Agricultural Residue BECCS: A Viable Path to Negative Emissions and Bioenergy Security

This article examines Bioenergy with Carbon Capture and Storage (BECCS) utilizing agricultural residues as a critical, yet complex, pathway for achieving negative emissions.

Agricultural Residue BECCS: A Viable Path to Negative Emissions and Bioenergy Security

Abstract

This article examines Bioenergy with Carbon Capture and Storage (BECCS) utilizing agricultural residues as a critical, yet complex, pathway for achieving negative emissions. Tailored for researchers and sustainability scientists, it explores the foundational science of residue conversion, details current capture methodologies, addresses technical and supply chain challenges, and validates performance through comparative life-cycle and techno-economic analyses. The synthesis provides a comprehensive roadmap for integrating agricultural waste into climate mitigation strategies, highlighting key research gaps and implementation priorities.

The Science and Promise of Agricultural Waste in Carbon-Negative Systems

This application note provides a standardized framework for characterizing agricultural residue feedstocks within Bioenergy with Carbon Capture and Storage (BECCS) research. Accurate definition of feedstock type, availability, and carbon content is fundamental for modeling carbon negativity, designing conversion processes, and assessing global scalability.

Types and Characterization of Key Residues

Agricultural residues are classified as primary (field residues like stalks) or secondary (processing residues like husks). Key feedstocks for thermochemical BECCS pathways (e.g., gasification, pyrolysis) include:

Cereal Straws: Wheat, rice, maize, and barley straws are predominant. They exhibit high cellulose/hemicellulose content and moderate ash. Stover: Corn and maize stover, consisting of cobs, leaves, and stalks, are bulkier with variable moisture. Husks & Shells: Rice husks, nut shells (e.g., coconut, almond) have higher lignin and ash (especially silica in rice husk). Bagasse: Fibrous matter from sugarcane processing, with high moisture at point of generation. Prunings: From perennial crops (e.g., olive, vine) are seasonal and heterogeneous.

Global Availability and Carbon Content Data

Quantitative data on annual global production (residue-to-product ratio based) and characteristic carbon content are summarized. Values are estimated means; local variability is significant.

Table 1: Global Annual Availability & Carbon Content of Key Residues

| Feedstock Type | Estimated Global Annual Production (Million tonnes, dry basis) | Typical Carbon Content (% dry basis) | Key Producing Regions |

|---|---|---|---|

| Rice Straw | 550 - 750 | 38 - 42 | Asia (China, India, SE Asia) |

| Wheat Straw | 450 - 600 | 40 - 45 | Asia, Europe, North America |

| Maize Stover | 400 - 600 | 42 - 47 | North America, Asia, South America |

| Sugarcane Bagasse | 180 - 250 | 45 - 50 | Brazil, India, China |

| Rice Husk | 120 - 180 | 35 - 40 | Asia (China, India, SE Asia) |

| Barley Straw | 80 - 120 | 40 - 44 | Europe, Russia, Australia |

| Nut Shells (Aggregate) | 15 - 30 | 48 - 55 | Varied (Asia, Americas) |

Note: Availability considers sustainable removal rates (typically 30-70% of total residue to protect soil health). Data synthesized from FAOStat, IEA Bioenergy reports, and recent literature (2022-2024).

Table 2: Proximate & Ultimate Analysis Ranges for BECCS Modeling

| Feedstock | Fixed Carbon (% db) | Volatile Matter (% db) | Ash (% db) | HHV (MJ/kg db) | N (% db) |

|---|---|---|---|---|---|

| Wheat Straw | 15 - 20 | 70 - 75 | 4 - 8 | 16 - 18 | 0.5 - 0.8 |

| Rice Husk | 18 - 23 | 60 - 65 | 15 - 22 | 14 - 16 | 0.3 - 0.6 |

| Maize Stover | 16 - 21 | 71 - 76 | 5 - 9 | 17 - 18.5 | 0.6 - 1.0 |

| Sugarcane Bagasse | 14 - 18 | 74 - 78 | 2 - 6 | 17 - 19 | 0.2 - 0.4 |

Experimental Protocols for Feedstock Characterization

Protocol 4.1: Determination of Sustainable Availability at Regional Scale

Objective: To estimate technically and sustainably harvestable residue for a given crop in a defined region. Materials: Regional crop production data (FAO/National stats), GIS software, soil type maps, residue-to-product ratios (RPR) from literature. Method:

- Acquire annual crop yield data (tonne/ha) for the target region for a 5-year average.

- Apply region-specific RPR (e.g., 1.4 for maize stover, 1.2 for wheat straw) to calculate total residue generated.

- Apply sustainability constraint factors: Determine fraction removable based on soil organic carbon maintenance, erosion prevention, and agronomic use. Use model-based factors (e.g., 0.4 for erosion-prone land, 0.7 for low-risk land).

- Calculate technically recoverable residue by applying machinery recovery efficiency factors (typically 0.6-0.8).

- Output: Map or table of sustainably harvestable dry tonne/year per sub-region.

Protocol 4.2: Standardized Feedstock Sampling & Preparation (ISO/ASTM Based)

Objective: To obtain a representative, homogeneous sample for compositional analysis. Materials: Sample bags (paper, breathable), jaw crusher, rotary mill (with sieve sets), desiccator, moisture analyzer, sample dividers. Method:

- Field Sampling: For field residues, use a randomized quadrant sampling method across the field. Collect minimum 10 sub-samples (≥1 kg each). Combine into a gross sample.

- Air Drying: Dry gross sample in a ventilated oven at ≤40°C until moisture <15% to prevent biodegradation.

- Size Reduction & Homogenization: Coarse crush to <10 mm. Use a coning and quartering or mechanical sample divider to obtain a representative lab sample (~500g). Mill a subset to <0.5 mm for chemical analysis, and <1.0 mm for thermal analysis.

- Storage: Store milled samples in airtight containers in a desiccator or freezer to prevent moisture uptake and degradation.

Protocol 4.3: Determination of Carbon Content via Elemental (Ultimate) Analysis

Objective: To accurately measure the total carbon mass fraction in the feedstock. Materials: Elemental analyzer (CHNS/O), tin/capsule sample cups, certified reference material (e.g., acetanilide), high-purity gases (He, O2), microbalance (0.001 mg accuracy). Method:

- Calibration: Weigh ~2-3 mg of certified reference material into a tin cup. Run 3-5 replicates to establish calibration curve for carbon detection.

- Sample Preparation: Pre-dry milled sample at 105°C for 2 hrs. Cool in desiccator. Precisely weigh 2-3 mg of dried sample into a tin cup. Crimp tightly.

- Combustion & Analysis: Load sample into the auto-sampler. The analyzer combusts the sample at ~1000°C in oxygen, reduces combustion gases, and separates/quantifies CO2 via gas chromatography/thermal conductivity detection.

- Calculation: The instrument software reports carbon content as a percentage of the dry sample mass based on the calibration curve. Report mean of triplicate analyses with standard deviation.

- QA/QC: Include a blank and a check standard every 10 samples. Recovery for the check standard should be within 98-102%.

Visualization of Workflows and Relationships

Feedstock Characterization Workflow for BECCS Research

Feedstock Screening for Thermochemical BECCS Pathways

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Reagents and Materials for Feedstock Analysis

| Item Name | Specification / Example | Primary Function in Protocol |

|---|---|---|

| Elemental Analyzer Standards | Acetanilide, BBOT, Aspartic Acid | Calibration and verification of carbon, hydrogen, nitrogen, and sulfur measurements. |

| Ash Crucibles | Porcelain or platinum, high-form | Used in proximate analysis for determination of ash content via muffle furnace combustion. |

| Anhydrous Magnesium Perchlorate [Desiccant] | ACS grade, for desiccators | Maintains a dry environment for cooling and storing moisture-sensitive samples after drying. |

| Inert Sample Cups | Tin or Silver capsules for CHNS | Encapsulation of solid samples for complete and controlled combustion in the elemental analyzer. |

| Certified Reference Biomass | NIST SRM 849x series (e.g., Poplar) | Quality control material to validate the accuracy of proximate, ultimate, and compositional analyses. |

| Silica Gel | Indicating, 2-5 mm mesh | Desiccant for storage of prepared samples to prevent moisture uptake prior to analysis. |

| Sieve Set | ASTM E11 Standard, 0.5mm & 1.0mm apertures | Standardized particle size reduction for homogeneous sub-sampling and representative analysis. |

| Extraction Thimbles | Cellulose, Soxhlet extraction | Used in solvent extraction protocols for determination of extractives content (e.g., ASTM D1105). |

Application Notes: BECCS with Agricultural Residues

Bioenergy with Carbon Capture and Storage (BECCS) is a negative emissions technology central to IPCC climate mitigation pathways. When applied to agricultural residues (e.g., corn stover, wheat straw, rice husks), it leverages recently fixed atmospheric CO₂, which, when combined with carbon capture during energy conversion and subsequent geological storage, results in net carbon removal.

Key Feedstock Characteristics & Availability

The viability of agricultural residue-based BECCS hinges on sustainable harvest rates, logistics, and biochemical composition affecting conversion efficiency.

Table 1: Global Annual Availability and Characteristics of Major Agricultural Residues

| Residue Type | Estimated Global Annual Availability (Mt dry matter) | Sustainable Harvestable Fraction (%) | Average Lower Heating Value (MJ/kg) | Average Carbon Content (% dry basis) |

|---|---|---|---|---|

| Corn Stover | 1280 | 30-50 | 17.5 | 45-48 |

| Wheat Straw | 1050 | 30-40 | 17.2 | 44-47 |

| Rice Husk | 770 | 60-80 | 15.5 | 38-42 |

| Sugarcane Bagasse | 540 | 70-90 | 18.0 | 46-49 |

Sources: IEA Bioenergy (2023), IPCC AR6 (2022), recent global biomass assessments.

Net Carbon Removal Potential

The net removal is calculated as: Captured CO₂ from flue gas minus Supply chain emissions minus Indirect Land-Use Change (iLUC) emissions.

