continuous emission monitoring system (CEMS), biomass feedstock of known origin and composition.

- Procedure:

- Baseline: Operate the biomass boiler without capture, measuring flue gas composition (CO₂, CO, NOx, SOx, particulates) and fuel input for 48 hours.

- Integrated Operation: Integrate the capture unit. Operate the full BECCS system at steady state for 72 hours.

- Sampling: Continuously measure: a) Biogenic CO₂ concentration pre- and post-capture; b) Amine solvent emissions (e.g., NH₃, nitrosamines) post-capture; c) All other stack emissions.

- Carbon Accounting: Mass balance is performed using fuel analysis, ash content, and captured CO₂ mass. Net CO₂ removal is calculated as: (Biogenic CO₂ captured) - (Fossil CO₂ emitted from process energy + Supply chain emissions from feedstock).

Visualization of System Workflows

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CDR Laboratory Research

| Item | Function & Relevance to BECCS/DAC | Example/Supplier |

|---|---|---|

| Amine-based Solvents (e.g., MEA, PZ) | Benchmark liquid absorbents for post-combustion capture; used to establish baseline performance for novel solvents in BECCS flue gas conditions. | Sigma-Aldrich (Monoethanolamine) |

| Functionalized Solid Sorbents | Amine-grafted silica or MOFs for DAC adsorption kinetics and cyclic capacity studies. Critical for evaluating degradation under realistic T/RH cycling. | Immobilized amines on porous silica (e.g., TRI-PE-MCM-41) |

| Gas Calibration Standards | Certified mixtures of CO₂ in N₂ or air (e.g., 400 ppm, 10%) for accurate calibration of NDIR analyzers and GC systems used in capture efficiency calculations. | NIST-traceable standards from Linde or Air Liquide |

| Isotopically Labeled CO₂ (¹³CO₂) | Tracer for studying carbonation kinetics in mineralization storage pathways or for detailed fate analysis in complex process streams. | Cambridge Isotope Laboratories |

| Accelerated Weathering Materials | High-purity, finely ground minerals (e.g., olivine, wollastonite) for testing enhanced weathering as a CO₂ sequestration endpoint linked to DAC or BECCS. | Ward's Science (Geological specimens) |

| Solvent Degradation Analysis Kits | HPLC/MS kits for quantifying amine degradation products (e.g., nitrosamines, heat-stable salts) which impact solvent longevity and environmental emissions. | Custom analytical protocols from NETL/DTI publications |

From Lab to Landscape: Methodologies, Systems, and Real-World Applications

1. Introduction: A Thesis Context Within the comparative assessment of carbon dioxide removal (CDR) technologies, Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC) represent two high-potential, yet fundamentally divergent pathways. This whitepaper provides a technical deep-dive into BECCS methodologies, serving as a foundational resource for evaluating its system complexities against the more direct, but energy-intensive, DAC approach. The core thesis hinges on comparing BECCS's reliance on biogenic carbon cycles and energy co-production with DAC's point-source capture of atmospheric CO2, with significant implications for scalability, cost, and integration into existing industrial frameworks.

2. Biomass Supply Chain Components & Quantitative Metrics A robust biomass supply chain is the foundational subsystem of BECCS, determining feedstock availability, carbon neutrality, and overall system efficiency. Key components include cultivation, harvesting, preprocessing, and transportation.

Table 1: Comparative Analysis of Primary BECCS Feedstocks

| Feedstock Type | Avg. Dry Yield (ton/ha/yr) | Avg. Energy Content (GJ/ton) | Avg. Biogenic Carbon Content (% dry weight) | Key Preprocessing Requirement |

|---|---|---|---|---|

| Miscanthus | 12-18 | 17-19 | ~48% | Size reduction, drying |

| Switchgrass | 10-15 | 17-18 | ~47% | Size reduction, densification |

| Short-Rotation Coppice (Willow) | 8-12 (odt) | 19-20 | ~49% | Chipping, drying |

| Forest Residues | N/A (byproduct) | 15-18 | ~50% | Sorting, grinding, drying |

| Agricultural Residues (e.g., straw) | 2-5 (byproduct) | 14-16 | ~45% | Collection, baling, drying |

3. Biomass Conversion Technologies with Integrated Capture The conversion stage transforms biomass into energy while producing a separable CO2 stream. Post-combustion capture is the most readily integrable technology.

Table 2: Comparison of Biomass Conversion Technologies for BECCS Integration

| Conversion Technology | Typical Scale | Primary Product | Capture Integration Point | Estimated Capture Rate (%) |

|---|---|---|---|---|

| Pulverized Coal/Biomass Co-firing | 100-1000 MWe | Electricity | Flue gas (Post-combustion) | 85-90% |

| Biomass-Fired Boiler (Bubbling/Circulating Fluidized Bed) | 20-150 MWe | Electricity/Heat | Flue gas (Post-combustion) | 85-95% |

| Biomass Gasification + Combined Cycle (BIGCC) | 10-100 MWe | Electricity | Syngas stream (Pre-combustion) | >90% |

| Biomass-to-Ethanol Fermentation | 50-500 ML/yr | Liquid Fuel | Fermentation off-gas (~99% CO2) | ~100% |

4. Experimental Protocol: Determining Biomass Carbon Fraction A standard method for quantifying the biogenic carbon content of a feedstock, critical for carbon accounting.

