BECCS Decoded: The Science of Bioenergy with Carbon Capture and Storage for Negative Emissions

This article provides a comprehensive technical analysis of Bioenergy with Carbon Capture and Storage (BECCS), a leading carbon dioxide removal (CDR) technology.

BECCS Decoded: The Science of Bioenergy with Carbon Capture and Storage for Negative Emissions

Abstract

This article provides a comprehensive technical analysis of Bioenergy with Carbon Capture and Storage (BECCS), a leading carbon dioxide removal (CDR) technology. Aimed at researchers and drug development professionals, we explore the foundational science of BECCS, detailing its mechanism for achieving net-negative emissions. The scope covers the biological and engineering methodologies, from biomass cultivation to geological sequestration. We analyze current implementation challenges, optimization strategies for efficiency and scalability, and a critical validation of its lifecycle emissions and comparative role within the portfolio of climate solutions. The implications for biotech innovation and sustainability in the pharmaceutical sector are discussed throughout.

BECCS Fundamentals: Understanding the Core Negative Emissions Cycle

Defining Negative Emissions and the Critical Role of CDR Technologies

Within the critical discourse on climate change mitigation, Negative Emissions refer to the net removal of carbon dioxide (CO₂) from the atmosphere and its durable storage. This is achieved when the rate of CO₂ removal by anthropogenic activities exceeds the rate of anthropogenic emissions. Carbon Dioxide Removal (CDR) technologies are the suite of methods designed to achieve this net negative flow.

This whitepaper is framed within a broader research thesis investigating the Bioenergy with Carbon Capture and Storage (BECCS) mechanism, which serves as a primary archetype for engineered negative emissions. BECCS integrates biomass energy production with carbon capture and storage, aiming for net-negative carbon emissions when executed at scale.

Core CDR Technology Categories: Mechanisms and Quantitative Potential

The following table summarizes major CDR approaches, their mechanisms, and current quantitative estimates for technical sequestration potential and costs, based on recent literature and assessment reports.

Table 1: Summary of Key CDR Technologies and Quantitative Metrics

| Technology Category | Core Mechanism | Estimated Annual Sequestration Potential by 2050 (Gt CO₂/yr) | Estimated Cost Range (USD/t CO₂) | Storage Durability |

|---|---|---|---|---|

| BECCS | Biomass growth (photosynthesis), conversion to energy, capture & geologic storage of resulting CO₂. | 0.5 – 5.0 | 100 – 200 | Centuries to millennia (geologic) |

| Direct Air Capture (DAC) | Chemical sorbents capture CO₂ directly from ambient air; concentrated CO₂ is geologically stored. | 0.5 – 5.0 | 125 – 335 | Centuries to millennia (geologic) |

| Enhanced Weathering | Spread finely ground silicate minerals (e.g., basalt) to accelerate natural carbon sequestration via weathering. | 2.0 – 4.0 | 50 – 200 | Centuries to millennia |

| Afforestation/Reforestation | Increase photosynthetic carbon storage in terrestrial biomass and soils. | 0.5 – 3.6 | 5 – 50 | Decades to centuries (vulnerable) |

| Soil Carbon Sequestration | Modified agricultural practices (e.g., biochar, no-till) to increase soil organic carbon. | 2.0 – 5.0 | 0 – 100 | Decades to centuries |

Experimental Protocol: Laboratory-Scale BECCS Pathway Validation

A foundational experiment for BECCS research involves quantifying the net carbon flux of a integrated biomass conversion and capture system.

Title: Laboratory Measurement of Net Carbon Removal in a Micro-scale BECCS Prototype

Objective: To empirically determine the net CO₂ removal efficiency of a coupled biomass gasification and amine-based CO₂ capture system.

Materials & Methods:

- Feedstock Preparation: 100g of standardized, pre-dried miscanthus grass (Miscanthus × giganteus) is milled to ≤2mm particle size. Its biogenic carbon content is determined via elemental analyzer (∼48% carbon by mass).

- Gasification: Feedstock is fed into a controlled, fixed-bed gasifier operating at 800°C under a limited oxygen environment (equivalence ratio = 0.3). The syngas output (H₂, CO, CO₂, CH₄) is analyzed via online gas chromatography (GC).

- CO₂ Capture: The syngas stream is cooled, and H₂O is condensed out. It is then bubbled through a 30% (v/v) monoethanolamine (MEA) solution in a packed absorption column (25°C). The CO₂-rich solvent is transferred to a stripper column heated to 120°C to release a high-purity (>99%) CO₂ stream.

- Quantification:

- Input Carbon: Measured as biogenic carbon in the feedstock.

- Captured Carbon: The volume and purity of the CO₂ stream from the stripper are measured using a calibrated mass flow meter and nondispersive infrared (NDIR) sensor.

- System Emissions: All direct energy inputs (for heating, pumping) are metered, and their associated CO₂ emissions are calculated using a standardized grid emission factor.

- Calculation: Net CO₂ Removed = (Captured Biogenic Carbon) - (System Emission Carbon).

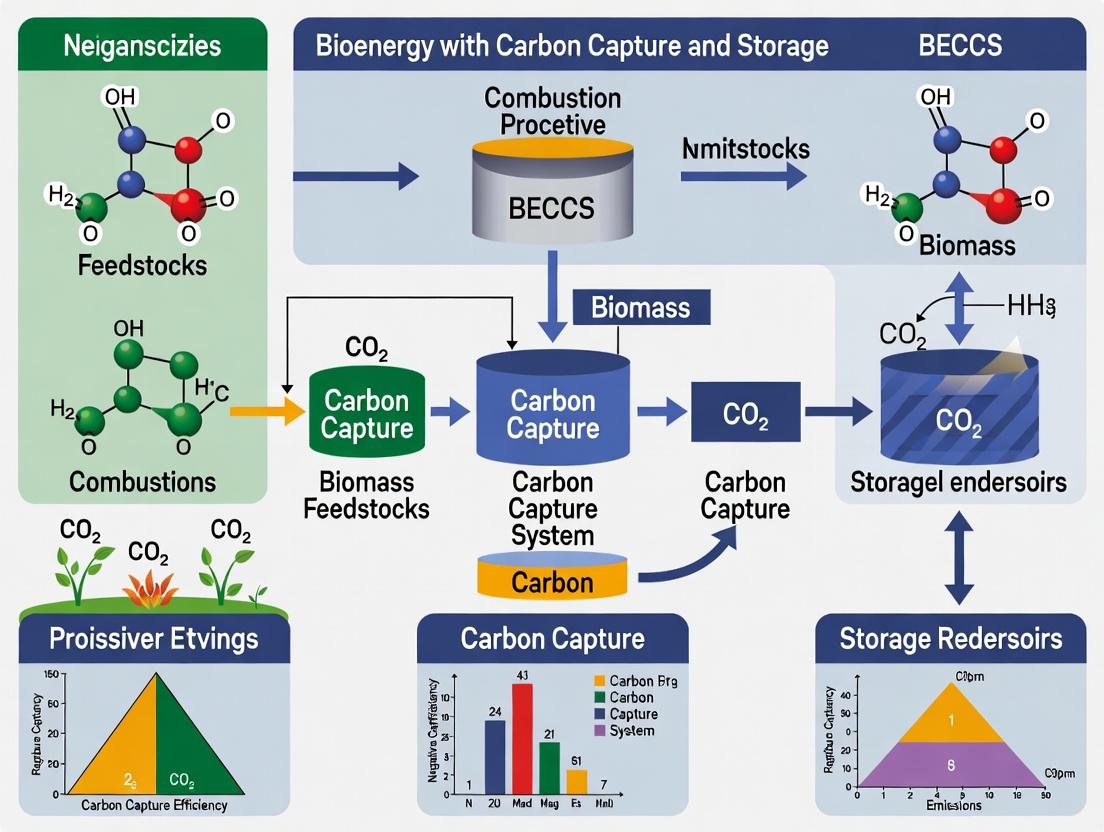

Visualizing the BECCS Negative Emissions Pathway

The Scientist's Toolkit: Key Research Reagent Solutions for BECCS Experiments

Table 2: Essential Research Reagents and Materials for BECCS Mechanism Studies

| Reagent/Material | Function/Application in Research |

|---|---|

| Standardized Biomass Feedstocks (e.g., Miscanthus, switchgrass, pine) | Provide consistent, well-characterized carbon input for conversion experiments; enable study of feedstock variability on yield and emissions. |

| Amino-Based Sorbents (e.g., Monoethanolamine - MEA, Piperazine) | Common liquid chemical absorbents for post-combustion CO₂ capture; used to study absorption kinetics, capacity, and degradation in syngas/flu gas conditions. |

| Solid Sorbents (e.g., Amine-functionalized silica, Metal-Organic Frameworks) | Investigated for lower-energy capture; used in experiments on adsorption/desorption cycling, stability, and gas selectivity. |

| Catalysts for Syngas Conditioning (e.g., Ni-based, Rh-based catalysts) | Used in water-gas shift or reforming reactors to optimize H₂:CO ratio and improve subsequent capture efficiency. |

| Stable Isotope Tracers (e.g., ¹³CO₂) | Allow precise tracking of carbon flow from atmosphere to biomass to final storage, distinguishing biogenic from process emissions. |

| GC-MS/TCD/FID Systems | Gas Chromatography with various detectors (Mass Spec, Thermal Conductivity, Flame Ionization) is essential for quantifying gas composition (CO₂, CO, CH₄, H₂) in syngas and process streams. |

| High-Pressure/Temperature Reactors | Enable simulation of geologic storage conditions (e.g., in saline aquifers) for studying CO₂-brine-rock interactions and storage integrity. |

Achieving climate stabilization targets now unequivocally requires the deployment of CDR technologies at scale to generate negative emissions. BECCS remains a prominently studied pathway due to its dual output of energy and negative emissions. However, significant research gaps persist in scaling, optimizing energy integration, ensuring sustainable biomass sourcing, and verifying long-term storage. For researchers and scientists, the focus must be on improving fundamental process efficiencies, reducing costs, developing robust monitoring, reporting, and verification (MRV) protocols, and conducting holistic life-cycle and techno-economic assessments to guide viable deployment.

