Optimizing Biomass Supply Chains with Linear Programming: Methods, Models, and Clinical Research Applications

This article provides a comprehensive overview of linear programming (LP) and Mixed-Integer Linear Programming (MILP) applications for biomass supply chain (BSC) optimization, tailored for researchers and drug development professionals.

Optimizing Biomass Supply Chains with Linear Programming: Methods, Models, and Clinical Research Applications

Abstract

This article provides a comprehensive overview of linear programming (LP) and Mixed-Integer Linear Programming (MILP) applications for biomass supply chain (BSC) optimization, tailored for researchers and drug development professionals. It explores the foundational principles that make biomass supply chains uniquely complex and suitable for operational research methods. The content delves into specific methodological approaches, including the integration of Geographic Information Systems (GIS) for spatial analysis and model formulation for strategic and tactical decisions. It further addresses troubleshooting common optimization challenges, such as handling uncertainty and computational complexity, and validates these approaches through comparative analysis of real-world case studies and performance metrics. The synthesis aims to demonstrate how robust BSC optimization can enhance the reliability and sustainability of biomass sources for biomedical and clinical research.

The Building Blocks: Understanding Biomass Supply Chains and the Role of Linear Programming

The efficient transformation of biomass into energy, fuels, and chemicals is critically dependent on a well-orchestrated supply chain. This network encompasses all operations from the procurement of raw organic material to the delivery of a refined feedstock suitable for conversion processes. For researchers and scientists, optimizing this chain via linear programming is paramount to enhancing the economic viability and environmental sustainability of bioenergy. These optimization models must account for the unique challenges of biomass, including its seasonal availability, geographical dispersion, low bulk density, and quality variations [1]. This document details the core components, provides quantitative data, and outlines experimental protocols essential for modeling and optimizing the biomass supply chain.

Core Components of the Biomass Supply Chain

The biomass supply chain can be segmented into four primary operational layers, each with distinct inputs, processes, and outputs that serve as critical variables and constraints in logistics optimization modeling.

Harvesting and Collection

This initial stage involves gathering biomass from its source, such as agricultural fields or forests.

- Decisions & Activities: Determining the optimal timing and method for harvest; integrating harvest with other operations (e.g., grain collection); selecting equipment systems (single-pass vs. multi-pass) [1] [2].

- Key Features & Complexities: Biomass availability is seasonal and geographically scattered. Harvesting methods significantly impact biomass quality and contamination levels (e.g., soil content). Equipment availability and cost are major constraints [1].

- Modeling Insight: Linear programming models must incorporate constraints related to harvest windows, equipment capacity, and sustainability guidelines that dictate the amount of residue that can be removed [3].

Storage and Preprocessing

After collection, biomass often requires conditioning to improve its handling properties and energy density for transport and conversion.

- Decisions & Activities: Selecting storage methods (outdoor, covered, inert atmosphere); determining pre-processing locations (fixed or portable depots); applying size reduction (chipping, grinding) and densification (baling, pelleting) [1] [4].

- Key Features & Complexities: Biomass can degrade during storage, leading to dry matter loss. Preprocessing (e.g., torrefaction) improves energy density but adds cost and complexity. The choice between Fixed Depots (FDs) and Portable Depots (PDs) is a key strategic decision; FDs benefit from economies of scale, while PDs offer flexibility for seasonal or dispersed biomass [1] [4].

- Modeling Insight: Optimization models must account for dry matter losses during storage and the cost-benefit trade-offs of different preprocessing technologies and depot locations [4].

Transportation

This component moves biomass from fields to storage sites, preprocessing depots, and finally to the conversion facility.

- Decisions & Activities: Selecting transportation modes (truck, rail, barge); routing and scheduling; managing multi-modal transfers [1] [5].

- Key Features & Complexities: Transportation can represent a very high percentage of total feedstock cost [1]. Low bulk density makes transportation inefficient, justifying preprocessing to reduce costs. Multimodal transport is often essential for larger plants [5].

- Modeling Insight: Models like the Biomass Logistics Model (BLM) simulate biomass flow and track changes in feedstock quality, which directly impacts transportation efficiency and cost [6].

Conversion

The final stage transforms the prepared biomass into energy, liquid fuels, or chemicals.

- Decisions & Activities: Selecting the appropriate conversion technology based on feedstock properties and desired products [7].

- Key Features & Complexities: Pathways are broadly categorized as:

- Thermochemical: Uses heat and catalysts. Processes include combustion (direct burning for power/heat), gasification (producing syngas), pyrolysis (producing bio-oil), and hydrothermal liquefaction (for wet feedstocks) [7]. These processes generally have shorter reaction times than biochemical routes.

- Biochemical: Utilizes enzymes and microorganisms. Processes include anaerobic digestion (producing biogas) and fermentation (producing ethanol) [7] [8]. These are typically suitable for wetter feedstocks with high sugar or starch content.

Table 1: Key Biomass Conversion Technologies and Their Characteristics

| Technology | Process Conditions | Primary Products | Typical Feedstock | Advantages | Challenges |

|---|---|---|---|---|---|

| Combustion [7] | 800-1000°C, presence of oxygen | Heat, Electricity | Dry biomass (e.g., wood chips) | Simplicity, commercial readiness | Air emissions, lower efficiency |

| Gasification [7] | 500-1400°C, limited oxygen | Syngas (CO, H₂) | Various dry feedstocks | Syngas versatility for power/fuels/chemicals | Tar formation, gas cleaning required |

| Pyrolysis [7] | 400-900°C, absence of oxygen | Bio-oil, Biochar, Gas | Dry biomass | High liquid fuel yield via fast pyrolysis | Bio-oil is acidic and unstable |

| Hydrothermal Liquefaction [7] | 250-400°C, high pressure, water | Bio-crude oil | Wet biomass (e.g., sludges, algae) | No drying required, high quality oil | High-pressure operation required |

| Anaerobic Digestion [7] [8] | 20-40°C, absence of oxygen, weeks | Biogas (CH₄, CO₂) | Wet organic waste (e.g., manure) | Handles high-moisture waste, produces fertilizer | Slow process, large reactor volumes |

| Fermentation [7] [8] | 20-30°C, days | Ethanol, other biofuels | Sugar/Starch crops (e.g., corn, cane) | Well-established for ethanol | Competition with food sources |

Quantitative Data for Modeling

Linear programming models require robust quantitative data to accurately represent the system. The following tables summarize key parameters essential for modeling the biomass supply chain, derived from literature.

Table 2: Representative Biomass Logistics and Cost Parameters

| Parameter | Typical Range or Value | Context / Notes | Source |

|---|---|---|---|

| Logistics Cost Share | Up to 90% of total feedstock cost | Highlights the critical importance of optimizing the supply chain. | [1] |

| Single-Pass Harvesting | ~33% cost reduction | Compared to traditional multi-pass systems for corn stover. | [2] |

| Stover-to-Grain Ratio | ~1:1 by weight | Maximum yield of stover per unit of grain harvested. | [2] |

| Moisture Content (Harvest) | 35% - 55% | For single-pass harvested corn stover; impacts transport weight. | [2] |

| Thermal Conversion Efficiency | >80% | For Hydrothermal Liquefaction. | [7] |

| Co-firing Demand (Indonesia) | 9 million tons/year | For 114 coal power plants; indicates large-scale demand. | [9] |

Table 3: Biomass Preprocessing Depot Characteristics for Model Selection

| Characteristic | Fixed Depot (FD) | Portable Depot (PD) | |

|---|---|---|---|

| Capital Investment | High | Lower | |

| Operational Cost | Lower per-unit (economies of scale) | Higher per-unit | |

| Flexibility | Low (fixed location) | High (relocatable) | |

| Best Suited For | Areas with high, consistent biomass density | Seasonal availability or geographically dispersed biomass | |

| Modeling Consideration | Strategic, long-term location decision | Tactical, medium-term deployment and scheduling | [4] |

Experimental Protocols for Supply Chain Analysis

Protocol: Biomass Logistics Model (BLM) Simulation

The BLM is an engineering process and supply chain accounting tool designed to estimate delivered feedstock cost and energy consumption [6].

1. Objective: To simulate the flow of biomass through a defined supply chain, tracking cost, energy use, and changes in feedstock quality (moisture, ash, bulk density). 2. Materials: - Software: Biomass Logistics Model (BLM) platform. - Input Data: Geospatial data of biomass sources, transportation network maps, equipment performance specifications, weather data, and feedstock quality metrics. 3. Methodology: - Step 1: System Definition. Define the supply chain scenario, including harvest method (single- or multi-pass), storage type and duration, preprocessing technology (e.g., baling, pelleting), and transportation modes and distances. - Step 2: Data Parameterization. Input all operational data into the BLM, including biomass yield, equipment efficiency, fuel consumption, labor rates, and storage loss rates. - Step 3: Simulation Execution. Run the model to simulate biomass flow from source to conversion plant gate. - Step 4: Output Analysis. Extract key outputs: total delivered cost ($/dry ton), total energy consumed (MJ/ton), and final feedstock quality characteristics. 4. Applications: Comparing alternative supply system designs, identifying cost and energy bottlenecks, and generating data for larger techno-economic analyses or linear programming models.