Title: Ultimate Analysis for Biomass Carbon Content Objective: To determine the carbon mass fraction in a dry biomass sample. Materials: Analytical balance, elemental analyzer (CHNS/O), tin capsules, crucibles, oven, desiccator. Procedure:

- Sample Preparation: Mill biomass to <0.2 mm. Dry at 105°C for 24 hours. Store in desiccator.

- Weighing: Precisely weigh 2-3 mg of homogenized dry sample into a tin capsule.

- Combustion: Load capsule into the elemental analyzer autosampler. The sample is combusted at ~1800°C in a pure oxygen environment.

- Separation & Detection: Resultant gases (CO2, N2, H2O, SO2) are separated via gas chromatography. CO2 is detected by a thermal conductivity detector (TCD).

- Calculation: The analyzer software calculates the mass percentage of carbon based on the detected CO2 relative to the sample weight, using calibration curves from standard compounds.

5. Storage Integration: Transport and Geological Sequestration Captured CO2 must be compressed, transported (typically via pipeline), and injected into suitable geological formations.

Table 3: Geological Storage Site Characterization Criteria

| Formation Type | Example Reservoirs | Estimated Global Capacity (Gt CO2) | Key Monitoring Parameter |

|---|---|---|---|

| Deep Saline Aquifers | Saline-filled porous rock | 1000 - 100,000 | Pressure plume migration, induced seismicity |

| Depleted Oil/Gas Fields | North Sea, Permian Basin | 100 - 1000 | Reservoir integrity, seal performance |

| Unmineable Coal Seams | Deep anthracite seams | 10 - 100 | Methane displacement, adsorption stability |

6. Visualization: BECCS End-to-End System Workflow

Diagram Title: BECCS Full-System Process Flow Diagram

7. Visualization: BECCS vs DAC Core Pathways Comparison

Diagram Title: BECCS vs DAC Carbon Pathways

8. The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Reagents & Materials for BECCS Laboratory Research

| Item Name | Function/Application | Key Characteristic |

|---|---|---|

| Monoethanolamine (MEA) Solution | Benchmark solvent for post-combustion CO2 capture experiments. | High reactivity, establishes baseline for absorption efficiency & degradation studies. |

| Advanced Amino-Silica Sorbents | Solid sorbents for CO2 capture from flue gas or air. | Lower regeneration energy than liquid amines, tested for cyclic capacity. |

| Stable Isotope 13C-Labeled Biomass | Tracing biogenic vs. fossil carbon in conversion processes and emissions. | Enables precise mass spectrometry analysis of carbon flows. |

| Porous ZIF/MOF Materials | Novel adsorbents for gas separation (CO2/N2). | High surface area & tunable selectivity for pre-combustion capture research. |

| Reservoir Brine Analogue Solutions | Geochemical studies on CO2-brine-rock interactions. | Simulates in-situ conditions for mineralization and seal integrity experiments. |

| Lignocellulolytic Enzyme Cocktails | Hydrolysis of biomass for biochemical conversion pathways. | Contains cellulases, hemicellulases for yield optimization studies. |

This whitepaper, framed within a broader thesis on BECCS (Bioenergy with Carbon Capture and Storage) versus Direct Air Capture (DAC) comparative potential, provides a technical analysis of the two primary technological pathways for DAC. The focus is a comparative examination of Liquid Solvent and Solid Sorbent systems, detailing their chemical principles, performance metrics, experimental protocols, and material requirements for a research and development audience.

BECCS and DAC are leading negative emission technologies (NETs). BECCS captures CO₂ from point-source bioenergy production, while DAC captures from ambient air anywhere. The choice between liquid solvent and solid sorbent DAC systems is critical for scaling, as it dictates energy demand, cost, and integration potential—key comparative factors against BECCS.

Core Chemical Principles & Pathways

Liquid Solvent Systems

Typically employs aqueous alkaline solutions (e.g., potassium hydroxide, KOH). CO₂ is absorbed and converted into a stable carbonate. Primary Chemical Pathway:

- Absorption: CO₂(aq) + OH⁻ → HCO₃⁻

- Carbonate Formation: HCO₃⁻ + OH⁻ → CO₃²⁻ + H₂O

- Regeneration: The carbonate solution is reacted with calcium hydroxide (slaked lime) to precipitate calcium carbonate (CaCO₃).

- Calcination: CaCO₃ is heated in a calciner (900-950°C) to release pure CO₂ and regenerate CaO.

Diagram Title: Liquid Solvent DAC Chemical Process Flow

Solid Sorbent Systems

Uses porous solid materials functionalized with amine groups (e.g., on silica, alumina, or MOFs) that adsorb CO₂. Regeneration is typically achieved via Temperature-Vacuum Swing Adsorption (TVSA). Primary Chemical Pathway:

- Adsorption: Amine (sorbent) + CO₂ + H₂O ⇄ AmineH⁺ + HCO₃⁻ (adsorbed)

- Saturation: Sorbent reaches capacity.

- Desorption: Application of heat (80-120°C) and/or vacuum releases pure CO₂ and regenerates the amine sorbent.

