Closing the Loop: The Integral Role of Bioenergy in a Sustainable Circular Economy

This article explores the transformative potential of bioenergy within the circular economy model, a critical framework for researchers and scientists focused on sustainable development.

Closing the Loop: The Integral Role of Bioenergy in a Sustainable Circular Economy

Abstract

This article explores the transformative potential of bioenergy within the circular economy model, a critical framework for researchers and scientists focused on sustainable development. It examines the foundational principles of using biological resources to convert waste into value, detailing advanced methodological approaches like enzymatic recycling and thermochemical conversion. The content addresses key challenges in optimization, including technological bottlenecks and economic viability, while providing robust validation through life cycle assessments and quantitative case studies. By synthesizing cutting-edge research and global initiatives, this review serves as a comprehensive resource for professionals driving innovation in waste valorization and renewable energy systems.

The Foundation: Defining Bioenergy's Role in a Circular Bioeconomy

The global economy is predominantly structured around a linear "take-make-dispose" model, characterized by the extraction of finite resources, energy-intensive production, and ultimate disposal, resulting in significant waste and environmental degradation [1]. This system is unsustainable; the world extracts over 100 billion tonnes of raw materials annually, with more than 90% wasted after a single use [1]. In contrast, the circular economy presents a systems solution framework designed to tackle global challenges like climate change, biodiversity loss, waste, and pollution [2]. It is based on three core principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature [2]. Framed within bioenergy research, this model transforms biological resources and waste streams into renewable energy and materials, creating a resilient, low-carbon system that supports sustainable development goals [3] [4]. This whitepaper details the core principles, quantitative metrics, and experimental methodologies underpinning the transition from linear waste to circular resource, with a specific focus on applications in bioenergy and biomanufacturing.

Core Principles of the Circular Economy Model

The circular economy model requires a fundamental redesign of our systems, shifting from a linear flow of materials to a closed-loop system. The following principles guide this transformation.

Principle 1: Eliminate Waste and Pollution

The first principle involves redefining the concept of 'waste' at the design stage. This means intentionally designing out waste and pollution from products, services, and systems, rather than attempting to manage them after the fact [2]. In a linear economy, waste is an inevitable by-product, leading to massive volumes of landfill and incineration. For instance, the UK produces 100 billion pieces of plastic packaging waste annually, and the global fashion industry discards a lorry's worth of textiles to landfill or incineration every second [1]. In a circular model, processes are designed to be waste-free, and materials are chosen to be safe and non-polluting. This principle is foundational to creating a system where materials never become waste [2].

Principle 2: Circulate Products and Materials

This principle focuses on keeping products, components, and materials in circulation at their highest utility and value at all times. This circulation can occur through technical cycles (for non-biological materials) and biological cycles (for biodegradable materials) [2].

- Maintenance and Reuse: Extending the lifespan of products through strategies like product-as-a-service models [1].

- Refurbishment and Remanufacture: Restoring products to a functional state, which is far more efficient than recycling the base materials [2].

- Recycling and Composting: Returning materials to the economy. Recycling is a last resort in the technical cycle, while composting returns biological nutrients to the soil, regenerating natural systems [2].

Principle 3: Regenerate Nature

The circular economy moves beyond 'doing less harm' to actively improving the natural environment. By shifting from a linear economy that depletes finite resources to one that uses renewable energy and materials, the circular economy aims to decouple economic activity from the consumption of finite resources [2]. This principle emphasizes returning valuable nutrients to the soil and other ecosystems, enhancing natural capital, and fostering biodiversity. It aligns economic activity with the regeneration of natural systems, creating a positive feedback loop that benefits both the economy and the environment.

Table 1: Linear Economy vs. Circular Economy Model

| Factor | Linear Economy | Circular Economy |

|---|---|---|

| Resource Use | Extract and discard | Reuse and regenerate [2] [1] |

| Waste Management | Landfill and incineration [1] | Recycling and remanufacturing [2] |

| Business Model | Sell and dispose | Product-as-a-service and resale [1] |

| Economic Value | Lost materials; rising disposal costs [1] | Retained material value; new job creation [1] |

| Environmental Impact | Resource depletion, pollution | Regeneration of nature [2] |

Quantitative Assessment of Circular Systems

Transitioning to a circular economy requires robust metrics to evaluate economic, material, and systemic performance. Input-output analysis and material flow accounting provide foundational tools for this quantitative evaluation [5].

Table 2: Quantitative Economic and Material Impact of Circular Transitions

| Metric | Linear Economy (Current Status) | Circular Economy (Potential) |

|---|---|---|

| Global Material Consumption | 100+ billion tonnes annually [1] | Aims to drastically reduce virgin material input |

| Circularity Rate | Could boost EU's GDP by €1.8 trillion by 2030 [1] | |

| Projected Waste by 2050 | 3.4 billion tonnes (70% increase) [1] | Aims to design out waste [2] |

| E-Waste Recycling Rate | 17% properly recycled [1] | Target: Near 100% through improved design and systems |

| Economic Value of Lost Materials | EU loses €600 billion annually from resource inefficiency [1] | Materials continuously cycled, retaining value |

The Role of Bioenergy and Biotechnology in a Circular Economy

Bioenergy and biotechnology are pivotal in implementing circular principles, particularly in managing biological cycles and creating renewable feedstocks. Modern bioenergy systems are a key component of clean energy portfolios, contributing to a low-carbon, circular economy [3]. Biotechnology accelerates the transition from a petroleum-based linear economy by enabling the sustainable production of chemicals, materials, and fuels from renewable feedstocks and waste streams [4].

Key Research and Experimental Protocols in Circular Biotechnology

Experimental Focus: One-Carbon (C1) Biomanufacturing from Renewable Formate The utilization of one-carbon building blocks like formate is a frontier in circular bioeconomy research, turning industrial off-gases and CO2 into valuable resources.

- Objective: To engineer microbial platforms for high-growth, high-titer bioproduction from formate as a sole carbon source, overcoming the limitation of low formate dehydrogenase (FDH) activity [4].

- Host Organism: Escherichia coli [4].

- Key Genetic Modification: Introduction of a heterologous, metal-dependent formate dehydrogenase (FDH) with superior catalytic speed into a synthetic formatotrophic E. coli strain [4].

- Methodology:

- Strain Engineering: The gene encoding the high-activity FDH is cloned into an appropriate expression plasmid under a strong, inducible promoter.

- Transformation: The plasmid is transformed into an E. coli host chassis equipped with the synthetic reductive glycine pathway.

- