BECCS and the Carbon Neutrality Clock: A Critical Analysis of Payback Periods for Sustainable Research

This article provides a comprehensive analysis of Bioenergy with Carbon Capture and Storage (BECCS) as a pathway to carbon neutrality for energy-intensive research and pharmaceutical development.

BECCS and the Carbon Neutrality Clock: A Critical Analysis of Payback Periods for Sustainable Research

Abstract

This article provides a comprehensive analysis of Bioenergy with Carbon Capture and Storage (BECCS) as a pathway to carbon neutrality for energy-intensive research and pharmaceutical development. We explore the foundational science of BECCS, detail methodologies for calculating its carbon payback period, address key challenges in implementation and optimization, and validate its efficacy through comparative life-cycle assessment. Tailored for researchers and industry professionals, this analysis offers a roadmap for integrating BECCS into sustainability strategies to achieve net-negative emissions while supporting critical scientific work.

Understanding BECCS: The Science of Carbon-Negative Energy for Labs and Facilities

This technical guide serves as a foundational component for a broader thesis investigating the carbon neutrality and payback period dynamics of Bioenergy with Carbon Capture and Storage (BECCS). A precise, system-level definition is critical for modeling the temporal fluxes of biogenic and fossil carbon, which directly influence net carbon removal calculations and the ultimate assessment of BECCS as a negative emissions technology (NET). This whitepaper deconstructs the BECCS value chain to establish the technical parameters essential for rigorous life-cycle and techno-economic analysis.

System Definition and Core Components

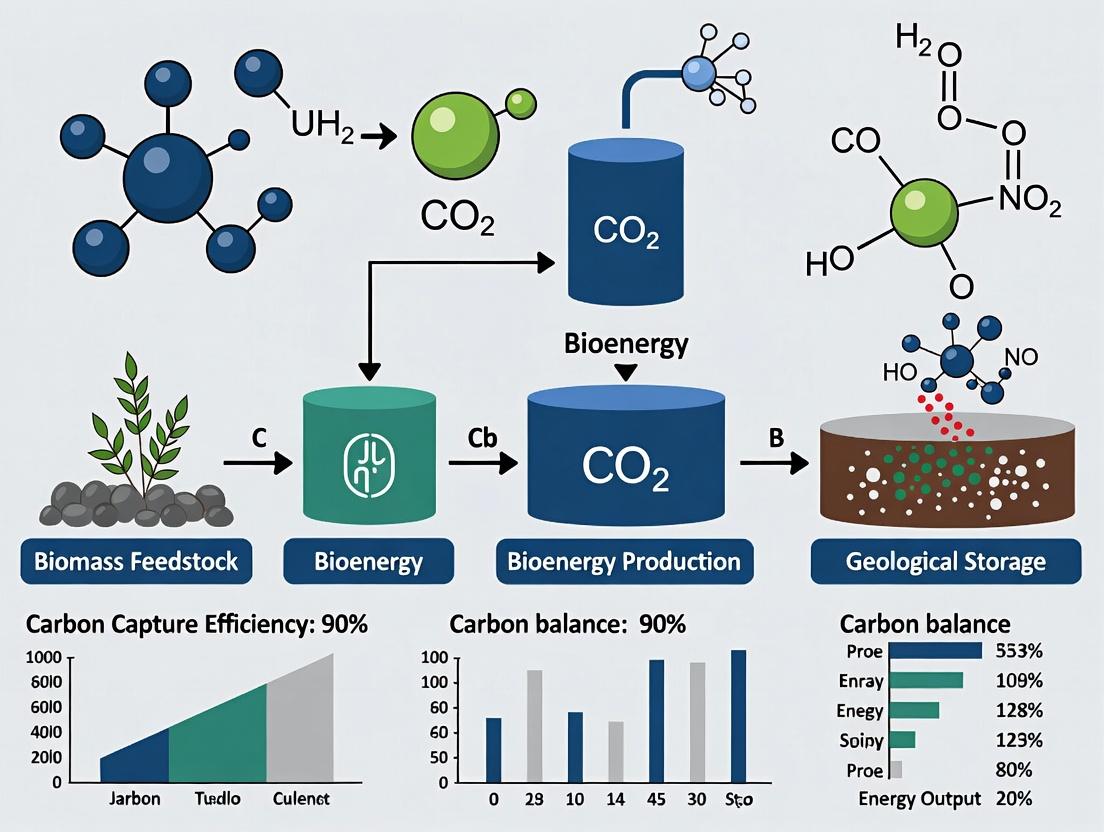

BECCS is an integrated process that combines biomass conversion to energy (bioenergy) with the capture and permanent geological storage of the resulting CO₂. The theoretical net removal occurs because the biomass, during growth, absorbs atmospheric CO₂ via photosynthesis. When its carbon is captured and stored geologically, it is not returned to the atmosphere, creating a net flux from the atmosphere to the lithosphere. The integrity of this chain is paramount; inefficiencies or emissions at any stage erode the net negative balance.

Biomass Feedstock Systems

Feedstock choice dictates the initial carbon debt, supply chain emissions, and scalability. Key categories include:

- Dedicated Energy Crops: Perennial grasses (e.g., Miscanthus, switchgrass) and fast-growing trees (e.g., willow, poplar). They offer high yields on marginal lands but require careful land-use change (LUC) analysis.

- Agricultural & Forestry Residues: Straw, corn stover, forest slash, and sawmill residues. Using wastes minimizes direct LUC impacts but must account for nutrient recycling and soil carbon stock implications.

- Processed Waste Streams: Municipal solid waste (MSW), wastewater sludge, and industrial organic wastes. Addresses waste management issues but involves heterogeneous composition.

Table 1: Comparative Analysis of Primary Biomass Feedstocks for BECCS

| Feedstock Category | Typical Dry Yield (ton/ha/yr) | Approximate Carbon Content (% dry weight) | Key Sustainability Considerations | Scale Potential (Gt CO₂/yr removal) |

|---|---|---|---|---|

| Dedicated Lignocellulosic Crops | 10-20 | ~48% | Direct/Indirect LUC, water use, biodiversity. | 0.5 - 3.5* |

| Agricultural Residues | 2-5 (straw) | ~45% | Soil health, erosion, nutrient removal. | 0.5 - 1.5* |

| Forestry Residues | 1-3 (slash) | ~50% | Soil biodiversity, long-term forest productivity. | 0.5 - 2.0* |

| Municipal Solid Waste (Biogenic Fraction) | Variable | 25-40% | Contamination, collection efficiency, competing uses. | 0.2 - 0.8* |

*Estimated technical potential ranges from literature; high uncertainty due to sustainability constraints and economic factors.

Protocol 3.1: Feedstock Carbon Content Analysis (Ultimate Analysis) Objective: Determine the carbon, hydrogen, nitrogen, and sulfur content of a biomass sample for combustion and LCA calculations. Method: ASTM D5373 / ISO 29541. A dried, homogenized sample is combusted in a high-temperature (≥950°C) furnace in an oxygenated environment. The resulting combustion gases (CO₂, H₂O, N₂, SO₂) are separated and measured quantitatively using thermal conductivity or infrared detection. Results are reported as weight percent of the dry sample.

Bioenergy Conversion & Capture Technologies

The conversion pathway determines the form of energy output (power, heat, fuel) and the suitability of capture methods.

- Combustion (Oxy-fuel or Post-Combustion): Biomass is burned with air (or oxygen in oxy-fuel) to produce steam for turbines. Post-combustion capture (PCC) uses chemical solvents (e.g., amine-based) to scrub CO₂ from flue gas.

- Gasification (Pre-Combustion): Biomass is converted to syngas (CO + H₂) at high temperature with limited oxygen. The CO is shifted to CO₂ and H₂, allowing for high-pressure, high-concentration CO₂ capture prior to combustion of the H₂.

- Fermentation (Bioprocessing): For biomass-to-ethanol plants, fermentation produces high-purity CO₂ as a by-product, requiring only dehydration and compression.

Table 2: Performance Parameters of Primary BECCS Conversion & Capture Pathways

| Conversion Pathway | Capture Technology | Typical CO₂ Capture Rate (%) | CO₂ Purity in Capture Stream | Primary Energy Penalty Estimate | Technology Readiness Level (TRL) |

|---|---|---|---|---|---|

| Pulverized Fuel Combustion | Post-Combustion (Amine Scrubbing) | 85 - 95 | >99% | 20-30% of plant output | 7-8 (Demonstration) |

| Biomass Gasification | Pre-Combustion (Physical Solvent, e.g., Selexol) | 90 - 99 | >95% | 15-25% | 6-7 (Pilot/Demo) |

| Biorefinery (Ethanol) | By-Product Separation (Dehydration) | ~100 | >99% | <5% | 9 (Commercial) |

| Anaerobic Digestion (Biogas) | Post-Combustion or Biogas Upgrading | 85 - 90 | >95% | 10-20% | 8 (Commercial) |

Protocol 4.1: Solvent-Based Post-Combustion CO₂ Capture Pilot Testing Objective: Determine the capture efficiency, energy requirement, and solvent degradation rate for a novel amine solvent. Method: A slipstream of real flue gas from a biomass boiler is fed to a bench-scale absorption/desorption column system. The gas flow rate, temperature, and CO₂ concentration are monitored pre- and post-absorption via NDIR analyzers. The rich solvent is pumped to a stripper column operated at 100-120°C. The thermal energy input for solvent regeneration is precisely measured via steam condensate flow and temperature. Solvent samples are taken weekly and analyzed by ion chromatography and total alkalinity titration to track degradation.

Transportation and Permanent Geological Storage

Captured CO₂ must be transported, typically via pipeline, and injected into deep geological formations for permanent isolation.

- Transport: Requires compression to a supercritical state (>73.8 bar, >31°C) to increase density and reduce transport costs.

- Storage Formations:

- Saline Aquifers: Deep, porous rock saturated with non-potable brine. Highest global capacity.

- Depleted Oil/Gas Reservoirs: Well-characterized geology with proven seal integrity. Can offer enhanced oil recovery (EOR) co-benefits but complicates carbon accounting.

- Trapping Mechanisms: Structural/stratigraphic trapping (immediate), residual trapping (capillary forces), solubility trapping (dissolution into brine), and mineral trapping (long-term conversion to carbonate minerals).

Title: CO2 Transport and Geological Trapping Mechanisms Timeline

Protocol 5.1: Reservoir Characterization for Storage Site Selection Objective: Assess the capacity, injectivity, and containment security of a candidate saline aquifer. Method: Integrate 3D seismic reflection surveys to map structure and faults. Analyze core samples from exploration wells for porosity, permeability, and mineralogy. Perform well tests (e.g., pressure transient analysis) to determine in-situ hydraulic properties. Use legacy data and stratigraphic models to define the geometry and thickness of the target formation and the overlying caprock (seal). Geochemical modeling of the formation brine and host rock is conducted to predict long-term reactivity with injected CO₂.

The Scientist's Toolkit: BECCS Research Reagent Solutions

Table 3: Key Research Reagents and Materials for BECCS Experimental Analysis

| Reagent / Material | Primary Function / Application | Key Consideration for BECCS Research |

|---|---|---|

| Monoethanolamine (MEA) / Novel Solvents (e.g., KS-1, AMP) | CO₂ Capture: Acts as a chemical absorbent in post-combustion capture systems. Bonds with CO₂ in the absorber, releases it in the stripper. | Degradation rate in presence of biomass flue gas impurities (SOx, NOx, O₂) is a critical research variable for cost and environmental impact. |

| Stable Isotope ¹³C-Labeled CO₂ | Carbon Tracing: Allows differentiation of biomass-derived CO₂ from fossil or background CO₂ in process streams, storage plumes, and potential leakage. | Essential for field-scale verification of storage permanence and attribution in BECCS monitoring, reporting, and verification (MRV). |

| Lignocellulose Reference Materials (NIST) | Feedstock Analysis: Certified materials for calibrating instruments analyzing cellulose, hemicellulose, and lignin content. | Ensures accuracy in feedstock characterization, which directly impacts conversion efficiency and life-cycle carbon accounting. |

| Porous Media Simulants (e.g., Berea Sandstone cores) | Geological Storage Lab Studies: Physical models of reservoir rock for core flooding experiments. | Used to study CO₂-brine-rock interactions, relative permeability, and capillary trapping efficiency under simulated reservoir conditions. |

| Fluorescent Microspheres or DNA Tracers | Subsurface Flow & Leakage Pathways: Biologically and chemically inert tracers to monitor fluid movement in complex media. | Can be used in field pilots to validate reservoir flow models and detect potential leakage with high sensitivity. |

The Carbon Neutrality Imperative in Research and Pharmaceutical Industries

The pursuit of carbon neutrality within the research and pharmaceutical industries represents a critical convergence of environmental stewardship and operational necessity. This whitepates the broader scientific and economic analysis of Bioenergy with Carbon Capture and Storage (BECCS) payback periods. The sector, characterized by energy-intensive laboratories, complex global supply chains, and high-value, low-volume products, faces unique decarbonization challenges. Achieving net-zero emissions is not merely a corporate social responsibility goal but an imperative for sustainable innovation, regulatory compliance, and long-term resilience. This guide provides a technical framework for integrating carbon neutrality into core research and development operations.

The Carbon Footprint of Pharma & Research: A Data-Driven Analysis

The pharmaceutical industry's carbon intensity is significantly higher than that of the automotive sector, with an estimated emission factor of 48.55 tonnes of CO2e per $1 million in revenue compared to 31.4 tonnes for automakers (Belkhir & Elmeligi, 2019). The majority of emissions (Scope 3) originate from the supply chain and product use phases. Research facilities contribute substantially through direct (Scope 1) and energy-related (Scope 2) emissions.

Table 1: Estimated Carbon Footprint of Key Research & Pharmaceutical Operations

| Operation / Activity | Average Annual CO2e (tonnes) | Primary Emission Scope | Key Contributing Factors |

|---|---|---|---|

| Ultra-Low Temperature (ULT) Freezer (-80°C) | 5-10 per unit | Scope 2 | Energy consumption (8,000-16,000 kWh/yr), refrigerants. |

| Fume Hood (Constant Flow) | 5-15 per unit | Scope 2 | HVAC load to condition exhaust air (≈3.5x lab ACH). |

| Multi-day Chromatography Run (HPLC/UPLC) | 0.05-0.2 per run | Scope 2 | Instrument power, solvent production & waste. |

| Animal Research Facility (per 100 cages) | 15-30 | Scopes 1 & 2 | HVAC, lighting, feed supply chain, waste management. |

| Single Clinical Trial (Phase III) | 100 - 1,000+ | Scope 3 | Patient travel, site operations, data centers, material transport. |

Integrating BECCS Payback Period Analysis into Sector Strategy

The thesis context of BECCS carbon neutrality and payback period analysis is directly applicable. The "carbon payback period" – the time required for an intervention to offset the carbon emitted during its implementation – is a crucial metric for capital investments in green labs and renewable energy.

Table 2: Payback Period Analysis for Common Decarbonization Interventions

| Intervention | Estimated Upfront Carbon Cost (tCO2e) | Annual Carbon Abatement (tCO2e/yr) | Estimated Carbon Payback Period (Years) | Financial ROI Notes |

|---|---|---|---|---|

| Retrofitting ULT Freezers to -70°C & Optimal Maintenance | 0.5 (manufacturing) | 1.5-2.5 per unit | <0.5 | High, with 20-30% energy savings. |

| Replacing Constant Flow Fume Hoods with High-Efficiency VAV | 1.0 (manufacturing) | 3-6 per unit | 0.3-0.5 | Very high, 50-70% energy reduction. |

| On-site Solar PV Installation (100 kW system) | 80-100 (production & installation) | 60-80 | ~1.5 | Moderate, subject to incentives and energy prices. |

| Transition to Green Chemistry Solvents (Bioprocess) | Low (R&D) | Varies; 0.1-10 per process | Immediate (operational) | Variable; may reduce purification costs. |

| Procurement of BECCS-generated Negative Emission Credits | N/A | User-defined offset | Immediate (compensatory) | Purely a cost; supports emerging technology. |

Technical Protocols for Carbon Accounting & Reduction in Labs

Protocol 4.1: Comprehensive Carbon Footprint Assessment for a Research Group

Objective: To quantify Scopes 1, 2, and relevant Scope 3 emissions for a discrete research unit. Materials: Utility bills, procurement records, lab equipment logs, travel records, waste manifests. Methodology:

- Define Organizational Boundary: Use operational control approach.

- Collect Activity Data: Gather 12 months of data for:

- Energy: Electricity (kWh), natural gas (therms), steam.

- Mobile Combustion: Fleet and researcher-owned vehicle fuel for work.

- Refrigerants: Purchases and leaks of F-gases.

- Purchased Goods: High-impact items (chemicals, single-use plastics, cryogens, cell culture media).

- Travel & Commuting: Air, rail, rental car mileage.

- Waste Generated: Hazardous, biological, solid waste weight.

- Apply Emission Factors: Use latest IPCC, DEFRA, or EPA GHG Emission Factors Hub factors. For chemicals, use cradle-to-gate life cycle assessment (LCA) data from suppliers or databases like Ecoinvent.

- Calculate:

Emissions = Activity Data × Emission Factor. - Normalize: Express data per FTE researcher, per $ research spend, or per experimental output unit.

Protocol 4.2: Experimental Life Cycle Assessment (LCA) for a Drug Discovery Assay

Objective: To compare the environmental impact of a traditional assay vs. a miniaturized or in silico alternative. Materials: LCA software (e.g., OpenLCA), detailed process maps for each assay version. Methodology:

- Goal & Scope: Define functional unit (e.g., "screening of 10,000 compounds at a single concentration").

- Inventory Analysis: Map all inputs/outputs for each step: compound synthesis/sourcing, plate manufacturing, reagent use (volumes, types), instrument energy consumption (qPCR, plate reader), plasticware (tip boxes, plates), waste treatment.

- Impact Assessment: Calculate climate change impact (kg CO2e) using relevant databases. Include midpoint indicators like water use and ecotoxicity.

- Interpretation: Identify hotspots (e.g., acetonitrile in HPLC, disposable pipette tips) and quantify percentage reduction offered by the greener alternative.

Diagram 1: Experimental LCA Workflow

The Scientist's Toolkit: Essential Reagents & Solutions for Sustainable Research

Table 3: Research Reagent Solutions for Carbon Reduction

| Item / Solution | Function / Application | Sustainability Rationale & Impact |

|---|---|---|

| Bio-based & Renewable Solvents (e.g., Cyrene from cellulose, 2-MeTHF) | Replacement for DMF, DMSO, NMP, and traditional THF in synthesis & purification. | Lower cradle-to-gate carbon footprint, reduced toxicity, often biodegradable. |

| Enzyme & Biocatalysts | For asymmetric synthesis, hydrolysis, and bond formation in API manufacturing. | Enable milder reaction conditions (lower T/P), reduce metal catalyst use, improve selectivity reducing waste. |

| Continuous Flow Reactors | Small-scale, continuous chemical synthesis. | Drastically reduces solvent and energy use vs. batch processes, enhances safety, improves yields. |

| High-Throughput & Microscale Chemistry | Screening and synthesis using mg-scale reagents in 96/384-well plates. | Reduces reagent consumption by >90%, minimizes hazardous waste generation. |

| Predictive In Silico ADMET/Tox Platforms | Computer models predicting compound properties and toxicity. | Prioritizes synthesis for only the most promising candidates, avoiding wasted resources on failed leads. |

| Reusable Labware (Glass cell culture flasks, sterilizable pipettes) | Replacement for single-use plastic consumables in routine processes. | Reduces plastic waste and the embodied carbon from manufacturing and disposal. |

| Green Energy-Powered Cold Storage | ULT freezers connected to renewable energy sources or retrofitted for higher efficiency. | Directly cuts Scope 2 emissions; using certified renewable energy can reduce footprint to near-zero for operation. |

Achieving carbon neutrality requires a multi-faceted strategy: 1) Avoid unnecessary emissions through experimental design (Green Chemistry principles, in silico methods); 2) Reduce through efficiency (equipment upgrades, virtualization); 3) Substitute with green energy and sustainable materials; and 4) Compensate for residual emissions through high-quality, verified carbon removal projects like BECCS, aligning with the thesis on durable carbon payback.

The integration of carbon accounting and LCA into the scientific method itself is the next frontier. By quantifying the environmental cost of research choices, scientists and drug developers can drive innovation that benefits both human and planetary health, ensuring the industry's social license to operate and its long-term viability in a carbon-constrained world.

Diagram 2: Decarbonization Strategy Hierarchy

This whitepaper elucidates the core technical principle enabling Bioenergy with Carbon Capture and Storage (BECCS) to achieve net-negative emissions. The analysis is framed within a broader research thesis focused on quantifying the carbon neutrality and payback period of BECCS deployment. For researchers, understanding this principle is fundamental to modeling the system's lifecycle carbon accounting, which determines the temporal dynamics of atmospheric CO₂ drawdown and the critical point at which net negativity is achieved.

The Fundamental Principle: Coupling Biogenic Carbon Cycles with Geologic Sequestration

BECCS achieves net-negative emissions by integrating two distinct processes: the closed-loop cycling of biogenic carbon and the permanent, one-way storage of fossil-origin carbon. The core principle rests on the sequential capture of carbon that was recently in the atmosphere (via biomass growth) and preventing its return to the atmosphere by coupling it with geological carbon capture and storage (CCS). This creates a one-way flow of carbon from the atmosphere to a geological sink.

Logical Process Diagram:

Diagram 1: The BECCS net-negativity principle

Detailed Technical Analysis of the Carbon Flows

The net negativity is quantified by the equation: Net CO₂ = (CO₂ₐₜₘ – CO₂b) – (Eᵥ + Eᵣ + Eₜ + Eᵢ), where:

- CO₂ₐₜₘ = CO₂ removed from atmosphere during biomass growth.

- CO₂b = CO₂ emitted back to atmosphere from biomass processing/combustion (now captured).

- Eᵥ, Eᵣ, Eₜ, Eᵢ = Lifecycle emissions from cultivation, transport, processing, and injection (typically fossil-based).

When (CO₂ₐₜₘ – CO₂b) > Σ(Eᵥ + Eᵣ + Eₜ + Eᵢ), the system is net-negative. The carbon payback period, a key thesis variable, is the time from system initiation until this inequality becomes permanently true, accounting for all upfront carbon costs.

Quantitative Data Table: Carbon Balance for Representative BECCS Pathways

| Pathway | Feedstock | Scale | Atmospheric CO₂ Captured by Biomass (tCO₂/TJ) | Fossil Lifecycle Emissions (tCO₂/TJ) | Net Atmospheric Removal (tCO₂/TJ) | Key Determining Factors |

|---|---|---|---|---|---|---|

| Power Generation | Woody Biomass (SRC) | 100 MWe | 101.5 | 14.2 (cultivation, transport, CCS energy) | +87.3 | Biomass yield, transport distance, capture rate (90-95%) |

| Ethanol Production | Corn Stover | 100 ML/yr | 89.7 | 23.8 (fertilizer residue, processing, transport) | +65.9 | Soil carbon loss (from residue removal), capture efficiency |

| Biogas Upgrade | Energy Crops | 50 MWth | 76.4 | 11.5 (cultivation, digestate management) | +64.9 | Methane slip avoidance, pipeline injection energy |

| Pulp & Paper Mill | Black Liquor | Industrial | 0 (waste stream) | 5.8 (incremental capture energy) | -5.8 (Net-positive without offset) | Baseline emissions, capture process efficiency |

Data synthesized from recent IEA (2023), IPCC AR6 (2022), and peer-reviewed LCA literature. Values are illustrative medians; ranges can vary ±40%.

Experimental Protocols for Key BECCS Research Parameters

Accurate payback period analysis requires empirical data from controlled experiments. Below are detailed protocols for key measurements.

Protocol: Measuring Soil Carbon Stock Change (ΔCₛ) from Feedstock Cultivation

Objective: Quantify the carbon debt or credit from land-use for biomass feedstock, a major variable in the payback period.

- Site Selection & Setup: Establish paired plots: (a) BECCS feedstock (e.g., switchgrass, willow), (b) Control (previous land use). Minimum triplicate plots of 10m x 10m.

- Soil Core Sampling: Use a stainless steel core sampler (3 cm diameter). Sample at 0-15, 15-30, and 30-60 cm depths at 5 random points per plot at time T₀ (establishment) and annually at T₁, T₂,...Tₙ.

- Sample Processing: Air-dry, remove visible roots and stones, grind to pass a 2mm sieve. Subsample for analysis.

- Carbon Content Analysis: Use dry combustion method (e.g., Elemental Analyzer). Weigh ~20mg of homogenized soil into a tin capsule. Measure total carbon (TC) and inorganic carbon (IC). Soil organic carbon (SOC) = TC – IC.

- Bulk Density Measurement: Collect intact core samples at each depth for bulk density calculation (oven-dry weight/known volume). Correct SOC stock for bulk density changes.

- Calculation: ΔCₛ (Mg C ha⁻¹ yr⁻¹) = (SOCₜ × BDₜ × Depth) – (SOCₜ₋₁ × BDₜ₋₁ × Depth) / Time.

Protocol: Laboratory-Scale Amine Scrubbing for Biogenic CO₂ Capture Efficiency

Objective: Determine the maximum capture rate (η) and solvent degradation profile for bio-flue gas contaminants.

- Apparatus Setup: Configure a bench-scale absorber-stripper column system. Absorber: packed column, 1m height, maintained at 40°C. Stripper: similar column, maintained at 120°C. Use 30% w/w Monoethanolamine (MEA) solution as base solvent.

- Gas Mix Preparation: Simulate bio-flue gas: 12% CO₂ (biogenic isotope signature), 6% O₂, balance N₂. Introduce controlled impurities: 50 ppm SO₂, 30 ppm NO₂.

- Absorption Cycle: Pump solvent (1 L/min) to absorber top. Introduce simulated flue gas (5 L/min) at bottom. Measure CO₂ concentration at inlet and outlet via NDIR analyzer continuously for 6 hours.

- Regeneration Cycle: Direct rich solvent to stripper. Apply steam heating (120°C). Measure CO₂ purity of the desorbed stream.

- Efficiency & Degradation Analysis: Calculate η = (CO₂ᵢₙ – CO₂ₒᵤₜ)/CO₂ᵢₙ. Daily, take 10mL solvent samples. Analyze for heat-stable salts (ion chromatography) and solvent concentration (titration). Correlate η decline with contaminant accumulation.

Key Signaling Pathways and System Interactions Diagram

Biomass-to-Storage System Integration:

Diagram 2: BECCS integration and feedback for payback analysis

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

| Item / Reagent | Function in BECCS Research | Key Consideration for Experimental Design |

|---|---|---|

| ¹³C-Depleted Biomass Standard | Isotopic tracer to distinguish biogenic CO₂ from fossil/geologic CO₂ in capture streams and storage monitoring. | Ensures measurement accuracy in MRV (Measurement, Reporting, Verification) protocols. Critical for attribution. |

| Stable Amine Solvents (e.g., Piperazine) | Advanced solvents for absorption with higher oxidative stability against bio-flue gas O₂, reducing degradation. | Lower regeneration energy and longer lifespan improve net-negative balance in LCA models. |

| Porous Media Reactors | Bench-scale models of geological reservoirs (e.g., packed sandstone columns) for CO₂-brine-rock interaction studies. | Used to simulate injection, plume migration, and mineralization rates for storage safety and capacity estimates. |

| Eddy Covariance Flux Towers | Micrometeorological systems to directly measure net ecosystem exchange (NEE) of CO₂ over feedstock plantations. | Provides real-world data on the "CO₂ₐₜₘ" term in the net negativity equation, reducing uncertainty. |

| Resistivity Tomography Array | Geophysical electrodes for laboratory and field-scale monitoring of CO₂ plume geometry in saline aquifers. | Non-invasive method to verify containment and calculate stored volume, a key input for payback calculations. |

| Life Cycle Inventory (LCI) Database | Curated datasets (e.g., Ecoinvent, GREET) for upstream emissions of fertilizers, diesel, steel, etc. | Essential for calculating the fossil emissions (Eᵥ, Eᵣ, Eₜ, Eᵢ) component. Must be spatially explicit. |

This technical guide details the core components essential for analyzing the carbon neutrality and payback period of Bioenergy with Carbon Capture and Storage (BECCS). The efficacy of BECCS as a negative emissions technology hinges on the integrated performance of sustainable biomass sourcing, efficient conversion, and reliable carbon capture and storage (CCS). This document provides researchers, particularly those in analytical fields like drug development, with the technical frameworks and methodologies to quantify and model these systems.

Sustainable Biomass: Feedstock Characterization & Sustainability Criteria

Sustainable biomass is the foundational element, determining the initial carbon debt and lifecycle emissions. Key metrics include specific yield, carbon content, and biochemical composition.