Diagram Title: Solid Sorbent DAC TVSA Cycle

Performance Data & Comparative Analysis

Table 1: Comparative Performance Metrics of DAC Pathways

| Metric | Liquid Solvent (KOH/CaO) | Solid Sorbent (Amine-functionalized) |

|---|---|---|

| Capture Efficiency (%) | > 90% (highly dependent on contactor design) | 70-90% (dependent on humidity & cycle time) |

| Typical Regeneration Temp. | High: 800-950°C (calcination) | Low-Medium: 80-120°C (desorption) |

| Primary Energy Demand (GJ/tCO₂) | 7-12 (mainly thermal for calcination) | 5-9 (balanced thermal & electrical for vacuum) |

| Current Cost Estimate (USD/tCO₂) | $250 - $600 (high capex, energy-intensive) | $200 - $400 (potential for cost reduction) |

| Water Consumption (t/tCO₂) | High: 1-10 (evaporation losses) | Low: < 1 (some for humidity control) |

| Technology Readiness Level | 6-7 (first commercial plants) | 5-6 (pilot and demonstration) |

| Key Advantage | Proven, continuous process | Lower regeneration temperature, modularity |

| Key Challenge | High-grade heat requirement, sorbent loss | Sorbent degradation, air pretreatment needs |

Detailed Experimental Protocols

Protocol: Testing Solid Sorbent Adsorption Kinetics

Objective: To measure the CO₂ adsorption capacity and rate of a novel amine-impregnated sorbent under controlled humidity. Methodology:

- Sorbent Preparation: Impregnate 5g of mesoporous silica support with 50% w/w aqueous polyethyleneimine (PEI) solution. Dry at 80°C for 12 hours under vacuum.

- Setup: Load 1.0g of prepared sorbent into a fixed-bed quartz reactor (ID = 1 cm) placed inside a temperature-controlled furnace.

- Conditioning: Flush reactor with N₂ (100 mL/min) at 105°C for 1 hour to remove impurities.

- Adsorption: Cool reactor to 25°C. Introduce a humidified gas stream (400 ppm CO₂, balance N₂, 60% RH) at a total flow of 200 mL/min.

- Measurement: Monitor CO₂ concentration at outlet via Non-Dispersive Infrared (NDIR) sensor until breakthrough (C/C₀ = 0.05). Integrate breakthrough curve to calculate dynamic capacity.

- Regeneration: Switch to pure N₂ flow and heat to 90°C for 30 minutes to desorb CO₂. Monitor outlet CO₂ with NDIR.

Protocol: Liquid Solvent Carbonation & Precipitation Efficiency

Objective: To determine the yield of CaCO₃ from a potassium carbonate solution using slaked lime. Methodology:

- Solution Preparation: Create a 1M K₂CO₃ solution using deionized water.

- Carbonation Reaction: In a 500 mL stirred batch reactor, add 250 mL of 1M K₂CO₃. Slowly add a slurry of 10g Ca(OH)₂ in 50 mL DI water while maintaining temperature at 40°C and constant stirring (500 rpm).

- Sampling & Analysis: At 10-minute intervals over 1 hour, extract 5 mL aliquots. Filter immediately (0.45 μm syringe filter). Titrate filtrate with 0.1M HCl to determine remaining carbonate concentration.

- Precipitate Analysis: Filter the final mixture, wash precipitate with DI water and ethanol, dry at 80°C overnight. Weigh final solid product (CaCO₃). Analyze purity via X-ray Diffraction (XRD).

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for DAC Laboratory Research

| Item | Function | Example/Notes |

|---|---|---|

| Amine Solutions | Functionalizing solid supports for sorbents. | Polyethyleneimine (PEI), Tetraethylenepentamine (TEPA). High nitrogen content for CO₂ chemisorption. |

| Porous Supports | High-surface-area scaffold for amine loading. | Silica gel, γ-Alumina, Metal-Organic Frameworks (MOFs) like MIL-101 or SBA-15. |

| Alkaline Solvents | Active capture medium for liquid systems. | Potassium Hydroxide (KOH), Sodium Hydroxide (NaOH). Corrosive, requires careful handling. |

| Calcium Precursors | For carbonate precipitation and solvent regeneration. | Calcium Hydroxide (Ca(OH)₂, slaked lime), Calcium Oxide (CaO, quicklime). |

| Standard Gas Mixtures | Calibration and controlled adsorption experiments. | 400-500 ppm CO₂ in N₂ or air, with/without humidity standards. |

| Non-Dispersive Infrared (NDIR) Sensor | Real-time, low-concentration CO₂ measurement. | Critical for breakthrough curve analysis. |

| Thermogravimetric Analyzer (TGA) | Measuring sorbent adsorption capacity & degradation. | Coupled with mass spectrometry (TGA-MS) for evolved gas analysis. |

| Fixed-Bed Reactor System | Bench-scale testing of adsorption/desorption cycles. | Includes temperature control, gas blending, and real-time analytics. |

Diagram Title: Solid Sorbent Lab Test Workflow

The liquid solvent pathway offers robustness and continuous operation but faces significant energy and water hurdles. The solid sorbent pathway promises lower energy penalties and modular design but must overcome sorbent stability and scaling challenges. For researchers comparing the potential of BECCS and DAC, the critical development trajectories are clear: liquid systems require integration with low-cost, low-carbon high-grade heat, while solid systems demand advances in sorbent longevity and structured contactor design. The choice between them will hinge on geographic context (energy/water availability) and the pace of innovation in materials science and process engineering.

Within the comparative analysis of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC), the profile of energy and utility inputs is a primary determinant of technical feasibility, cost, and scalability. This whitepaper provides a critical, data-driven analysis of these requirements, serving researchers and process development professionals engaged in evaluating carbon dioxide removal (CDR) pathways. The analysis underscores that while BECCS is a energy-producing process with significant ancillary resource demands, DAC is a energy-consuming process where the source and form of energy dictate its viability.