Within the imperative framework of climate change mitigation, Bioenergy with Carbon Capture and Storage (BECCS) has emerged as a critical negative emissions technology (NET). This whitepaper explicates the BECCS principle, framed within a broader thesis on the BECCS negative emissions mechanism. The core thesis posits that BECCS achieves net atmospheric CO₂ removal by integrating the natural, cyclical carbon fixation of photosynthesis with engineered, permanent sequestration via carbon capture and storage (CCS). The mechanism's efficacy is not a simple sum of its parts but a synergistic engineered system whose net negative emissions are contingent upon rigorous lifecycle assessment and optimal integration.

Core Principle: Coupling Biological and Engineered Systems

The BECCS principle operates on a two-stage carbon transfer:

- Photosynthetic Carbon Fixation: Biomass feedstocks (e.g., perennial grasses, forestry residues, algae) absorb atmospheric CO₂, converting it into organic carbon compounds through photosynthesis. This creates a temporary, biogenic carbon stock.

- Engineered Carbon Sequestration: The biomass is utilized for energy production (e.g., combustion, gasification, fermentation). The resulting CO₂-rich flue gases or process streams are captured using engineered CCS technologies. The captured CO₂ is then compressed, transported, and injected into deep geological formations for permanent storage.

The net result is a flux of carbon from the atmosphere to geological reservoirs, creating a quantifiable carbon sink. The fundamental equation governing the net removal is:

Net CO₂ Removed = (Carbon Fixed by Biomass - Emissions from Supply Chain) - (Carbon Not Captured during Conversion)

Detailed Technical Pathways and Protocols

Biomass Cultivation & Carbon Fixation (The Photosynthetic Engine)

Protocol for Determining Net Biogenic Carbon Uptake:

- Objective: Quantify the net atmospheric CO₂ removal of a designated biomass cultivation system.

- Methodology:

- Site Selection & Baseline: Establish paired test plots. Measure initial soil organic carbon (SOC) and above-ground carbon stocks.

- Cultivation: Plant high-yield, low-input feedstock (e.g., Miscanthus x giganteus). Implement standard agronomic practices; document all inputs.

- Carbon Flux Monitoring: Use eddy covariance towers to continuously measure net ecosystem exchange (NEE) of CO₂ over a full cultivation cycle.

- Harvest Analysis: At maturity, harvest biomass from a known area. Determine dry weight and analyze carbon content via elemental analyzer (typically ~50% carbon by dry weight).

- Lifecycle Inventory (LCI): Catalog all fossil-based inputs (fertilizer, diesel for machinery) and associated emissions using standard databases (e.g., GREET).

- Calculation: Net Biogenic Carbon = (Total Carbon in Harvested Biomass + ΔSOC) - (Carbon Emitted from Cultivation Inputs).

Bioenergy Conversion with Carbon Capture

The choice of conversion technology dictates the capture method.

A. Post-Combustion Capture from a Biomass Power Plant

- Protocol (Bench-Scale Amine Scrubbing):

- Simulated Flue Gas Generation: Create a gas mixture of 10-15% CO₂, 5-10% O₂, balance N₂, saturated with H₂O, to mimic biomass flue gas.

- Absorption Column Operation: Pump a 30 wt% monoethanolamine (MEA) solution into a packed absorption column (height: 1m, packing: Mellapak 250Y). Flow simulated flue gas counter-currently at a gas-to-liquid ratio of 2.

- Rich-Lean Cycle: The "rich" amine (loaded with CO₂) is pumped to a stripping column (regenerator) heated to 120°C at 2 bar pressure to release high-purity CO₂.

- Measurement: Use inline NDIR CO₂ sensors at inlet and outlet streams to determine capture efficiency. Quantify energy penalty via heat input to the regenerator.

B. Pre-Combustion Capture via Biomass Gasification

- Workflow: Biomass is gasified in a limited oxygen environment to produce syngas (CO + H₂). The CO is shifted with steam to produce CO₂ and more H₂. The CO₂ is separated pre-combustion using physical solvents (e.g., Selexol), and the clean H₂ is combusted for power.

C. Biochemical Conversion (Bioethanol with Fermentation CO₂ Capture)

- Protocol: In ethanol fermentation, yeast metabolizes sugars to produce ethanol and nearly pure CO₂. This stream is dehydrated and compressed directly, requiring minimal separation energy. Capture rates can exceed 99%.

Data Presentation: Quantitative System Performance

Table 1: Comparative Performance of BECCS Pathways (Theoretical & Reported Ranges)

| Pathway | Typical Feedstock | Conversion Process | Capture Technology | Reported Capture Efficiency (%) | Estimated Net Negative Emissions (tCO₂eq/GJ) | Key Challenges |

|---|---|---|---|---|---|---|

| Combustion-Based | Wood chips, pellets | Pulverized fuel boiler | Post-combustion (Amine) | 85 - 95 | -0.15 to -0.60 | Low CO₂ flue concentration, high energy penalty |

| Gasification-Based | Agricultural residues | Integrated Gasification Combined Cycle (IGCC) | Pre-combustion (Physical absorption) | 85 - 90 | -0.20 to -0.70 | Syngas cleaning, process complexity, cost |

| Biochemical | Sugar cane, corn | Fermentation & Distillation | Fermentation off-gas (Direct) | >99 | -0.50 to -0.90 | Limited to fermentable feedstocks, land-use concerns |

Table 2: Lifecycle Assessment (LCA) Key Input Parameters for BECCS Modeling

| Parameter Category | Specific Parameter | Typical Value Range | Source/Measurement Method |

|---|---|---|---|

| Biomass Cultivation | Carbon Sequestration in Soil (ΔSOC) | -1 to +5 tCO₂/ha/yr | IPCC Tier 2/3 methodology, long-term field trials |

| N₂O Emissions from Fertilizer | 0.5 - 2.0% of applied N | Eddy covariance, chamber measurements | |

| Fossil Inputs (Diesel, etc.) | 0.5 - 2.0 GJ/ha | Farm machinery fuel logs | |

| Supply Chain | Biomass Transport Emissions | 5 - 15 kgCO₂/t-km | GREET model, transport mode specific |

| Drying & Pelletization Energy | 1 - 3 GJ/t dry matter | Industrial process data | |

| CCS Component | Capture Energy Penalty | 15 - 30% of plant output | Pilot plant data (e.g., DECC, 2019) |

| Capture Solvent Degradation Rate | 0.5 - 3.0 kg/ton CO₂ | Long-term solvent testing rigs | |

| Pipeline Transport & Injection | 5 - 15 kgCO₂/tCO₂ transported | NETL Baseline Studies |

Visualizing the BECCS Mechanism and Workflows

Diagram 1: The BECCS Principle: Integrating Natural and Engineered Systems (76 chars)

Diagram 2: End-to-End BECCS Project Workflow with MRV (71 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for BECCS Laboratory Research

| Item/Category | Function in BECCS Research | Example/Specification |

|---|---|---|

| Isotopic Tracers | To distinguish biogenic from fossil carbon and trace carbon flow through the system. | ¹³C-CO₂ for photosynthetic uptake studies; ¹⁴C (or surrogate) for mineralization studies in storage reservoirs. |

| Advanced Solvents | For testing and optimizing CO₂ capture efficiency and degradation rates. | 30 wt% Monoethanolamine (MEA), Piperazine (PZ), Ionic Liquids (e.g., [bmim][BF₄]), Chilled Ammonia. |

| Gas Standards & Analyzers | To calibrate sensors and verify CO₂ concentrations/purity at all stages. | Certified CO₂ in N₂ mix (e.g., 12% CO₂). NDIR Analyzers, Gas Chromatographs with TCD/FID. |

| Geochemical Reactors | To simulate CO₂-water-rock interactions in storage reservoirs under high pressure/temperature. | Batch or flow-through reactors (Hastelloy), equipped with pH, Eh sensors, and sampling ports. |

| Biomass Enzymes & Assay Kits | To analyze feedstock composition and conversion potential. | Cellulase/hemicellulase enzyme cocktails for saccharification assays. Lignin content determination kits. |

| Porous Media & Core Samples | To study CO₂ flow and trapping mechanisms in geological formations. | Berea sandstone cores, synthetic silica packs. Equipment for core flooding experiments. |

| Lifecycle Inventory (LCI) Databases | To model emissions from supply chains and calculate net carbon balance. | GREET Model, Ecoinvent, IPCC Emission Factor Database. |

Within the framework of a broader thesis on Bioenergy with Carbon Capture and Storage (BECCS) as a negative emissions technology (NET), this guide provides a detailed technical breakdown of the integrated process. BECCS represents a critical mechanism for achieving net-negative CO₂ emissions by coupling the renewable energy from biomass with permanent geological sequestration. This in-depth analysis targets researchers and scientists, dissecting the chain from photosynthetic carbon fixation to secure subsurface storage, with an emphasis on quantifiable data, experimental protocols, and essential research tools.

The BECCS mechanism can be deconstructed into four primary, interconnected stages: Biomass Cultivation, Feedstock Processing & Conversion, Carbon Capture, and Transport & Storage. Each stage involves distinct biological, thermochemical, and geochemical processes that collectively determine the net carbon removal efficiency.

Diagram Title: The Four-Stage BECCS Negative Emissions Chain

Stage 1: Biomass Cultivation & Carbon Uptake

This stage focuses on the biological fixation of atmospheric CO₂. Key metrics include the Net Primary Productivity (NPP) and the specific carbon content of the biomass.

Table 1: Carbon Sequestration Potential of Selected Biomass Feedstocks

| Feedstock Type | Average Growth Cycle | Approx. Dry Biomass Yield (t/ha/yr) | Average Carbon Content (% dry weight) | Approx. CO₂ Sequestration Potential (t CO₂/ha/yr)* |

|---|---|---|---|---|

| Miscanthus | Perennial (10-15 yrs) | 10 - 25 | ~48% | 18 - 44 |

| Switchgrass | Perennial (10 yrs) | 5 - 15 | ~47% | 9 - 25 |

| Short Rotation Coppice (Willow) | 3-5 years | 8 - 12 | ~49% | 14 - 21 |

| Fast-Growing Pine | 20-30 years | 4 - 10 | ~50% | 7 - 18 |

| Microalgae (PBR) | Continuous | 20 - 50 (ash-free) | ~50% | 36 - 90 |

*Calculated as: Biomass Yield × Carbon Content × (44/12). Values are indicative and highly site-dependent.

Experimental Protocol: Determining Biomass Carbon Content Title: Ultimate Analysis of Biomass via Dry Combustion (ASTM D5373) Principle: Complete combustion of a dried sample in an oxygen-rich environment, followed by quantitative measurement of the resulting CO₂. Methodology:

- Sample Preparation: Oven-dry biomass at 105°C to constant mass. Pulverize to pass a 250 µm sieve. Homogenize.

- Instrument Calibration: Calibrate the CHNS elemental analyzer using a certified standard (e.g., acetanilide).

- Combustion: Precisely weigh 2-3 mg of sample into a tin capsule. Introduce into a high-temperature combustion tube (≥950°C) with pure oxygen.

- Gas Separation & Detection: Pass combustion gases through reduction tubes and specific adsorbents. Measure evolved CO₂ via thermal conductivity detection (TCD) or infrared (IR) detection.

- Calculation: Carbon content (%) is calculated from the CO₂ signal relative to the calibration curve. Report result as mean of triplicate analyses.

Stage 2: Feedstock Processing & Conversion to Energy

This stage converts biomass into useful energy (heat/power) or intermediate carriers, producing a CO₂-rich gas stream.

Table 2: Key Conversion Pathways for BECCS

| Conversion Pathway | Primary Technology | Operating Temperature/Pressure | Output Stream for Capture | Typical CO₂ Concentration in Flue/Syngas |

|---|---|---|---|---|

| Combustion | Fixed bed, Fluidized Bed, Pulverized fuel boilers | 800-1200°C, 1 atm | Flue Gas | 8-15% (in air) |

| Gasification | Entrained flow, Fluidized bed gasifiers | 700-1500°C, 1-30 bar | Raw Syngas (primarily CO, H₂, CO₂) | 15-40% (pre-shift) |

| Anaerobic Digestion + Combustion | Digester + CHP engine | 35-55°C (digester) | Engine Exhaust | 5-10% |

| Bioethanol Fermentation + Distillation | Fermentation, Molecular Sieves | 30-35°C, 1 atm | Fermentation Off-Gas | ~100% (after dehydration) |

Diagram Title: Biomass Conversion Pathways and Output Streams

Stage 3: Carbon Capture from Process Streams

This is the core technological stage where CO₂ is separated from other gases. Post-combustion capture from flue gas is the most developed route for BECCS.

Experimental Protocol: Solvent-Based Post-Combustion Capture Screening Title: Gravimetric CO₂ Absorption Capacity Test for Amine Solvents Principle: Measuring the mass increase of a solvent sample upon exposure to a pure CO₂ atmosphere at controlled temperature. Methodology:

- Apparatus Setup: Calibrate a high-precision microbalance (0.01 mg resolution) inside a temperature-controlled chamber. Connect a gas delivery system (CO₂, N₂) with mass flow controllers.

- Baseline Measurement: Place 5-10 g of fresh solvent (e.g., 30 wt% MEA, or novel amino-siloxane) in an open tared vial on the balance. Flush chamber with N₂ at 40°C until solvent mass stabilizes. Record dry mass (m_dry).

- Absorption Cycle: Switch inlet gas to pure CO₂ at a fixed flow rate (e.g., 50 mL/min). Maintain constant temperature (typically 40°C). Record mass increase every minute until saturation (constant mass for >10 min). Record saturated mass (m_sat).

- Desorption Cycle: Switch back to N₂ and increase temperature to 80-100°C to strip CO₂. Record final stable mass (m_reg) to assess solvent regenerability.

- Calculation: CO₂ loading capacity (α) in mol CO₂/kg solvent is calculated as: α = [(msat - mdry) / MCO₂] / (mdry), where MCO₂ is the molar mass of CO₂. Cyclic capacity is αabsorption - α_desorption.

Table 3: Performance Metrics of Selected Capture Technologies

| Capture Technology | Typical Solvent/Sorbent | Regeneration Energy (GJ/t CO₂) | CO₂ Purity Achieved | Technology Readiness Level (TRL) |

|---|---|---|---|---|

| Post-combustion (Chemical Absorption) | Aqueous Amines (e.g., MEA) | 3.5 - 4.5 | >99% | 9 (Commercial) |

| Pre-combustion (Physical Absorption) | Selexol, Rectisol | 1.5 - 2.5 | >99% | 9 (Commercial) |

| Oxy-fuel Combustion | Cryogenic Air Separation | 0.8 - 1.2 (for O₂ production) | 80-98% (needs purification) | 7-8 (Demonstration) |

| Calcium Looping | CaO/CaCO₃ | 2.5 - 3.5 | >95% | 6-7 (Pilot) |

| Direct Air Capture (DAC) | Solid Amine Sorbents | 7 - 10+ | >99% | 6-8 (Pilot/Commercial) |

Stage 4: CO₂ Transport and Geological Storage

Captured CO₂ is compressed, transported, and injected into deep geological formations for permanent isolation.

Table 4: Geological Storage Reservoir Types and Characteristics

| Reservoir Type | Example Formations | Typical Depth (m) | Key Sealing Mechanism | Estimated Global Capacity (Gt CO₂) |

|---|---|---|---|---|

| Deep Saline Aquifers | North Sea Utsira Sandstone, Alberta Basin | >800 | Impermeable caprock (shale, salt) | 1,000 - 10,000 |

| Depleted Oil/Gas Fields | Sleipner (North Sea), Weyburn (Canada) | 1500 - 3000 | Original hydrocarbon seal | 100 - 1,000 |

| Unmineable Coal Seams | Alberta Deep Coal | >800 | Adsorption to coal matrix (with ECBM*) | 10 - 100 |

| Basalt Formations | Columbia River Basalt, Iceland | 500 - 2000 | Rapid mineral carbonation | Uncertain but large |

*ECBM: Enhanced Coal Bed Methane recovery.

Diagram Title: Geological Storage Integrity and Monitoring Techniques

The Scientist's Toolkit: Key Research Reagent Solutions

Table 5: Essential Materials and Reagents for BECCS Research

| Item/Category | Example Product/Supplier | Function in BECCS Research |

|---|---|---|

| Stable Isotope Tracers | ¹³C-CO₂ (Cambridge Isotopes), ¹⁴C-labeled biomass | Tracing carbon flow through biological and chemical systems; verifying biogenic origin of captured CO₂. |

| Advanced Solvents & Sorbents | Phase-change amines (e.g., DMX), MOFs (e.g., Mg-MOF-74), Ionic liquids | Screening for higher CO₂ capacity, lower regeneration energy, and degradation resistance in capture experiments. |

| Geochemical Brine Simulants | Synthetic formation brine kits (e.g., Corexport) | Studying CO₂-water-rock interactions (dissolution, precipitation) in reservoir conditions via batch/flow experiments. |

| Biomass Reference Standards | NIST SRM 8492 (Sugarcane Bagasse), 8493 (Switchgrass) | Calibrating analytical instruments (CHNS, ICP-MS) for precise biomass composition analysis. |

| High-Pressure/High-Temperature Reactors | Parr instruments, High-pressure view cells | Simulating gasification, supercritical CO₂ conditions, or sorbent regeneration kinetics. |

| Core Flooding Systems | Vinci Technologies, Core Lab systems | Evaluating CO₂ injectivity, relative permeability, and residual trapping in reservoir rock cores. |

| Numerical Simulation Software | TOUGH2/TOUGHREACT, CMG-GEM, ECLIPSE | Modeling subsurface CO₂ plume migration, pressure buildup, and long-term geochemical fate. |

Bioenergy with Carbon Capture and Storage (BECCS) is a critical negative emissions technology (NET) identified by the IPCC for achieving net-zero and net-negative CO₂ emissions. The efficacy of the entire BECCS value chain is fundamentally dependent on the sustainable supply and tailored properties of biomass feedstocks. This whitepaper provides a technical analysis of primary feedstock categories—dedicated energy crops, agricultural residues, and forestry residues—evaluating their characteristics, availability, and suitability for conversion pathways within integrated BECCS research frameworks aimed at atmospheric carbon dioxide removal (CDR).

Feedstock Categories & Quantitative Analysis

Table 1: Key Characteristics of Primary Biomass Feedstocks for BECCS

| Feedstock Category | Example Species/Type | Avg. Yield (Dry Mg/ha/yr) | Avg. Carbon Content (% Dry Weight) | Lignin Content (% Dry Weight) | Ash Content (% Dry Weight) | Key Advantages for BECCS | Key Challenges for BECCS |

|---|---|---|---|---|---|---|---|

| Herbaceous Energy Crops | Miscanthus x giganteus | 10-25 | 47-49 | 15-20 | 1.5-4.5 | High productivity, low fertilizer input, perennial growth | Land use competition, establishment cost |

| Short Rotation Woody Crops | Willow (Salix spp.), Poplar | 8-15 | 48-50 | 20-25 | 0.5-2.0 | High biomass density, coppicing regeneration, soil carbon sequestration | Longer establishment period, harvest logistics |

| Agricultural Residues | Corn Stover, Wheat Straw | 2-5 (residue-specific) | 45-47 | 16-21 | 4-10 | No direct land use change, widely available | Removal impacts soil health (C, nutrients), scattered distribution |

| Forestry Residues | Logging Slash, Thinnings | 1-3 (recoverable) | 49-52 | 25-30 | 0.5-3.0 | Utilizes waste streams, supports forest management | High collection cost, variable composition, transportation |

Table 2: Current and Projected Global Sustainable Supply Potential (Annual)

| Feedstock Category | Current Sustainable Supply (EJ/yr) | Projected 2050 Sustainable Supply (EJ/yr) | Associated Carbon Debt Risk | Key Sustainability Constraints |

|---|---|---|---|---|

| Dedicated Energy Crops | ~5-15 | 20-100 | Moderate to High (if on natural land) | Land availability, water use, biodiversity impact |

| Agricultural Residues | ~15-35 | 20-50 | Very Low | Soil organic carbon depletion, nutrient cycling, erosion |

| Forestry Residues | ~10-20 | 15-30 | Low | Forest ecosystem health, soil nutrient removal, economic viability |

Experimental Protocols for Feedstock Analysis in BECCS Research

Protocol 3.1: Determination of Biochemical Composition for Conversion Yield Prediction

Objective: Quantify cellulose, hemicellulose, lignin, and ash content to predict bioenergy yield and pre-treatment requirements.

- Milling: Reduce feedstock samples to particle size <0.5 mm using a laboratory mill.

- Extractives Removal: Use a Soxhlet apparatus with ethanol or water solvent for 6-8 hours.

- Structural Carbohydrate & Lignin Analysis: Perform according to NREL/TP-510-42618 (Slutter et al., 2008). a. Two-stage acid hydrolysis of extractive-free sample with 72% H₂SO₄ followed by 4% H₂SO₄. b. Quantify sugars in hydrolysate via HPLC (Aminex HPX-87P column). c. Acid-Insoluble Lignin (AIL) determined gravimetrically after filtration.

- Ash Content: Combust known mass of sample in a muffle furnace at 575±25°C for 4 hours (ASTM E1755-01).

Protocol 3.2: Feedstock Carbon Stock and Sequestration Potential Assessment

Objective: Measure total carbon in biomass and soil to calculate net carbon balance for BECCS lifecycle assessment.

- Biomass Carbon: a. Determine dry matter yield from field trials (quadrat sampling). b. Subsample for ultimate analysis (CHNS-O) using an elemental analyzer (e.g., Flash 2000). Multiply dry mass by %C.

- Soil Organic Carbon (SOC) Monitoring: a. Collect soil cores (0-30 cm depth) pre-establishment and annually post-harvest. b. Dry, grind, and analyze SOC via dry combustion (e.g., CN analyzer) or wet oxidation (Walkley-Black method). c. Calculate SOC stock (Mg C/ha) using bulk density.

Protocol 3.3: Thermogravimetric Analysis (TGA) for Pyrolysis/Gasification Behavior

Objective: Characterize thermal decomposition profiles to optimize thermochemical conversion parameters.

- Load 5-10 mg of milled sample into a platinum crucible.

- Operate TGA under inert (N₂) or reactive (CO₂, air) atmosphere.

- Apply a heating ramp (e.g., 10-50°C/min) from ambient to 900°C.

- Record mass loss (TG) and derivative mass loss (DTG) curves.

- Identify key temperature zones for hemicellulose (220-315°C), cellulose (315-400°C), and lignin (160-900°C) decomposition.

Visualizations

Feedstock to BECCS Analysis Workflow

BECCS Carbon Flow with Feedstock Pathways

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Research Reagents and Materials for Feedstock Analysis

| Item Name | Supplier Example (Catalogue Potential) | Function in Research | Critical Application |

|---|---|---|---|

| NREL Standard Biomass Analytical Procedures Kit | LAP Supplier | Provides standardized protocols and reference methods for compositional analysis. | Ensures reproducibility & comparability of lignin/carbohydrate data across labs. |

| Sulfuric Acid, 72% w/w (ACS Grade) | Sigma-Aldrich (339741) | Primary hydrolysis agent in the two-stage acid hydrolysis for structural carbohydrates. | Critical for accurate quantification of cellulose and hemicellulose. |

| Sugar Standard Kit for HPLC (Cellobiose, Glucose, Xylose, etc.) | Restek, Agilent | Calibration standards for High-Performance Liquid Chromatography (HPLC) analysis. | Essential for quantifying sugar monomers in hydrolysates. |

| Elemental Analysis Standards (e.g., BBOT) | Elemental Microanalysis | Calibration standard for CHNS-O elemental analyzers. | Required for precise measurement of carbon and nitrogen content in biomass and soil. |

| Soil Organic Carbon Standard (e.g., NIST SRM 2711a) | National Institute of Standards and Technology | Certified reference material for soil carbon analysis. | Validates accuracy of SOC measurements via combustion or chemical oxidation. |

| Inert Gas (Ultra-high purity N₂, Argon) | Local Gas Supplier | Creates inert atmosphere for TGA and other thermal analysis. | Prevents oxidation during pyrolysis studies, mimicking gasification conditions. |

| ASE (Accelerated Solvent Extraction) Cells & Solvents | Thermo Fisher Scientific | Enables high-throughput removal of extractives from biomass samples. | Prepares samples for compositional analysis, removing non-structural compounds. |

This whitepaper establishes the fundamental carbon accounting principles required to robustly assess and verify negative emissions technologies (NETs), with a specific focus on the Bioenergy with Carbon Capture and Storage (BECCS) mechanism. For researchers and scientists, precise lifecycle thinking is not ancillary but central to claiming net CO₂ removal. A BECCS system's efficacy is not a given; it is a net outcome derived from a full systemic analysis that must counterbalance emissions across the biomass supply chain, processing, and sequestration against the gross carbon captured. This document provides the technical foundation and methodologies for such an analysis.

Core Carbon Accounting Principles

The "Carbon Accounting Foundation" rests on two pillars:

- Net CO₂ Removal: The critical metric is the net change in atmospheric CO₂ over a defined temporal boundary (e.g., 100 years). It is calculated as: Gross Carbon Sequestrated minus Lifecycle Emissions plus any System-Induced Changes (e.g., land-use change emissions or altered albedo).

- Lifecycle Thinking: A systems approach mandating the compilation of an exhaustive greenhouse gas (GHG) inventory across all relevant stages, from biomass feedstock cultivation or sourcing to final geological storage integrity.

Quantifying BECCS: Key Data and System Boundaries

A credible BECCS assessment requires analysis of the following interconnected system. The quantitative ranges below are synthesized from recent literature and meta-analyses.

Table 1: BECCS System Component Analysis & Key Quantitative Ranges

| System Component | Key Processes | Critical Carbon Fluxes & Data Ranges | Primary Uncertainties |

|---|---|---|---|

| 1. Biomass Feedstock | Cultivation, Harvest, Transport | C Sequestration Rate: 0.5 - 10 t CO₂/ha/yr (species & region dependent).N₂O from Fertilizer: 0.5 - 2.5% of N applied emits as N₂O (GWP~265-298).Transport Emissions: 0.005 - 0.05 t CO₂/t biomass/100km. | Soil carbon stock change, indirect land-use change (iLUC) magnitude, fertilization efficiency. |

| 2. Biogenic Carbon | Photosynthesis, Combustion | Carbon Neutrality Assumption: Biogenic CO₂ emission at plant = 0 in LCA*, pending sustainable regrowth. | Temporal mismatch (decadal scale) between emission and re-sequestration. |

| 3. Power/Process Plant | Conversion, CCS Operation | Capture Rate: 85 - 95% of CO₂ in flue gas.Energy Penalty for CCS: 15 - 30% increased fuel demand.Fugitive Process Emissions: <1-5% of captured CO₂. | Long-term plant efficiency, parasitic load variability, solvent degradation emissions. |

| 4. CO₂ Transport & Storage | Compression, Pipeline, Injection | Compression/Pipeline Energy: 5 - 15 kWh/t CO₂ transported.Storage Site Leakage Rate: Modeled as <0.1% per annum for certified sites.Monitoring Verification (MRV) Baseline: Essential for quantifying net removal. | Geological integrity over millennial scales, verification of containment. |

| 5. Reference Systems | Counterfactual Land Use, Fossil Displacement | iLUC Emission Factor: Can range from -10 to +50 t CO₂/ha/yr if displacing natural ecosystems.Grid Displacement Effect: Varies by regional grid carbon intensity (e.g., 0.05 - 0.8 t CO₂/MWh). | Defining a plausible baseline scenario for land and energy systems. |

*Life Cycle Assessment

Experimental & Analytical Protocols for Verification

Protocol: Direct Measurement of Soil Carbon Stock Change (Feedstock Stage)

Objective: Quantify net carbon flux in biomass cultivation soils to validate sequestration claims. Methodology:

- Site Stratification: Divide feedstock plantation into homogeneous strata based on soil type, topography, and management history.

- Baseline Sampling: Prior to cultivation, collect soil cores (0-30cm and 30-100cm depths) using a standardized corer at georeferenced points (minimum 3 cores per stratum).

- Time-Series Sampling: Repeat sampling at defined intervals (e.g., 5-year cycles) at permanent plots adjacent to baseline points.

- Lab Analysis: Dry, grind, and analyze samples for % Organic Carbon via dry combustion (e.g., EA-IRMS). Calculate stock (t C/ha) using bulk density.

- Control Plot: Compare to an appropriate control (e.g., native vegetation or previous land use).

Protocol: MRV for Geologically Stored CO₂

Objective: Monitor, report, and verify the integrity of CO₂ containment in a storage reservoir. Methodology:

- Establish Baseline: Pre-injection, conduct 3D seismic survey and sample groundwater/soil gas for isotopic (δ¹³C-CO₂) and compositional baselines.

- Continuous Monitoring:

- Deep: Use 4D time-lapse seismic and downhole pressure/temperature sensors.

- Shallow: Deploy soil flux chambers and atmospheric tunable diode laser (TDL) sensors at the surface to detect anomalies.

- Tracer Injection: Co-inject a chemically inert, detectable tracer (e.g., SF₅CF₃, perfluorocarbons) with the CO₂ stream.

- Data Integration & Modeling: Feed monitoring data into coupled geochemical-reservoir models to quantify total stored mass and confirm containment. Any detected leakage must be subtracted from the net removal total.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for BECCS Carbon Accounting

| Reagent / Material | Primary Function in Research Context |

|---|---|

| ¹³C-Labeled CO₂ Tracer | Isotopic tracer for distinguishing biogenic from geogenic CO₂ in storage MRV and leakage detection experiments. |

| Perfluorocarbon Tracers (PFTs: PTCH, PMCH) | Chemically inert, ultra-trace detectable gases co-injected with CO₂ for unique fingerprinting and plume migration tracking. |

| Li-Cor Soil Flux Chamber & LI-850 Analyzer | Portable, high-precision system for direct field measurement of CO₂ and CH₄ flux from soil (baseline & leakage monitoring). |

| Cavity Ring-Down Spectroscopy (CRDS) Analyzer | Lab/field instrument for high-frequency, precise measurement of CO₂, CH₄, and H₂O concentrations and isotopic ratios (δ¹³C). |

| Dry Combustion Elemental Analyzer | Standard lab instrument for determining total organic carbon and nitrogen content in soil and biomass samples. |

| Geochemical Reservoir Simulation Software (e.g., TOUGH2, GEM) | Numerical modeling platforms to simulate multi-phase CO₂ flow, reaction, and long-term fate in geological formations. |

| Life Cycle Assessment (LCA) Software (e.g., OpenLCA, SimaPro) | Databases and computational engines for structuring and calculating emissions inventories across the full supply chain. |

Asserting negative emissions via BECCS is a quantitatively rigorous claim contingent on comprehensive carbon accounting. It demands moving beyond simplified assumptions to embrace full lifecycle thinking, supported by direct measurement protocols and continuous MRV. For the research community, the challenge lies in reducing uncertainties within each system component—particularly iLUC and long-term storage integrity—and integrating these into a defensible, transparent net removal figure. This foundation is essential for scaling any negative emissions technology from a conceptual mechanism to a verifiable climate solution.

Implementing BECCS: From Biomass Selection to Geological Sequestration

This whitepaper details the sustainable cultivation and sourcing of biomass within the context of Bioenergy with Carbon Capture and Storage (BECCS). As a proposed negative emissions technology, BECCS relies on a robust, verifiably sustainable feedstock supply chain. This guide provides technical criteria and protocols for researchers, particularly those intersecting with bio-derived pharmaceutical feedstocks, to ensure biomass sustainability from cultivation to conversion.

Core Sustainability Criteria for BECCS Feedstock

Sustainable biomass for BECCS must mitigate lifecycle greenhouse gas (GHG) emissions while avoiding detrimental environmental and social impacts. The following criteria are derived from current certification schemes and life cycle assessment (LCA) literature.

Table 1: Core Sustainability Criteria and Quantitative Thresholds

| Criterion Category | Key Indicator | Quantitative Threshold / Requirement | Measurement Protocol |

|---|---|---|---|

| Greenhouse Gas (GHG) Savings | Lifecycle GHG emission savings vs. fossil comparator | ≥70% for installations starting operation from 2021 (EU RED II) | LCA per ISO 14040/44, IPCC guidelines. System boundary: Cradle-to-gate (to biomass) or cradle-to-stack (for full BECCS). |

| Carbon Stock & Land Use | No conversion of high-carbon-stock land (e.g., peatlands, primary forest). | Carbon stock loss from direct land-use change (dLUC) must be compensated within max. 10-15 years. | IPCC Tier 1 or 2 carbon stock assessment; remote sensing (LIDAR, SAR) for historical land-use verification. |

| Soil Health & Quality | Maintain or improve soil organic carbon (SOC). | SOC decline not >5% over 20-year period (voluntary schemes). | ISO 14239/16072 for SOC mineralization; routine analysis of bulk density, nutrients, and erosion rates. |

| Water Use & Quality | Water use efficiency; no eutrophication. | Nitrogen leaching <50 kg N/ha/yr; P Index maintained. | Soil water balance modeling (e.g., APSIM); water sampling for nitrate, phosphate, BOD. |

| Biodiversity | No conversion of high-biodiversity-value areas. | Maintain ≥10% of ecological focus area on farm (EU CAP). | Habitat suitability indices (HSI); species richness surveys per CBD Aichi Targets. |

| Productivity & Traceability | Yield improvement and chain of custody. | Full traceability from plot to plant via certified systems. | Georeferenced plot mapping; mass balance or segregation supply chain models. |

Experimental Protocols for Sustainability Verification

Protocol: Field-Level GHG Flux Measurement (Static Chamber Method)

Purpose: To quantify direct soil GHG fluxes (N₂O, CH₄) from biomass cultivation. Materials: Gas chromatograph (GC), static chambers (base + lid), septa, syringes, temperature probes, GPS. Procedure:

- Site Selection: Establish triplicate chambers per treatment/land type using a randomized block design.

- Sampling: Seal chamber lid onto permanently installed base at time (t=0). Extract 20 mL gas sample via syringe at t=0, 20, 40 min. Record soil temperature at 5 cm depth.

- Analysis: Inject gas samples into GC equipped with flame ionization (FID) and electron capture (ECD) detectors for CH₄ and N₂O.

- Calculation: Flux is calculated from linear concentration change over time, chamber volume, and soil area. Annual emissions are temporally integrated. Key Reagents: High-purity calibration gas standards (N₂O, CH₄, CO₂ in N₂ balance), carrier gases (He, N₂).

Protocol: Life Cycle Assessment (Cradle-to-Gate)

Purpose: To calculate the fossil GHG intensity of cultivated biomass (MJ/MJ or gCO₂e/MJ). Materials: LCA software (e.g., SimaPro, openLCA), background databases (ecoinvent, Agri-footprint), primary activity data. Procedure:

- Goal & Scope: Define functional unit (e.g., 1 MJ of oven-dry biomass). System boundaries include all inputs, field operations, and emissions from dLUC.

- Inventory (LCI): Collect primary data on fuel, fertilizer, pesticide use, irrigation, yields, and soil C flux. Use secondary data for upstream inputs.

- Impact Assessment (LCIA): Apply IPCC AR6 GWP100 factors to convert CH₄ and N₂O to CO₂-equivalents.

- Interpretation: Conduct sensitivity analysis on key parameters (yield, N₂O emission factor, soil C change). Key Reagents: Not applicable; this is a computational protocol.

Protocol: Soil Organic Carbon Stock Assessment

Purpose: To measure change in SOC over time under biomass cultivation. Materials: Soil auger (standardized volume), drying oven, elemental analyzer (CN), balance. Procedure:

- Sampling Design: Use a stratified random sampling scheme. Take soil cores at 0-30 cm depth at the same georeferenced points biennially.

- Sample Prep: Dry at 105°C to constant weight. Sieve (<2 mm), grind, and homogenize.

- Analysis: Weigh ~20 mg of soil into a tin capsule. Analyze via dry combustion on a CN elemental analyzer.

- Calculation: SOC stock (Mg C/ha) = [SOC concentration (%) × bulk density (g/cm³) × depth (cm) × 100] / 10. Correct for equivalent soil mass. Key Reagents: Acetanilide (standard for CN analyzer), high-purity O₂ and He gases.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Sustainability Research

| Item | Function | Example/Supplier |

|---|---|---|

| High-Precision Gas Standards | Calibration of GC for accurate N₂O/CH₄/CO₂ quantification. | NIST-traceable custom mixes (e.g., Linde, Restek). |

| Elemental Analyzer Combustion Tubes | Facilitate high-temperature oxidation/reduction for CN analysis. | Packed columns with copper oxide, reduced copper (e.g., Costech). |

| Soil Reference Materials | Quality control for SOC and nutrient analysis. | Certified reference materials (e.g., NIST SRM 2709a). |

| Stable Isotope Tracers (¹³C, ¹⁵N) | Tracing C and N pathways in soil-plant systems for mechanistic studies. | ¹³C-cellulose, K¹⁵NO₃ (e.g., Cambridge Isotope Labs). |

| LiDAR/Satellite Imagery | Remote sensing for land-use change detection and biomass yield modeling. | Commercial providers (e.g., Planet, Sentinel Hub) or UAV-mounted sensors. |

| Chain-of-Custody Software | Digital traceability and mass balance tracking of biomass batches. | Blockchain or database solutions (e.g., SAP S/4HANA, trace:original). |

BECCS Biomass Supply Chain Logic

The integrity of BECCS as a negative emissions mechanism depends on a fully documented, low-leakage supply chain. The following diagram outlines the critical verification nodes.

BECCS Carbon Accounting Workflow

The credibility of negative emissions hinges on rigorous, transparent accounting that subtracts supply chain emissions from captured biogenic CO₂.

For BECCS to function as a verifiable negative emissions mechanism, the biomass feedstock must be sourced under stringent, measurable sustainability criteria. This requires the integration of field-level experimental monitoring, robust LCA, and transparent, auditable supply chains. The protocols and tools outlined here provide a foundational framework for researchers and industry professionals to quantify and validate the carbon negativity of BECCS pathways, ensuring environmental integrity and supporting its role in climate mitigation portfolios.

Within the strategic framework of Bioenergy with Carbon Capture and Storage (BECCS), the selection of biomass conversion technology is paramount. BECCS aims to generate energy while removing carbon dioxide from the atmosphere, creating a net-negative emissions system. This process hinges on the sustainable cultivation of biomass, which absorbs atmospheric CO₂, followed by its conversion to energy and the subsequent capture and permanent geological storage of the resulting CO₂. This whitepaper provides a technical analysis of three core conversion pathways—combustion, gasification, and fermentation—evaluating their engineering principles, efficiency, and suitability for integration within BECCS infrastructures to achieve scalable negative emissions.

Technical Pathways for Biomass Conversion

Combustion

Combustion is the direct exothermic oxidation of biomass with a stoichiometric or excess amount of oxygen, producing heat, flue gas (primarily CO₂ and H₂O), and ash. The heat is typically used to generate steam for electricity production via a Rankine cycle.

- Key Reaction: Biomass (CₓHᵧO₂) + O₂ → CO₂ + H₂O + Heat

- BECCS Integration: Post-combustion carbon capture technologies, such as amine-based scrubbing, are applied to the flue gas stream to isolate CO₂ for compression and storage.