Table 1: Comparative Analysis of Biomass Feedstocks for BECCS

| Feedstock Type | Avg. Yield (ton dry/ha/yr) | Avg. Carbon Content (% dry weight) | Lignin Content (% dry weight) | Key Sustainability Indicators (Metrics) |

|---|---|---|---|---|

| Miscanthus | 10-25 | ~48% | 10-20% | Carbon Payback Period (CPP): 0-1 yr; Soil Organic Carbon (SOC) change |

| Switchgrass | 8-15 | ~47% | 12-20% | CPP: 1-3 yr; Water Use Efficiency (L/kg biomass) |

| Short Rotation Coppice (Willow) | 8-12 | ~49% | 20-25% | CPP: 2-4 yr; Biodiversity Impact Score |

| Agricultural Residues (Corn Stover) | 2-4 | ~45% | 15-20% | Indirect Land Use Change (iLUC) risk; Soil erosion mitigation |

| Forestry Residues | Varies | ~50% | 25-30% | Harvesting residue retention rate (>30% recommended) |

Experimental Protocol: Biomass Carbon Content Analysis (Elemental Analyzer)

- Sample Preparation: Dry biomass feedstock at 105°C to constant mass. Pulverize to a homogeneous fine powder (< 0.2 mm particle size).

- Calibration: Use acetanilide or a similar certified standard to calibrate the elemental analyzer (CHNS/O mode).

- Combustion & Measurement: Weigh 2-3 mg of sample into a tin capsule. Introduce into the combustion reactor at ~1000°C in a pure oxygen environment. The resulting gases (CO2, H2O, N2) are separated via gas chromatography.

- Detection & Calculation: CO2 is detected by a thermal conductivity detector (TCD). Carbon content percentage is calculated from the CO2 signal relative to the calibration curve and sample mass.

- Replication: Perform in triplicate. Report mean ± standard deviation.

Conversion Technologies: Efficiency and Syngas Composition

Biomass conversion technology dictates the form and concentration of CO2 for capture. Major pathways include biochemical (e.g., fermentation) and thermochemical (e.g., gasification).

Table 2: Performance Metrics of Biomass Conversion Technologies

| Conversion Technology | Typical Efficiency (η %) | Syngas/Output CO2 Concentration (%) | Primary Output | Suitability for CCS Integration |

|---|---|---|---|---|

| Anaerobic Digestion | 35-50% (Biogas) | 30-45% (CO2 in Biogas) | CH4, CO2 | Post-combustion capture from biogas upgrading |

| Gasification | 60-75% (Cold Gas) | 15-25% (Raw Syngas) | CO, H2, CO2 | Pre-combustion capture; high-pressure advantage |

| Fast Pyrolysis | 60-70% (Liquid) | 10-20% (Process gas) | Bio-oil, Char | Capture from process gas or bio-oil combustion |

| Direct Combustion (CFB) | 25-35% (Power) | 10-15% (Flue Gas) | Heat, Power | Post-combustion capture (standard flue gas) |

| Hydrothermal Liquefaction | 70-85% (Biorude) | 5-15% (Aqueous phase) | Biorude | Capture from aqueous phase or subsequent processing |

Experimental Protocol: Bench-Scale Gasification & Syngas Analysis

- Reactor Setup: Configure a fluidized-bed or downdraft gasifier. Ensure all gas lines are leak-tested and purged with inert gas (N2).

- Feedstock Introduction: Load dried, sized biomass (1-2 mm pellets). Set a controlled feed rate (e.g., 1 kg/hr).

- Gasification: Initiate with a start-up heater. Introduce a controlled flow of air/steam/O2 as the gasifying agent. Maintain reactor temperature at 750-900°C using external heaters and monitored by thermocouples.

- Syngas Sampling & Cleanup: Pass raw syngas through a series of coolers, condensers (to remove tars), and particulate filters. Use a heated line to prevent condensation before analysis.

- Online Gas Analysis: Connect cleaned syngas stream to a gas analyzer (NDIR for CO2, CO; TCD for H2; Paramagnetic for O2). Record composition data at steady-state conditions (minimum 30 mins).

- Data Calculation: Calculate cold gas efficiency: η = (LHVsyngas * mass flow ratesyngas) / (LHVbiomass * mass flow ratebiomass) * 100.

CCS Integration: Capture Efficiency and Energy Penalty

The integration point and capture method significantly impact the overall net efficiency and cost of BECCS.

Table 3: Carbon Capture Technologies for BECCS Integration

| Capture Type | Typical Integration Point | Capture Efficiency (%) | Energy Penalty (% of plant output) | Key Solvent/Material |

|---|---|---|---|---|

| Post-Combustion (Amine Scrubbing) | After combustion boiler | 85-90% | 20-30% | Monoethanolamine (MEA) |

| Pre-Combustion (Physical Absorption) | After gasifier & water-gas shift | 90-95% | 15-25% | Selexol, Rectisol |

| Oxy-Combustion | Combustion with pure O2 | >95% | 20-35% | Cryogenic Air Separation Unit |

| Calcium Looping | Post-combustion or sorbent cycling | 90-95% | 10-20% | CaO (Lime) |

| Direct Air Capture (DAC) | Ambient air (theoretical) | N/A | High | Solid Sorbents (e.g., MOFs) |

Experimental Protocol: Amine-Based CO2 Capture Efficiency Test

- Apparatus Setup: Assemble a packed absorption column and a stripping column with reboiler. Install liquid and gas flow controllers, CO2 sensors at inlet and outlet, and temperature/pressure gauges.

- Solution Preparation: Prepare a 30 wt.% aqueous solution of Monoethanolamine (MEA). Degas the solution by sparging with N2.

- Absorption Cycle: Pump the MEA solution to the top of the absorption column. Introduce a simulated flue gas (10-15% CO2, balanced N2) at the bottom. Operate in counter-current flow at ambient pressure and 40°C.

- Stripping/Regeneration Cycle: Route the CO2-rich MEA solution to the stripper. Heat the reboiler to 100-120°C to break the carbamate bond and release high-purity CO2. The lean MEA is recycled.

- Measurement: Use inline NDIR CO2 sensors to measure concentrations at the gas inlet (Cin) and outlet (Cout) of the absorber.

- Calculation: Capture Efficiency (%) = [(Cin - Cout) / C_in] * 100. Measure steam/energy input to the reboiler to calculate the specific regeneration energy (GJ/tonne CO2).

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Research Materials for BECCS Component Analysis

| Item/Category | Example Product/Reagent | Primary Function in Research |

|---|---|---|

| Biomass Composition | NREL LAP Standards (e.g., Corn Stover RM 8494) | Certified reference material for validating lignin, sugar, and ash analysis methods. |

| Elemental Analysis | Acetanilide (C8H9NO), Sulfanilamide | Calibration standards for CHNS/O elemental analyzers to determine carbon content. |

| Gas Calibration | Certified Gas Mixtures (e.g., 15% CO2, 20% H2, 10% CO in N2) | Calibrating GC-TCD, NDIR analyzers for accurate syngas/biogas composition. |

| Capture Solvents | Monoethanolamine (MEA), 2-Amino-2-methyl-1-propanol (AMP) | Benchmark solvents for testing post-combustion CO2 absorption kinetics and capacity. |

| Sorbent Materials | Zeolite 13X, Amine-functionalized Silica (TRI-PE-MCM-41) | Solid sorbents for evaluating adsorption/desorption cycles in capture processes. |

| Catalysts | Nickel-based Catalyst (Ni/Al2O3), Ru/TiO2 | For studying tar reforming in gasification or the water-gas shift reaction. |

| Isotope Tracers | 13C-Labeled CO2, 14C-Labeled Biomass | Tracing carbon flow through the entire BECCS chain for LCA and carbon accounting. |

| pH/Conductivity | Certified Buffer Solutions (pH 4, 7, 10), KCl Conductivity Standard | Monitoring solvent degradation and ion formation in capture process streams. |

Within the context of a broader thesis on Bioenergy with Carbon Capture and Storage (BECCS) carbon neutrality and payback period analysis research, the Carbon Payback Period (CPP) emerges as a central, non-negotiable metric for techno-economic and environmental feasibility. It quantifies the time required for a carbon-negative technology, such as BECCS, to offset the upfront greenhouse gas (GHG) emissions generated from its construction, feedstock supply chain, and operation. For researchers and drug development professionals, the CPP provides a robust, temporal framework analogous to pharmacokinetic models, assessing the "net carbon debt" of a system. This whitepaper serves as an in-depth technical guide to its calculation, application, and the experimental protocols underpinning its critical variables.

Core Concept and Mathematical Formalism

The Carbon Payback Period (CPP) is defined as the time ( t ) at which cumulative net carbon sequestration equals cumulative upfront and operational carbon emissions. The fundamental equation is:

[ CPP = \frac{E{upfront} + E{operational} - S{operational} \times t}{S{operational} - E_{operational_rate}} ]

Where:

- ( E_{upfront} ): Total upfront emissions (biomass cultivation, facility construction, equipment manufacturing).

- ( E_{operational} ): Annual operational emissions (energy input, chemicals, transport).

- ( S_{operational} ): Annual net carbon sequestration rate (CO₂ captured and stored minus supply chain emissions).

- ( E_{operational_rate} ): Rate of change of operational emissions (often assumed zero for simplicity).

A more common simplified form for a system with constant annual net sequestration is:

[ CPP = \frac{E{upfront}}{S{net}} ]

Where ( S{net} ) is the annual net carbon sequestration (( S{operational} - E_{operational} )).

Key Data Inputs and Life Cycle Assessment (LCA) Protocols

Accurate CPP calculation is contingent on rigorous Life Cycle Assessment (LCA). Key data categories and their associated experimental or analytical methodologies are summarized below.

Table 1: Core Data Inputs for CPP Calculation in BECCS Systems

| Data Category | Specific Parameter | Typical Measurement Units | Primary Methodology |

|---|---|---|---|

| Upfront Emissions (E_upfront) | Biomass cultivation (N₂O from fertilizer, diesel) | kg CO₂-eq / ha | IPCC Tier 1/2 methodologies; soil flux chambers. |

| Biomass transportation | kg CO₂-eq / ton-km | Fuel consumption models; vehicle emission factors. | |

| Facility & infrastructure construction | kg CO₂-eq / MW | Economic Input-Output LCA (EIO-LCA); material inventories. | |

| Operational Emissions (E_operational) | Process energy consumption | kg CO₂-eq / MWh | Continuous emission monitoring systems (CEMS). |

| Solvent production & degradation (e.g., MEA) | kg CO₂-eq / kg solvent | Chemical synthesis LCA; solvent degradation rate analysis. | |

| Sequestration Potential (S_operational) | CO₂ capture efficiency | % | Gas chromatography (GC) or FTIR analysis of inlet/outlet flue gas. |

| CO₂ purity for storage | % CO₂ | GC-TCD (Thermal Conductivity Detector). | |

| Geological storage integrity | % leakage / year | Seismic monitoring; tracer tests; pressure monitoring. |

Detailed Experimental Protocol: Soil GHG Flux Measurement for Biomass Feedstock

Objective: Quantify direct soil-derived N₂O and CH₄ emissions from biomass cultivation for inclusion in ( E_{upfront} ).

Protocol:

- Site Selection: Establish static chambers in triplicate across representative plots (control, fertilized).

- Sampling: Use non-steady-state static chambers. Gas samples are extracted from chamber headspace at time intervals (0, 15, 30, 45 mins) post-deployment using gas-tight syringes.

- Analysis: Analyze gas samples via Gas Chromatograph (GC) equipped with an Electron Capture Detector (ECD) for N₂O and a Flame Ionization Detector (FID) for CH₄.

- Calculation: Flux is calculated from the linear change in gas concentration over time, adjusted for chamber volume, area, and environmental conditions.

- Upscaling: Daily fluxes are interpolated and summed with modeled CO₂ emissions from farm machinery to generate annual per-hectare emission factors.

Signaling Pathway: The CPP Decision Framework

The CPP is integrated into a larger decision-support framework for evaluating BECCS projects, interacting with economic and policy variables.

Diagram Title: BECCS Project Feasibility Decision Framework

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for CPP-Related Research

| Item | Function in CPP Analysis | Example/Supplier (Illustrative) |

|---|---|---|

| Gas Standards | Calibration of GC for precise N₂O, CH₄, CO₂ quantification. | Certified CRM (e.g., 1.0 ppm N₂O in N₂ balance, Scott Specialty Gases). |

| Isotopic Tracers | Tracing carbon flow in BECCS systems; verifying biogenic CO₂. | ¹³C-labeled CO₂ or biomass (e.g., Cambridge Isotope Laboratories). |

| Amine Solvents | Benchmarking capture efficiency & degradation rates for LCA. | Monoethanolamine (MEA), Piperazine (PZ) (e.g., Sigma-Aldrich). |

| Soil Flux Chambers | Direct field measurement of agricultural GHG emissions. | Non-steady-state static chambers (e.g., LI-COR 8100A chamber). |

| LCA Software | Modeling upstream emissions and compiling inventory data. | SimaPro, OpenLCA, GREET model. |

| Geochemical Models | Predicting long-term mineral trapping of stored CO₂. | PHREEQC, TOUGHREACT. |

Critical Pathways and System Dynamics

The CPP is not static. It is influenced by interconnected system pathways, most critically the biomass supply chain and the carbon capture process.

Diagram Title: BECCS System Pathways Impacting Carbon Payback

The Carbon Payback Period is the definitive metric for establishing the temporal viability of carbon-removal technologies. For BECCS, a CPP exceeding policy-relevant timeframes (e.g., less than 30 years for 2°C targets) negates its climate mitigation value. This guide underscores that precise CPP determination relies on standardized, transparent LCA protocols and continuous monitoring of system components. Future research must focus on integrating dynamic life-cycle inventories and probabilistic models to account for spatial and temporal variability in feedstock emissions and capture performance, thereby refining CPP accuracy for robust feasibility analysis.

This technical guide examines the deployment of Bioenergy with Carbon Capture and Storage (BECCS) within energy-intensive research campuses. The analysis is framed within a broader thesis investigating the carbon neutrality timelines and dynamic payback periods of BECCS infrastructure. For research institutions—particularly those with high-energy facilities like particle accelerators, supercomputers, and pharmaceutical cleanrooms—BECCS represents a critical pathway to mitigate operational emissions while providing a platform for applied climate research.

Case Study Data & Comparative Analysis

Current deployments are in pilot or early operational phases, primarily integrated with campus Combined Heat and Power (CHP) or waste management systems.

Table 1: BECCS Deployment Case Studies on Research Campuses

| Campus / Project Name | BECCS Configuration | Annual CO₂ Capture Capacity (Metric Tons) | Feedstock Source | CO₂ Storage/Sink | Primary Research Focus |

|---|---|---|---|---|---|

| University of Illinois Urbana-Champaign (UIUC) – CCS from Biomass Boiler | Post-combustion capture (solvent-based) on biomass boiler. | Pilot Scale: ~1,500 | Miscanthus grass, forest residue. | Geologic storage in Illinois Basin. | Integration with agricultural supply chains, monitoring/verification. |

| Princeton University – Pilot Plant | Modular, containerized post-combustion unit. | Pilot Scale: ~50 | Waste biomass, renewable natural gas. | Not yet at scale; research on utilization. | System optimization, catalyst & solvent testing for flue gas variability. |

| UK Bioenergy Research Center (UKBRC) Campuses | Coupled gasification & pyrolysis with CCS. | Lab/Pilot Scale: Variable. | Energy crops, waste wood. | Research on mineralization. | Fundamental process engineering, life-cycle assessment (LCA). |

| Chalmers University of Technology – Gothenburg | Waste-to-Energy CHP with amine scrubbing. | Demonstration: ~10,000+ (full plant) | Municipal & industrial waste. | Geologic storage in North Sea. | System integration, cost analysis, policy frameworks. |

Table 2: Key Performance Indicators (KPIs) & Payback Analysis Framework

| KPI Category | Metric | Typical Range (Current Pilots) | Relevance to Payback Thesis |

|---|---|---|---|

| Technical | Capture Rate (% of flue gas CO₂) | 85-95% | Directly impacts carbon negativity rate. |

| Energetic | Energy Penalty (% of plant output) | 15-30% | Critical for net energy balance of campus. |

| Economic | Levelized Cost of CO₂ Captured ($/ton) | $80 - $200 | Drives financial payback period analysis. |

| Carbon | Net Negative Emissions (tons CO₂e/year) | Site-specific. | Core to calculating carbon payback period. |

Experimental Protocols & Methodologies

Protocol for Solvent-Based Capture Efficiency Testing (Post-Combustion)

Objective: Determine the CO₂ absorption efficiency and degradation rate of amine-based solvents under simulated campus boiler flue gas conditions.

- Setup: A bench-scale absorption column is fitted with gas analyzers (NDIR for CO₂) at inlet and outlet. The solvent (e.g., 30wt% Monoethanolamine - MEA) is circulated at a controlled temperature (40-45°C).

- Gas Simulation: A synthetic flue gas mix (12% CO₂, 5% O₂, balance N₂, with optional SOx/NOx traces) is prepared using mass flow controllers.

- Absorption Run: Gas is bubbled through the solvent at a defined gas-liquid ratio. Outlet CO₂ concentration is logged continuously until saturation.

- Regeneration: The rich solvent is transferred to a stripper column and heated to 100-120°C to release captured CO₂. Energy input is measured precisely.

- Analysis: Capture efficiency = [(CO₂in - CO₂out)/CO₂_in] * 100. Solvent samples are analyzed weekly via titration and ICP-MS to track degradation and metal contamination.

Protocol for Life-Cycle Assessment (LCA) for Campus BECCS

Objective: Quantify the net carbon negative potential and environmental payback period.

- System Boundaries: Cradle-to-grave: includes biomass cultivation/transport, conversion, capture, compression, transport, and permanent storage.

- Inventory Analysis: Collect primary data from campus operations (fuel use, electricity, chemicals) and secondary data from databases (Ecoinvent, GREET) for upstream processes.

- Allocation: Use system expansion to handle co-products (e.g., district heat).

- Impact Assessment: Calculate Global Warming Potential (GWP) over 100 years using IPCC factors. Net GWP = (Emissions from supply chain + operations) - (CO₂ sequestered).

- Payback Calculation: Dynamic carbon payback period is calculated by comparing the cumulative radiative forcing of the BECCS system against a reference fossil system over time.

Visualizations

Diagram 1: BECCS System Integration on a Research Campus (92 chars)

Diagram 2: Dynamic Carbon Payback Period Analysis Workflow (80 chars)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Key Research Reagents & Materials for BECCS Laboratory Studies

| Item / Reagent | Function in BECCS Research | Example & Notes |

|---|---|---|

| Amine Solvents (e.g., MEA, PZ, AMP) | CO₂ absorption in post-combustion capture. Benchmark for performance and degradation studies. | 30wt% MEA solution. Must be monitored for oxidative degradation (formation of nitrosamines, heat-stable salts). |

| Solid Sorbents (e.g., MOFs, Zeolites, Activated Carbon) | Adsorptive capture; research focuses on selectivity, capacity, and regeneration energy. | Metal-Organic Frameworks (MOFs) like Mg-MOF-74 offer high CO₂ affinity at low partial pressures. |

| Biomass Feedstock Standards | Provide consistent material for gasification/pyrolysis experiments and LCA. | NIST reference materials (e.g., pine wood, corn stover) for ultimate/proximate analysis and kinetic studies. |

| Gas Calibration Standards | Calibrate analyzers (GC, NDIR) for accurate CO₂, CH₄, CO, SO₂ measurement. | Certified gas mixtures in N₂ balance (e.g., 12% CO₂, 100ppm SO₂) simulating flue gas composition. |

| Tracers for Monitoring & Verification (M&V) | Tag captured CO₂ for safe storage verification and leak detection. | Perfluorocarbon tracers (PFTs) or SF₆ (with caution) injected into CO₂ stream pre-injection. |

| Catalysts for Gasification/Syngas Cleaning | Promote tar reforming and optimize H₂:CO ratio in biomass gasification pathways. | Nickel-based catalysts on Al₂O₃ support; researched for resistance to coking and sulfur poisoning. |

Calculating the Payback: Methodologies for BECCS Lifecycle Assessment (LCA) in Research Settings

Within the broader thesis research on Bioenergy with Carbon Capture and Storage (BECCS) carbon neutrality and payback period analysis, establishing precise system boundaries is paramount. This technical guide delineates the functional unit, spatial, and temporal boundaries for a comprehensive Life Cycle Assessment (LCA) of BECCS, from biomass cultivation to permanent geological sequestration. Accurate boundary definition is critical for determining the true net negative emissions potential and the temporal dynamics of the carbon debt payback period.

Defining the Core System Boundary

The primary system encompasses all processes directly involved in the BECCS value chain. The functional unit is defined as 1 Megajoule (MJ) of net usable energy delivered, coupled with the net CO₂ sequestered (kg CO₂e).

Table 1: Core System Boundary Components

| Stage | Included Processes | Key Inputs/Outputs |

|---|---|---|

| 1. Biomass Cultivation & Harvesting | Land preparation, sowing, fertilization, irrigation, pesticide application, harvesting, chipping. | Inputs: Diesel, fertilizers, pesticides, water, land. Outputs: Biomass feedstock, soil N₂O emissions, biogenic carbon stock changes. |

| 2. Biomass Transport | Road, rail, or barge transport of biomass from field to processing/conversion facility. | Inputs: Diesel/electricity. Outputs: CO₂, CH₄, NOx from fuel combustion. |

| 3. Bioenergy Conversion | Gasification/Combustion, coupled with power/heat generation or biofuel production. | Inputs: Biomass, chemicals (e.g., for gas cleaning), water. Outputs: Electricity/heat/biofuel, flue gas, ash. |

| 4. Carbon Capture | Post-combustion (amine scrubbing), oxy-fuel, or pre-combustion capture applied to flue gas. | Inputs: Flue gas, solvent/energy for regeneration. Outputs: High-purity CO₂ stream, waste heat, degraded solvent. |

| 5. CO₂ Compression & Transport | Drying, compression to supercritical state, pipeline/infrastructure transport to storage site. | Inputs: Electricity/energy for compression. Outputs: Compressed, pipeline-ready CO₂, fugitive emissions. |

| 6. Carbon Sequestration | Geological injection, monitoring, measurement, and verification (MMV) over mandated period. | Inputs: Compressed CO₂, water/brine (for enhanced recovery). Outputs: Sequestered CO₂, potential induced seismicity, brine displacement. |

Critical Boundary Decisions & Methodologies

Temporal Boundaries

- Biogenic Carbon Cycle: The growth period of biomass (1-20 years) must be temporally aligned with the instantaneous emissions from processing and the long-term storage (≥1000 years). Dynamic LCA or time-adjusted global warming potential (GWP) metrics are recommended for payback period analysis.

- Technological Lifetime: The assessment should cover a typical plant lifetime of 20-30 years, including decommissioning.

- Monitoring Period: Post-injection MMV is typically required for 20-50 years by regulation, but modeling of permanence must extend centuries.

Spatial & Market Boundaries

- Geographical Specificity: Biomass yield, soil carbon, and grid electricity carbon intensity are highly region-specific. Data must be location-attributed.

- Land Use Change (LUC): Direct LUC (dLUC) and Indirect LUC (iLUC) must be accounted for if biomass cultivation displaces previous land use (e.g., forest, food crops), significantly impacting the carbon payback period. iLUC assessment requires economic equilibrium modeling.

Protocol 1: Dynamic Life-Cycle Assessment for Carbon Payback

- Model Carbon Flows: Quantify all carbon fluxes (biogenic uptake, fossil emissions, sequestration) as a time-series.

- Apply Time-Discounting: Use a chosen climate metric (e.g., GWP, GTP) with dynamic characterization factors or apply a radiative forcing model.

- Calculate Cumulative Climate Impact: Plot the cumulative radiative forcing over time (e.g., 100 years).

- Determine Payback Point: Identify the time (t) at which the cumulative forcing of the BECCS system falls below that of a reference fossil system. This is the carbon payback period.

Upstream & Downstream Boundaries

- Included Upstream: Production of capital goods (machinery, buildings), extraction and production of all inputs (fertilizers, diesel, chemicals, solvents).

- Excluded Downstream: Use phase of the produced energy (e.g., electricity in an electric vehicle), except as it defines the functional unit.

- Allocation: For multi-product processes (e.g., biorefinery producing fuel and chemicals), use system expansion (avoided burden) or energy/mass-based allocation consistently.

Key Experimental & Analytical Protocols

Protocol 2: Soil Organic Carbon (SOC) Stock Measurement (via Dry Combustion)

- Objective: Quantify baseline and changes in SOC due to biomass cultivation.

- Materials: Soil auger, core sampler, aluminum tins, oven, desiccator, ball mill, elemental analyzer (CNHS).

- Method:

- Collect soil cores (0-30 cm, 30-60 cm) from multiple random plots in the field using a standardized corer.

- Dry samples at 105°C to constant weight. Determine bulk density.

- Homogenize, grind, and sieve (2mm) the dried soil.

- Weigh ~20 mg of finely ground soil into a tin capsule.

- Analyze using a CHNS elemental combustor. SOC is derived from the measured carbon content, assuming inorganic carbon is negligible or separately removed.

- Calculate SOC stock (Mg C/ha) = SOC concentration * bulk density * layer depth * (1 - fragment content).

Protocol 3: Amine-Based CO₂ Capture Efficiency & Solvent Degradation

- Objective: Determine CO₂ capture rate and solvent degradation products in a pilot-scale absorber-stripper unit.

- Materials: Simulated flue gas (CO₂/N₂/O₂), 30 wt% Monoethanolamine (MEA) solution, absorber column, stripper column with reboiler, condenser, gas analyzers (NDIR for CO₂), HPLC for solvent analysis.

- Method:

- Circulate MEA solvent at a fixed flow rate (L/min).

- Introduce simulated flue gas (12-15% CO₂) counter-currently into the absorber at a set temperature (40-50°C).

- Measure CO₂ concentration at inlet and outlet of absorber using NDIR analyzers to calculate capture efficiency: Efficiency (%) = [(CO₂in - CO₂out)/CO₂_in] * 100.

- Pump rich solvent to stripper. Apply steam via reboiler (120°C) to release CO₂.

- Periodically sample lean solvent. Analyze via HPLC for thermal degradation products (e.g., oxazolidinone, HEI, HEP) and via IC for heat-stable salts (formate, acetate, sulfate).

- Correlate degradation rates with capture efficiency drop over time.

Visualization of System Boundaries & Carbon Flow

Title: BECCS System Boundary Diagram with Carbon Flow

Title: Conceptual Model of Carbon Payback Period Dynamics

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Research Materials for BECCS Boundary Analysis

| Item/Category | Example Product/Specification | Primary Function in Research |

|---|---|---|

| Soil Carbon Analysis | LECO TruMac CN Combustion Analyzer | Precisely measures total carbon and nitrogen content in soil and biomass samples for SOC and yield calculations. |

| Greenhouse Gas Flux | Picarro G2508 Gas Concentration Analyzer | High-precision, in-situ measurement of N₂O, CH₄, CO₂, NH₃, and H₂O fluxes from soil in cultivation studies. |

| CO₂ Capture Solvent | 30 wt% Monoethanolamine (MEA), High Purity (≥99%) | Benchmark solvent for post-combustion capture experiments; used to establish baseline efficiency and degradation rates. |

| Solvent Degradation Analysis | Agilent 1260 Infinity II HPLC with DAD/ELSD | Separates and quantifies MEA and its degradation products (e.g., HEIA, OZD, HEPO) in liquid samples. |

| Ion Chromatography (IC) | Thermo Scientific Dionex ICS-6000 HPIC | Quantifies heat-stable salts (anions like formate, acetate, oxalate, sulfate) in degraded amine solvents. |

| Flue Gas Simulant | Custom N₂/CO₂/O₂/SO₂/NOx calibration gas mixtures | Provides a consistent, adjustable synthetic flue gas for bench- and pilot-scale carbon capture unit testing. |

| Geochemical Modeling | PHREEQC or TOUGHREACT software | Simulates water-rock-CO₂ interactions in the storage formation to assess long-term mineralization and leakage risks. |

| LCA Software | SimaPro, OpenLCA, GaBi | Provides databases and modeling frameworks to implement system boundaries and calculate lifecycle impacts. |

1. Introduction Within the critical research framework of Bioenergy with Carbon Capture and Storage (BECCS) carbon neutrality and payback period analysis, the precise quantification of upfront "carbon debt" is paramount. This technical guide provides a structured methodology for researchers to inventory and apportion greenhouse gas (GHG) emissions accrued before the operational carbon-negative phase of a BECCS facility. This debt, comprising embedded emissions from the supply chain, construction, and commissioning, directly defines the temporal offset to net carbon negativity—the carbon payback period.

2. System Boundary & Life Cycle Stages for Carbon Debt Accounting The carbon debt is defined within a cradle-to-gate system boundary, preceding biogenic carbon sequestration. The following stages are considered:

- A1-A3: Supply Chain & Material Production: Extraction, processing, and transport of all raw materials (steel, concrete, chemicals, membranes, solvents).

- A4-A5: Construction & Installation: Transportation to site, on-site construction, assembly, and commissioning.

- B6: Operational Energy (Initial): Emissions from grid energy or auxiliary fuels used during start-up and initial ramp-up, prior to sustainable biomass fuel autonomy.

Table 1: Carbon Debt Inventory Categories and Examples

| Life Cycle Stage | Category | Emission Source Examples | Primary GHG |

|---|---|---|---|

| A1-A3: Supply Chain | Material Production | Cement clinker production, steel manufacturing, amine solvent synthesis | CO₂, N₂O |

| Material Transport | Freight (maritime, rail, road) of processed materials to fabrication site | CO₂ | |

| A4-A5: Construction | On-site Activities | Diesel combustion in construction equipment, on-site electricity generation | CO₂, CH₄ |

| Installation & Commissioning | Fugitive emissions from pressure testing, system purging (e.g., with natural gas) | CO₂, CH₄ | |

| B6: Initial Operation | Energy Consumption | Grid electricity for pumps/compressors before bio-energy self-sufficiency | CO₂ |

3. Methodological Protocols for Emission Quantification

3.1. Tiered Hybrid Life Cycle Assessment (LCA) Protocol

- Objective: To calculate embedded emissions for major capital components.

- Procedure:

- Bill of Materials (BoM) Inventory: Create a detailed BoM for key components (e.g., boiler, capture tower, compressor, CO₂ storage tanks).

- Process-Based LCA (Tier 1): For core materials (>80% mass), use primary data with background databases (e.g., Ecoinvent, GREET). Apply formula:

E_material = Σ(Mass_i × EF_production_i) + Σ(Mass_i × Distance_ij × EF_transport_ij). - Economic Input-Output LCA (Tier 2): For specialized, low-mass/high-cost components (e.g., control systems, specialized alloys), use EEIO models (e.g., USEEIO) to estimate broader supply chain emissions:

E_component = Cost_component × EEIO_Sector_Coefficient. - Aggregation & Uncertainty: Sum Tier 1 and Tier 2 results. Perform Monte Carlo simulation (≥10,000 iterations) to propagate uncertainty in emission factors and cost data.

3.2. On-site Construction Activity Monitoring Protocol

- Objective: To directly measure fuel- and energy-use emissions during construction.

- Procedure:

- Fuel Reconciliation: Install fuel tracking for all major equipment. Record daily/weekly fuel logs (type, volume).

- Emissions Calculation: Use standard emission factors (e.g., EPA EF for diesel).

E_construction = Σ(Fuel_Volume_k × EF_k × GWP_k). - Grid Electricity Apportionment: Sub-meter temporary site power. Use real-time or regional grid emission factors.

4. Visualization of Carbon Debt in BECCS Payback Analysis

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials and Tools for Carbon Debt Analysis

| Item / Solution | Function in Research | Technical Specification / Example |

|---|---|---|

| Life Cycle Inventory (LCI) Database | Provides emission factors for materials and energy processes. | Ecoinvent 3.8, US Life Cycle Inventory (USLCI) Database, GREET Model. |

| Economic Input-Output (EEIO) Model | Estimates economy-wide supply chain emissions for financial data. | USEEIO model (US EPA), EXIOBASE. |

| Process Simulation Software | Models energy and mass balances for technology-specific emission factors. | Aspen Plus, Aspen HYSYS, for capture solvent regeneration energy. |

| High-Purity Reference Gases | Calibration of GHG analyzers for direct on-site emission measurement. | NIST-traceable CO₂, CH₄, N₂O in balance air or nitrogen. |

| Carbon Accounting Software | Integrates LCA, EEIO, and primary data for final carbon debt calculation. | openLCA, SimaPro, GaBi LCA software. |

| Uncertainty Analysis Tool | Quantifies variance in final carbon debt figure. | Monte Carlo simulation packages (@Risk, Oracle Crystal Ball) or mc2d in R. |

6. Data Synthesis and Payback Calculation The carbon payback period (CPP) is calculated by integrating the quantified carbon debt with the projected net-negative sequestration rate of the operational BECCS plant.

Table 3: Payback Period Calculation Inputs

| Parameter | Symbol | Unit | Data Source |

|---|---|---|---|

| Total Carbon Debt | CD | t CO₂e | Sum of Tables 1 & 2 outputs. |

| Annual Operational Sequestration | AS | t CO₂e/yr | Process model of BECCS plant at nameplate capacity. |

| Annual Residual Operational Emissions | AE | t CO₂e/yr | LCA of biomass supply chain, solvent degradation, fugitive CO₂. |

| Net Annual Sequestration | NS = AS - AE | t CO₂e/yr | Derived value. |

| Carbon Payback Period | CPP = CD / NS | Years | Key Result. |

7. Conclusion A rigorous, staged quantification of carbon debt from supply chain, construction, and early operation is non-negotiable for validating the carbon neutrality thesis of BECCS. The methodologies and tools outlined herein enable researchers to establish a robust baseline, against which the efficacy of carbon removal and the duration of the carbon payback period can be accurately assessed. This forms the critical foundation for credible net-negative carbon accounting.

This whitepaper, framed within a broader thesis on Bioenergy with Carbon Capture and Storage (BECCS) carbon neutrality and payback period analysis, provides a technical guide for modeling the annual net sequestration rates of BECCS systems. BECCS is a critical negative emissions technology (NET) for achieving climate targets, integrating biomass energy conversion with permanent geological CO₂ storage. Accurate modeling of its net sequestration rate—the net CO₂ removed from the atmosphere per year—is essential for assessing its role in mitigation pathways and its economic viability.

Core Conceptual Model

The annual net sequestration (ANS) of a BECCS system is the net flux of CO₂ from the atmosphere to geological storage. It is calculated by accounting for all carbon flows and emissions associated with the full lifecycle of the system.

ANS (t CO₂/yr) = Carbon Captured & Stored - (Supply Chain Emissions + Capture Process Emissions + Leakage)

A positive ANS indicates net atmospheric removal.

Key Model Parameters & Quantitative Data

Modeling requires integrating data from agronomy, process engineering, and geology. The following tables summarize critical parameters and typical ranges based on current literature and pilot projects.

Table 1: Biomass Supply Chain Parameters

| Parameter | Symbol | Typical Range | Unit | Notes |

|---|---|---|---|---|

| Biomass Yield | Y_b | 5 - 20 | t DM/ha/yr | Highly crop & location dependent. |

| Carbon Content | C_frac | 0.45 - 0.50 | t C/t DM | For woody biomass. Herbaceous may be lower. |

| Supply Chain Emissions | E_sc | 0.1 - 0.3 | t CO₂e/t DM | Includes cultivation, harvest, transport, processing. |

| Indirect Land Use Change (iLUC) | E_iLUC | 0 - >1 | t CO₂e/t DM | High uncertainty; can negate sequestration if significant. |

Table 2: BECCS Plant Performance Parameters

| Parameter | Symbol | Typical Range | Unit | Notes |

|---|---|---|---|---|

| Plant Capacity | P | 1 - 1000 | MW_th | Thermal input from biomass. |

| Biomass-to-Energy Efficiency | η | 0.25 - 0.40 | MWe/MW_th | Lower for oxy-combustion, higher for BIGCC. |

| Capture Rate | CR | 0.80 - 0.95 | t CO₂ captured / t CO₂ produced | Fraction of process CO₂ captured. |

| Specific Capture Energy Penalty | EP | 0.2 - 0.4 | MJe / kg CO₂ | Energy for solvent regen/compression reduces net output. |

| Process Emissions Factor | E_proc | 0.05 - 0.15 | t CO₂e / t biomass | Non-capturable emissions from plant operations. |

Table 3: Storage & Monitoring Parameters

| Parameter | Symbol | Typical Value/Range | Unit | Notes |

|---|---|---|---|---|

| Storage Site Leakage Rate | L | < 0.001 - 0.01 | % / yr | Regulatory targets are <0.1%/yr. |

| Monitoring, Measurement & Verification (MMV) Costs | C_MMV | 0.5 - 2.0 | $ / t CO₂ stored | Ongoing cost for liability management. |

Experimental & Methodological Protocols

Protocol for Life Cycle Assessment (LCA) of a BECCS Value Chain

Objective: To determine the net carbon balance and ANS of a specific BECCS project. Methodology:

- Goal & Scope: Define functional unit (e.g., 1 MWh net electricity delivered, 1 t CO₂ stored). Set system boundaries (cradle-to-grave).

- Inventory Analysis (LCI):

- Biomass Cultivation: Collect data on fertilizer use, fuel for machinery, N₂O emissions, and changes in soil carbon stocks.

- Biomass Transport: Log distances, modes (truck, ship), and fuel types.

- Conversion & Capture: Use mass and energy balances from process simulation software (e.g., Aspen Plus) to determine key flows: biomass input, net power output, captured CO₂ stream, solvent/amine demands, and ancillary emissions.

- CO₂ Transport & Storage: Model compression energy, pipeline transport emissions, and injection energy. Include site characterization emissions.

- Impact Assessment (LCIA): Apply the Global Warming Potential (GWP-100) indicator. Sum all CO₂e emissions (positive) and subtract the biogenic CO₂ that is captured and stored (negative). The net result is the ANS per functional unit.

- Sensitivity & Uncertainty Analysis: Use Monte Carlo simulation to propagate uncertainty in key parameters (e.g., iLUC, soil carbon, capture rate).

Protocol for Laboratory-Scale Capture Efficiency Testing

Objective: To empirically determine the capture rate (CR) and energy penalty (EP) for a novel solvent under flue gas conditions simulating biomass combustion. Methodology:

- Apparatus Setup: Construct a bench-scale absorber-stripper unit. Install online gas analyzers (NDIR for CO₂) at absorber inlet, outlet, and stripper outlet. Precisely control gas flow, temperature, and solvent circulation rates.

- Simulated Flue Gas Preparation: Mix gases to match the composition of biomass-derived flue gas (~12-15% CO₂, balanced with N₂, O₂, and trace SOx/NOx).

- Baseline Operation: Use a standard solvent (e.g., 30 wt% MEA) to establish baseline performance. Measure CO₂ concentration in and out of the absorber to calculate baseline capture rate. Measure thermal energy input to the reboiler.

- Novel Solvent Testing: Repeat with the novel solvent under identical conditions.

- Data Calculation:

- Capture Rate: CR = (CO₂in - CO₂out) / CO₂_in.

- Specific Reboiler Duty: SRD = Qreboiler / mCO₂ captured.

- Compare SRD between solvents to determine relative energy penalty.

Diagram Title: LCA Workflow for BECCS Net Sequestration

Diagram Title: Bench-Scale Carbon Capture Unit Flow

The Scientist's Toolkit: Research Reagent Solutions & Key Materials

Table 4: Essential Materials for BECCS Research

| Item | Function in Research | Example/Note |

|---|---|---|

| Process Simulation Software | Modeling mass/energy balances, optimizing plant design, and estimating performance parameters. | Aspen Plus, gPROMS, DWSIM. |

| Life Cycle Inventory Database | Providing background emissions data for supply chain components (e.g., fertilizers, diesel, electricity). | Ecoinvent, GREET, GaBi databases. |

| Lab-Scale Absorber-Stripper Rig | Empirically testing novel solvents or adsorbents for capture efficiency and energy penalty. | Custom-built or commercially available bench-scale units. |

| Online Gas Analyzers | Precisely measuring CO₂ concentrations in gas streams for capture rate calculations. | NDIR (Non-Dispersive Infrared) analyzers. |

| Novel Solvents/Sorbents | Researching materials with lower energy penalties and degradation rates than standard amines. | Ionic liquids, phase-change solvents, metal-organic frameworks (MOFs). |

| Soil Carbon Modeling Tools | Estimating changes in soil organic carbon (SOC) from biomass cultivation, critical for net carbon accounting. | IPCC Tier 1/2 methods, process-based models like DayCent or RothC. |

| Geological Reservoir Simulators | Modeling the fate of injected CO₂, predicting plume migration, and assessing leakage risks. | TOUGH2, Eclipse, CMG-GEM. |

The financial and environmental viability of Bioenergy with Carbon Capture and Storage (BECCS) is critical to its deployment as a carbon-negative technology. A core component of this assessment is the Payback Period (PBP), which determines the time required to recoup an initial investment. This technical guide details the static and dynamic calculation models for PBP, framing them within the broader thesis of evaluating when a BECCS project achieves its "carbon investment" payback—the point at which net carbon removal begins after accounting for the embedded emissions of construction and operation.

Core Formulae and Calculation Models

Static (Non-Discounted) Payback Period

The static model calculates PBP without considering the time value of money or discount rates. It is simpler but less accurate for long-term projects like BECCS.

Formula:

Static PBP = Initial Investment / Annual Net Cash Flow

- Initial Investment: Total capital expenditure (CAPEX) for the BECCS facility.

- Annual Net Cash Flow: Annual revenue (from energy sales, carbon credits) minus annual operating costs (OPEX).

Table 1: Example Static PBP Calculation for a Hypothetical BECCS Pilot

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Total Initial Investment (CAPEX) | 25,000,000 | USD | Includes capture unit, storage, biomass preprocessing. |

| Annual Revenue | 5,500,000 | USD/yr | From electricity and carbon removal credits. |

| Annual Operating Cost (OPEX) | 3,000,000 | USD/yr | Biomass fuel, maintenance, labor. |

| Annual Net Cash Flow | 2,500,000 | USD/yr | Revenue - OPEX. |

| Static Payback Period | 10.0 | years | 25,000,000 / 2,500,000. |

Dynamic (Discounted) Payback Period

The dynamic model incorporates the time value of money by discounting future cash flows back to their present value. This is essential for BECCS, where cash flows and carbon benefits occur over decades.

Formula:

The dynamic PBP is the time (t) at which the cumulative discounted cash flows equal the initial investment.

Σ [Net Cash Flow_t / (1 + r)^t] = Initial Investment

Where r is the discount rate and t is the time period.

Table 2: Dynamic PBP Calculation (Discount Rate = 5%)

| Year | Annual Net Cash Flow (USD) | Discount Factor (1/(1+0.05)^t) | Discounted Cash Flow (USD) | Cumulative Discounted Cash Flow (USD) |

|---|---|---|---|---|

| 0 | -25,000,000 | 1.0000 | -25,000,000 | -25,000,000 |

| 1 | 2,500,000 | 0.9524 | 2,381,000 | -22,619,000 |

| 2 | 2,500,000 | 0.9070 | 2,267,500 | -20,351,500 |

| ... | ... | ... | ... | ... |

| 13 | 2,500,000 | 0.5303 | 1,325,750 | -1,045,825 |

| 14 | 2,500,000 | 0.5051 | 1,262,750 | 216,925 |

Dynamic Payback Period: Approximately 13.8 years (interpolated from Year 13 and 14 data).

Table 3: Comparison of Payback Models

| Feature | Static Payback Period | Dynamic Payback Period |

|---|---|---|

| Time Value of Money | Ignored. | Incorporated via discount rate. |

| Accuracy for Long-Term Projects (e.g., BECCS) | Low. Overestimates financial attractiveness. | High. Provides a more conservative, realistic view. |

| Calculation Complexity | Simple, single formula. | Requires iterative calculation or financial modeling. |

| Sensitivity | Insensitive to financing costs. | Highly sensitive to the chosen discount rate. |

| Primary Use | Quick, preliminary screening. | Detailed project feasibility and investment analysis. |

Experimental Protocol: Integrating Carbon Payback Analysis

A comprehensive BECCS analysis requires integrating the financial PBP with a carbon PBP—the time to recoup embedded carbon emissions.

Title: Protocol for Coupled Financial and Carbon Payback Analysis of BECCS

Methodology:

- Life Cycle Assessment (LCA) Inventory:

- Quantify the total embedded CO₂-equivalent emissions (kg CO₂e) from the BECCS plant's construction and ongoing operations (Scope 1-3).

- Annual Net Carbon Removal Calculation:

- Measure:

Annual Net CO₂ Removal = (Biogenic CO₂ Captured & Stored) - (Life Cycle Emissions from Operations & Feedstock) - This requires precise monitoring of captured CO₂ and a full LCA for annual inputs.

- Measure:

- Carbon Payback Period Calculation:

Carbon PBP = Total Embedded Emissions (from LCA) / Annual Net Carbon Removal

- Coupled Sensitivity Analysis:

- Model both financial and carbon PBP under varying key parameters (discount rate, carbon credit price, biomass feedstock carbon intensity, plant efficiency).

Diagram: BECCS Payback Period Analysis Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials & Tools for BECCS Payback Research

| Item / Solution | Function in Analysis | Technical Specification / Example |

|---|---|---|

| Life Cycle Inventory (LCI) Database | Provides emission factors for materials, energy, and processes to calculate embedded carbon. | Ecoinvent, GaBi Databases, or region-specific government LCI data. |

| Process Modeling Software | Models BECCS plant efficiency, energy output, and capture rates for cash flow and carbon removal projections. | Aspen Plus, gPROMS, or open-source tools like DWSIM. |

| Financial Modeling Platform | Performs dynamic discounted cash flow analysis and sensitivity testing. | Microsoft Excel with precision add-ins, Python (Pandas, NumPy), or specialized software like @RISK. |

| Carbon Accounting Protocol | Standardized method for calculating net carbon removal, ensuring credibility. | IPCC Guidelines for National Greenhouse Gas Inventories, ISO 14064, or the GHG Protocol. |

| Sensitivity & Monte Carlo Analysis Tool | Quantifies uncertainty in PBP outcomes by varying multiple input parameters simultaneously. | Integrated in @RISK, Palisade DecisionTools, or programmed in R/Python. |

| Geospatial Analysis Data | Assesses feedstock supply chain emissions and transportation costs, critical for accurate OPEX and carbon LCA. | GIS data on biomass availability, road/rail networks, and soil carbon stocks. |

This whitepaper, framed within a broader thesis on BECCS carbon neutrality and payback period analysis, provides a technical guide for integrating Bioenergy with Carbon Capture and Storage (BECCS) into the energy-intensive operations of research laboratories, particularly those involved in pharmaceutical development. It addresses the tripartite energy demand—heat, power, and process steam—common in such facilities and evaluates BECCS as a pathway to achieve negative emissions while meeting rigorous operational requirements.

Laboratories, especially in drug discovery and life sciences, are energy-intensive per unit area. Autoclaves, glassware washers, environmental chambers, and distillation columns create significant baseload demands for process steam and heat, alongside stable electrical power for sensitive instrumentation. Integrating BECCS involves using sustainably sourced biomass (e.g., wood chips, energy crops, agricultural residues) in a combined heat and power (CHP) or boiler system, with post-combustion carbon capture, to meet these profiles. This synergy can transform labs from net carbon sources to net carbon sinks, a critical consideration for research institutions committing to carbon neutrality.

Quantifying Laboratory Energy Profiles

A laboratory's energy profile must be characterized before BECCS integration. Key demands are summarized below.

Table 1: Typical Energy Demand Profile for a Mid-Scale Pharmaceutical Research Laboratory

| Energy Vector | Primary Uses in Lab | Typical Demand (kWh/m²/yr)* | Load Characteristics |

|---|---|---|---|

| Heat (Low-Temp) | Space heating, water heating, incubators | 300 - 500 | Seasonal, steady baseload |

| Process Steam | Autoclaves, sterilizers, glassware washers, reactors | 200 - 400 | Intermittent, high-grade (120-150°C) |

| Electrical Power | Fume hoods, HVAC, analytical instruments (HPLC, MS), computing | 500 - 800 | Constant, high-quality, reliable |

*Data synthesized from recent analyses of high-performance lab buildings and industry benchmarks.

BECCS System Configurations for Labs

Two primary configurations are applicable for lab integration:

- BECCS-CHP (Combined Heat & Power): A biomass gasifier or boiler drives a steam turbine or Stirling engine, generating electricity. Waste heat is recovered for space heating and to raise process steam. Flue gas is routed to the capture unit.

- Biomass Boiler with Capture: A dedicated biomass boiler produces high-pressure steam. This steam can be used directly for process needs, for heating via heat exchangers, or to drive a turbine for power. Capture is applied to the boiler exhaust.

The choice depends on the ratio of power to heat/steam demand, space constraints, and capital availability.

Carbon Capture Integration: Amine Scrubbing for Lab-Scale BECCS

Post-combustion capture using amine-based solvents is the most readily deployable technology for integration with a lab biomass system.