The core thesis differentiating BECCS and DAC posits that BECCS offers a co-product (energy) but is constrained by biomass sustainability and geographic factors, whereas DAC is energy-intensive but offers siting flexibility. The magnitude, type (heat vs. electricity), temperature grade, and continuity of energy inputs directly govern the efficiency, operational cost, and net carbon removal efficacy of each technology.

Quantitative Analysis of Energy & Utility Demands

The following tables synthesize current data on energy and utility consumption for leading DAC and BECCS configurations.

Table 1: Direct Air Capture (DAC) Process Energy Requirements

| DAC Technology | Thermal Energy Demand (GJ/tCO₂) | Electrical Energy Demand (GJ/tCO₂) | Temperature Requirement (°C) | Primary Utility Inputs |

|---|---|---|---|---|

| Solid Sorbent (Low-Temp) | 5 - 8 | 1.5 - 2.5 | 80 - 120 | Low-grade heat (e.g., industrial waste, geothermal), Electricity |

| Liquid Solvent (High-Temp) | 8 - 12 | 0.2 - 0.5 | 800 - 900 | High-grade heat (natural gas combustion, advanced nuclear), Electricity |

Sources: Data consolidated from recent operational analyses of Orca (Climeworks) and Carbon Engineering plants, and peer-reviewed system modeling (2023-2024).

Table 2: BECCS Pathway Energy & Resource Balance

| BECCS Configuration | Feedstock | Gross Energy Output (GJ/t Biomass) | CCS Energy Penalty (% of output) | Net Energy Output (GJ/tCO₂ removed) | Key Ancillary Utilities |

|---|---|---|---|---|---|

| Biomass Power + Amine CCS | Wood Chips | 10-12 | 20-30% | 2 - 4 | Process Water, Solvent (MEA), Compression Power |

| Bioethanol + Sequestration | Corn/ Sugarcane | 6-8 (as ethanol) | 15-25% | 1.5 - 3 | Irrigation Water, Fertilizer, Fermentation Nutrients |

Sources: Integrated assessment models (IAMs) and life-cycle inventory data from facilities like the Illinois Industrial CCS Project (2023-2024).

Experimental Protocols for System Analysis

Protocol 1: Measuring Specific Energy Consumption in Solid Sorbent DAC Systems

- Objective: Quantify the thermal and electrical energy required per metric ton of CO₂ captured in a temperature-vacuum swing adsorption (TVSA) cycle.

- Materials: Bench-scale packed-bed reactor with solid amine sorbent, mass flow controllers for simulated air, programmable temperature oven, vacuum pump, CO₂ analyzer (NDIR), precision power meters (thermal & electrical).

- Procedure:

- Adsorption Phase: Condition the sorbent bed. Pass a defined flow of humidified, 420 ppm CO₂ air at 25°C over the sorbent until breakthrough is detected by the NDIR analyzer. Record electrical energy for fans/blowers.

- Desorption Phase: Isolate the reactor. Initiate the desorption cycle by applying controlled thermal energy to the bed (recorded via power meter) while pulling a vacuum. Capture the released, concentrated CO₂ stream.

- Calculation: Integrate total thermal (Joules from heater) and electrical (Joules from pump/blowers) input over a complete cycle. Divide by the mass of CO₂ captured (measured via NDIR integration) to obtain GJ/tCO₂.

Protocol 2: Life-Cycle Inventory for BECCS Utility Footprint

- Objective: Develop a cradle-to-gate inventory of direct and indirect energy/utility inputs for a biomass power plant with post-combustion capture.

- Materials: Process simulation software (e.g., Aspen Plus), agricultural input data (fertilizer, diesel for harvesting), transportation models, power plant performance specifications, amine scrubbing unit models.

- Procedure:

- Feedstock Cultivation Module: Collect data on diesel, electricity, and fertilizer inputs per hectare of biomass cultivation. Allocate proportionally to biomass yield.

- Conversion & Capture Module: Model the power plant and attached stripper unit. Using simulation, determine the parasitic load (in MW) for solvent circulation, pump work, and CO₂ compression.

- Allocation: Sum all direct and embodied energy inputs across the chain. Allocate net CO₂ captured between energy output and the removal service. Report total process water, chemicals, and net energy output per tCO₂ sequestered.

System Visualization: Energy Flows and Comparative Pathways

DOT script for generating the "DAC Energy Input & Process Flow" diagram.

DOT script for generating the "BECCS Energy & Utility Flow Diagram".

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Research Materials for Energy Analysis Experiments

| Material / Solution | Function in Analysis | Typical Specification / Example |

|---|---|---|

| Solid Aminosilica Sorbents | DAC model system for measuring adsorption capacity and regeneration energy. | PEI-impregnated SBA-15, Classified particle size (150-250 µm). |

| Aqueous Amine Solvents (e.g., MEA, KOH) | Benchmark liquid absorbent for comparative energy studies in both DAC and BECCS contexts. | 30 wt% Monoethanolamine (MEA) solution, ACS grade. |

| NDIR CO₂ Analyzer | Precise, real-time measurement of CO₂ concentration for calculating capture rates and system efficiency. | Multi-gas analyzer with 0-5000 ppm range, ±2% accuracy. |

| Calorimetry System | Measures enthalpy of absorption/desorption, a critical parameter for thermal energy demand calculations. | Differential scanning calorimeter (DSC) or custom flow calorimeter. |

| Process Modeling Software License | Enables thermodynamic modeling of energy and mass balances for full-scale system extrapolation. | Aspen Plus, gPROMS, or open-source equivalent (DWSIM). |

| Precision Power & Flow Meters | Quantifies electrical and thermal energy inputs (kWh) and fluid flow rates in bench-scale setups. | Clamp-on power meters, Coriolis mass flow meters, thermal energy meters. |

Within the broader research context comparing the potential of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC), defining their optimal application niches is critical. This technical guide provides a framework for researchers and drug development professionals to evaluate these negative emission technologies (NETs) based on geographic, sectoral, and technical parameters. The efficacy of each technology is not uniform but is governed by localized resource availability, infrastructure, and economic drivers.

BECCS and DAC operate on fundamentally different principles, leading to distinct input requirements and output profiles.

- BECCS: Integrates energy production from biomass with post-combustion, pre-combustion, or oxy-fuel combustion carbon capture, followed by geological storage. It is a co-product system yielding carbon-negative energy.

- DAC: Uses chemical sorbents or solvents (typically liquid hydroxides or solid amines) to absorb CO₂ directly from the ambient atmosphere, followed by a energy-intensive regeneration cycle to release a pure CO₂ stream for storage or utilization.

Geographic Niches Analysis

Optimal deployment is highly sensitive to regional characteristics. Key determining factors include biomass sustainability, low-carbon energy availability, and suitable geology.

Table 1: Geographic Suitability Analysis for BECCS and DAC Deployment

| Geographic Factor | High Suitability for BECCS | High Suitability for DAC | Rationale & Key Constraints |

|---|---|---|---|

| Biomass Availability | Regions with sustainable, large-scale biomass production (e.g., forestry residues, energy crops on marginal land). Examples: Southeastern USA, Northern Europe, Brazil. | Not a direct requirement. | BECCS scalability is bounded by sustainable biomass supply, land-use competition, and water availability. |

| Low-Carbon Energy Density | Moderate requirement for process heat/power, which can be self-supplied. | Regions with abundant, cheap, low-carbon electricity (geothermal, hydro, solar, wind) or waste heat. Examples: Iceland, Norway, SW USA, Middle East (with solar). | DAC's energy intensity (6-10 GJ/tCO₂ for liquid systems; 8-16 GJ/tCO₂ for solid sorbent) makes renewable energy cost critical. |

| Geological Storage Proximity | High suitability near sedimentary basins with proven storage capacity (e.g., North Sea, Gulf Coast, Alberta Basin). | Same high requirement as BECCS. | Transporting CO₂ over long distances via pipeline is economically and politically challenging. Proximity to storage is a major cost driver for both. |

| Land Footprint | High land-use due to biomass cultivation; suitable for lower-population density areas. | Compact industrial plants; suitable for arid, non-arable land or industrial zones. | DAC's small land footprint allows siting flexibility, avoiding land-use conflicts. |

| Atmospheric CO₂ Concentration | Insensitive to ambient CO₂ levels (~420 ppm). | Technically insensitive, but economic efficiency is constant regardless of location. | Unlike point-source capture, DAC performance does not vary with local air composition, allowing global uniformity. |

Sectoral Application Niches

Different industrial sectors present unique opportunities and challenges for integration with BECCS or DAC.

Table 2: Sectoral Integration Potential for BECCS and DAC

| Sector | BECCS Applicability | DAC Applicability | Key Considerations & Experimental Protocols |

|---|---|---|---|

| Power Generation | High. Can retrofit existing biomass/co-firing power plants or build new bioenergy plants with CCS. | Low. DAC is not coupled to power generation. | BECCS Protocol (Post-Combustion): 1. Flue gas from biomass combustion is cooled and scrubbed. 2. CO₂ is absorbed using a solvent (e.g., 30 wt% Monoethanolamine - MEA). 3. Rich solvent is regenerated in a stripper at 100-120°C, releasing high-purity CO₂. 4. Capture efficiency is measured via continuous gas analyzers pre- and post-absorption column. |

| Pulp, Paper & Forestry | Very High. Large, centralized sources of biogenic CO₂ from recovery boilers and biomass residues on-site. | Low. Typically a point-source, making DAC less efficient. | BECCS Protocol (Oxy-fuel): 1. Biomass is combusted in >95% O₂ (from an ASU), producing a flue gas primarily of CO₂ and H₂O. 2. After dehydration and purification, a >95% pure CO₂ stream is achieved. 3. Key measurement: Continuous O₂ concentration monitoring to ensure combustion stability and purity. |

| Waste-to-Energy | High. Municipal solid waste contains significant biogenic fraction. Capturing emissions can yield negative emissions. | Low. | Experimental Protocol for Biogenic Fraction Determination: Use the 14C Radiocarbon Method. 1. Sample flue gas CO₂ onto a molecular sieve. 2. Convert sampled CO₂ to benzene or graphite. 3. Analyze via Accelerator Mass Spectrometry (AMS) to determine 14C/12C ratio. 4. Calculate biogenic fraction by comparing to modern carbon reference. |

| Chemical & Fuel Synthesis | Medium. Biogenic CO₂ can be a feedstock, but BECCS prioritizes storage. | Very High. DAC provides pure, atmospheric CO₂ for electrochemical or thermochemical synthesis of e-fuels (e.g., methanol, synthetic hydrocarbons). | DAC Integration Protocol (for e-Methanol): 1. CO₂ captured via solid sorbent DAC unit. 2. H₂ produced via electrolysis using renewable power. 3. Catalytic synthesis (Cu/ZnO/Al₂O₃ catalyst) at 50-100 bar, 200-300°C: CO₂ + 3H₂ → CH₃OH + H₂O. 4. Purity is assessed via Gas Chromatography (GC). |

| Pharmaceutical & Biotechnology R&D | Low. Not typically a sectoral application. | Medium/High. For carbon labeling in drug development. Atmospheric CO₂ captured via DAC provides a uniform, traceable carbon source for synthesizing 14C-labeled compounds for ADME (Absorption, Distribution, Metabolism, Excretion) studies. | Protocol for 14C-Labeling Precursor Synthesis using DAC: 1. Operate a specialized DAC unit to concentrate atmospheric CO₂. 2. Catalytically convert CO₂ to a foundational precursor (e.g., CH₄, CH₃OH) using renewable H₂. 3. Use biosynthetic or chemosynthetic pathways to incorporate the uniform 14C into target molecular scaffolds (e.g., APIs). 4. Radio-HPLC is used to verify specific activity and purity. |

Visualization of Technology Pathways & Decision Logic

Decision Logic for Technology Siting

DAC Chemical Process Pathways

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Key Research Reagents and Materials for NETs Experiments

| Item Name | Supplier Examples (for Reference) | Function in BECCS/DAC Research | Typical Application Protocol |

|---|---|---|---|

| Monoethanolamine (MEA) Solution | Sigma-Aldrich, Fisher Scientific | Benchmark solvent for post-combustion CO₂ capture kinetics and degradation studies. | Prepared as 30 wt% aqueous solution for lab-scale absorption column experiments to establish baseline efficiency. |

| Amine-Functionalized Silica Sorbents | Material Vendors (e.g., SRI) / Lab-synthesized | Model solid sorbents for DAC adsorption isotherm and cycling stability tests. | Packed into a fixed-bed reactor; exposed to simulated air/CO₂ mix; cycled with temperature/pressure swings. |

| Potassium Hydroxide (KOH) pellets | Common chemical suppliers | Used in liquid DAC pathway simulations and solvent characterization. | Dissolved in water to create concentrated solutions for air contactor mock-up experiments. |

| 14C-Labeled Sodium Bicarbonate (NaH14CO₃) | American Radiolabeled Chemicals, Inc. | Critical tracer for quantifying biogenic carbon fraction (BECCS) and tracing carbon in utilization pathways. | Used in lab-scale bioreactors or chemical synthesis to track carbon flow via scintillation counting or AMS. |

| Gas Chromatography System with TCD & FID | Agilent, Shimadzu | Essential for analyzing gas composition (CO₂, CH₄, CO, N₂, O₂) in process streams from capture experiments. | Regular calibration with certified standard gas mixtures is required before sampling experimental output streams. |

| Accelerator Mass Spectrometry (AMS) Service | Commercial AMS labs (e.g., Beta Analytic) | Gold-standard for distinguishing fossil vs. biogenic carbon via 14C measurement. | Samples (e.g., captured CO₂, biomass) are converted to graphite and analyzed for 14C/12C ratio. |

| Cu/ZnO/Al₂O₃ Catalyst pellets | Alfa Aesar, lab-prepared | Standard catalyst for studying CO₂ hydrogenation to methanol, a key DAC utilization pathway. | Loaded into a high-pressure continuous-flow reactor system under controlled temperature and syngas (CO₂/H₂) feed. |

Within the comparative analysis of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC), operational facilities provide critical, real-world data on technological pathways for achieving negative emissions. This whitepaper examines two leading BECCS projects and two commercial DAC plants, focusing on their core technologies, performance metrics, and operational protocols. The analysis is structured to inform researchers, including those in related fields like drug development who require rigorous data evaluation, on the current state of technological readiness and scalability.

Operational BECCS Case Study: Illinois Industrial Carbon Capture and Storage (ICCS)

The Illinois ICCS project at the Archer Daniels Midland (ADM) ethanol bio-refinery in Decatur is one of the world's first large-scale BECCS operations. It captures CO₂ from bio-ethanol fermentation—a nearly pure stream—for geological sequestration.

Core Technology & Protocol

The facility employs a post-combustion capture system using an amine-based solvent (primarily monoethanolamine - MEA). The standard protocol for carbon capture in this context involves:

- Gas Conditioning: The fermentation-derived CO₂ is cooled and scrubbed to remove impurities.

- Absorption: The gas contacts the MEA solution in an absorber column, where CO₂ is chemically bound.

- Regeneration: The CO₂-rich solvent is pumped to a stripper column and heated (typically to 100-120°C) to break the chemical bond, releasing high-purity CO₂.

- Compression & Dehydration: The captured CO₂ is compressed to a supercritical state and dehydrated for pipeline transport.

- Injection & Monitoring: The CO₂ is injected via a dedicated well into the Mount Simon Sandstone reservoir at ~2,100 meters depth. A comprehensive monitoring, verification, and accounting (MVA) protocol is implemented, including downhole pressure monitoring, time-lapse vertical seismic profiling, and fluid sampling.

Quantitative Data: Illinois ICCS

| Metric | Value | Notes |

|---|---|---|

| Annual Capture Capacity | ~1.0 million tonnes CO₂ | As of Phase 2 expansion (operative 2017) |

| Capture Rate (%) | >90% | From fermentation process |

| Cumulative Stored CO₂ | >3.5 million tonnes | Since operations began (2011-2017 for Phase 1, 2017-present for Phase 2) |

| Injection Depth | ~2,100 m | Into the Mount Simon Sandstone |

| Storage Reservoir | Saline Aquifer | Deep, porous sandstone formation |

| Primary Capture Solvent | Amine-based (MEA) | Industry-standard for high-purity streams |

Operational DAC Case Studies: Orca and STRATOS

Direct Air Capture technology extracts CO₂ directly from the ambient atmosphere using chemical sorbents. Two leading operational plants are Climeworks' Orca in Iceland and Occidental's STRATOS (Direct Air Capture 1 plant) in Texas, USA.

Core Technology & Protocol: Solid Sorbent DAC (Orca)

Climeworks' Orca plant uses a modular, solid sorbent filter system. The experimental cycle is as follows:

- Air Intake: Fans draw ambient air through a series of collectors.

- Adsorption: CO₂ in the air is chemically bound to the surface of amine-functionalized solid sorbent filters.

- Separation & Desorption: Once saturated, the collector is closed and heated to ~100°C using low-grade or geothermal energy. This releases the purified CO₂.

- Product Delivery & Storage: The released CO₂ is mixed with water and pumped underground by Carbfix's partner system, where it mineralizes in basalt formations. A key protocol involves the verification of mineralization via tracer tests and groundwater sampling.

Core Technology & Protocol: Liquid Solvent DAC (STRATOS)

The STRATOS plant (DAC 1) uses a potassium hydroxide (KOH) based liquid solvent system, adapted from legacy gas treating processes.

- Air Contact: A large air contactor (fan system) exposes a potassium hydroxide solution to ambient air. CO₂ reacts with KOH to form potassium carbonate (K₂CO₃).

- Pellet Reactor: The K₂CO₃ solution is transferred to a pellet reactor where it reacts with calcium hydroxide (Ca(OH)₂) to precipitate calcium carbonate (CaCO₃) pellets.

- Calcination (Regeneration): The CaCO₃ pellets are heated in a high-temperature (≈900°C) calciner powered by natural gas (with plans for transition to renewables/capture), releasing a pure CO₂ stream and regenerating calcium oxide (CaO).

- Slaking & Recycle: The CaO is slaked with water to reform Ca(OH)₂ for reuse.

- Compression & Utilization: The pure CO₂ stream is compressed for use in enhanced oil recovery (EOR) or dedicated storage.

Quantitative Data: Orca vs. STRATOS

| Metric | Orca (Climeworks) | STRATOS (Occidental/1PointFive) |

|---|---|---|

| Annual Capture Capacity (Design) | 4,000 tonnes CO₂ | Up to 500,000 tonnes CO₂ (at full capacity) |

| Technology | Solid Amine Sorbent | Liquid Hydroxide Solvent (KOH) |

| Energy Source | Geothermal (Renewable) | Natural Gas (with plans for transition) |

| Heat Requirement | Low-grade (~100°C) | High-grade (~900°C for calcination) |

| CO₂ Fate | Mineral Storage (Carbfix) | Mainly EOR / Dedicated Geologic Storage |

| Status | Operational (2021) | Commissioning / Early Operation (2024) |

Comparative Analysis: Critical Methodologies for Evaluation

Researchers evaluating these technologies must consider standardized protocols for life-cycle assessment (LCA) and techno-economic analysis (TEA).

Protocol 1: Net Negative Emissions Calculation

For a comparative thesis, the core calculation for net removal must account for the full lifecycle.

- For BECCS (e.g., Illinois ICCS):

Net CO₂ Removed = (Biogenic CO₂ Captured & Stored) - (Emissions from Cultivation + Processing + Capture Process Energy + Transport & Injection)Methodology: Requires detailed attributional LCA of biomass supply chain and plant operations. The Decatur project uses site-specific emissions data for operations and literature values for sustainable corn cultivation. - For DAC (e.g., Orca/STRATOS):

Net CO₂ Removed = (CO₂ Captured from Air) - (Emissions from Sorbent/Solvent Production + Plant Construction + Operational Energy)Methodology: Requires rigorous energy system modeling. Orca's use of geothermal energy minimizes the operational penalty. STRATOS's current reliance on natural gas necessitates careful accounting of associated emissions, which are partially mitigated by using captured CO₂ in secure storage via EOR.

Protocol 2: Sorbent/Solvent Performance Testing

A key experimental protocol in both fields involves testing the durability and capacity of capture media.

- Cycling Test: The sorbent (solid amine) or solvent (KOH/MEA) is subjected to repeated adsorption/desorption cycles in a lab-scale reactor.

- Degradation Measurement: Samples are analyzed periodically via techniques like Fourier-Transform Infrared Spectroscopy (FTIR) or titration to quantify loss of active sites due to oxidation, thermal degradation, or impurity poisoning.

- Capacity Measurement: The CO₂ adsorption/absorption capacity (e.g., mol CO₂/kg sorbent) is measured before and after defined cycle numbers (e.g., 1, 10, 100, 1000 cycles) to establish a degradation curve.