Table 2: Estimated Carbon Removal Potential per Feedstock Type

| Feedstock | System Boundary | Estimated Net CO₂ Removal (tCO₂/t dry feedstock) | Key Uncertainties & Notes |

|---|---|---|---|

| Corn Stover | Farm-to-Storage | 0.6 - 0.9 | Highly sensitive to soil carbon repayment from removal. |

| Wheat Straw | Farm-to-Storage | 0.5 - 0.8 | Dependent on residue management practices. |

| Rice Husk | Farm-to-Storage | 0.8 - 1.1 | Higher ash content challenges conversion efficiency. |

| Sugarcane Bagasse | Farm-to-Storage | 0.9 - 1.2 | Often considered a processing byproduct, lower iLUC risk. |

Note: Ranges reflect variations in supply chain efficiency, capture rate (85-95%), and geological storage integrity.

Experimental Protocols

Protocol: Life Cycle Assessment (LCA) for BECCS System Analysis

Objective: Quantify the net greenhouse gas (GHG) balance of a BECCS value chain using a specific agricultural residue.

Methodology:

- Goal & Scope Definition: Define functional unit (e.g., 1 MWh electricity or 1 t dry feedstock). Set system boundaries (cradle-to-grave: cultivation, harvest, transport, pre-treatment, conversion, CCS, storage).

- Inventory Analysis (LCI):

- Feedstock Production: Collect data on fertilizer inputs, diesel for harvesting, and changes in soil organic carbon (SOC) using models like DAYCENT or IPCC Tier 2 methods.

- Logistics: Model transport distances, modes, and energy use for collection, densification, and delivery.

- Conversion & CCS: Use process simulation software (e.g., Aspen Plus) for a biomass-fired power plant with post-combustion amine-based capture (e.g., 30 wt% MEA). Obtain mass/energy balances. Include capture solvent manufacturing and degradation.

- Storage: Model pipeline transport and injection energy. Assume 99% permanence over 1000 years.

- Impact Assessment: Calculate Global Warming Potential (GWP) using IPCC AR6 factors. Net CO₂ removal = (Biogenic CO₂ captured + stored) - (Total supply chain GHG emissions).

- Interpretation & Sensitivity Analysis: Test sensitivity to key parameters: SOC change, capture rate, grid electricity carbon intensity, and transport distance.

Protocol: Laboratory-Scale Biomass Gasification with Syngas CO₂ Capture

Objective: Determine the CO₂ yield and capture efficiency from the gasification of milled agricultural residue.

Materials: See Scientist's Toolkit. Procedure:

- Feedstock Preparation: Dry feedstock at 105°C for 24h. Mill and sieve to 500-800 µm.

- Gasification: Load 100g feedstock into a fluidized-bed gasifier reactor. Purge with N₂. Heat to 850°C under controlled N₂ flow (1 L/min). Introduce steam (0.5 kg/h) as gasification agent.

- Syngas Conditioning: Pass raw syngas through a series of condensers (0°C) and filters (glass wool, 5 µm) to remove tars and particulate matter.

- CO₂ Capture Unit: Direct cleaned syngas into a packed-bed absorption column (height: 50 cm, diameter: 5 cm) containing 500 mL of 3M Monoethanolamine (MEA) solution at 40°C. Operate in counter-current flow mode.

- Measurement & Analysis:

- Online Gas Analysis: Use inline NDIR CO₂ sensor pre- and post-absorption column to measure CO₂ concentration continuously.

- Capture Efficiency Calculation: Record volumetric flow rates and concentrations. Calculate: Capture Efficiency (%) = [(CO₂in - CO₂out) / CO₂_in] * 100.

- Solvent Regeneration: Heat rich solvent to 120°C in a separate flask to desorb CO₂. Measure desorbed CO₂ volume using a gasometer.

- Data Recording: Record temperature, pressure, flow rates, and CO₂ concentrations at 5-minute intervals for a minimum of 1 hour of stable operation.

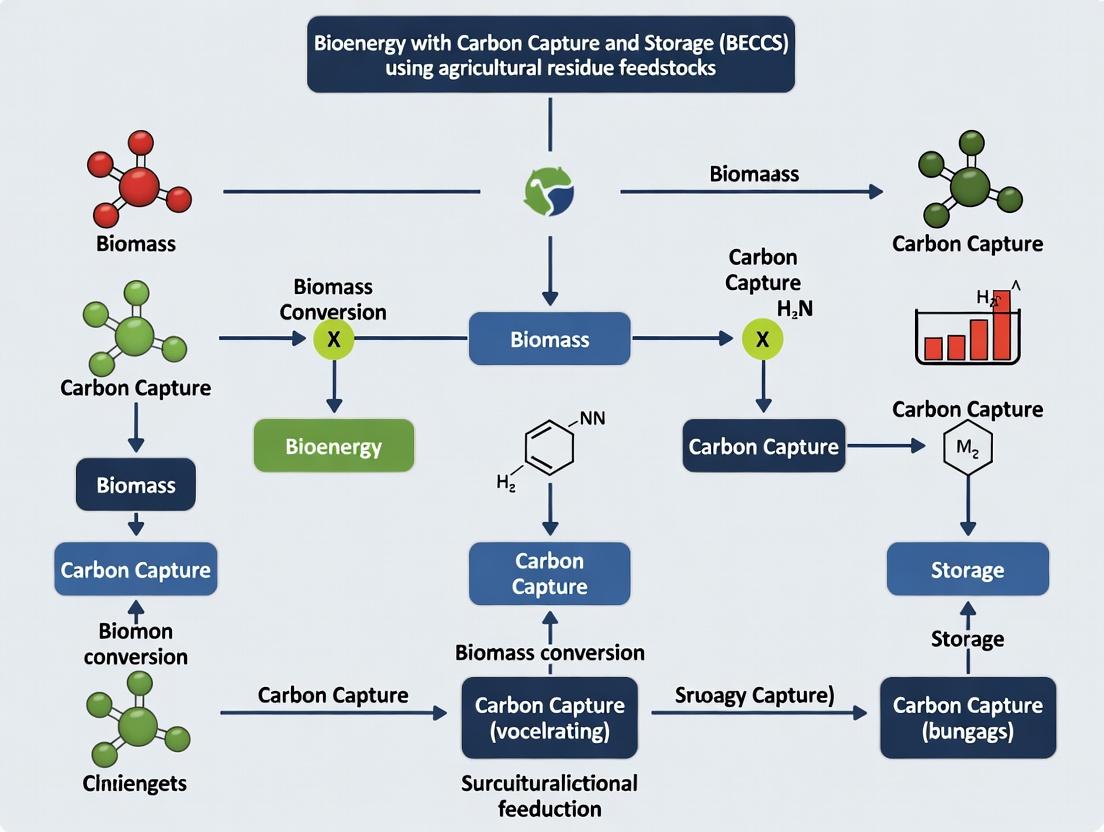

Visualizations

BECCS Carbon Flow from Biomass to Storage

LCA Workflow for BECCS Carbon Accounting

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for BECCS Laboratory Research

| Item / Reagent | Function & Application | Example Vendor / Specification |

|---|---|---|

| Milled Agricultural Residue | Standardized feedstock for gasification/pyrolysis experiments. Particle size critical for kinetics. | In-house prepared, sieved to 500-800 µm. |

| Monoethanolamine (MEA) Solution | Benchmark solvent for post-combustion CO₂ capture in absorption/desorption experiments. | Sigma-Aldrich, 30 wt% in H₂O, reagent grade. |

| Fluidized Bed Gasifier (Lab-Scale) | Enables controlled thermochemical conversion of biomass under various atmospheres (steam, O₂). | Custom or from specialist manufacturers (e.g., Carbolite Gero). |

| Online NDIR CO₂ Analyzer | Real-time measurement of CO₂ concentration in gas streams pre- and post-capture. | Vaisala CARBOCAP or Siemens Ultramat 23. |

| Aspen Plus Process Simulator | Software for modeling mass/energy balances of full-scale BECCS plant configurations. | AspenTech. |

| Soil Organic Carbon (SOC) Model | Quantifies carbon debt from residue removal (critical for LCA). | DAYCENT model or IPCC Inventory Software. |

Within the strategic framework of Bioenergy with Carbon Capture and Storage (BECCS), the utilization of agricultural residues as feedstocks presents a critical pathway for achieving negative carbon emissions. While corn stover and rice husks are well-characterized, a broader array of underutilized residue streams offers significant potential to enhance biomass availability, diversify supply chains, and improve the sustainability profile of BECCS systems. This application note details the characterization, pre-treatment, and conversion protocols for three such underutilized residues: tomato vine waste, cocoa pod husk, and artichoke threshing residue.

Feedstock Characterization: Quantitative Analysis

Recent analyses (2023-2024) of underutilized residues reveal compositional data critical for predicting conversion efficiency and bioenergy yield in BECCS processes. The data is summarized in the table below.

Table 1: Proximate and Ultimate Analysis of Selected Underutilized Residues

| Feedstock | Lignin (% Dry Basis) | Cellulose (% Dry Basis) | Hemicellulose (% Dry Basis) | Ash Content (% Dry Basis) | Higher Heating Value (MJ/kg) | C/N Ratio |

|---|---|---|---|---|---|---|

| Tomato Vine | 18.2 ± 1.5 | 32.5 ± 2.1 | 16.8 ± 1.3 | 10.5 ± 0.8 | 17.1 ± 0.3 | 28:1 |

| Cocoa Pod Husk | 24.7 ± 2.0 | 28.4 ± 1.8 | 20.3 ± 1.5 | 8.3 ± 0.7 | 16.3 ± 0.4 | 35:1 |

| Artichoke Threshing Residue | 15.1 ± 1.2 | 35.8 ± 2.3 | 22.5 ± 1.6 | 14.2 ± 1.0 | 15.8 ± 0.3 | 25:1 |

| Corn Stover (Reference) | 17-21 | 35-40 | 20-25 | 4-6 | 17.5-18.5 | ~40:1 |

Source: Compiled from recent studies in 'Biomass and Bioenergy' and 'Waste and Biomass Valorization' (2023-2024).

Experimental Protocols

Protocol 3.1: Standardized Feedstock Pre-treatment for Enzymatic Saccharification

Objective: To prepare underutilized residues for optimal sugar release via enzymatic hydrolysis, a key step for subsequent fermentation to bioethanol (with integrated carbon capture).

Materials:

- Dried, milled residue (<2 mm particle size).

- Dilute sulfuric acid (1-3% w/w) or sodium hydroxide solution (2% w/w).