Protocol: On-Farm Storage and Pretreatment Evaluation

This protocol assesses the feasibility of using storage as a passive or active pretreatment step to improve biomass digestibility for biochemical conversion [2].

1. Objective: To evaluate the effectiveness of various on-farm pretreatment methods in enhancing the enzymatic digestibility of biomass prior to biorefining. 2. Materials: - Biomass Samples: Corn stover, switchgrass, or other perennial grasses. - Reagents: Dilute acid (e.g., Hâ‚‚SOâ‚„), alkali (e.g., lime, NaOH), ozone, and novel enzyme cocktails. - Equipment: Laboratory-scale storage simulators (sealed containers with environmental control), analytical equipment for composition analysis (e.g., HPLC, NIR). 3. Methodology: - Step 1: Sample Preparation. Biomass is harvested and processed to a uniform size. - Step 2: Treatment Application. Apply pretreatment reagents at controlled levels to biomass samples in simulated storage conditions (e.g., ensilage). Include untreated control samples. - Step 3: Incubation. Store samples for a predetermined period (e.g., 30-180 days) while monitoring temperature and composition. - Step 4: Digestibility Analysis. After storage, subject samples to standard enzymatic hydrolysis assays. Measure the yield of fermentable sugars (glucose, xylose). - Step 5: Economic Screening. Compare the incremental sugar yield against the cost of reagents and storage to determine economic viability. 4. Applications: Developing low-cost pretreatment strategies, decentralizing biorefinery operations, and improving the overall carbon balance of biofuel production.

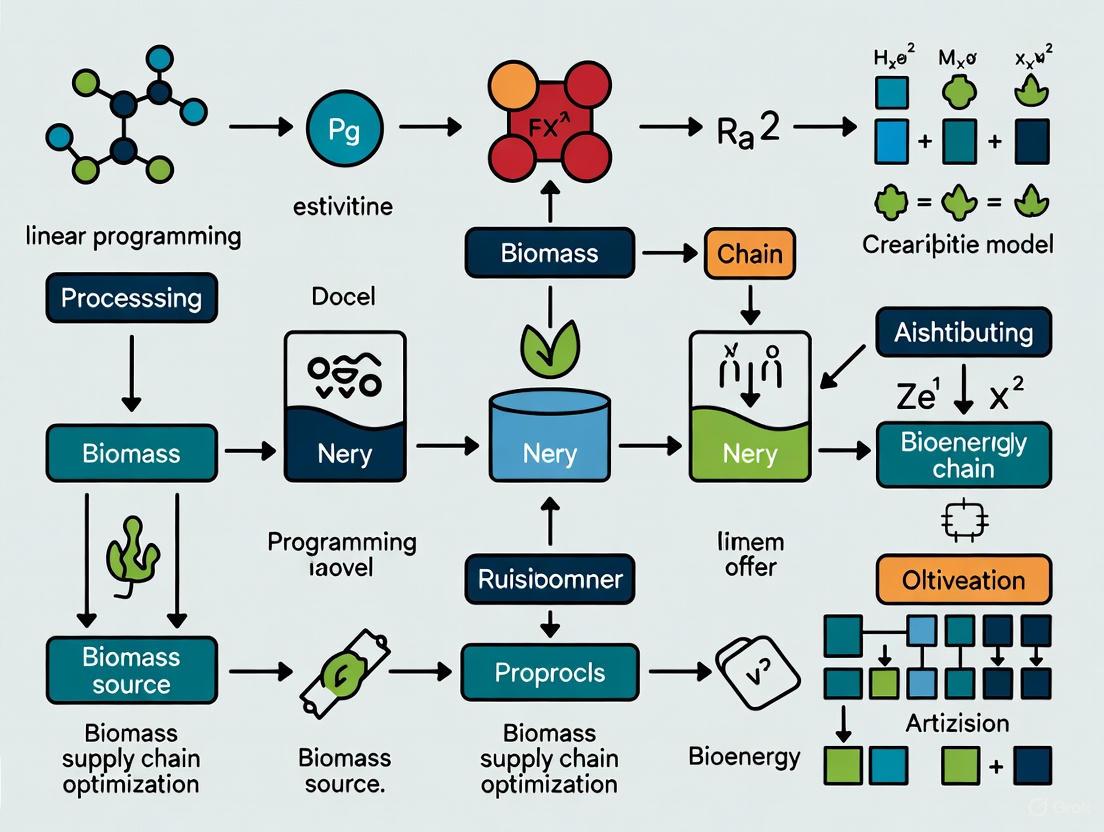

Visualization of Supply Chain and Optimization Framework

The following diagrams, generated using DOT language, illustrate the logical flow of the biomass supply chain and the corresponding optimization framework.

Diagram 1: Biomass Supply Chain Workflow

Diagram 2: Linear Programming Optimization Framework

The Scientist's Toolkit: Research Reagent Solutions

This section details key materials, models, and tools essential for research in biomass supply chain optimization.

Table 4: Essential Tools and Models for Biomass Supply Chain Research

| Item Name | Function / Application | Specifications / Notes |

|---|---|---|

| Biomass Logistics Model (BLM) [6] | A hybrid engineering process and supply chain accounting model to estimate delivered feedstock cost and energy consumption. | Developed by Idaho National Laboratory (INL). Tracks changes in moisture, ash, and bulk density. |

| Mixed Integer Linear Programming (MILP) [4] [5] | A mathematical optimization framework for making strategic and tactical decisions in supply chain design. | Used for facility location, sourcing, and logistics planning. Handles discrete (yes/no) and continuous variables. |

| Single-Pass Harvesting System [2] | Experimental apparatus for simultaneous collection of grain and biomass residue (e.g., corn stover). | Modified combine harvester; allows for collection of clean, soil-free biomass fractions. |

| Geographic Information System (GIS) [9] | A tool for mapping biomass potential, identifying optimal facility locations, and calculating transport distances. | Critical for spatial analysis in supply chain modeling. Often integrated with Multi-Criteria Decision Analysis (MCDA). |

| Torrefaction Reactor | A laboratory-scale unit for thermal pretreatment of biomass to increase energy density and improve grindability. | Operates at 200-300°C in an inert atmosphere. Produces "bio-coal" for improved logistics and co-firing. |

| Vegfr-2-IN-61 | Vegfr-2-IN-61, MF:C27H25N5O, MW:435.5 g/mol | Chemical Reagent |

| FC-116 | FC-116, MF:C21H20FNO4, MW:369.4 g/mol | Chemical Reagent |

Biomass logistics encompasses the planning, coordination, and execution of moving biomass from its origin to processing facilities, a process critical for bioenergy production and bioproducts. The supply chain involves multiple stages—cultivation, harvesting, preprocessing, storage, and transportation—each presenting significant challenges related to cost efficiency, handling of material variability, and ensuring environmental sustainability. With the global biomass logistics service market projected to grow from $4.01 billion in 2024 to $6.40 billion by 2029, addressing these challenges is paramount for advancing the bioeconomy [10]. This document details these challenges within the context of utilizing linear programming for supply chain optimization, providing application notes and experimental protocols for researchers and industrial professionals.

Application Note: Quantifying Key Challenges in Biomass Logistics

The core logistical challenges can be categorized into three interconnected domains: economic (cost), operational (variability), and environmental (sustainability). Table 1 summarizes these primary challenges, their underlying causes, and their direct impacts on the biomass supply chain (BSC). These factors represent the key constraints and objectives that must be modeled within a Linear Programming (LP) framework for optimization.