Gasification

Gasification is a partial oxidation process conducted at elevated temperatures (700–1500°C) in a controlled, oxygen-limited environment. It converts solid biomass into a combustible synthesis gas ("syngas") consisting primarily of CO, H₂, CH₄, and CO₂.

- Key Process Steps: Drying → Pyrolysis → Oxidation → Reduction.

- Key Reactions:

- C + ½O₂ → CO (Partial Oxidation)

- C + H₂O → CO + H₂ (Water-Gas Reaction)

- C + CO₂ → 2CO (Boudouard Reaction)

- BECCS Integration: CO₂ can be captured from the syngas stream pre-combustion (via physical solvents like Selexol) at high partial pressure, often at a lower energy penalty than post-combustion capture. The cleaned syngas is then combusted for power or synthesized into biofuels.

Fermentation (Biochemical Conversion)

Fermentation employs microbial organisms (e.g., yeast, bacteria) to break down sugar, starch, or cellulose components of biomass into liquid fuels, primarily ethanol or butanol, and CO₂ as a byproduct.

- Key Reaction (Ethanol): C₆H₁₂O₆ (Glucose) → 2 C₂H₅OH + 2 CO₂

- BECCS Integration: The CO₂ produced is of high purity (nearly 100%) in the fermentation off-gas, significantly simplifying and reducing the cost of capture compared to more dilute streams. This presents a highly efficient point-source for CO₂ collection within the BECCS chain.

Quantitative Comparison of Pathways

The following table summarizes key performance metrics for the three conversion pathways, critical for BECCS system analysis.

Table 1: Comparative Analysis of Biomass Conversion Pathways for BECCS

| Parameter | Combustion | Gasification | Fermentation (for Ethanol) |

|---|---|---|---|

| Primary Product | Heat & Power | Syngas (for Power/Fuels) | Ethanol |

| Typical Efficiency (Energy Out/In) | 20-35% (Power only) | 35-50% (IGCC Power); Up to 60% (Fuels) | 35-45% (Fuel energy) |

| CO₂ Stream Concentration | 10-15% vol. (in flue gas) | 20-40% vol. (pre-cleanup); >95% (post-shift) | >99% vol. (fermentation off-gas) |

| CCS Integration Point | Post-combustion | Pre-combustion | During fermentation |

| CCS Energy Penalty | High (20-30% of plant output) | Moderate (15-25% of plant output) | Very Low (primarily compression) |

| Technology Readiness Level (TRL) | 9 (Commercial) | 7-8 (Demonstration/Commercial) | 9 (Commercial) |

| BECCS Suitability | High (retrofit potential) | Very High (efficient pre-combustion capture) | High (low-cost, pure CO₂ stream) |

Experimental Protocol: Gasification & Syngas Analysis for BECCS Research

Title: Bench-Scale Fluidized Bed Gasification and Syngas Composition Analysis.

Objective: To determine the yield and composition of syngas from a defined biomass feedstock under controlled gasification conditions, simulating a pre-combustion BECCS feedstock preparation step.

Materials & Methodology:

- Feedstock Preparation: 500g of milled and sieved (500-800 µm) woody biomass is dried to a constant weight (<10% moisture).

- Reactor System: A bench-scale, electrically heated fluidized bed gasifier (quartz reactor, 2" diameter) is used. The bed material is silica sand.

- Procedure: a. The reactor is heated to the target temperature (800°C) under an inert N₂ flow (1 L/min). b. The gasifying agent (steam or a defined O₂/N₂ mixture) is introduced at a set flow rate. c. The biomass feedstock is fed continuously via a screw feeder at a rate of 0.5-2 g/min. d. The produced syngas passes through a cyclonic separator (to remove particulates) and a series of condensers (to remove tar and water). e. Online Analysis: The dry, clean gas is analyzed in real-time using a non-dispersive infrared (NDIR) sensor for CO and CO₂, a thermal conductivity detector (TCD) for H₂, and a paramagnetic sensor for O₂. f. Gas Chromatography (GC) Validation: Periodically, gas samples are injected into a Gas Chromatograph equipped with a TCD and a Plot-Q column for precise quantification of H₂, CO, CO₂, CH₄, and N₂. g. Data on gas composition, yield (Nm³/kg biomass), and carbon conversion efficiency are recorded over a steady-state period of 60 minutes.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Research Materials for Biomass Conversion Experiments

| Item | Function in Research |

|---|---|

| Lignocellulosic Biomass Standards | Certified, homogenized feedstock (e.g., NIST RM 8490 - Wheat Straw) for reproducible pyrolysis/gasification studies. |

| Custom Syngas Calibration Mixtures | Certified gas cylinders with precise blends of H₂, CO, CO₂, CH₄, and N₂ for calibrating analyzers and GCs. |

| Amino-Based Sorbent (e.g., MEA Solution) | 30% Monoethanolamine solution for bench-scale post-combustion CO₂ capture simulation studies. |

| Physical Sorbent (e.g., Selexol/ PEGDME) | Dimethyl ethers of polyethylene glycol for pre-combustion CO₂ absorption experiments on synthetic syngas. |

| Genetically Modified Saccharomyces cerevisiae | Engineered yeast strains for the co-fermentation of C5 and C6 sugars, enhancing ethanol yield from lignocellulose. |

| Cellulase & Hemicellulase Enzyme Cocktails | Standardized enzyme preparations for the controlled saccharification of biomass prior to fermentation studies. |

Process Visualization

Diagram 1: Biomass Conversion and CO₂ Capture Pathways in BECCS

Diagram 2: Bench-Scale Gasification Experiment Workflow

Within the framework of Bioenergy with Carbon Capture and Storage (BECCS) research, achieving verifiable negative emissions hinges on the effective integration of robust carbon capture technologies. This technical guide provides an in-depth analysis of the three primary capture methodologies—post-combustion, oxy-fuel, and pre-combustion—detailing their operational principles, experimental protocols, and quantitative performance within the context of BECCS optimization for climate-critical applications.

The selection of a carbon capture technique is determined by the process configuration, fuel type, and integration requirements for downstream carbon storage or utilization. The following table summarizes the core quantitative parameters of each method.

Table 1: Comparative Analysis of Carbon Capture Techniques for BECCS Integration

| Parameter | Post-Combustion | Oxy-Fuel Combustion | Pre-Combustion |

|---|---|---|---|

| Primary Process | Chemical absorption (e.g., amine scrubbing) of CO₂ from flue gas after combustion. | Combustion in high-purity O₂, producing a flue gas of mainly CO₂ and H₂O. | Fuel gasification to produce syngas (H₂ + CO), followed by water-gas shift and CO₂ separation. |

| Typical CO₂ Capture Efficiency | 85-90% | >90% (near-total capture possible) | 85-95% |

| CO₂ Purity in Product Stream | >99% (after compression/drying) | >95% (after dehydration) | >95-99% |

| Primary Energy Penalty | High (15-30% of plant output) | Moderate-High (20-25% for ASU + compression) | Moderate (15-20% for gasification & separation) |

| Key Advantage | Retrofit-ready to existing infrastructure. | High concentration stream simplifies purification. | High-pressure CO₂ stream reduces compression costs. |

| Key Challenge for BECCS | Low CO₂ partial pressure in flue gas reduces solvent efficiency. | High cost and energy demand of air separation unit (ASU). | Complex system integration; best for new build plants. |

| Integration with Bioenergy | Suitable for biomass-fired power plants (pulverized coal or fluidized bed). | Suitable for biomass boilers and circulating fluidized beds. | Ideal for biomass gasification plants producing biofuels or hydrogen. |

Detailed Methodologies & Experimental Protocols

Post-Combustion Capture via Amine Scrubbing

This protocol details a bench-scale experiment for evaluating amine-based solvent performance, critical for optimizing BECCS systems.

Experimental Protocol: Solvent Screening for Post-Combustion Capture

- Objective: To determine the CO₂ absorption capacity, kinetics, and regeneration energy of novel amine solvents.

- Materials: (See Scientist's Toolkit below).

- Procedure:

- Flue Gas Simulation: Prepare a simulated flue gas mixture (10-15% CO₂, balance N₂) using mass flow controllers.

- Absorption Phase: Circulate the gas mixture through a packed column absorber (maintained at 40-50°C) containing the aqueous amine solvent (e.g., 30 wt% MEA or proprietary blend). Monitor inlet/outlet CO₂ concentrations via NDIR analyzer.

- Data Collection: Record CO₂ breakthrough curves. Calculate dynamic absorption capacity (mol CO₂ / mol amine).

- Desorption/Regeneration: Transfer the rich solvent to a heated stripper column (100-120°C). Apply controlled heat to liberate CO₂. Capture and measure the desorbed CO₂ volume.

- Energy Analysis: Measure the total heat input required for solvent regeneration per mole of CO₂ captured.

Post-Combustion Amine Scrubbing Process Flow

Oxy-Fuel Combustion Capture

This protocol outlines a lab-scale oxy-fuel combustion experiment for characterizing burner stability and flue gas composition.

Experimental Protocol: Oxy-Fuel Burner Performance Analysis

- Objective: To assess combustion stability and flue gas composition under varying O₂/recycled flue gas (RFG) ratios.

- Materials: High-purity O₂ and N₂ cylinders, gaseous or atomized liquid biofuel burner, recycled flue gas simulation system, high-temperature probes, gas analyzers (O₂, CO₂, CO, NOx).

- Procedure:

- System Baseline: Establish stable air-fuel combustion. Analyze baseline flue gas.

- Oxy-Fuel Transition: Gradually replace N₂ in the oxidant stream with CO₂ to simulate RFG. Increase O₂ concentration to 21-30% by volume to maintain adiabatic flame temperature.

- Parameter Variation: Systematically vary the O₂/CO₂ ratio (e.g., 21/79, 25/75, 30/70). For each condition, allow the system to reach steady state.

- Data Collection: Record flame temperature (thermocouple), stability (visual/imaging), and detailed flue gas composition. Note any increase in radiative heat transfer or changes in pollutant formation (e.g., SOx, NOx).

- Condensation Analysis: Simulate downstream flue gas cooling to separate water, yielding a high-concentration CO₂ stream for analysis.

Oxy-Fuel Combustion System Configuration

Pre-Combustion Capture via Gasification & WGS

This protocol describes the steps for producing a separable CO₂ stream from syngas via the water-gas shift (WGS) reaction.

Experimental Protocol: Syngas Production and Shift Reaction

- Objective: To convert CO in syngas to CO₂ via catalytic WGS reaction, producing a high-pressure H₂/CO₂ mixture for separation.

- Materials: Lab-scale biomass gasifier, syngas cleanup system (filters, scrubbers), catalytic WGS reactor (Fe-Cr or Cu-Zn catalysts), mass flow controllers, steam generator, gas chromatograph.

- Procedure:

- Syngas Generation: Gasify biomass feedstock (e.g., wood pellets) in a fluidized bed gasifier using steam and/or O₂. Clean the raw syngas of tars and particulates.

- Shift Reaction Setup: Mix the cleaned syngas with superheated steam at a defined H₂O/CO ratio (typically 2:1 to 3:1). Preheat the mixture to the catalyst activation temperature (e.g., 300-350°C for high-temperature shift).

- Catalytic Conversion: Pass the mixture over the fixed-bed WGS catalyst. Monitor temperature profile along the reactor bed.

- Product Analysis: Analyze the effluent gas stream using GC to determine the final composition (%H₂, %CO₂, residual %CO). Calculate CO conversion efficiency.

- Separation Simulation: The resulting gas stream (now primarily H₂ and CO₂) is ready for physical solvent-based CO₂ separation (e.g., Selexol, Rectisol).

Pre-Combustion Gasification and Shift Pathway

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Carbon Capture Experimentation

| Item | Function in Research | Typical Example/Specification |

|---|---|---|

| Amine Solvents | Chemical absorbent for post-combustion CO₂ capture. Performance is measured by capacity, kinetics, and degradation rate. | Monoethanolamine (MEA, 30% aqueous), Piperazine (PZ), Methyldiethanolamine (MDEA), Novel blended amines. |

| Physical Solvents | For high-pressure, pre-combustion CO₂ separation via physical absorption. | Selexol (dimethyl ethers of polyethylene glycol), Rectisol (chilled methanol). |

| WGS Catalysts | Promotes the water-gas shift reaction to convert CO to CO₂ and additional H₂. | High-Temperature Shift (HTS): Fe₃O₄-Cr₂O₃. Low-Temperature Shift (LTS): Cu-ZnO-Al₂O₃. |

| Oxygen Sorbents | For advanced oxy-fuel processes (Chemical Looping Combustion). Materials that transport oxygen via redox cycles. | Calcium-based (CaO/CaCO₃), Metal oxides (NiO, Fe₂O₃, Mn₂O₃ on inert supports). |

| Gas Analyzers | Critical for quantifying inlet/outlet gas compositions to calculate capture efficiency. | NDIR for CO₂, Paramagnetic for O₂, FTIR or GC for multi-component analysis. |

| Structured Packing/Porous Sorbents | Provides high surface area for gas-liquid or gas-solid contact in absorption/adsorption columns. | Ceramic or metal structured packing, Zeolites (13X), Metal-Organic Frameworks (MOFs), Activated Carbon. |

The integration of post-combustion, oxy-fuel, or pre-combustion carbon capture is the pivotal engineering component that transforms a carbon-neutral bioenergy process into a carbon-negative BECCS system. The choice of technology dictates the overall system efficiency, cost, and feasibility of large-scale deployment. Continuous research and optimization of the described protocols and materials are essential to reduce energy penalties, improve integration, and scale these technologies to meet global negative emissions targets.

The efficacy of Bioenergy with Carbon Capture and Storage (BECCS) as a negative emissions technology (NET) hinges not only on biomass conversion and CO2 capture but on the secure, efficient, and reliable transport of captured CO2 to designated geological sequestration sites. This guide details the critical mid-stream component: the pipeline networks and compression systems that form the backbone of large-scale CO2 transport logistics, a pivotal element in realizing a closed carbon cycle for climate mitigation.

Pipeline Network Design & Engineering

Pipeline Specifications and Material Considerations

CO2 transport via pipeline is the most established method for large-volume, long-distance movement. The design must account for the unique thermophysical properties of dense-phase or supercritical CO2, including its corrosivity in the presence of impurities (e.g., H2O, H2S, SOx).

Table 1: Key Design Parameters for CO2 Transmission Pipelines

| Parameter | Typical Specification | Rationale & Impact |

|---|---|---|

| Operating Pressure | 8.6 - 15 MPa (1240 - 2175 psi) | Maintains CO2 in dense phase (liquid or supercritical) to minimize pressure drops and pumping power. |

| Operating Temperature | 20 - 40 °C | Optimized to balance viscosity, density, and material constraints. |

| Pipe Material | API 5L X65/X70 Carbon Steel, with internal corrosion allowance or cladding. | Standard high-strength steel; cladding (e.g., stainless) required if impurities exceed limits. |

| Diameter | 6" to 48" (150 - 1200 mm) | Determined by mass flow rate (1-20 MtCO2/yr). Larger diameters reduce pressure loss. |

| Depth of Burial | 0.9 - 1.2 meters | Provides mechanical protection and thermal insulation. |

| Impurity Limits (e.g., Sleipner project) | H2O < 50 ppm, O2 < 100 ppm, H2S < 200 ppm | Prevents corrosion, ensures pipeline integrity, and complies with storage site regulations. |

Hydraulic Modeling and Network Optimization

Steady-state and transient flow models are essential to predict pressure, temperature, and flow distribution. The governing equation is the modified isothermal or adiabatic flow equation, accounting for real-gas behavior via an Equation of State (EOS) like GERG-2008 or Peng-Robinson.

Experimental Protocol: Hydraulic Loop Testing for CO2-mixture Flow

- Objective: To validate pressure drop and heat transfer correlations for CO2 streams with realistic BECCS-derived impurities.

- Materials: High-pressure loop (stainless steel), reciprocating pump, pre-cooler, electric pre-heater, Coriolis mass flow meter, differential pressure transducers, thermocouples, gas chromatograph for composition.

- Methodology:

- Prepare a calibrated mixture of CO2, N2, O2, and Ar to simulate captured flue gas composition.

- Pressurize the loop to supercritical conditions (e.g., 10 MPa) using the pump.

- Circulate the mixture at a fixed mass flow rate. Maintain constant inlet temperature via the pre-cooler/heater.

- Record pressure drop across a test section of known length and roughness.

- Vary flow rate (Reynolds number) and inlet temperature in subsequent runs.

- Compare measured pressure gradients against computational fluid dynamics (CFD) and model predictions.

Diagram: CO2 Pipeline Network Flow Logic

Title: CO2 Pipeline Transport System Workflow

Compression & Pumping Technology

Thermodynamic Pathway to Dense Phase

Captured CO2 is typically at near-ambient pressure. Compression must elevate it to pipeline pressure while managing heat of compression and phase changes to maximize efficiency.

Table 2: Comparison of CO2 Compression & Pumping Technologies

| Technology | Typical Inlet State | Outlet State | Stages | Key Advantage | Key Disadvantage | Energy Penalty (Approx.) |

|---|---|---|---|---|---|---|

| Integrally Geared Centrifugal Compressor | Gas, ~0.1 MPa | Supercritical, ~15 MPa | 6-8 | High volumetric flow, proven technology. | Requires intercooling, sensitive to impurities. | 90-110 kWh/t CO2 |

| Reciprocating Compressor | Gas, ~0.1 MPa | Supercritical, ~15 MPa | 4-6 | High pressure ratio per stage, handles varying load. | Pulsating flow, more maintenance. | 95-115 kWh/t CO2 |

| Liquefaction + Pump | Gas, ~0.1 MPa | Liquid, ~0.7 MPa | 1 (Refrig.) + Pump | Pumping more efficient than gas compression. | Added complexity of refrigeration cycle. | 70-90 kWh/t CO2 (incl. refrigeration) |

| Supercritical CO2 Pump | Liquid/Dense, >7.4 MPa | Supercritical, ~15 MPa | 1 (or 2) | Very efficient for boosting pressure. | Requires dense phase inlet (pre-compression). | ~10-20 kWh/t CO2 |

Protocol: Optimizing Multi-Stage Compression with Intercooling

- Objective: To determine the optimal interstage pressure and cooling temperature to minimize total compression work for a given BECCS flue gas composition.

- Materials: Multi-stage test compressor rig with variable-speed drives, intercoolers (shell & tube), precise temperature controllers, pressure sensors, power meters, data acquisition system.

- Methodology:

- Set the final discharge pressure target (e.g., 15 MPa).

- For a 4-stage system, assume equal pressure ratios across stages as a baseline. Calculate interstage pressures.

- Operate the compressor at a fixed inlet mass flow rate. Cool the gas after each stage to a fixed temperature (e.g., 30°C). Measure shaft power for each stage.

- Vary the interstage cooling temperature in subsequent experiments (e.g., 25°C, 35°C).

- Employ an optimization algorithm (e.g., Lagrange multipliers with real-gas EOS) to calculate the theoretical interstage pressures that minimize total work.

- Adjust the compressor rig to the calculated optimal interstage pressures and measure the total power consumption. Compare with baseline.

Diagram: Multi-stage Compression Thermodynamic Pathway

Title: Four-Stage CO2 Compression with Intercooling

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for CO2 Transport Research

| Item/Category | Function in Research | Specific Example & Notes |

|---|---|---|

| High-Pressure, High-Temperature (HPHT) Reactors / Flow Loops | Simulate pipeline conditions for corrosion, flow assurance, and chemical interaction studies. | Autoclave made of Hastelloy C276 or Super Duplex Stainless Steel, with sapphire windows for visualization. |

| Corrosion Inhibitors & Tracers | Study mitigation of internal pipeline corrosion and monitor fluid flow/leak detection. | Imidazoline-based inhibitors for carbon steel; Perfluorocarbon tracers (PFTs) or SF6 for leak detection. |

| Dehydration & Purification Media | Remove water and specific impurities from CO2 streams to meet pipeline specifications. | Molecular sieves (3Å or 4Å) for dehydration; activated carbon beds for VOC removal. |

| Advanced Equation of State (EOS) Software | Accurately predict thermophysical properties (density, viscosity) of impure CO2 mixtures. | Commercial packages with GERG-2008 or EOS-CG models (e.g., REFPROP, Multiflash, OLGA). |

| Pipeline Steel Coupon Samples | Perform standardized corrosion rate measurements under simulated transport conditions. | API 5L X65/X70, polished to specified finish, with precisely measured surface area. |

| Hydrate Inhibitors | Prevent formation of CO2 hydrates (clathrates) which can plug pipelines, especially in cold sections or with impurities. | Thermodynamic inhibitors (methanol, monoethylene glycol) or low-dose kinetic inhibitors. |

| Fiber Optic Sensing Systems | Enable distributed real-time monitoring of pipeline temperature and strain (for leak detection). | Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) cables. |

Geological sequestration is the cornerstone subsurface component of Bioenergy with Carbon Capture and Storage (BECCS), a critical negative emissions technology (NET). BECCS generates energy from biomass while capturing the resulting CO₂, achieving net-negative emissions when the biomass is sustainably sourced. The permanent storage of this captured CO₂ in geological formations completes the carbon removal cycle. This whitepaper details the two primary geological sinks—depleted hydrocarbon reservoirs and saline aquifers—and the monitoring, measurement, and verification (MMV) protocols essential for validating long-term sequestration efficacy and safety.

Geological Sink Characterization & Comparative Analysis

Depleted Oil and Gas Reservoirs

These formations have proven capacity to trap hydrocarbons over geological timescales, defined by a structural or stratigraphic seal. Their advantages include well-characterized geology and existing infrastructure (wells, seismic data). Key risks involve potential leakage through legacy wells and the necessity of managing reservoir pressure post-production.

Saline Aquifers

Deep, porous, permeable sedimentary rock formations saturated with non-potable saline water offer the largest potential storage capacity globally. They lack commercial value, reducing conflict. Challenges include relative geological uncertainty and the need for extensive site characterization to predict CO₂ plume migration and pressure fronts.

Table 1: Comparative Analysis of Geological Sinks for CO₂ Sequestration

| Parameter | Depleted Reservoirs | Saline Aquifers |

|---|---|---|

| Proven Containment | High (known trap) | Variable (requires demonstration) |

| Storage Capacity | Moderate (limited by original pore volume) | Very High (largest potential) |

| Characterization Data | Extensive (from production history) | Limited (requires new baseline surveys) |

| Infrastructure Re-use | High (wells, pipelines, platforms) | Low (typically greenfield) |

| Key Risk | Legacy well integrity | Reservoir heterogeneity & plume prediction |

| Injection Pressure | Lower (due to prior depletion) | Higher (must overcome native pressure) |

| Regulatory Framework | More mature (linked to oil/gas) | Evolving |

Table 2: Quantitative Data for Representative Geological Sinks

| Project/Formation | Type | Estimated Capacity (Mt CO₂) | Depth (km) | Injectivity (Mt/yr/well) | Status |

|---|---|---|---|---|---|

| Sleipner (Utsira Fm.) | Saline Aquifer | 1000+ | ~0.8 | ~1 | Operational since 1996 |

| Weyburn-Midale | Depleted Oil Field | 50+ | ~1.5 | 1.5-3 | Operational (EOR) |

| Illinois Basin – Decatur | Saline Aquifer | ~300 | 2.1 | 1.0 | Operational |

| Alberta Carbon Trunk Line (ACTL) | Depleted Reservoirs | Variable | 1.5-3.0 | Up to 14.6 (collective) | Operational |

Monitoring, Measurement, and Verification (MMV) Protocols

MMV is a non-negotiable pillar of safe sequestration, ensuring conformance (plume behaves as predicted) and containment (no leakage to biosphere). Protocols are deployed across three domains: atmosphere, near-surface, and subsurface.

Subsurface Monitoring Protocols

Method 1: 4D (Time-Lapse) Seismic Surveys

- Objective: Track the spatial evolution of the CO₂ plume and monitor pressure changes in the reservoir.

- Protocol:

- Baseline Survey: Acquire high-resolution 3D seismic data prior to injection.

- Repeat Surveys: Conduct subsequent 3D surveys at scheduled intervals (e.g., annually).

- Processing: Subtract baseline seismic volume from repeat volumes to generate a "difference volume" highlighting changes due to CO₂ saturation (acoustic impedance contrast).

- Interpretation: Map plume geometry, migration pathways, and identify potential anomalies.

Method 2: Well-Based Logging and Sampling

- Objective: Obtain direct, high-resolution measurements of fluid composition and well integrity.

- Protocol:

- Installation: Deploy permanent downhole sensors (pressure, temperature, geophones) in injection and observation wells.

- Logging Campaigns: Periodically run wireline tools (e.g., pulsed neutron logs for saturation, cement bond logs).

- Fluid Sampling: Use downhole samplers to capture fluid for geochemical analysis (e.g., tracer detection, pH, ion composition).

- Data Integration: Correlate continuous sensor data with discrete logging measurements.

Near-Surface and Atmospheric Monitoring Protocols

Method 3: Soil Gas and Groundwater Geochemical Monitoring

- Objective: Detect any leakage of CO₂ into shallow groundwater or soil.

- Protocol:

- Network Installation: Establish a grid of soil gas flux chambers and shallow groundwater monitoring wells.

- Baseline Characterization: Sample over multiple seasons to establish natural background variability of CO₂ flux, soil gas composition (O₂, N₂, CO₂, CH₄), and groundwater chemistry.

- Routine Sampling: Collect samples at regular intervals (quarterly).

- Analysis: Analyze for CO₂ concentration, δ¹³C isotopic signature (to distinguish deep CO₂ from biogenic CO₂), and tracer elements (e.g., perfluorocarbon tracers injected with CO₂).

Method 4: Atmospheric Eddy Covariance Flux Towers

- Objective: Quantify net ecosystem exchange of CO₂ to detect surface leaks over large areas.

- Protocol:

- Tower Deployment: Install one or more towers instrumented with a 3D sonic anemometer and fast-response infrared gas analyzer.

- Continuous Measurement: Record high-frequency (10-20 Hz) wind velocity, direction, and CO₂ concentration.

- Data Processing: Compute turbulent fluxes of CO₂ using the eddy covariance method, averaging over 30-minute intervals.

- Background Correction: Compare fluxes to upwind background towers to isolate potential leak signal.

Diagram 1: Integrated MMV workflow for CO2 sequestration

Diagram 2: BECCS system role of geological sequestration

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 3: Essential Reagents and Materials for Sequestration Research & MMV

| Item | Function/Application |

|---|---|

| Perfluorocarbon Tracers (PFTs) | Chemically inert atmospheric and subsurface tracers injected with CO₂ to provide unambiguous leak detection. |

| Stable Isotopes (¹³C, ¹⁸O) | Used to label injected CO₂ or monitor water-rock interactions; critical for distinguishing sequestration CO₂ from natural background. |

| Resistivity & Acoustic Logging Tools | Wireline tools to measure formation properties and monitor changes in fluid saturation over time. |

| Fiber-Optic Distributed Temperature Sensing (DTS) | Provides continuous, high-resolution temperature profiling along a wellbore to monitor injection and flow. |

| Eddy Covariance Instrumentation | Sonic anemometer & IRGA for direct measurement of atmospheric CO₂ fluxes over the storage complex. |

| Geochemical Reservoir Simulators (e.g., TOUGH2, CMG-GEM) | Numerical modeling software to predict multiphase flow, plume migration, and geochemical reactions. |

| Cement & Casing Corrosion Inhibitors | Additives used in wellbore completion to ensure long-term zonal isolation and integrity. |

| Downhole Fluid Samplers | Pressurized vessels for capturing representative formation fluid samples for geochemical analysis. |

| Soil Gas Flux Chambers | Portable enclosures for measuring the rate of CO₂ exchange between soil and atmosphere. |

| Seismic Piezoelectric Sources & Receivers | Generate and record acoustic waves for 2D/3D/4D seismic imaging of the subsurface. |

Challenges and Optimization of BECCS for Scalability and Efficiency

Addressing Land-Use Conflict and Biodiversity Impacts

Bioenergy with Carbon Capture and Storage (BECCS) is a central negative emissions technology (NET) in many climate stabilization pathways, including those outlined by the IPCC. It involves cultivating biomass, converting it to energy, capturing the resultant CO₂, and storing it geologically. The scale of land required for biomass feedstock production in IPCC scenarios (e.g., up to 724 Mha by 2100 in some models) creates direct competition with other land uses, including food production, urban expansion, and—critically—the conservation of natural ecosystems and biodiversity. This guide examines the technical frameworks for assessing and mitigating these conflicts within BECCS research and deployment.

Quantifying the Conflict: Key Data and Metrics

The primary conflict arises from the direct and indirect land-use change (LUC/iLUC) triggered by large-scale biomass cultivation. The following table summarizes core quantitative impacts derived from recent literature and models.

Table 1: Projected Land-Use and Biodiversity Impacts of BECCS at Scale

| Metric | Low-Impact Scenario Estimate | High-Impact Scenario Estimate | Key Source/Model | Notes |

|---|---|---|---|---|

| Land Area Required (by 2100) | ~300 Mha | ~724 Mha | IPCC AR6 / IAMs | Highly dependent on climate target and energy mix. |

| Potential Biodiversity Loss (Species Richness) | 5-10% reduction in impacted regions | >25% reduction in high-risk ecoregions | Global biodiversity models (GLOBIO, PREDICTS) | Losses are non-linear and concentrated in biodiversity hotspots. |

| Carbon Debt Payback Time | 10-50 years | 100-1000+ years | Life Cycle Assessment (LCA) studies | Depends on prior land cover (e.g., grassland vs. forest). |