- Autoclave or pressurized heating reactor.

- Vacuum filtration setup.

- pH meter and neutralization chemicals (Ca(OH)₂ or H₂SO₄).

- Deionized water.

Methodology:

- Loading: Charge 10g of dry biomass into a 500 mL reactor vessel.

- Impregnation: Add pre-mixed acid or alkali solution at a 10:1 liquid-to-solid ratio.

- Reaction: Seal reactor and heat to 160°C (for acid) or 120°C (for alkali) for 30 minutes under autogenous pressure.

- Quenching & Recovery: Rapidly cool reactor to 50°C. Filter the slurry through a Büchner funnel.

- Washing & Neutralization: Wash solid fraction thoroughly with deionized water until effluent pH is neutral. Record mass of recovered solid (pretreated biomass).

- Analysis: Analyze solid for compositional change (per Table 1 methods) and store at 4°C for hydrolysis.

Protocol 3.2: High-Throughput Enzymatic Hydrolysis & Sugar Yield Assay

Objective: To quantitatively evaluate the saccharification potential of pretreated residues.

Materials:

- Pretreated biomass (from Protocol 3.1).

- Commercial cellulase/hemicellulase cocktail (e.g., CTec3).

- Sodium citrate buffer (50 mM, pH 4.8).

- 96-well deep-well plates and orbital shaker incubator.

- DNS (3,5-dinitrosalicylic acid) reagent or HPLC for sugar quantification.

Methodology:

- Slurry Preparation: Dispense 100 mg (dry weight equivalent) of pretreated biomass into each well.

- Enzyme Loading: Add sodium citrate buffer to achieve 2% (w/v) solids concentration. Add enzyme cocktail at a loading of 20 mg protein/g glucan.

- Incubation: Seal plates and incubate at 50°C with continuous agitation at 150 rpm for 72 hours.

- Sampling: At 0, 6, 24, 48, and 72 hours, remove 100 µL aliquots, centrifuge, and collect supernatant.

- Quantification: Analyze supernatant glucose and xylose concentration using HPLC (Gold standard) or a calibrated DNS assay. Calculate yield as g sugar per 100g raw dry biomass.

Signaling & Process Pathways

Title: BECCS Pathway for Underutilized Agricultural Residues

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Residue Conversion Research

| Item | Function/Benefit | Example/Notes |

|---|---|---|

| CTec3 / HTec3 Enzyme Cocktails | High-efficiency cellulase/hemicellulase blends for saccharification of pretreated lignocellulose. | Novozymes. Critical for quantifying achievable sugar yields. |

| YPD Broth / Agar | Medium for cultivation of fermentative microorganisms (e.g., S. cerevisiae, engineered strains). | Supports bioethanol production trials from hydrolysates. |

| Dionex CarboPac PA1 Column | HPLC column for precise separation and quantification of monomeric sugars (glucose, xylose, arabinose). | Essential for accurate saccharification yield data. |

| 3,5-Dinitrosalicylic Acid (DNS) Reagent | Colorimetric assay for quantifying reducing sugars in hydrolysates. | Rapid, high-throughput screening tool. |

| Lignin Reference Standard (Kraft Lignin) | Standard for calibrating lignin content analysis (e.g., Klason method). | Necessary for compositional analysis. |

| Anaerobic Chamber Gloves/Bags | Maintains anoxic conditions for sensitive fermentation or microbial consortium studies. | Crucial for simulating industrial bioreactor conditions. |

| Solid Residue Sampling Kit | Includes moisture meters, portable grinders, and sterile containers. | Ensures representative and stable field sampling of residues. |

Geospatial Analysis of Residue Availability and Proximity to Storage Sites

Abstract Within the broader thesis on Bioenergy with Carbon Capture and Storage (BECCS) utilizing agricultural residues, this protocol details a geospatial methodology to quantify feedstock availability and optimize pre-processing storage site locations. It provides a replicable framework for integrating disparate data sources—satellite imagery, agricultural statistics, and logistical parameters—into a decision-support model, crucial for supply chain feasibility studies in BECCS deployment.

Application Note: Geospatial Data Integration for BECCS Feedstock Logistics

Objective: To model the spatial and temporal distribution of agricultural residue biomass and identify optimal storage hub locations to minimize transport costs and feedstock degradation for a BECCS facility.

Core Datasets & Pre-processing Protocol Table 1: Primary Geospatial and Statistical Data Requirements

| Data Layer | Source Example | Key Attributes | Pre-processing Step |

|---|---|---|---|

| Land Use/Land Cover (LULC) | USGS Landsat, ESA Sentinel-2 | Crop type classification, harvest dates | Supervised classification (Random Forest) to map residue-producing crops (e.g., corn, wheat). |

| Agricultural Yield Statistics | USDA NASS, FAO STAT | County/district-level crop production (bu/acre, ton/ha) | Spatial disaggregation (dasymetric mapping) using LULC raster to create high-resolution yield maps. |

| Residue-to-Production Ratio (RPR) | Literature Review (e.g., NREL) | Crop-specific coefficients (e.g., Corn Stover: 1.0 dry ton/acre) | Application of RPR to yield maps to generate theoretical residue availability raster. |

| Road Network | OpenStreetMap, TIGER/Line | Road type, speed limit, tolls | Network topology creation, impedance assignment (travel time/cost per segment). |

| Digital Elevation Model (DEM) | SRTM, ASTER GDEM | Elevation, slope | Calculate terrain difficulty factor for transport cost models. |

| Existing Infrastructure | GIS Databases | Location of potential storage sites (e.g., former granaries), protected lands | Buffer analysis to exclude environmentally sensitive areas. |

Key Experimental Workflow: Network Analysis for Site Suitability Protocol 1: Cost-Weighted Distance and Service Area Analysis

- Data Preparation: Convert the residue availability raster to point features representing biomass concentration centroids. Load the road network and potential storage sites as vector layers.

- Network Impedance Modeling: Using GIS software (e.g., ArcGIS Pro, QGIS), assign a cost per unit length to each road segment based on type (e.g., highway, local road) and slope-derived terrain difficulty. Define average truck speed and operating cost for each class.

- Service Area Calculation: For each candidate storage site, run a Network Analysis to determine all biomass points reachable within a specified maximum transport cost or time (e.g., $10/dry ton, 45 minutes). This defines the site's feedstock procurement basin.

- Biomass Aggregation: Sum the available residue tonnage from all points within each procurement basin. This provides the total serviceable feedstock for each candidate site.

- Multi-Criteria Decision Analysis (MCDA): Rank candidate sites using a weighted suitability model (Table 2).

Table 2: MCDA Criteria for Storage Site Selection

| Criterion | Weight (%) | Measurement | Objective |

|---|---|---|---|

| Total Serviceable Feedstock (tons/yr) | 35 | Sum within procurement basin | Maximize |

| Average Transport Cost ($/ton) | 30 | Cost-weighted distance from all serviceable points | Minimize |

| Site Acreage (hectares) | 20 | Area available for storage and handling | Maximize |

| Proximity to Major Roads (km) | 15 | Euclidean distance to nearest highway | Minimize |

Diagram Title: Geospatial Workflow for Biomass Storage Siting

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Software & Data Tools for Geospatial BECCS Analysis

| Item / Solution | Function / Role | Example / Vendor |

|---|---|---|

| GIS Platform | Core software for spatial data manipulation, analysis, and cartography. | ArcGIS Pro, QGIS (Open Source) |

| Remote Sensing Software | Processes satellite imagery for crop classification and change detection. | ENVI, Google Earth Engine |

| Network Analyst Extension | Performs network-based routing, service area, and closest facility analysis. | ArcGIS Network Analyst, QGIS pgRouting |

| Spatial Analyst Extension | Conducts raster calculations (e.g., yield disaggregation, cost surfaces). | ArcGIS Spatial Analyst, QGIS Raster Calculator |

| Python (geopandas, arcpy) | Automates repetitive geospatial workflows and data processing pipelines. | Jupyter Notebook, IDE (VS Code, PyCharm) |

| Agricultural Statistics API | Programmatic access to current and historical crop production data. | USDA Quick Stats API, FAO API |

Experimental Protocol: Field Validation of Residue Estimates

Protocol 2: Ground-Truthing and Model Calibration

- Stratified Random Sampling: Based on the residue availability raster, stratify the study area into high, medium, and low availability zones. Randomly generate at least 30 sample points per stratum.

- Field Measurement: At each sample point (within a homogenous field), establish a 1m x 1m quadrant post-harvest.

- Collect all above-ground residue within the quadrant.

- Oven-dry samples at 70°C until constant weight to determine dry matter content.

- Calculate dry tons per acre/hectare.

- Model Calibration: Statistically compare field-measured residue values with model-predicted values at the sample coordinates using linear regression. Use the regression parameters to calibrate (adjust) the initial RPR coefficients, improving the model's predictive accuracy.

Diagram Title: Field Validation Protocol for Residue Models

Fundamental Thermochemical vs. Biochemical Conversion Pathways for Residues

This application note details the experimental characterization of thermochemical and biochemical conversion pathways for agricultural residues (e.g., corn stover, wheat straw) within a BECCS (Bioenergy with Carbon Capture and Storage) research framework. The objective is to provide a comparative analysis of pathways for generating energy and/or platform chemicals while enabling carbon-negative outcomes through coupled carbon capture. Selection of the optimal pathway is critical for the techno-economic viability and life-cycle assessment of large-scale BECCS deployment.

Table 1: Fundamental Characteristics of Conversion Pathways

| Parameter | Thermochemical Pathway (Gasification/Pyrolysis) | Biochemical Pathway (Anaerobic Digestion/ Fermentation) |

|---|---|---|

| Primary Feedstock Suitability | Lignocellulosic residues; high heterogeneity tolerated. | Residues with high carbohydrate (C5/C6) content; lower lignin preferred. |

| Core Process Drivers | High temperature (300–1200°C), pressure, sometimes catalyst. | Microbial/enzymatic action, mild conditions (20–70°C, ambient pressure). |

| Key Intermediate Products | Syngas (CO, H₂), Bio-oil, Biochar. | Soluble sugars (glucose, xylose), biogas (CH₄, CO₂), organic acids. |

| Typical Final Energy Vectors | Heat, electricity, synthetic fuels (FT diesel, H₂). | Biogas (CH₄), bioethanol, biohydrogen. |

| Process Duration | Seconds to minutes (fast pyrolysis) or hours (slow pyrolysis/gasification). | Days (fermentation) to weeks (anaerobic digestion). |

| Net Carbon Efficiency (Feedstock C to Product C) | 60–85% (Gasification to syngas) | 70–90% (Fermentation to ethanol) |

| Carbon Capture Integration Point | Post-combustion of syngas/biogas, or biochar sequestration. | Pre-combustion from biogas upgrade, or post-fermentation CO₂. |

| Key Challenge for BECCS | Tar formation in syngas; gas cleaning for CCS. | Recalcitrance of lignin; slow hydrolysis rates. |

Table 2: Recent Experimental Yields from Corn Stover (2022-2024 Data)

| Conversion Process | Experimental Condition | Primary Product Yield | CO₂ Stream Purity for Capture |

|---|---|---|---|

| Fast Pyrolysis | 500°C, short vapor residence. | Bio-oil: 60-70 wt.% | Low (dilute in flue gas, post-combustion). |

| Steam Gasification | 750°C, catalyst (Na₂CO₃). | Syngas: 1.5 m³/kg (H₂: 35% vol) | High (pre-combustion, ~30% vol in syngas). |

| Enzymatic Hydrolysis + Fermentation | Pretreatment: Dilute acid. Enzymes: 15 FPU/g. | Bioethanol: 280 L/ton dry matter | High (nearly pure from fermentation off-gas). |

| Anaerobic Digestion | Wet process, 35°C, 30 days. | Biogas: 450 m³/ton VS (CH₄: 55%) | Medium (~45% CO₂ in raw biogas). |

Detailed Experimental Protocols

Protocol 1: Thermochemical – Catalytic Steam Gasification for Enhanced H₂/CO₂ Yield

Objective: To produce a hydrogen-rich syngas with a concentrated CO₂ stream amenable to capture from agricultural residue.

Materials: Milled residue (<2 mm), lab-scale fluidized bed reactor, steam generator, Na₂CO₃ catalyst, gas chromatography (GC-TCD), condensate trap.

Procedure:

- Feedstock Preparation: Dry corn stover to <10% moisture. Impregnate with 10 wt.% Na₂CO₃ solution (catalyst), then re-dry.

- Reactor Setup: Load 200g of catalysed feedstock into reactor. Set temperature to 750°C under N₂ purge (1 L/min).

- Steam Introduction: Initiate steam flow (0.5 g H₂O/min) once temperature stabilizes.

- Gas Sampling & Analysis: After 10 minutes of stable steam flow, connect outlet to condensate trap (to remove tars/water). Collect dry gas sample in a Tedlar bag at 15-minute intervals for 1 hour.

- GC Analysis: Analyze gas samples for H₂, CO, CO₂, CH₄ composition using a calibrated GC-TCD.

- Data Calculation: Calculate syngas yield (m³/kg dry feed) and H₂/CO ratio. The CO₂ concentration in the dry syngas is the pre-combustion capture target.

Protocol 2: Biochemical – High-Solid Enzymatic Hydrolysis & Fermentation with CO₂ Off-Gas Monitoring

Objective: To hydrolyze cellulose/hemicellulose to fermentable sugars and convert them to ethanol while collecting high-purity CO₂.

Materials: Dilute-acid pretreated corn stover, commercial cellulase/hemicellulase cocktail, Saccharomyces cerevisiae strain, bioreactor with off-gas condenser, CO₂ analyzer, HPLC.

Procedure:

- Hydrolysis: Load pretreated stover at 20% solids (w/w) into a bioreactor. Adjust pH to 5.0. Add enzyme cocktail at 15 FPU/g cellulose. Incubate at 50°C with mixing (150 rpm) for 72 hours.

- Fermentation Inoculation: Cool hydrolysate to 32°C. Inoculate with S. cerevisiae at 5 g/L cell density. Seal reactor, connect off-gas line to a cooled condenser and then to a calibrated CO₂ analyzer/mass flow meter.

- Monitoring: Monitor CO₂ evolution rate (g/hour) and total volume for 48-72 hours. Periodically sample broth (1 mL) for HPLC analysis (glucose, xylose, ethanol, inhibitors).

- Product Recovery: At endpoint, centrifuge broth. Distill supernatant to recover ethanol. Calculate ethanol yield (g/g sugar consumed). The logged CO₂ mass is the directly capturable stream.

Visualization of Pathways and Workflows

Diagram Title: BECCS Integration Pathways for Agricultural Residues

Diagram Title: Catalytic Gasification & CO2 Capture Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Residue Conversion Research

| Item Name / Solution | Function in Experiment | Typical Specification / Example |

|---|---|---|

| Cellulase Enzyme Cocktail | Hydrolyzes cellulose to glucose. Essential for biochemical saccharification. | CTec3 or similar; activity ≥ 150 FPU/mL. |

| Na₂CO₃ / K₂CO₃ Catalyst | Catalyzes tar reforming and water-gas shift reaction in gasification, increasing H₂ yield. | ACS grade, >99% purity. |

| Dilute Sulfuric Acid | Standard reagent for pretreatment to solubilize hemicellulose and alter lignin structure. | 1-3% (w/w) solution in water. |

| S. cerevisiae Ethanol Red | Robust yeast strain for hexose fermentation, tolerant to inhibitors. | Genetically defined, lyophilized. |

| Gas Chromatograph with TCD & FID | For precise quantification of syngas components (TCD) and organic compounds (FID). | Agilent 7890B or equivalent with appropriate columns. |

| Anhydrous Ethanol Standard | HPLC calibration for quantification of fermentation ethanol yield. | ≥99.8%, HPLC grade. |

| Tedlar Gas Sample Bags | Inert collection and storage of gas samples for subsequent GC analysis. | 1L volume, PTFE fitting, certified clean. |

| NH₄VO₃ Catalyst (for SCR) | Research into catalytic cleaning of syngas (NOx reduction) pre-combustion/capture. | 99.95% trace metals basis. |

From Field to Storage: Implementing Residue-Based BECCS Systems

Application Notes: Logistics for Agricultural Residue BECCS

Optimizing the supply chain for agricultural residues (e.g., corn stover, wheat straw) is critical for the economic viability and carbon balance of Bioenergy with Carbon Capture and Storage (BECCS). The system's net carbon removal is highly sensitive to logistics emissions. Key phases are interdependent, requiring integrated modeling.

Phase 1: Harvesting & Collection: This initial phase dictates feedstock quality, quantity, and subsequent cost. A multi-pass system (separate grain and residue harvest) is common but incurs higher fuel and labor costs. Single-pass systems, utilizing combined harvesters with residue collection attachments, reduce field operations but may require more sophisticated machinery. Critical decisions include residue removal rate (typically 30-70%) to maintain soil health.

Phase 2: Densification: Low bulk density of residues (~50-80 kg/m³ loose) makes transportation over long distances inefficient. In-field or near-field densification (e.g., baling, pelletization, pyrolysis to bio-oil) increases density (e.g., pellets: ~600 kg/m³). The choice of densification method trades off energy input, cost, and downstream handling ease. Baling (round or square) is standard but results in intermediate density.

Phase 3: Transportation: Models range from direct trucking of bales to centralized depots or biorefineries, to hub-and-spoke systems where multiple satellite storage/densification sites feed a central hub. Transportation emissions (g CO₂e/tonne-km) are a major component of the supply chain footprint. Optimization software is used to determine the most efficient routing and mode (truck, rail).

Integration with BECCS: The entire logistics chain must be analyzed through a Life Cycle Assessment (LCA) lens. Every MJ of fossil fuel used in harvesting, densification, and transport reduces the net carbon negativity of the BECCS operation. Optimal network design minimizes total system cost and emissions per tonne of CO₂ sequestered.

Table 1: Characteristics of Common Densification Methods for Agricultural Residues

| Densification Method | Bulk Density Range (kg/m³) | Typical Energy Input (MJ/tonne) | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| Loose Chop | 50 - 80 | 5 - 15 | Lowest upfront cost | Very high transport cost, storage issues |

| Round Bales | 120 - 180 | 80 - 120 | Well-established, field-storable | Moderate density, manual handling |

| Square Bales | 180 - 250 | 100 - 150 | Efficient stacking & transport | Higher baler cost |

| Pelletization | 550 - 700 | 500 - 800 | Highest density, flows easily | High capital & energy cost |

| Fast Pyrolysis (Bio-oil) | ~1000 (oil equivalent) | 1500 - 3000 (for conversion) | Liquid fuel, easier to transport | Very high conversion loss & cost |

Table 2: GHG Emissions for Transportation Modes (2023 Estimates)

| Transportation Mode | Average GHG Emission Factor (g CO₂e/tonne-km) | Typical Capacity (tonnes) | Effective Radius |

|---|---|---|---|

| Class 8 Truck | 62 - 85 | 20 - 25 | < 200 km |

| Rail Transport | 22 - 30 | 2000 - 3000 | > 200 km |

| Barge Transport | 15 - 22 | 5000+ | Along waterways |

Experimental Protocols

Protocol 1: Field Measurement of Sustainable Residue Removal Rate Objective: To determine the maximum residue removal rate that preserves soil organic carbon (SOC) for a specific crop and soil type. Materials: Quadrat frame (1m x 1m), precision scale, drying oven, soil corer, soil test kits for SOC. Procedure:

- Post-harvest, randomly place at least 10 quadrats per test field.

- Manually collect all residue within each quadrat.

- Weigh residue, then dry at 70°C to constant weight for dry mass.

- Calculate total residue yield per hectare.

- Using paired plots, remove 30%, 50%, and 70% of this calculated yield. Leave control plots with no removal.

- Annually, using a soil corer, take 0-30 cm soil samples from each plot.

- Analyze SOC content using dry combustion (e.g., CN analyzer).

- Monitor SOC trends over 3-5 years to establish a sustainable removal threshold.

Protocol 2: Life Cycle Assessment (LCA) of a Logistics Pathway Objective: To calculate the gate-to-gate GHG emissions for supplying 1 dry tonne of residue to a BECCS biorefinery. System Boundaries: From standing residue in field to receipt at biorefinery preprocessing hopper. Procedure:

- Define Scenario: Specify harvest method (single/multi-pass), baler type (round/square), transport distance, and mode.

- Collect Inventory Data: a. Fuel consumption (liters/ha) for harvesting, raking, baling. b. Diesel consumption for in-field equipment (l/tonne). c. Transport distance (km) and truck payload (tonnes). d. Electricity use (kWh/tonne) for any stationary densification.

- Apply Emission Factors: Convert all energy inputs to CO₂e using current databases (e.g., GREET model factors). Use Table 2 for transport.

- Calculate: Sum emissions from all unit operations. Express result as kg CO₂e per dry tonne of delivered feedstock.

- Sensitivity Analysis: Vary key parameters (transport distance, removal rate) to model their impact.

Protocol 3: Bulk Density and Durability Testing of Pellets Objective: To evaluate the quality of densified pellets according to ISO standards. Materials: Pellet sample, drying oven, balance, graduated cylinder, pellet durability tester (PDT), sieves (3.15 mm). Procedure:

- Bulk Density (ISO 17828): a. Oven-dry a pellet sample. b. Pour pellets gently into a 1L graduated cylinder from a set height. c. Level the top without compaction. d. Weigh the cylinder's contents. Calculate mass/volume (kg/m³).

- Mechanical Durability (ISO 17831-1): a. Sieve 500g of pellets to remove fines. b. Place sample in the PDT drum. c. Rotate the drum for 500 revolutions at 50 rpm. d. Sieve the sample again on a 3.15 mm sieve. e. Weigh the retained pellets. Durability = (Mass retained / Initial mass) * 100%.

Visualization Diagrams

Title: Agricultural Residue Harvesting and Collection Workflow

Title: LCA Protocol for Logistics Emissions

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Logistics and Feedstock Analysis

| Item | Function in Research Context |

|---|---|

| CN Elemental Analyzer | Precisely measures carbon and nitrogen content in soil and biomass samples, crucial for calculating carbon balances and soil health impacts. |

| Bomb Calorimeter | Determines the higher heating value (HHV) of feedstock samples, a key parameter for biorefinery energy yield calculations. |

| Portable Soil Moisture Probe | Allows for rapid, in-field measurement of residue and soil moisture, critical for planning harvest timing and drying requirements. |

| GPS Data Logger & GIS Software | Enables precise mapping of field boundaries, residue yield variability, and optimal route planning for collection and transport. |

| Pellet Durability Tester (PDT) | Quantifies the mechanical strength of densified pellets according to ISO standards, predicting handling and storage losses. |

| Custom LCA Software (e.g., openLCA, GREET) | Models the greenhouse gas emissions and energy inputs of complex, multi-step supply chain scenarios. |

| Unmanned Aerial Vehicle (UAV) with Multispectral Camera | Provides remote sensing data to estimate residue cover, biomass yield, and soil conditions at a field scale. |

Within the framework of Bioenergy with Carbon Capture and Storage (BECCS) utilizing agricultural residues, feedstock pre-processing is a critical determinant of system efficiency and carbon negativity. Agricultural residues (e.g., wheat straw, rice husks, corn stover) are heterogeneous, high-moisture, and low-bulk-density materials, posing significant challenges for transport, handling, gasification/combustion, and subsequent carbon capture. This application note details standardized protocols for drying, torrefaction, and pelletization to transform raw biomass into a homogeneous, energy-dense, and stable feedstock suitable for advanced BECCS value chains, thereby enhancing system reliability and net carbon removal potential.

Table 1: Comparative Analysis of Pre-processing Stages for Agricultural Residues

| Process Stage | Primary Objective | Key Operational Parameters | Typical Output Characteristics (for wheat straw) | Impact on BECCS Value Chain |

|---|---|---|---|---|

| Drying | Reduce moisture to enable further processing & prevent degradation. | Temp: 105-120°C; Time: 1-4 hrs; Moisture Target: <10% (w.b.). | Moisture Content: <10%; Energy Density: ~15 MJ/kg (LHV); Mass Yield: ~92-96%. | Reduces transport mass, prevents biological decay, essential for torrefaction. |

| Torrefaction | Improve grindability, hydrophobicity, and energy density via mild pyrolysis. | Temp: 200-300°C; Atmosphere: N₂ or O₂-lean; Residence Time: 10-60 min. | Solid Mass Yield: 60-80%; Energy Yield: 75-90%; O/C Ratio: Reduced by 20-50%. | Produces stable, coal-like fuel; reduces milling energy; improves gasifier syngas quality. |

| Pelletization | Increase bulk density for efficient transport and handling. | Die Temp: 80-100°C; Pressure: 100-300 MPa; Binder: Optional (e.g., starch, 1-3%). | Bulk Density: 600-750 kg/m³; Durability Index: >95%; Pellet Density: ~1200 kg/m³. | Enables automated feeding in gasifiers; reduces storage volume; minimizes dust. |

Table 2: Feedstock Property Evolution Through Pre-processing

| Property | Raw Straw | After Drying | After Torrefaction (250°C) | After Pelletization (Torr. Pellets) |

|---|---|---|---|---|

| Moisture Content (% w.b.) | 15-25 | <10 | 1-3 | 3-5 |

| Bulk Density (kg/m³) | 60-100 | 70-110 | 150-200 | 600-750 |

| Higher Heating Value (MJ/kg, d.b.) | 17-19 | 18-19 | 21-24 | 21-24 |

| Volatile Matter (% d.b.) | 70-80 | ~75 | 55-70 | 55-70 |

| Fixed Carbon (% d.b.) | 15-20 | ~18 | 25-35 | 25-35 |

Detailed Experimental Protocols

Protocol 3.1: Convective Oven Drying for Feedstock Preparation Objective: To standardize moisture reduction of agricultural residues to a target of <10% wet basis. Materials: Forced-air convection oven, analytical balance (±0.01g), moisture pans, crucible tongs, desiccator, raw biomass. Procedure:

- Record the mass of an empty, clean moisture pan (M_pan).

- Place approximately 50g of representative, chopped biomass (<10mm) into the pan. Record the total mass (M_initial).

- Place the pan in the oven preheated to 105±2°C.

- Dry for a minimum of 4 hours, or until constant mass is achieved (mass change <0.1% over 1 hour).

- Using tongs, transfer the pan to a desiccator to cool to room temperature (~30 min).

- Record the final mass (M_final).

- Calculate Moisture Content (MC, % w.b.) = [(Minitial - Mfinal) / (Minitial - Mpan)] * 100.

Protocol 3.2: Bench-Scale Fixed-Bed Torrefaction Objective: To produce torrefied biomass under controlled inert atmosphere at temperatures between 200-300°C. Materials: Horizontal or vertical tube furnace, quartz reactor tube, N₂ gas cylinder with flowmeter, thermocouples, data logger, sample crucible, gas scrubber (optional). Procedure:

- Load 20-50g of pre-dried (<10% MC) biomass into the sample crucible.

- Place the crucible in the center of the reactor tube. Seal the system.

- Purge the reactor with N₂ at a flow rate of 1 L/min for 15 minutes to establish an inert atmosphere.

- Initiate furnace heating at a ramp rate of 10°C/min to the target torrefaction temperature (e.g., 250°C).

- Maintain the target temperature and N₂ flow (0.5 L/min) for the desired residence time (e.g., 30 min).

- After the holding period, rapidly cool the reactor by sliding it out of the furnace or initiating cooling while maintaining N₂ flow.

- Once cool (<50°C), remove the crucible and weigh the torrefied biomass. Calculate mass yield.

- Collect solid product for subsequent analysis (proximate/ultimate analysis, grindability) or pelletization.

Protocol 3.3: Single-Die Pelletization Unit Operation Objective: To produce dense pellets from raw or torrefied biomass, with or without binders. Materials: Laboratory-scale single-die pellet press (e.g., hydraulic press with heated die), hammer mill with 1mm screen, balance, binder solution (e.g., 5% starch gel), calipers. Procedure:

- Mill the feedstock (dried or torrefied) to a particle size of <1mm.

- (Optional) Homogeneously mix in binder solution to achieve target addition rate (e.g., 2% starch by dry mass). Adjust moisture content of mixture to 8-12%.

- Pre-heat the pellet die to 90±5°C.

- Weigh a precise mass of feedstock (e.g., 1.0g) and load it into the die cavity.

- Apply pressure gradually using the hydraulic press. Hold at the target pressure (e.g., 150 MPa) for a dwell time of 30 seconds.

- Eject the pellet and allow it to cool in ambient air.

- Measure pellet dimensions and mass to calculate density. Perform mechanical durability tests per ASABE S269.5.

Visualizations

Diagram 1: BECCS Feedstock Pre-processing Workflow

Diagram 2: Property Evolution Pathways

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

Table 3: Essential Materials for Feedstock Pre-processing Research

| Item | Function in Research | Typical Specification/Example |

|---|---|---|

| Forced Convection Oven | Precise and uniform drying of biomass samples. | Temperature range: 30-300°C, ±1°C stability. |

| Tube Furnace with Reactor | Controlled thermal treatment (torrefaction) under inert atmosphere. | Max Temp: 1200°C, with programmable controller; Quartz reactor tube. |

| Inert Gas Supply (N₂) | Creates oxygen-free environment for torrefaction, preventing combustion. | High-purity (>99.99%) nitrogen with pressure regulator and flow meter. |

| Laboratory Pellet Press | Forms biomass powder into densified pellets for property testing. | Hydraulic, with heated dies and pressure gauge (capability >200 MPa). |

| Analytical Balance | Accurate measurement of mass yields for all processes. | Capacity 500g, readability 0.01mg. |

| Hammer Mill / Grinder | Reduces particle size for homogenous feedstock and pelletization. | Variable speed, with interchangeable sieves (0.5-2.0mm). |

| Proximate Analyzer (TGA) | Measures moisture, volatile matter, fixed carbon, and ash content. | Thermogravimetric analyzer with controlled atmosphere. |

| Bomb Calorimeter | Determines the higher heating value (HHV) of raw and processed feedstocks. | Isoperibolic or adiabatic, with benzoic acid calibration. |

| Pellet Durability Tester | Quantifies mechanical strength of pellets post-production. | Standardized tumbler box per ASABE/EN norms. |

Application Notes: Integration with Biomass Conversion for BECCS

The integration of carbon capture (CC) technologies with biomass conversion processes is the core engineering challenge for achieving negative emissions via Bioenergy with Carbon Capture and Storage (BECCS). Utilizing agricultural residues (e.g., straw, husks, stover) as feedstocks introduces specific constraints, including high alkali and ash content, variable composition, and lower energy density. The selection and tailoring of CC technology are paramount for system efficiency and economic viability.

Post-Combustion Capture (PCC) is the most readily applicable to existing or new-build biomass power plants. It separates CO₂ from the flue gas after combustion, typically using amine-based solvents. For biomass flue gases, key considerations are the presence of trace contaminants (SOx, NOx, particulates) which degrade solvents, requiring robust pre-cleaning. The lower partial pressure of CO₂ in biomass flue gas (compared to coal) can reduce absorption efficiency.

Oxy-fuel Combustion involves burning biomass in an atmosphere of nearly pure oxygen, diluted with recycled flue gas, resulting in a flue gas stream highly concentrated in CO₂ and water vapor. This method is highly effective for biomass but demands a dedicated, energy-intensive Air Separation Unit (ASU) and careful control of combustion temperature. The high alkali content in agricultural residue ash can exacerbate slagging and fouling under oxy-fuel conditions.

Pre-Combustion Capture involves gasifying the biomass feedstock to produce a syngas (a mixture of H₂, CO, and CO₂). The CO is then shifted with steam to produce more H₂ and CO₂. The CO₂ is separated, leaving a hydrogen-rich fuel for combustion or use in fuel cells. This pathway is complex but offers potential for high-efficiency power generation or biohydrogen production. The challenge lies in tar management and adapting gas cleanup systems for biomass-derived syngas.

Table 1: Comparative Analysis of CC Technologies for Agricultural Residue Conversion

| Parameter | Post-Combustion (Amine-based) | Oxy-fuel Combustion | Pre-Combustion (IGCC pathway) |

|---|---|---|---|

| Technology Readiness Level (TRL) | 9 (Commercial) | 7-8 (Demonstration) | 6-7 (Pilot for biomass) |

| Typical CO₂ Capture Rate (%) | 85-90 | >90 | 85-95 |

| CO₂ Purity in Output Stream (%) | >99.5 | >95 (after drying) | >95-99 |

| Key Energy Penalty Source | Solvent regeneration (2.1-2.5 GJ/t CO₂) | Air Separation (0.7-1.1 GJ/t O₂) & compression | Gasification, ASU, & shift reactor |

| *Estimated Efficiency Penalty (%-points) | 8-12 | 7-10 | 6-9 |

| Major Challenge (Biomass-specific) | Solvent degradation from impurities | Combustion stability & ash behavior | Tar cracking & syngas cleanup |

| Capital Cost Relative Index | 1.0 (Baseline) | 1.3 - 1.5 | 1.5 - 2.0 |

| Best Suited For | Retrofitting existing plants | New-build, high-purity CO₂ streams | Polygeneration (H₂, power, fuels) |

*Based on net electrical efficiency reduction for a biomass power plant.

Experimental Protocols for BECCS Pathway Evaluation

Protocol 2.1: Bench-Scale Post-Combustion Capture with Simulated Biomass Flue Gas

Objective: To evaluate the absorption efficiency and solvent stability of a novel amine blend (e.g., CESAR-1: AMP/PZ) when exposed to a synthetic flue gas containing trace contaminants representative of wheat straw combustion.

Materials & Equipment:

- Gas blending system (mass flow controllers)

- Absorber column (packed bed, 1 m height)

- Desorber/regenerator column (with reboiler)

- Condenser unit

- Online GC or NDIR CO₂ analyzer

- Aqueous amine solvent (2M AMP/1M PZ)

- Gas cylinders: N₂, CO₂, O₂, SO₂ (1000 ppm in N₂), NO (1000 ppm in N₂)

- Peristaltic pumps, thermocouples, pH meter

Methodology:

- Flue Gas Simulation: Prepare a synthetic flue gas mixture of 12% CO₂, 6% O₂, 500 ppm SO₂, 200 ppm NO, balance N₂. Maintain total flow at 1 L/min.

- Absorption Cycle: Pre-heat the flue gas to 40°C. Circulate the solvent (20°C) from the reservoir to the top of the absorber at 50 mL/min, counter-current to the rising gas.

- Monitoring: Measure CO₂ concentration at absorber inlet and outlet continuously. Capture efficiency is calculated as

[(CO2_in - CO2_out)/CO2_in] * 100. - Rich Solvent Loading: After steady-state is reached (≈30 min), sample the "rich" solvent exiting the absorber. Determine CO₂ loading via barium chloride precipitation titration.

- Regeneration: Pump the rich solvent to the desorber column. Apply heat via the reboiler to maintain solvent temperature at 110-120°C for 60 minutes. Capture and measure the evolved CO₂.

- Degradation Study: Repeat cycles 1-5 for 72 hours of continuous operation. Take periodic solvent samples for analysis via Total Inorganic Carbon (TIC) and Ionic Chromatography (IC) to quantify nitrosamine/amine degradation products and heat-stable salt formation.

Protocol 2.2: Oxy-fuel Combustion of Rice Husk in a Drop-Tube Furnace

Objective: To characterize combustion performance and ash deposition propensity of milled rice husk under O₂/CO₂ atmospheres compared to conventional O₂/N₂.

Materials & Equipment:

- Drop-tube furnace (DTF) with controllable temperature zones (up to 1400°C)

- O₂, CO₂, N₂ gas supplies and blending system

- Biomass feeder (vibratory or screw type)

- Ash collection probes (deposition and ultimate collection)

- Scanning Electron Microscope with Energy Dispersive X-ray Spectroscopy (SEM-EDX)

- X-ray Diffraction (XRD) analyzer

- Rice husk feedstock, milled to 150-200 μm.

Methodology:

- Atmosphere Setup: Establish two test atmospheres: i) Conventional: 21% O₂ / 79% N₂. ii) Oxy-fuel: 30% O₂ / 70% CO₂ (to simulate recycled flue gas).

- Combustion Run: Set furnace wall temperature to 1000°C. Introduce feedstock at a constant rate of 0.5 g/min. Allow system to stabilize for 15 minutes.

- Ash Sampling: Insert a water-cooled deposition probe (surface temp ~600°C) into the gas stream for 60 minutes. Collect remaining fly ash in a downstream filter.

- Analysis:

- Burnout: Calculate from mass balance of char collected.

- Ash Deposition: Weigh the deposit on the probe. Analyze deposit morphology and composition via SEM-EDX.

- Ash Fusibility: Analyze filter-collected ash chemistry and determine initial deformation temperature under reducing atmosphere.

- Mineral Transformation: Use XRD on powdered ash to identify crystalline phases (e.g., cristobalite, potassium silicates).

Protocol 2.3: Pre-Combustion Sorption-Enhanced Water-Gas Shift (SEWGS)

Objective: To test a bifunctional catalyst-sorbent material for in-situ CO₂ removal during the water-gas shift reaction of biomass-derived syngas, concentrating the H₂ product stream.

Materials & Equipment:

- High-pressure fixed-bed reactor system (Hastelloy, 1/2" diameter)

- Back-pressure regulator, downstream gas sampling loop

- Online micro-GC for H₂, CO, CO₂, CH₄ analysis

- Syngas mixture cylinder (40% H₂, 30% CO, 20% CO₂, 10% CH₄)

- SEWGS material (e.g., K-promoted hydrotalcite with Pt/WGS catalyst)

- High-precision syringe pump for steam injection

Methodology:

- Reactor Loading: Pack 5g of SEWGS pellets into the isothermal zone of the reactor. Load quartz wool on both ends.

- Pre-treatment: Under N₂ flow (100 mL/min), heat to 300°C for 1 hour to remove physisorbed water.

- Reaction Cycle:

- Adsorption/Shift Phase: Switch feed to simulated wet syngas. Introduce steam via syringe pump at a H₂O:CO molar ratio of 3:1. Maintain total pressure at 20 bar, temperature at 400°C. Monitor outlet gas composition every 2 minutes. The CO₂ will be adsorbed, driving the WGS reaction (CO + H₂O → CO₂ + H₂) towards high-purity H₂ production (>95% dry basis).

- Breakthrough Detection: When CO₂ concentration at the outlet exceeds 1% (breakthrough), stop the syngas feed.

- Regeneration: Switch to a 100% N₂ purge at 400°C to desorb weakly held CO₂. Then perform a pressure swing or temperature swing regeneration (e.g., reduce pressure to 1 bar or increase temperature to 500°C) to fully regenerate the sorbent. Capture the desorbed CO₂ stream.

- Cyclic Stability: Repeat steps 3-4 for 50 cycles. Monitor and record the CO conversion and H₂ purity at the start of each adsorption phase to assess sorbent/catalyst stability.

Diagrams

BECCS Technology Pathways from Biomass to Storage

Post-Combustion Capture Process Workflow

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for BECCS-CC Experimental Research

| Item Name | Function & Relevance | Example Product / Specification |

|---|---|---|

| Amino Solvents (Blends) | Reactive absorbents for post-combustion CO₂ capture. Tailored blends (e.g., AMP/PZ) offer improved kinetics, capacity, and degradation resistance. | CESAR-1 (30% AMP/10% PZ), 5M MEA (benchmark), KS-1 (hindered amine). |

| High-Temperature Sorbents | Solid materials for pre-combustion or direct air capture, often operating on pressure/temperature swing principles. | K-promoted Hydrotalcite, CaO-based sorbents, Zeolite 13X, Metal-Organic Frameworks (MOFs). |

| Biomass Reference Materials | Standardized, characterized biomass feeds for reproducible gasification/combustion experiments. | NIST Willow Shrub (SRM 8496), University of Vienna Beech Wood Char. |

| Synthetic Flue Gas Mixtures | Calibrated gas cylinders for simulating precise combustion atmospheres without operating a burner. | 12% CO₂, 6% O₂, 500 ppm SO₂, balance N₂. Custom blends available. |

| Trace Gas Analyzers | Critical for monitoring low concentrations of CO₂, SO₂, NOx, and O₂ in inlet/outlet streams to calculate capture efficiency. | NDIR CO₂ Analyzer (e.g., Vaisala GMP252), FTIR Multi-Gas Analyzer (e.g., Gasmet DX4000). |

| WGS Catalyst-Sorbent Composite | Bifunctional material for Sorption-Enhanced Water-Gas Shift (SEWGS) experiments in pre-combustion setups. | Pt/CeO₂-Al₂O³ catalyst mixed with or coated on hydrotalcite sorbent. |

| Ash Fusion Analyzer | Determines ash melting behavior under controlled atmospheres, critical for oxy-fuel and boiler design. | LECO AF700, capable of reducing and oxidizing atmospheres. |

| Ionic Chromatography (IC) Standards | For quantifying anion (formate, acetate, nitrate, sulfate) and cation (alkali metals) concentrations in solvent or ash leachates. | EPA Method 300.1 Anion Standard Mix, multi-element cation standard. |

Application Notes: Comparative Analysis of BECCS Integration Pathways

This note compares two primary pathways for integrating Bioenergy with Carbon Capture and Storage (BECCS) using agricultural residues. The analysis is framed within a thesis investigating the technical feasibility and carbon accounting of region-specific residue feedstocks.

Table 1: Key Comparative Metrics for BECCS Integration Pathways

| Metric | Co-firing in Existing Coal Power Plants | Dedicated BECCS Facility |

|---|---|---|

| Primary Feedstock | Blended fuel (e.g., 5-20% biomass with coal). | 100% pre-processed agricultural residue (e.g., wheat straw, rice husk). |

| Capital Expenditure (CAPEX) | Lower retrofit costs for boiler/CCS unit. Higher costs for feedstock prep & storage. | Higher greenfield costs. Optimized, integrated design reduces per-unit cost at scale. |

| Technology Readiness Level (TRL) | High (9) for co-firing; Medium-High (7-8) for CCS retrofit on coal flue gas. | Medium (6-7) for fully integrated, biomass-optimized gasification-CCS systems. |

| Net Carbon Removal Potential (tCO₂/MWh) | 0.05 - 0.15 (Highly dependent on co-firing ratio and biomass supply chain emissions). | 0.30 - 0.45 (Optimized for high-efficiency carbon-negative operation). |

| Key Technical Challenge | Inconsistent flue gas composition; Alkali & chlorine-induced slagging/fouling; Fuel feed system adaptation. | Feedstock variability & preprocessing; Tar cracking in gasification; System scale-up. |

| Operational Flexibility | High. Can adjust biomass ratio based on price/availability; base-load capable. | Lower. Economies of scale require steady, high-volume feedstock supply. |

Table 2: Feedstock Preprocessing Requirements (For ~50 MWe equivalent)

| Process Step | Co-firing Protocol | Dedicated BECCS Protocol |

|---|---|---|

| Drying | To ~15-25% moisture content (air or low-temp dryer). | To ~10-15% moisture (efficient dryer integral to feed system). |

| Size Reduction | Coarse chipping (~50 mm). May require pulverization for high % blends. | Fine grinding (<2 mm) for fluidized beds/gasifiers. |

| Leaching/Washing | Often omitted, increasing fouling/corrosion risks. | Recommended for high-K, Cl residues; reduces slagging and ash sintering. |

| Pelletization/Torrefaction | Beneficial for long-distance transport and handling. | Critical for uniform feeding in pressurized gasification systems. |

Experimental Protocols

Protocol A: Simulated Flue Gas Corrosion Testing for Co-firing Environments Objective: To assess high-temperature corrosion rates of boiler superheater materials under co-firing flue gas conditions.

- Reagent Setup: Prepare synthetic flue gas mixture: N₂ (base), 12% CO₂, 3% O₂, 500 ppm SO₂, 200 ppm HCl. Introduce alkali salt aerosols (K₂SO₄, KCl) via a nebulizer into a pre-heated gas stream.

- Sample Preparation: Cut candidate alloy coupons (e.g., 304H, Sanicro 28) to 15x10x2 mm. Polish to a 1 µm finish, clean ultrasonically in acetone/ethanol, and dry.

- Exposure Experiment: Place coupons in a horizontal tube furnace. Expose to simulated flue gas at 600°C ± 5°C for 500 hours. Control gas flow rate at 100 ml/min.

- Post-Exposure Analysis: Cool in N₂ atmosphere. Weigh to determine mass change. Analyze corrosion products using Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM-EDS) and X-ray Diffraction (XRD).

- Data Normalization: Report corrosion rate as µm/year based on metal loss calculated from mass gain and oxide density.

Protocol B: Bench-Scale Fluidized Bed Gasification of Pelletized Residue Objective: To determine syngas composition and tar yield from gasification of pretreated agricultural residue pellets.

- Reactor Setup: Use a continuous feed, electrically heated bubbling fluidized bed reactor (ID: 50 mm, H: 1000 mm). Bed material: 500g olivine sand (300-500 µm).

- Feedstock Preparation: Mill and pelletize wheat straw to 3mm pellets. Dry at 105°C for 24h to <10% moisture. Characterize proximate/ultimate analysis.

- Gasification Run: Fluidize bed with N₂ and heat to 850°C. Introduce steam as gasifying agent (Steam/Biomass ratio = 0.8 w/w). Initiate biomass feed at 1 kg/h. Maintain steady state for 60 mins.

- Gas & Tar Sampling: After steady state, pass product gas through a series of condensers (ice/acetone) and tar-absorbing solvent traps (dichloromethane). Measure permanent gas composition (H₂, CO, CO₂, CH₄, C₂) via online micro-GC every 10 mins.

- Tar Analysis: Recover and quantify tars gravimetrically from solvent. Analyze tar composition via Gas Chromatography-Mass Spectrometry (GC-MS).

Visualization Diagrams

Diagram 1: BECCS Integration Pathway Comparison

Diagram 2: Corrosion Test Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for BECCS Feedstock & Process Research

| Reagent/Material | Function & Application | Key Specification |

|---|---|---|

| Olivine Sand | Catalytic bed material for fluidized bed gasification experiments. Reduces tar yield. | (Mg, Fe)₂SiO₄; particle size 300-600 µm. |

| Monoethanolamine (MEA) Solution | Benchmark solvent for post-combustion CO₂ capture simulation studies. | 30 wt.% in H₂O for absorption/desorption tests. |

| Synthetic Flue Gas Mixture | Corrosive environment simulation for material testing in co-firing scenarios. | Custom blend: N₂/CO₂/O₂/SO₂/HCl. Certified ±2%. |

| Dichloromethane (DCM) | Solvent for absorbing and recovering tars from gasification product streams. | HPLC grade, for tar quantification and GC-MS analysis. |

| Alkali Salts (KCl, K₂SO₄) | Key components of biomass ash. Used to study fouling/slagging and aerosol generation. | ACS reagent grade, ≥99.0% purity. |

| Certified Gas Mixtures (H₂, CO, CO₂, CH₄ in N₂) | Calibration standards for syngas analysis via Gas Chromatography (GC). | Certified to ±1% of stated value for each component. |

| Torrefied Biomass Reference Material | Standardized feedstock for comparing gasifier performance across studies. | Defined proximate/ultimate analysis and grindability index. |

Within the research framework of Bioenergy with Carbon Capture and Storage (BECCS) utilizing agricultural residues, the management of solid by-products—primarily biochar and ash—is critical for system sustainability, economic viability, and carbon sequestration verification. These materials represent both a potential carbon sink and a source of valuable soil amendments or industrial materials. This document provides application notes and standardized protocols for the characterization, analysis, and application of these by-products, tailored for researchers and scientists in BECCS and related fields.

Proximate and Ultimate Analysis Protocol

Objective: To determine the basic chemical composition and property profile of biochar and ash samples.

Materials:

- Analytical balance (±0.0001 g)

- Muffle furnace

- Elemental (CHNS/O) analyzer

- Desiccator

- Crucibles (porcelain or platinum)

Procedure:

- Moisture Content: Weigh 1g of sample (Wwet) in a pre-weighed crucible. Dry at 105°C for 24 hours. Cool in a desiccator and re-weigh (Wdry). Moisture (%) = [(Wwet - Wdry)/Wwet] x 100.

- Volatile Matter: Place the dried sample from Step 1 in a muffle furnace at 950°C for 6 minutes in a covered crucible. Cool and weigh. Calculate mass loss.

- Ash Content: Heat the residue from Step 2 at 750°C for 6 hours in an open crucible. The remaining mass is the ash.

- Fixed Carbon: Calculate by difference: Fixed Carbon (%) = 100% - (Moisture% + Volatile% + Ash%).

- Ultimate Analysis: Submit dried, homogenized sample to an elemental analyzer for Carbon, Hydrogen, Nitrogen, Sulfur, and Oxygen (by difference) content.

Table 1: Representative Data from Agricultural Residue-Derived By-products

| Parameter | Unit | Corn Stover Biochar (500°C) | Rice Husk Ash (700°C) | Wheat Straw Biochar (550°C) |

|---|---|---|---|---|

| pH | - | 9.2 ± 0.3 | 10.5 ± 0.4 | 8.9 ± 0.2 |

| Specific Surface Area | m²/g | 120 ± 15 | 35 ± 8 | 95 ± 12 |

| Carbon Content | % d.b. | 72.5 ± 2.1 | 12.3 ± 1.5 | 68.4 ± 2.3 |

| H:Corg ratio | mol/mol | 0.35 ± 0.05 | N/A | 0.41 ± 0.06 |

| O:Corg ratio | mol/mol | 0.15 ± 0.03 | N/A | 0.18 ± 0.04 |

| Total Porosity | % | ~60 | ~45 | ~58 |

| Cation Exchange Capacity | cmolc/kg | 35.2 ± 4.1 | 12.1 ± 2.2 | 30.5 ± 3.8 |

| Plant-Available K | g/kg | 8.5 ± 1.0 | 25.3 ± 2.5 | 7.2 ± 0.9 |

d.b. = dry basis; Data compiled from recent literature (2023-2024).

Stability Assessment via Incubation Protocol

Objective: To quantify the biochar carbon stability (persistence) in a simulated soil environment.

Materials:

- Incubation jars with gas-tight septa

- 1M NaOH traps

- Thermostated incubator

- Fine-textured, C-deficient soil (control)

- Gas Chromatograph or Titration setup

Procedure:

- Mix biochar with pre-dried soil at a rate of 2% (w/w). A soil-only control is mandatory.

- Adjust soil-biochar mixture to 60% Water Holding Capacity.