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

For researchers conducting lab-scale simulations or analyses related to BECCS and DAC technologies, the following reagents and materials are fundamental.

| Item | Function in Research | Example Application |

|---|---|---|

| Monoethanolamine (MEA) | Benchmark amine solvent for CO₂ absorption. | Simulating post-combustion or fermentation-based capture in batch reactors; kinetic studies. |

| Potassium Hydroxide (KOH) | Strong liquid alkali solvent for CO₂ chemisorption. | Modeling liquid DAC processes; studying carbonate precipitation kinetics. |

| Amine-Functionalized Solid Sorbents | Porous supports (e.g., silica, alumina) with grafted amines for CO₂ adsorption. | Testing cyclic capacity and degradation in fixed-bed reactors for solid sorbent DAC. |

| Calcium Hydroxide (Ca(OH)₂) | Reagent for converting carbonate solutions into solid precipitates. | Studying the pelletization and calcination steps in liquid solvent DAC cycles. |

| Gas Chromatograph (GC) with TCD | Analytical instrument for quantifying gas composition (CO₂, N₂, O₂). | Measuring capture efficiency, solvent degradation byproducts, and gas purity. |

| Benchtop Parr Reactor | Pressurized, temperature-controlled reaction vessel. | Conducting solvent performance tests under realistic temperature/pressure conditions. |

| Titration Setup | For quantifying amine concentration or carbonate loading in solutions. | Measuring solvent degradation (amine loss) and CO₂ absorption capacity. |

Visualizations

Title: Solid Sorbent DAC Process Flow (e.g., Orca)

Title: BECCS Process at Illinois ICCS Facility

Title: BECCS vs DAC Comparative Overview

Navigating Hurdles: Critical Challenges, Costs, and Optimization Strategies

Within the comparative assessment of Bioenergy with Carbon Capture and Storage (BECCS) and Direct Air Capture (DAC) as negative emission technologies (NETs), significant bottlenecks threaten the scalability and sustainability of BECCS. This whitepaper details the core constraints of land-use change, water resource demand, and systemic sustainability, which are less pronounced in engineered DAC systems. The viability of BECCS as a large-scale climate solution hinges on addressing these interrelated challenges.

Quantitative Analysis of Bottlenecks

Table 1: Land-Use and Water Demand Estimates for BECCS Scalability

| Parameter | Low Estimate | Median/Common Estimate | High Estimate | Notes & Source (2023-2024) |

|---|---|---|---|---|

| Land Required per Gt CO₂/yr | 300 Mha | 380 - 700 Mha | Up to 1,200 Mha | Highly crop & region dependent. High end assumes lower yields. |

| Water Consumption (km³/yr per Gt CO₂) | 1,500 | ~3,000 | 8,000 - 10,000 | Irrigated biomass significantly increases demand. |

| Potential Global Sequestration (Gt CO₂/yr) | 5 | 3 - 7 (theoretical) | 11 - 12 | Constrained by sustainable land/water limits, not technical potential. |

| Comparative Water Use: BECCS vs. DAC (m³/tCO₂) | ~100 - 1,000+ | BECCS: 50-600; DAC: 1-10 | BECCS >> DAC | DAC water use primarily for cooling, often in closed loops. |

| Fertilizer Demand (Mt N/yr per Gt CO₂) | 20 | 30 - 100 | 150 | Key for non-leguminous crops; source of indirect emissions. |

Table 2: Sustainability and Impact Indicators

| Indicator | Impact Range | Primary Concerns | Mitigation Strategy Relevance |

|---|---|---|---|

| Biodiversity Loss | Moderate to Severe | Monoculture plantations, ILUC, habitat fragmentation. | Use of marginal/degraded lands, polycultures. |

| Food Security Displacement | High Risk at Scale | Direct & indirect land competition with agriculture. | Strict governance, use of residual & waste biomass. |

| Soil Carbon Debt | Net loss in short-term (5-50 yrs) | Land conversion releases soil carbon, offsetting CCS benefits. | Perennial crops, no-till practices, protect existing stocks. |

| Net Energy Return (NER) | Wide range (2:1 to 10:1) | Low NER reduces net carbon removal efficacy. | Optimize supply chain, use high-yield feedstocks. |

| Social Acceptance | Highly Variable | Land rights, water access, local community impacts. | Early and inclusive stakeholder engagement. |

Experimental Protocols for Key Assessments

Protocol 1: Life Cycle Assessment (LCA) for BECCS Sustainability

Objective: Quantify the net carbon removal and environmental impacts of a BECCS value chain. Methodology:

- Goal & Scope: Define functional unit (e.g., 1 MWh electricity + 1 tCO₂ sequestered), system boundaries (cradle-to-grave), and impact categories (GWP, land use, water consumption, eutrophication).

- Inventory Analysis (LCI):

- Biomass Cultivation: Collect data on feedstock yield, land-use history, inputs (fertilizer, pesticides, irrigation), farm machinery use, and direct N₂O emissions from soil.

- Biomass Logistics: Model transport emissions (distance, mode) and preprocessing energy (drying, pelletizing).

- Conversion & CCS: Obtain plant data on efficiency, fuel use, capture solvent (e.g., MEA) consumption and degradation rates, and CO₂ capture rate (e.g., 90%). Include CO₂ compression, transport (pipeline), and geological injection.

- Impact Assessment (LCIA): Apply characterization factors (e.g., IPCC AR6 for GWP) to inventory flows. Critical Step: Account for direct and indirect land-use change (d/iLUC) emissions using models like ECAM or GLOBIOM.

- Interpretation: Calculate net carbon balance:

Net CO₂e = (CO₂ sequestered) - (Supply Chain Emissions + iLUC Emissions + CCS Energy Penalty Emissions). Perform sensitivity analysis on key parameters.

Protocol 2: Assessing Water Footprint of BECCS Feedstocks