Table 1: Core Challenges in Biomass Logistics and Their Implications

| Challenge Domain | Specific Challenge | Primary Causative Factors | Impact on Supply Chain |

|---|---|---|---|

| Cost | High Transportation Costs | Low bulk and energy density of raw biomass; Geographically dispersed feedstock [11] [12]; Remote resource locations [13]. | Significant portion of total cost; disadvantages resources in remote areas [13]. |

| High Capital & Operational Expenditure | Need for specialized equipment for handling, storage, and pre-processing [11]; Significant upfront investment [11]. | Poor profitability, limits financing channels, and high market risk [12]. | |

| Variability | Seasonal & Inconsistent Supply | Tie to agricultural and forestry cycles [11]; Regional variations in availability [12]. | Fluctuating supplies throughout the year, complicating continuous reactor feeding [13]. |

| Feedstock Quality Degradation | Material biodegradation during storage; inconsistencies in moisture and composition [13] [12]. | Loss of heating value, adverse impacts on biorefinery yield and throughput [13]. | |

| Sustainability | Environmental Footprint | Greenhouse gas emissions from logistics activities; soil nutrient depletion from intensive farming [11] [12]. | Conflicts with decarbonization goals; potential loss of biodiversity [11]. |

| Land Use and Social Concerns | Competition between energy crops and food production; land use changes [11]. | Potential for deforestation, increased food prices, and social disputes [11]. |

Application Note: Linear Programming for Biomass Supply Chain Optimization

Mixed-Integer Linear Programming (MILP) is a powerful operational research technique for addressing the challenges outlined in Table 1. It is particularly suited for optimizing decisions that involve discrete choices (e.g., facility location, vehicle routing) and continuous variables (e.g., biomass flow, inventory levels). The primary goal is typically to minimize total system cost or maximize profit while adhering to constraints related to supply, demand, capacity, and sustainability.

Key Modeling Considerations for MILP in Biomass Logistics

- Objective Function: The most common objective is cost minimization, encompassing feedstock acquisition, preprocessing, storage, transportation, and capital costs [14] [15]. Alternatively, profit maximization can be formulated, incorporating revenue from selling final products like electricity or biofuels [15].

- Critical Constraints:

- Supply Constraints: Model the seasonal and geographic availability of different biomass feedstocks (e.g., agricultural residues, energy crops) [11] [12].

- Demand Constraints: Ensure the supply chain meets the consistent quantity and quality requirements of the conversion facility [13].

- Capacity Constraints: Account for the storage capacity at warehouses and the processing capacity of biorefineries and pre-processing facilities [14].

- Transportation Constraints: Include vehicle capacity and maximum travel distance limitations to realistically model routing and shipping costs [14].

- Mass Balance Constraints: Ensure the flow of biomass is conserved across all nodes of the supply chain.

- Addressing Variability: To handle supply and demand uncertainty, stochastic MILP or robust optimization models can be employed, incorporating probabilistic scenarios or worst-case analyses to enhance the supply chain's resilience [15].

Workflow for MILP Model Development and Solution

The following diagram illustrates the systematic workflow for developing and solving an MILP model for biomass supply chain optimization, integrating data inputs, model construction, and solution implementation.

Experimental Protocol: MILP for Vineyard Pruning Residual Biomass

This protocol is adapted from a case study applying an MILP model to optimize the collection and transportation of vineyard pruning biomass in Portugal [14]. It provides a replicable methodology for researchers.

Research Reagent Solutions

Table 2: Essential Materials and Computational Tools for MILP Modeling

| Item | Function in the Experiment | Specification / Notes |

|---|---|---|

| Biomass Data | Represents the supply inputs for the model. | Synthetic or real data on biomass quantity per collection point (e.g., 100 points, 5 tons/point avg.) [14]. |

| Geospatial Data | Used to calculate distances and transportation costs. | Coordinates of biomass collection points and processing facility(ies). GIS software can be used. |

| MILP Solver | Software to compute the optimal solution. | Commercial (e.g., Gurobi, CPLEX) or open-source (e.g., GLPK) solvers. |

| Programming Language | Environment for model formulation and data processing. | Python (with Pyomo library), MATLAB, or AMPL. |

| Cost Parameters | Define the economic objective of the model. | Transportation cost per km, vehicle fixed costs, handling costs at facilities. |

Step-by-Step Procedure

Problem Scoping and Parameter Definition:

- Define the geographic boundaries and the number of biomass collection points (n).

- Quantify biomass availability at each point.

- Define the location and capacity of the processing point.

- Set parameters for the transport vehicle(s): capacity (e.g., 10 tons), maximum allowable travel distance per trip (e.g., 50 km), and transportation cost per unit distance [14].

Model Formulation:

- Objective Function: Formulate the objective to minimize the total transportation cost.

- Decision Variables:

- Binary variables: ( x{ij} = 1 ) if vehicle travels from point ( i ) to point ( j ).

- Continuous variables: ( yi ) = quantity of biomass collected at point ( i ).

- Constraints:

- Each collection point is visited no more than once.

- The total biomass collected on a route cannot exceed vehicle capacity.

- The total distance of any route cannot exceed the predefined maximum distance.

- Flow conservation constraints to ensure routes are continuous.

Data Input and Model Execution:

- Input the defined parameters and spatial data into the chosen programming environment.

- Run the MILP model using the integrated solver to find the optimal set of collection routes.

Output Analysis and Validation:

- The primary output is an optimal routing plan that specifies the sequence of collection points for each vehicle.

- Calculate key performance indicators (KPIs): total cost, total distance traveled, total biomass collected, and vehicle utilization rate.

- Validate the model by comparing its results with a baseline scenario without optimization (e.g., ad-hoc collection) to quantify improvements in cost and efficiency.

Advanced Optimization and Integrated Methodologies

Integration of Machine Learning with LP

Machine Learning (ML) can significantly enhance LP models by providing more accurate input parameters and simplifying model complexity [16].

- Predictive Modeling: Use ML algorithms (e.g., Random Forest, Neural Networks) to forecast biomass supply and quality at different locations, transforming the variable supply constraint into a more predictable input for the LP model [16].

- Data-Driven Classification: ML can classify biomass feedstocks or pre-evaluate supplier reliability, reducing the number of variables or constraints the LP model needs to handle directly [16].

Multi-Objective Optimization for Sustainability

While classic MILP often focuses on cost, multi-objective optimization is crucial for addressing sustainability. A model can be extended to simultaneously minimize cost and environmental impact (e.g., GHG emissions from logistics) [15]. This involves:

- Defining an environmental objective function, often derived from Life Cycle Assessment (LCA) data [11].

- Using techniques like the epsilon-constraint method or weighted sum approach to generate a set of Pareto-optimal solutions, allowing decision-makers to choose a balance between economic and environmental performance.

Value Chain and System-Level Analysis

Optimization should not view logistics in isolation. The highest value of biomass may lie not just in its energy content, but in its biogenic carbon for negative emissions technologies (BECCS) or as a feedstock for hard-to-decarbonize sectors like aviation [17]. The following diagram illustrates this integrated value chain perspective, which can inform the strategic parameters of a tactical LP model.

The challenges of cost, variability, and sustainability in biomass logistics are complex but not insurmountable. As demonstrated, Mixed-Integer Linear Programming provides a powerful and flexible mathematical framework to optimize supply chain decisions, directly addressing economic and operational inefficiencies. The integration of machine learning for forecasting and the expansion towards multi-objective optimization that includes environmental metrics are critical advancements for developing robust, sustainable, and cost-effective biomass logistics systems. Future research should focus on enhancing the adaptability of these models with real-time data, improving the granularity of sustainability metrics within the objective function, and exploring the synergies between logistical optimization and the strategic valuation of biomass across the entire energy system.

Why Linear Programming? Addressing BSC Optimization with Linear Objectives and Constraints

Linear Programming (LP) is a fundamental mathematical optimization technique widely employed to achieve the best outcome in mathematical models whose requirements are represented by linear relationships. Its application spans numerous fields, including strategic management through frameworks like the Balanced Scorecard (BSC) and the optimization of complex physical systems such as biomass supply chains. The primary strength of LP lies in its ability to find optimal solutions for problems involving linear objectives subject to linear constraints, making it exceptionally valuable for resource allocation, cost minimization, and strategic alignment challenges.

Within biomass supply chain research, LP provides a robust foundation for modeling complex logistical networks. Biomass supply chains encompass multiple stages including harvesting, collection, transportation, storage, preprocessing, and conversion—each with associated costs, capacities, and operational constraints [4] [18]. The linear nature of many supply chain relationships, such as transportation costs proportional to distance or processing costs proportional to volume, makes LP particularly suitable for optimizing these systems. Furthermore, when strategic management frameworks like BSC are applied to oversee such supply chains, LP offers quantitative rigor for aligning operational decisions with strategic perspectives.

Integrating Linear Programming with Balanced Scorecard Frameworks

The Balanced Scorecard as a Strategic Management Tool

The Balanced Scorecard is a strategic planning and management system that enables organizations to translate their vision and strategy into a coherent set of performance measures across four perspectives: Financial, Customer/Stakeholder, Internal Process, and Learning & Growth [19]. Originally developed as a performance measurement framework, the BSC has evolved into a comprehensive strategic management system that helps organizations clarify vision and strategy, align daily work with strategic objectives, prioritize projects and initiatives, and measure progress toward strategic targets [20] [19].

A key strength of the modern BSC is its ability to integrate with other management frameworks while maintaining strategic focus. As noted in contemporary analyses, "While OKRs and Agile dominate business conversations in 2025, the Balanced Scorecard remains uniquely relevant because it does what these newer frameworks can't: provide a complete strategic picture" [20]. This comprehensive viewpoint makes BSC particularly valuable for complex optimization challenges where multiple competing priorities must be balanced.

Methodological Integration of AHP and LP for Strategy Mapping

Research demonstrates the effective integration of Analytical Hierarchy Process (AHP) and Linear Programming to formalize strategic relationships within BSC strategy maps. This combined methodology follows three key stages:

- Modeling Strategic Relationships: Strategic objectives are identified for each BSC perspective, and all potential cause-effect relationships between these objectives are defined using a hierarchical AHP model [21].

- Quantifying Relationship Importance: AHP is employed to estimate the priority (importance) of every potential causal relationship within the strategy map through expert judgment and pairwise comparisons [21].

- Optimal Relationship Selection: A linear programming model selects the most important relationships for inclusion in the final strategy map, maximizing total importance while minimizing complexity through constraint management [21].

The LP formulation for this application can be represented as:

Objective Function: Maximize Total Importance = Σ(Iij * Xij) for all possible relationships Constraints:

- X_ij ∈ {0,1} for each potential relationship between objectives i and j

- ΣX_ij ≤ MaxRelationships (complexity constraint)

- Relationship selection consistency constraints

This integrated approach provides a rigorous mathematical foundation for strategy map development, moving beyond subjective selection criteria to an optimized network of strategic objectives [21].

LP Formulations for Biomass Supply Chain Optimization

Core Components of Biomass Supply Chain Optimization

Biomass supply chain optimization addresses the complex logistics of transporting low-density biomass materials from dispersed production sites to centralized processing facilities [22]. LP models excel at solving the strategic, tactical, and operational decision problems inherent in these networks. The general structure follows a cost minimization or profit maximization objective function subject to constraints including biomass availability, processing capacities, storage limitations, and demand requirements [4].

Table 1: Key LP Model Components for Biomass Supply Chains

| Component Type | Description | Example Parameters |

|---|---|---|

| Decision Variables | Quantities to be determined through optimization | Biomass flow between locations, Facility utilization levels, Inventory levels |

| Objective Function | Linear function to minimize or maximize | Minimize total cost; Maximize net present value [22] |

| Constraints | Limitations and requirements that must be satisfied | Supply availability, Processing capacity, Demand fulfillment, Transportation capacity |

Specific LP Applications in Biomass Research

Agricultural Waste Optimization for Co-firing

In Indonesia, researchers developed an LP model to optimize agricultural waste biomass supply chains for co-firing in coal power plants. The model incorporated geographic information systems (GIS) to map biomass potential from rice, corn, cassava, palm oil, and other agricultural waste sources [9]. Assuming a 5% biomass mix ratio, the total annual bio-pellet demand was estimated at 3.34 million tons for power plants in Java and Sumatra regions. Optimization results confirmed that available biomass supply could adequately meet co-firing requirements, with the model identifying optimal locations for storage facilities and bio-pellet factories near power plant sites [9].

Vineyard Pruning Biomass Valorization

A Mixed-Integer Linear Programming (MILP) approach was applied to optimize the collection and transportation of vineyard pruning biomass in Portugal's Douro Valley [14]. The model considered 100 collection points with an average of 5 tons of biomass each, transport vehicle capacity constraints (10 tons), and maximum travel distance limitations (50 km). The MILP formulation demonstrated significant improvements, achieving cost reductions of up to 30% while enhancing operational efficiency and resource utilization [14].

Table 2: Quantitative Results from Biomass Supply Chain Optimization Studies

| Study Focus | Region | Optimization Method | Key Outcomes |

|---|---|---|---|

| Agricultural waste for co-firing [9] | Java and Sumatra, Indonesia | Linear Programming with GIS | Met 3.34 million ton demand; Identified optimal facility locations |

| Vineyard pruning biomass [14] | Douro Valley, Portugal | Mixed-Integer Linear Programming | 30% cost reduction; Enhanced resource utilization |

| Forest residue supply chain [4] | Oregon, USA | MILP with fixed/portable depots | Improved cost efficiency; Better sustainability metrics |

Experimental Protocols for BSC-Driven Biomass Optimization

Protocol 1: Strategic Objective Prioritization using AHP-LP Integration

Purpose: To identify and prioritize cause-effect relationships within a BSC strategy map for biomass supply chain management.

Materials and Reagents:

- Expert panel: multidisciplinary stakeholders (5-10 participants)

- AHP software: Expert Choice, SuperDecisions, or equivalent

- LP solver: Excel Solver, LINGO, CPLEX, or open-source alternatives

- Data collection templates: structured questionnaires for pairwise comparisons

Procedure:

- Identify strategic objectives for each BSC perspective (Financial, Customer, Internal Process, Learning & Growth) specific to biomass supply chain operations.

- Construct a hierarchical model with overall goal at the top, perspectives at the intermediate level, and strategic objectives at the lowest level.

- Conduct pairwise comparison surveys with expert panel to evaluate the relative importance of:

- Perspectives relative to the overall goal

- Objectives within each perspective

- Potential cause-effect relationships between objectives

- Calculate consistency ratios for each set of comparisons; revise judgments if ratio exceeds 0.10.

- Synthesize results to obtain local and global priorities for all strategic objectives and potential relationships.

- Formulate LP model to select optimal set of relationships for strategy map:

- Objective function: Maximize sum of relationship priorities

- Decision variables: Binary selection variables for each potential relationship

- Constraints: Maximum number of relationships, logical relationship constraints

- Solve LP model and construct the optimized strategy map.

- Validate results with expert panel and refine as necessary.

Analysis: The output is a validated strategy map showing the most critical cause-effect pathways for achieving biomass supply chain optimization, providing a strategic framework for subsequent mathematical optimization models.

Protocol 2: Biomass Transportation Network Optimization

Purpose: To minimize total transportation costs in a multi-facility biomass supply chain using LP.

Materials and Reagents:

- Geographic data: coordinates of biomass sources, processing facilities, and demand centers

- Transportation cost matrix: cost per unit distance per unit biomass

- Biomass availability data: seasonal yields from different sources

- Facility capacity data: maximum throughput for processing facilities

- LP modeling software: AMPL, GAMS, MATLAB, or Python with PuLP library

Procedure:

- Define sets and indices:

- Biomass supply sources (i ∈ I)

- Processing facilities (j ∈ J)

- Demand centers (k ∈ K)

- Time periods (t ∈ T)

- Compile parameters:

- Supply capacity: Sit ∀ i,t

- Processing capacity: Pjt ∀ j,t

- Demand requirements: D_kt ∀ k,t

- Transportation costs: Cij, Cjk

- Define decision variables:

- Xijt: biomass flow from source i to facility j in period t

- Yjkt: processed biomass flow from facility j to demand center k in period t

- Formulate objective function:

- Minimize Z = ΣΣΣ Cij * Xijt + ΣΣΣ Cjk * Yjkt

- Specify constraints:

- Supply limits: Σ Xijt ≤ Sit ∀ i,t

- Processing capacity: Σ Xijt ≤ Pjt ∀ j,t

- Demand fulfillment: Σ Yjkt ≥ Dkt ∀ k,t

- Flow conservation: Σ Xijt = Σ Yjkt ∀ j,t

- Non-negativity: Xijt ≥ 0, Yjkt ≥ 0

- Implement model in chosen software environment.

- Solve using appropriate LP algorithm (Simplex, Interior Point).

- Perform sensitivity analysis on key parameters (supply availability, demand levels).

- Validate model with historical data if available.

Analysis: The solution provides optimal biomass flows throughout the supply network, minimizing total transportation costs while respecting all capacity and demand constraints. Shadow prices from the dual solution identify binding constraints and opportunities for capacity expansion.

Visualization of Methodological Framework

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools for BSC and Supply Chain Optimization

| Tool Category | Specific Solutions | Function in Research | Application Examples |

|---|---|---|---|

| Optimization Software | IBM ILOG CPLEX, Gurobi, LINGO | Solving large-scale LP/MILP models | Biomass network design [4], Transportation optimization [14] |

| AHP/ANP Platforms | Expert Choice, SuperDecisions, MakeItRational | Multi-criteria decision analysis | Strategy map relationship prioritization [21] |

| Geographic Analysis | ArcGIS, QGIS, GRASS GIS | Spatial analysis and mapping | Biomass potential mapping [9], Facility location optimization |

| Programming Languages | Python (PuLP, Pyomo), R (lpSolve), MATLAB | Custom model development | Algorithm implementation, data preprocessing [18] |

| Supply Chain Simulators | AnyLogic, Simul8, Arena | Discrete-event simulation | Biomass flow validation, scenario testing [18] |

| UC-857993 | UC-857993, MF:C25H22ClNO2, MW:403.9 g/mol | Chemical Reagent | Bench Chemicals |

| Dorrigocin A | Dorrigocin A, MF:C27H41NO8, MW:507.6 g/mol | Chemical Reagent | Bench Chemicals |

Linear Programming provides a robust mathematical foundation for addressing optimization challenges across both strategic management frameworks like Balanced Scorecard and physical systems such as biomass supply chains. The methodology's strength lies in its ability to handle linear objective functions and constraints efficiently, even for large-scale problems. Through the integration of AHP for strategic relationship prioritization and LP for optimal selection, organizations can develop quantitatively rigorous strategy maps that reflect the most critical cause-effect pathways.

In biomass supply chain applications, LP models have demonstrated significant practical benefits, including cost reductions up to 30% in documented cases [14], efficient fulfillment of large-scale biomass demands [9], and improved sustainability metrics through optimized network designs [4]. The complementary relationship between strategic frameworks like BSC and mathematical optimization techniques like LP enables organizations to align operational decisions with strategic objectives while maintaining mathematical rigor in resource allocation and logistics planning.

Future research directions should focus on enhancing LP applications in biomass supply chains through integration with emerging technologies, including real-time data assimilation for dynamic optimization [22], hybrid simulation-optimization approaches [18], and multi-objective formulations that simultaneously address economic, environmental, and social sustainability criteria [4].

The design and management of a biomass supply chain (BMSC) are complex endeavors that require balancing multiple, often competing, priorities. Operations research, particularly linear programming (LP) and mixed-integer linear programming (MILP), provides a powerful analytical framework for navigating these challenges by transforming strategic goals into quantifiable, optimized decisions [4]. Within the broader context of a thesis on linear programming for BMSC research, defining the core objectives is a foundational step. These objectives guide the entire modeling process, from the selection of parameters and variables to the interpretation of results. The three predominant objectives explored in contemporary research are cost minimization, profit maximization, and the achievement of environmental goals [4] [23] [24]. These are not always mutually exclusive; multi-objective models frequently integrate them to identify solutions that offer the best possible compromise, ensuring the supply chain is not only economically viable but also environmentally sustainable and resilient [23].

This document serves as an application note for researchers and scientists, detailing the practical formulation of these core objectives, the experimental protocols for implementing optimization models, and the key reagents—in this context, data inputs and analytical tools—required for a successful BMSC analysis.

Core Objectives and Their Mathematical Formulations

Cost Minimization

Cost minimization is the most prevalent objective in BMSC optimization, focusing on reducing the significant logistical expenses that can determine the economic feasibility of the entire chain [24]. The primary costs considered include harvesting, transportation, preprocessing, and facility setup [4] [25].

A canonical LP formulation for cost minimization is structured as follows [25] [26]:

Objective Function: Minimize ( C = \sum{i=1}^{n} \sum{j=1}^{k} (x{ij} \times Pj) + (x{ij} \times li \times T_j) )

Subject to:

- Energy Demand Constraint: ( \sum{i=1}^{n} \sum{j=1}^{k} x{ij} \times \gammaj \geq E )

- Supply Availability Constraint: ( x{ij} \leq V{ij} )

- Non-negativity Constraint: ( x_{ij} \geq 0 )

Where:

- ( C ): Total cost of purchasing and transporting biomass.

- ( i ): Index for biomass source spatial unit.

- ( j ): Index for type of biomass.

- ( x_{ij} ): Quantity of biomass type ( j ) to purchase from unit ( i ) (decision variable).

- ( P_j ): Purchase price per ton of biomass type ( j ).

- ( l_i ): Distance from power plant to spatial unit ( i ).

- ( T_j ): Transportation cost per ton-km for biomass type ( j ).

- ( \gamma_j ): Calorific value (MJ/ton) of biomass type ( j ).

- ( E ): Total energy demand of the power plant.

- ( V_{ij} ): Maximum available quantity of biomass type ( j ) at unit ( i ).

Profit Maximization

An alternative to cost minimization is profit maximization, which incorporates revenue from the sale of generated energy or bio-products. This approach is useful for evaluating the overall business case and profitability of a BMSC investment [4] [23].

The objective function shifts to: Maximize ( Z = R - C ) Where ( R ) is the total revenue from selling energy, and ( C ) is the total cost as defined in the cost minimization model [23]. The constraints related to supply availability and energy demand remain critical.

Environmental Goals

Environmental objectives are increasingly integrated into BMSC models to align with global sustainability targets and regulations. The most common environmental goal is the minimization of greenhouse gas (GHG) emissions across the supply chain [23]. This can be modeled as a separate objective in a multi-objective framework or as a constraint within a cost-minimization model.

- Emissions-Focused Objective Function: Minimize ( G = \sum{i=1}^{n} \sum{j=1}^{k} x{ij} \times EFj ) Where ( G ) is the total GHG emissions and ( EF_j ) is the emission factor for biomass type ( j ) throughout its lifecycle [23]. Social objectives, such as creating jobs in rural areas, can also be incorporated to build a comprehensive sustainability model [23].

Table 1: Key Model Parameters for Core Objectives

| Objective | Key Cost Parameters | Key Revenue Parameters | Key Environmental Parameters | Common Constraints |

|---|---|---|---|---|

| Cost Minimization | Harvesting, Transport, Preprocessing, Facility Setup [4] [24] | Not Applicable | Not Primary Focus | Biomass Availability, Energy Demand, Facility Capacity [25] |

| Profit Maximization | All parameters from Cost Minimization | Selling Price of Energy/Bio-products [23] | Can be added as a constraint | Biomass Availability, Energy Demand, Market Limits |

| Environmental Goals | Can be added as a constraint | Not Primary Focus | GHG Emission Factors, Carbon Sequestration Potential [23] | Budget, Biomass Availability, Energy Demand |

Experimental Protocols for BMSC Optimization

Protocol 1: GIS-Integrated Linear Programming for Sourcing Optimization

This protocol outlines the integration of Geographic Information Systems (GIS) with LP to identify optimal biomass sourcing strategies, a method successfully applied in case studies in Poland and Indonesia [9] [25] [26].

Workflow Diagram: GIS-LP Integration

1. Define Study Area and Biomass Sources:

- Delineate the geographical boundary for the analysis (e.g., a 100-200 km radius around the power plant) [25] [26].

- Identify and categorize all potential biomass sources within the area (e.g., agricultural residues, forest residues, energy crops) [9].

2. Spatial Data Collection and Database Construction:

- GIS Data: Collect spatial data on land use, forest cover, road networks, and administrative boundaries [9].

- Biomass Potential: Calculate the annual available biomass for each spatial unit (e.g., county, forest district). For agricultural waste, this is often the excess of production over internal consumption. For forestry, it is based on timber harvest projections and biomass expansion factors [26].

- Economic and Biophysical Data: Gather data on biomass purchase prices, transportation costs, and calorific values for each biomass type [25] [26].

3. GIS Analysis and Cost Calculation:

- Determine the centroid of each spatial unit and calculate the road distance to the conversion plant [26].

- For each potential biomass source ( (i, j) ), calculate the total unit cost, which includes the purchase price and the transportation cost ( (Pj + li \times T_j) ) [25].

4. LP Model Formulation and Execution:

- Formulate the objective function (e.g., cost minimization as in Section 2.1) and constraints [25].

- Implement the model in an optimization solver (e.g., CPLEX, Gurobi, or open-source alternatives) and execute it to determine the optimal quantity ( x_{ij} ) to source from each location.

5. Scenario Analysis and Validation:

- Run the model under different scenarios (e.g., varying energy demand, different biomass types available, ecological restrictions) to test the robustness of the solution [26].

- Validate the model outputs against known benchmarks or through sensitivity analysis on key parameters like transportation cost [4].

Protocol 2: Strategic Network Design with Fixed and Portable Depots

This protocol details the use of a MILP model to make strategic decisions about the number, location, and type of preprocessing facilities, a critical factor in reducing overall BMSC costs [4].

Workflow Diagram: Depot Integration Strategy

1. Problem Definition and Data Preparation:

- Define the set of biomass supply locations (watersheds), potential locations for Fixed Depots (FDs) and Portable Depots (PDs), and the energy conversion plant(s) [4].

- Collect data on biomass availability per location, costs for harvesting, transportation between all nodes, and capital/operational costs for FDs and PDs [4].

2. MILP Model Formulation:

- Objective Function: Minimize total cost, including feedstock, transport, and depot costs [4].

- Decision Variables:

- Binary variables: Whether to open an FD at a potential location; whether to deploy a PD to a specific area.

- Continuous variables: Flow of biomass from supply points to depots and from depots to the plant.

- Key Constraints:

- Biomass flow conservation at all nodes.

- Capacity limits of FDs and PDs.

- Demand satisfaction at the energy plant.

3. Model Implementation and Numerical Experimentation:

- Code the MILP model in a modeling language and solve it using a MILP solver.

- Conduct numerical experiments to compare the total cost and configuration of a network using only FDs versus a hybrid network with both FDs and PDs. Research shows the hybrid model can reduce total costs by up to 27% by cutting transportation expenses from collection points to preprocessing facilities [4] [27].

4. Case Study Application:

- Apply the model to a real-world case, such as a specific power plant (e.g., a case study in Oregon, USA) [4] [27]. Use local data to generate a tailored, optimal BMSC design that demonstrates the model's practical applicability and quantifies its benefits for stakeholders.

The Scientist's Toolkit: Research Reagent Solutions

The following table outlines the essential "reagents"—data inputs and analytical tools—required for conducting BMSC optimization research.

Table 2: Essential Research Reagents for BMSC Optimization

| Category | Reagent / Tool | Specifications & Function | Application Example |

|---|---|---|---|

| Spatial Data | GIS Software (e.g., QGIS, ArcGIS) | Function: Maps biomass availability, calculates transport distances, and identifies optimal facility locations. | Mapping agricultural waste potential in Java/Sumatra for co-firing [9]. |

| Biomass Data | Calorific Values (( \gamma_j )) | Specs: MJ/ton for each biomass type (e.g., stacked wood: 17.5, straw: 14.0) [25]. Function: Converts mass to energy for demand constraints. | Calculating if sourced biomass meets a power plant's energy requirement [25] [26]. |

| Biomass Expansion Factors (BEFs) | Function: Converts timber volume to dry biomass of residues (e.g., branches) [26]. | Estimating the availability of forest residues from timber harvest data [26]. | |

| Economic Data | Transportation Cost Rates (( T_j )) | Specs: €/ton-km. Function: A primary component of the total logistical cost to be minimized [24] [25]. | Evaluating the cost-effectiveness of sourcing from distant but high-yield areas. |

| Facility Setup & Operational Costs | Function: Capital and operational costs for Fixed and Portable Depots. Function: Used in MILP to decide on facility investments [4]. | Comparing the economic trade-off between fixed infrastructure and flexible portable units [4]. | |

| Optimization Tools | Linear & MILP Solvers (e.g., Gurobi, CPLEX) | Function: Computes the optimal solution to the formulated LP/MILP model. | Solving the cost minimization problem for a supply chain with thousands of variables and constraints [4] [25]. |

| Modeling Framework | Multi-Objective Optimization | Function: Algorithms (e.g., weighted sum, ε-constraint) to handle conflicting goals like cost and emissions. | Designing a supply chain that balances profitability with carbon footprint reduction [23]. |

| Lzfpn-90 | Lzfpn-90, MF:C33H36N8O2S, MW:608.8 g/mol | Chemical Reagent | Bench Chemicals |

| UCB9386 | UCB9386, MF:C27H26N8O, MW:478.5 g/mol | Chemical Reagent | Bench Chemicals |

The Expanding Role of Biomass in Renewable Energy and Bio-Based Product Development

Application Note: Biomass Supply Chain Optimization via Linear Programming

Market Context and Quantitative Landscape

The global biomass power generation market is demonstrating substantial growth, transitioning from a niche renewable source to a significant component of the global energy portfolio. The table below summarizes key market metrics and regional growth trends.

Table 1: Global Biomass Power Generation Market Overview

| Metric | 2024 Value | 2030 Projection | CAGR | Key Regional Trends |

|---|---|---|---|---|

| Global Market Value | US$90.8 Billion | US$116.6 Billion | 4.3% | Strongest growth in Asia-Pacific, followed by Europe and North America |

| U.S. Market Value | $6.6 Billion | - | - | Part of broader renewables segment (24% of 2024 U.S. electricity) |

| Bulk Density & Preprocessing | Critical cost factors | - | - | Technologies like torrefaction can improve energy density by up to 30% |

| Bio-pellet Supply-Demand (Indonesia Case) | 143.58 million tons production capacity | - | - | Demand for co-firing: 3.34 million tons (5% mix in Java-Sumatra) |

Biomass currently contributes significantly to renewable energy targets, with solid feedstocks like wood chips and pellets constituting 86% of global biomass feedstock and contributing 69% of total biomass energy in 2020 [4]. In the U.S. power sector, renewable energy sources including biomass accounted for 24% of total electricity generation in 2024 [28]. The biomass supply chain encompasses multiple critical stages from harvesting to conversion, with preprocessing playing a pivotal role in enhancing biomass quality and reducing logistics costs [4].

Technical Challenges in Biomass Logistics

Biomass supply chains face several inherent challenges that optimization models must address:

- Low Bulk Density: Raw biomass materials possess low energy density per unit volume, making transportation inefficient and costly without preprocessing [4]

- Geographical Dispersion: Biomass sources are typically scattered across large regions, complicating collection and aggregation [4] [14]

- Seasonal Availability: Biomass availability fluctuates seasonally, particularly agricultural residues, requiring flexible supply chain designs [4]

- Infrastructure Requirements: Preprocessing facilities represent significant capital investments that must be optimally located [4]

These challenges directly impact the overall cost and environmental footprint of biomass utilization, making optimization through linear programming methodologies not merely beneficial but essential for economic viability.

Protocol: Mixed-Integer Linear Programming for Biomass Supply Chain Design

Experimental Setup and Model Formulation

This protocol outlines the implementation of a Mixed-Integer Linear Programming model for optimizing biomass supply chain networks with integrated fixed and portable preprocessing depots.

Table 2: Research Reagent Solutions for Supply Chain Modeling

| Component | Function | Implementation Example |

|---|---|---|

| MILP Solver | Computational engine for optimization | Commercial (CPLEX, Gurobi) or open-source (SCIP) solvers |

| Geographic Information System (GIS) | Spatial analysis of biomass availability and facility locations | Mapping biomass sources and calculating transport distances [9] |

| Multi-Criteria Decision Analysis (MCDA) | Evaluate and rank potential facility locations | Integrate environmental, economic, and social factors [9] |

| Biomass Logistics Simulator | Test model performance under varying conditions | Synthetic datasets simulating vineyard regions [14] |

Model Objective Function: The primary objective is to minimize total supply chain cost, comprising harvesting, transportation, preprocessing, and fixed facility costs [4]:

Where:

Hit= Harvesting cost at watershed i in period tTCij= Transportation cost from location i to jPCj= Processing cost at depot jFCj= Fixed cost of establishing/operating depot jXit, Yij, Zj= Decision variables for biomass flowWj= Binary variable for facility establishment

Key Constraints:

- Biomass Availability: Total biomass shipped from source i cannot exceed available biomass

- Demand Fulfillment: Total biomass to conversion facility k must meet demand

- Capacity Limits: Processing at depot j cannot exceed capacity

- Flow Conservation: Biomass inflow equals outflow at preprocessing depots

- Binary Logic: Facility establishment triggers fixed costs [4]

Workflow Implementation and Analysis

The optimization follows a structured workflow with defined inputs, processing stages, and outputs.

Implementation Steps:

Data Collection and Preparation (1-2 weeks)

- Geospatial data on biomass availability (watersheds, agricultural areas)

- Transportation network (distances, routes, costs)

- Candidate locations for fixed and portable depots

- Technical parameters (processing capacities, conversion efficiencies)

Model Parameterization (3-5 days)

- Define cost coefficients (harvesting, transport, processing)

- Set capacity constraints for facilities

- Establish demand requirements from conversion plants

- Define environmental constraints (carbon emissions, energy efficiency)

Solution and Validation (1 week)

- Execute MILP model using appropriate solver

- Validate solution feasibility through scenario testing

- Conduct sensitivity analysis on key parameters

- Compare against baseline scenarios without optimization

Case Study Application and Performance Metrics

Oregon Power Plant Case Study: A real-world application at a 600 MW coal power plant in Oregon, USA demonstrated the model's effectiveness. The plant required approximately 2.5 million tons of coal annually, emitting 4.6 million tons of COâ‚‚. Through biomass co-firing optimization, the model identified optimal locations for fixed and portable depots to supply biomass, reducing logistics costs while maintaining plant efficiency [4].

Performance Metrics: The optimized supply chain model demonstrated:

- Cost reductions of up to 30% compared to non-optimized networks [14]

- Improved resource utilization through strategic depot placement

- Enhanced flexibility to handle seasonal biomass availability variations

- Reduced transportation distances and associated emissions

Table 3: Optimization Results Comparison

| Performance Indicator | Baseline Scenario | Optimized Scenario | Improvement |

|---|---|---|---|

| Total Logistics Cost | Base value | 30% reduction | High |

| Facility Utilization | Suboptimal | Balanced loading | Significant |

| Transportation Distance | Longer routes | Optimized routes | 15-25% reduction |

| Carbon Footprint | Higher emissions | Reduced emissions | Proportional to distance reduction |

Application Note: Advanced Biomass Conversion Pathways

Technological Innovations in Biomass Utilization

Beyond direct combustion, several advanced conversion technologies are expanding biomass applications:

Thermochemical Processes:

- Torrefaction: Thermal pretreatment at 200-300°C in inert environment to improve biomass grindability, energy density, and storage stability [4] [29]

- Gasification: Conversion of biomass into syngas (CO + H₂) at high temperatures (800-1200°C) with controlled oxygen [29]

- Pyrolysis: Thermal decomposition in absence of oxygen to produce bio-oil, char, and gases [28]

Biological Processes:

- Anaerobic Digestion: Microbial breakdown of organic matter to produce biogas [29]

- Fermentation: Conversion of biomass sugars to biofuels like ethanol [4]

Emerging Applications:

- Bioproducts Development: USDA's Bioproduct Pilot Program supports using agricultural commodities for construction and consumer products as low-cost alternatives to conventional materials [30]

- Bioactive Compounds: Green bioprocessing techniques extract high-value bioactive products from biomass for functional foods, biocosmetics, and biopharmaceuticals [31]

Integrated Supply Chain Configuration

Modern biomass supply chains incorporate multiple preprocessing options to optimize overall efficiency.

Protocol: GIS-Integrated Multi-Criteria Biomass Assessment

Spatial Analysis Methodology

This protocol details the integration of Geographic Information Systems (GIS) with optimization models for comprehensive biomass supply chain design, as demonstrated in Indonesian case studies [9].

Data Collection Phase:

- Biomass Resource Mapping (2-3 weeks)

- Identify agricultural and forestry waste areas using satellite imagery

- Quantify biomass availability by type (rice, corn, palm oil, sugarcane residues)

- Calculate seasonal variations in biomass availability

- Determine collection radii and transportation access routes

- Facility Suitability Analysis (1-2 weeks)

- Analyze candidate locations for preprocessing facilities

- Evaluate proximity to biomass sources and conversion plants

- Assess infrastructure requirements (power, water, transport access)

- Identify environmental and social constraints

Multi-Criteria Decision Analysis: The GIS integration employs weighted factors to evaluate potential facility locations:

- Biomass availability (30% weight)

- Transportation network accessibility (25%)

- Proximity to power plants (20%)

- Environmental impact (15%)

- Social acceptance (10%)

Implementation Framework

The integrated GIS-MILP framework enables comprehensive supply chain optimization:

Spatial Data Integration

- Convert geospatial data into model parameters

- Calculate transportation distances and costs

- Define biomass availability constraints by region

Multi-Objective Optimization

- Primary objective: Minimize total supply chain cost

- Secondary objectives: Reduce environmental impact, enhance social benefits

- Weighted approach to balance competing objectives

Scenario Analysis

- Test different biomass co-firing ratios (1-10%)

- Evaluate impact of policy changes (carbon taxes, incentives)

- Assess robustness to biomass availability fluctuations

Case Study Results: Application in Java and Sumatra, Indonesia demonstrated the protocol's effectiveness. With 14 and 12 coal power plants respectively in these regions, a 5% biomass co-firing ratio required 3.34 million tons of bio-pellets annually. The assessment revealed annual production capacity of 143.58 million tons, indicating sufficient biomass availability with proper supply chain design [9]. The optimized network identified strategic locations for storage facilities and bio-pellet factories near power plants, significantly reducing transportation costs and improving overall supply chain efficiency.

From Theory to Practice: Implementing LP and MILP Models for Biomass Logistics

The optimization of the Biomass Supply Chain (BSC) is a critical step in ensuring the economic viability, environmental sustainability, and social acceptability of bioenergy production. Linear Programming (LP) and its extensions, such as Mixed-Integer Linear Programming (MILP), provide a robust mathematical framework for modeling the complex network of decisions involved in the BSC, from biomass harvesting to energy delivery. This document outlines the core mathematical formulations—objective functions and key constraints—essential for designing and optimizing these systems, framed within the context of academic thesis research. The formulations presented serve as a standardized toolkit for researchers and industry professionals to develop customized models for specific biomass scenarios.

Core Objective Functions in BSC Optimization

The design of a BSC is inherently multi-faceted, requiring a balance between competing priorities. Single-objective optimization is often used for focused analysis, while multi-objective approaches are necessary for a holistic, sustainable design [32]. The table below summarizes the primary objective functions found in BSC literature.

Table 1: Core Objective Functions in BSC Optimization Models

| Objective Type | Mathematical Formulation (Representative) | Description & Components |

|---|---|---|

| Economic: Cost Minimization | Minimize: Total Cost = Harvesting Cost + Transportation Cost + Processing Cost + Inventory Cost [33] [25] [4] |

Aims to minimize the total cost of the supply chain. Transportation costs often constitute the largest portion [24]. |

| Economic: Profit Maximization | Maximize: Total Profit = Revenue from Energy/Product Sales - Total Cost [4] |

Focuses on maximizing the net profit of the entire BSC operation. |

| Environmental Impact Minimization | Minimize: Total CO₂ Emissions = ∑(Emission Factor_i,j * Quantity_i,j) [33] [32] |

Seeks to minimize the greenhouse gas emissions, typically COâ‚‚, across all supply chain activities (transport, processing). |

| Social Benefit Maximization | Maximize: Total Social Benefit = ∑(Job Creation Potential_i * Activity Level_i) [33] |

Aims to maximize positive social impact, often quantified by the number of green job hours created by the supply chain [33]. |

Key Constraints in BSC Optimization Models

Constraints define the feasible operational space for the optimization model. They ensure that the solution adheres to physical, logical, and strategic limitations.

Table 2: Key Constraints in BSC Optimization Models

| Constraint Category | Mathematical Formulation (Representative) | Description |

|---|---|---|

| Supply Constraints | Biomass Shipped from Source i ≤ Biomass Available at Source i [33] [4] |

Ensures that the amount of biomass procured from a supply location (e.g., a watershed or forest) does not exceed its available capacity. |

| Demand Constraints | Biomass Received at Plant k ≥ Energy Plant Demand k [25] [4] |

Guarantees that the energy conversion facility (e.g., power plant) receives sufficient biomass to meet its production demand. |

| Capacity Constraints | Biomass Flow through Facility j ≤ Capacity of Facility j [34] [4] |

Restricts the amount of biomass that can be processed or stored at a facility (e.g., preprocessing depot, storage yard) within a given period. |

| Flow Conservation | Biomass In = Biomass Out + Biomass Loss [4] |

Ensures the mass balance of biomass across the network nodes, accounting for processing losses or moisture reduction. |

| Logical & Facility Constraints | Number of Facilities Opened ≤ Maximum Number of Available Facilities [4] |

Manages strategic decisions, such as the number and location of preprocessing depots to establish, often involving binary (0-1) variables [4]. |

Multi-Objective Optimization and Solution Approaches

Real-world BSC problems often involve simultaneous optimization of multiple, conflicting objectives. For instance, minimizing cost may conflict with minimizing emissions [32]. A common approach is to use the weighted-sum method or goal programming to aggregate multiple objectives into a single function [32]. The Pareto optimality concept is fundamental, where a solution is Pareto optimal if no objective can be improved without worsening another [34].

Sample Multi-Objective Formulation: A goal programming approach can be structured as follows [32]:

Where d_i⻠and d_i⺠are deviational variables representing under-achievement and over-achievement of goals, and w_i are weights reflecting decision-maker preferences.

Modeling Uncertainty in the BSC

Biomass supply chains are subject to significant uncertainties, including biomass availability, market prices, and technology performance [35]. A deterministic MILP model may produce solutions that are not robust to real-world variability. Common methods to handle uncertainty include:

- Fuzzy Programming: Used when parameters are unpredictable and best represented by membership functions (e.g., for vague biomass quality data) [34].

- Globalized Robust Optimization (GRO): Suitable when only a general value range for uncertain parameters (e.g., unit emissions, social scores) is known, providing solutions that are less conservative than classic robust optimization [32].

- Stochastic Programming: Applied when uncertain parameters can be described by probability distributions, optimizing the expected value of the objective across many scenarios [35].

Experimental Protocol: Implementing a BSC Optimization Model

This protocol provides a step-by-step methodology for formulating and solving a typical BSC optimization problem using an MILP framework.

Problem Scoping and Data Collection

- Define System Boundaries: Identify the geographic scope, time horizon (single-period or multi-period), and the biomass types (e.g., forest residues, agricultural straw) [33] [25].

- Map the Network: Identify all nodes: biomass supply sources (e.g., watersheds, farms), potential facility locations (e.g., preprocessing depots, storage sites), and energy conversion plants (e.g., power plants) [4].

- Gather Data: Collect all relevant parameters.

- Economic: Biomass purchase price, harvesting cost, transportation cost per ton-km, processing costs at depots and plants, fixed costs for opening facilities, and revenue from energy sales [33] [25].

- Environmental: COâ‚‚ emission factors for transportation and processing activities [33].

- Social: Job creation factors (hours per ton of biomass handled) for different supply chain activities [33].

- Physical: Biomass availability at each source, calorific value of biomass types, capacity of all facilities, and demand at the power plant [25] [4].

Model Formulation

- Define Sets and Indices: (e.g.,

i ∈ Ifor supply sources,j ∈ Jfor depots,k ∈ Kfor plants). - Define Parameters: (e.g.,

Supply_i,Demand_k,Cost_Transport_i,j,Capacity_j). - Define Decision Variables: (e.g.,

X_i,j= continuous flow from i to j,Y_j= binary variable for opening depot j). - Formulate Objective Function: Select one or combine multiple from Table 1. A common single objective is

Minimize: Total Cost[25] [4]. - Formulate Constraints: Implement the relevant constraints from Table 2 to model the system accurately.

Model Implementation and Solution

- Coding: Implement the MILP model in a modeling language (e.g., Python with Pyomo, AMPL, GAMS).

- Solver Selection: Use a commercial or open-source MILP solver (e.g., CPLEX, Gurobi, GLPK).

- Execution & Validation: Solve the model and validate the results for practical feasibility. Conduct sensitivity analysis on key parameters (e.g., biomass price, demand) to test solution robustness.

Analysis and Interpretation

- Result Analysis: Analyze the optimal biomass flows, facility utilization, and total cost/emissions.

- Scenario Analysis: Run different scenarios (e.g., changes in policy, availability of different biomass types) to support strategic decision-making [25] [4].

- Multi-Objective Analysis: If using a multi-objective approach, analyze the Pareto frontier to understand trade-offs between objectives [32].

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Computational Tools and Data Sources for BSC Research

| Tool / Resource | Type | Function in BSC Research |

|---|---|---|

| CPLEX / Gurobi | Commercial Solver | Solves large-scale MILP optimization models to proven optimality [32]. |

| Python (Pyomo) | Modeling Language | Provides a flexible, open-source platform for formulating and solving optimization models. |

| Geographic Information System (GIS) | Data Analysis Tool | Determines accurate transport distances, locates biomass sources, and visualizes optimal supply networks [25]. |

| Life Cycle Assessment (LCA) Database | Environmental Data Source | Provides emission factors for transportation and processing activities to quantify environmental objectives [33]. |

| National Biomass Atlas | Data Resource | Offers regional data on biomass availability and characteristics, crucial for defining supply constraints [25]. |

| Lqb-118 | Lqb-118, MF:C19H12O4, MW:304.3 g/mol | Chemical Reagent |

| GMB-475 | GMB-475, MF:C43H46F3N7O7S, MW:861.9 g/mol | Chemical Reagent |

Workflow and Constraint Relationships

The following diagram illustrates the logical sequence of formulating and solving a BSC optimization problem, highlighting the interaction between its core components.

Diagram 1: BSC optimization model formulation workflow.

The relationships between different constraint types and their role in shaping a feasible solution are visualized below.

Diagram 2: Constraint relationships defining a feasible BSC network.

The optimization of biomass supply chains (BSCs) is a critical research area for advancing renewable energy and supporting the transition to a circular bioeconomy. Biomass supply chains encompass the integrated management of activities from biomass cultivation and harvesting to collection, preprocessing, storage, transportation, and final conversion to energy or bioproducts [4] [16]. The complex, geographically dispersed, and variable nature of biomass resources presents significant logistical challenges that require sophisticated mathematical modeling approaches for effective decision-making. Operations Research (OR) provides analytical tools to address these complexities, with optimization models playing a pivotal role in supporting strategic, tactical, and operational planning [4].

Selecting the appropriate optimization model is fundamental to developing efficient, cost-effective, and sustainable biomass supply chain systems. The choice between Linear Programming (LP) and Mixed-Integer Linear Programming (MILP) is primarily dictated by the nature of the decisions required. LP models are suitable for problems involving continuous decisions, such as determining optimal biomass flow quantities between locations. In contrast, MILP is essential when the problem involves discrete, yes-or-no decisions—such as whether to open a facility, which technology to select, or which vehicle route to take—alongside continuous flow decisions [4] [14]. This protocol provides a structured framework for researchers and practitioners to select and implement the appropriate model for their specific biomass supply chain optimization context.

Theoretical Foundation: LP vs. MILP

Core Model Formulations

Linear Programming (LP) is a mathematical method for determining the optimal outcome (such as maximum profit or lowest cost) in a model whose requirements are represented by linear relationships. It is applicable when all decision variables can assume fractional values. A standard LP formulation is:

Objective Function: Maximize or Minimize ( Z = \sum{j=1}^{n} cj x_j )

Subject to: ( \sum{j=1}^{n} a{ij} xj \leq bi \quad \text{for } i = 1, 2, ..., m ) ( x_j \geq 0 \quad \text{for } j = 1, 2, ..., n )

Here, ( xj ) are continuous decision variables, ( cj ) are coefficients of the objective function, ( a{ij} ) are technological coefficients, and ( bi ) are resource limitations.

Mixed-Integer Linear Programming (MILP) extends LP by allowing some decision variables to take only integer values (e.g., 0 or 1), which enables modeling of discrete choices. A standard MILP formulation is:

Objective Function: Maximize or Minimize ( Z = \sum{j=1}^{n} cj xj + \sum{k=1}^{p} dk yk )

Subject to: ( \sum{j=1}^{n} a{ij} xj + \sum{k=1}^{p} g{ik} yk \leq bi \quad \text{for } i = 1, 2, ..., m ) ( xj \geq 0 \quad \text{for } j = 1, 2, ..., n ) ( y_k \in \mathbb{Z} \quad \text{for } k = 1, 2, ..., p )

Here, ( y_k ) are integer decision variables, often binary (0 or 1), used to model on/off decisions [4] [14].

Comparative Analysis and Application Scope

Table 1: Decision Guide for Model Selection

| Feature | Linear Programming (LP) | Mixed-Integer Linear Programming (MILP) |

|---|---|---|

| Variable Types | Continuous only | Continuous and Integer (typically binary) |

| Primary Use Case | Resource allocation, continuous flow optimization | Facility location, technology selection, unit commitment |

| Problem Complexity | Lower; broadly solvable for large-scale problems | Higher; computational effort grows with integer variables |

| Solution Time | Generally faster, polynomial time for most cases | Generally slower, can be exponential in worst case |

| Real-World Fit | Optimizing within a fixed supply chain structure | Designing the structure of the supply chain itself |

| Example in BSC | Determining optimal biomass shipment quantities between established facilities | Selecting optimal locations for preprocessing depots and assigning biomass sources [4] |

Application in Biomass Supply Chain Optimization

Strategic Planning with MILP

MILP is the predominant model for strategic biomass supply chain design, as it simultaneously determines the optimal network structure and material flows. A key application is the design of a multi-echelon supply chain incorporating fixed depots (FDs) and portable depots (PDs). FDs are permanent processing facilities that benefit from economies of scale, while PDs are mobile units that can be relocated to areas with seasonal biomass availability, introducing remarkable flexibility and adaptability [4]. An MILP model can determine the number and locations of FDs, the allocation of PDs across different watersheds, and the biomass flow from collection points to depots and then to bioenergy plants, minimizing total cost or maximizing profit [4].

Another strategic application is demand selection, where an MILP model decides which market demands to fulfill to maximize profitability under constrained biomass resources and operational capacities [15]. Furthermore, MILP models can integrate sustainability objectives by incorporating constraints on greenhouse gas emissions or by formulating multi-objective functions to balance economic and environmental goals [36].

Tactical and Operational Planning

While MILP dominates strategic planning, both LP and MILP find applications at tactical and operational levels. LP is highly effective for optimizing continuous flows in a fixed network. For instance, once depot locations are chosen, an LP model can determine the optimal procurement, production, and distribution quantities for each planning period to minimize operational costs [37].

MILP, however, remains necessary for tactical problems involving discrete decisions. A prime example is the vehicle routing problem for biomass collection. An MILP model can define optimal collection routes from multiple, dispersed biomass sources (e.g., vineyard pruning points) to a central processing facility, ensuring that constraints on vehicle capacity, maximum travel distance, and collection time are respected [14]. Such a model uses binary variables to encode the sequence of visits on a route, a classic discrete decision problem.

Experimental Protocols for Model Implementation

Protocol 1: Designing a Biomass Supply Chain with Fixed and Portable Depots