- Place mixture in incubation jar. Include a vial with 10 mL of 1M NaOH to trap mineralized CO2.

- Incubate at 25°C in the dark. Replace NaOH traps at intervals (e.g., 1, 3, 7, 14, 30, 60 days).

- Quantify trapped CO2 via titration with 1M BaCl2 and HCl, or by weighing precipitated BaCO3.

- Calculate cumulative C mineralization and model the stable C fraction.

Application Notes

Soil Amendment for Enhanced Carbon Sequestration

Biochar application to agricultural soil is a core strategy for securing the "C" in BECCS. Key protocols include:

- Application Rate: Based on C sequestration targets and agronomic limits. Typical field trial rates range from 5-20 tonnes/ha.

- Mixing Protocol: For field studies, use a rotary tiller or disc harrow to incorporate biochar uniformly into the top 15-20 cm of soil.

- Co-amendment with Ash: Wood ash can be applied at 1-5 tonnes/ha to adjust soil pH and supply K, P, and Ca. Critical: Avoid ash application to alkaline soils. Conduct a preliminary soil pH test.

Table 2: Contaminant Screening Limits for Safe Land Application

| Element | Maximum Concentration in Biochar/Ash (mg/kg, dry basis) | Common Analytical Method |

|---|---|---|

| Arsenic (As) | 13-100 | ICP-MS |

| Cadmium (Cd) | 1.4-39 | ICP-MS |

| Chromium (Cr) | 93-1200 | ICP-OES |

| Copper (Cu) | 600-4000 | ICP-OES |

| Lead (Pb) | 150-300 | ICP-MS |

| Zinc (Zn) | 700-7400 | ICP-OES |

| PAHs (16 EPA) | 6-20 | HPLC/GC-MS |

Ranges reflect international guidelines (EBC, IBI, national standards). Mandatory analysis prior to field trials.

Material Science Applications

Protocol for Biochar-Based Catalyst Support:

- Activation: Load 10g of crushed biochar (500-800 µm) into a quartz reactor. Under N2 flow, heat to 800°C at 10°C/min. Introduce steam (20% v/v in N2) for 45 minutes to develop porosity. Cool under N2.

- Metal Impregnation: Use incipient wetness impregnation with a metal salt solution (e.g., K2CO3 for K, Fe(NO3)3 for Fe). Dry at 105°C and calcine at 400°C.

Visualizations

Diagram Title: BECCS By-product Management and Utilization Pathways

Diagram Title: Proximate and Ultimate Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for By-product Research

| Item | Function/Application | Key Considerations |

|---|---|---|

| Elemental Analyzer (CHNS/O) | Quantifies fundamental organic/inorganic composition. | Required for C sequestration calculations and H/C, O/C ratios (stability indices). |

| Brunauer-Emmett-Teller (BET) Analyzer | Measures specific surface area and pore size distribution of biochar. | Critical for evaluating reactivity and catalyst support potential. |

| Inductively Coupled Plasma Spectrometer (ICP-OES/MS) | Detects and quantifies major, minor, and trace metal contaminants. | Mandatory for safety screening prior to land application (see Table 2). |

| 1M Sodium Hydroxide (NaOH) Traps | Absorbs CO2 during mineralization incubation studies. | Used with titration (BaCl2/HCl) to quantify C mineralization. |

| pH/EC Meter with Soil Probe | Measures pH and electrical conductivity of biochar/ash-soil mixtures. | Guides safe application rates; ash is highly alkaline. |

| Polycyclic Aromatic Hydrocarbon (PAH) Standards | Calibration for HPLC/GC-MS analysis of organic contaminants. | Required to assess pyrolysis process quality and product safety. |

| Isotope-Labeled (¹³C) Compounds | Tracers for detailed studies on biochar degradation pathways and interactions. | Enables precise tracking of biochar-C in complex environmental systems. |

Overcoming Technical and Economic Hurdles in Residue-Fed BECCS

The viability of Bioenergy with Carbon Capture and Storage (BECCS) using agricultural residues (e.g., wheat straw, rice husk, corn stover) is critically undermined by severe ash-related challenges during combustion. These feedstocks contain high concentrations of alkali metals (K, Na) and chlorine, which transform into low-melting-point compounds (e.g., alkali silicates, chlorides, sulfates). This leads to accelerated ash fouling (deposits on heat exchanger surfaces) and slagging (molten or fused deposits in the furnace), reducing heat transfer efficiency, increasing corrosion rates, and causing unscheduled plant shutdowns. For BECCS, these operational issues decrease the net energy output and increase the cost of captured CO₂. This application note details protocols for characterizing fuels, simulating ash behavior, and testing mitigation strategies essential for developing robust BECCS systems.

Table 1: Typical Alkali and Chlorine Content in Selected Agricultural Residues

| Feedstock | Potassium (K₂O) [wt.% dry] | Sodium (Na₂O) [wt.% dry] | Chlorine (Cl) [wt.% dry] | SiO₂ [wt.% ash] | Initial Deformation Temp. (Reducing) [°C] |

|---|---|---|---|---|---|

| Wheat Straw | 10 - 20 | 0.2 - 1.5 | 0.3 - 1.5 | 25 - 50 | ~950 - 1050 |

| Rice Husk | 1 - 5 | 0.1 - 0.5 | 0.1 - 0.5 | 85 - 95 | >1300 |

| Corn Stover | 10 - 25 | 0.5 - 2.0 | 0.5 - 1.8 | 30 - 60 | ~900 - 1000 |

| Barley Straw | 5 - 15 | 0.5 - 2.0 | 0.5 - 1.2 | 25 - 45 | ~950 - 1100 |

Table 2: Key Ash Transformation Reactions and Their Impact

| Reaction | Typical Temperature Range | Resulting Compound/Phase | Primary Impact |

|---|---|---|---|

| KCl(g) + SO₂ + ½O₂ + H₂O → K₂SO₄ + HCl | 700 - 900°C | K₂SO₄ (s) | Fouling, Corrosion |

| 2KCl(g) + SiO₂ + H₂O → K₂SiO₃ + 2HCl | >700°C | K-silicates (s, l) | Slagging, Bed Agglomeration |

| K⁺ + Al-Si minerals → K-Al-silicates (e.g., KAlSi₃O₈) | >1000°C | Alkali Alumino-silicates (s) | Can increase ash melting point |

| CaO + SiO₂ + K₂CO₃ → Ca-K-silicates (low m.p.) | 800 - 1100°C | Low-melting eutectics (l) | Severe slagging |

Experimental Protocols

Protocol 1: Fuel Analysis and Ash Preparation Objective: To determine the elemental composition and prepare standardized ash samples for subsequent analysis. Methodology:

- Fuel Milling: Mill the air-dried feedstock to a particle size of <250 µm using a vibratory disc mill.

- Ultimate & Proximate Analysis: Perform using standard ASTM methods (D3172, D3176, D4239). Specifically analyze for Cl via bomb combustion/ion chromatography (ASTM D4208).

- Ash Preparation (Low-Temperature): Ash the fuel in a muffle furnace at 575±25°C (ASTM D3174) for 24 hours to preserve alkali volatiles. Store in a desiccator.

- ICP-OES/MS Analysis: Digest 0.1g of low-T ash in a microwave-assisted acid digestion system (HNO₃/HF/H₂O₂). Analyze the solution via Inductively Coupled Plasma Optical Emission Spectrometry/Mass Spectrometry (ICP-OES/MS) for K, Na, Ca, Mg, P, Si, Al, Fe, S.

Protocol 2: Ash Fusion Behavior and Melting Temperature Determination Objective: To characterize the sintering and melting behavior of ash under simulated combustion atmospheres. Methodology:

- Sample Preparation: Press the low-T ash into a conical cylinder using a standard ash fusion test mold.

- Ash Fusion Test (ASTM D1857): Place the cone in a controlled atmosphere furnace (reducing: 60% CO, 40% CO₂; oxidizing: ambient air). Equip with a digital camera for profile monitoring.

- Temperature Program: Heat at 8±3°C/min from 538°C to a maximum of 1600°C.

- Data Collection: Record the four characteristic temperatures: Initial Deformation (IDT), Softening (ST), Hemispherical (HT), and Fluid (FT). IDT is the most critical for slagging propensity.

Protocol 3: Lab-Scale Deposit Formation and Fouling Propensity Test Objective: To simulate and quantify the initial stages of ash deposition on a heat exchanger surface. Methodology:

- Reactor Setup: Use an electrically heated tube furnace with an alumina reactor tube.

- Probe Configuration: Insert a temperature-controlled air-cooled alloy probe (material: e.g., Sanicro 28) into the hot zone. Maintain probe surface temperature at 450-550°C (typical superheater temp).

- Combustion Simulation: Introduce a synthetic flue gas (N₂, CO₂, O₂, H₂O, SO₂). Continuously feed milled feedstock (<1 mm) at a controlled rate using a screw feeder into the hot gas stream upstream of the probe.

- Experiment Duration: Run for 4-8 hours.

- Post-Test Analysis: a) Deposit Weight: Measure deposit mass per unit area. b) Morphology/Composition: Analyze deposit cross-section via Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM-EDX). c) Adhesion Strength: Perform a controlled shear force test using a calibrated rig.

Diagrams

Ash Formation and Fouling Pathway

Ash Characterization Experimental Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials and Reagents for Combustion Challenge Research

| Item | Function/Application | Key Characteristics |

|---|---|---|

| Microwave Digestion System (e.g., CEM Mars, Milestone Ethos) | Complete dissolution of ash samples for elemental analysis by ICP. | High-pressure/temperature vessels, programmable digestion methods for complex silicate matrices. |

| ICP-OES/MS Calibration Standards (Multi-element & Single-element) | Quantitative calibration for elements including K, Na, Ca, Si, Al, P, S, Cl. | Traceable certification, acid matrix matched to samples (e.g., 2% HNO₃, 1% HF). |

| Standard Ash Fusion Test Mold | Forms reproducible ash cones for fusion temperature testing. | Precise dimensions per ASTM D1857, stainless steel construction. |

| Temperature-Controlled Deposition Probe | Simulates heat exchanger tubes in lab-scale furnaces. | Air/water-cooled, alloy (e.g., 304H, Sanicro 28) or ceramic tip, embedded thermocouples. |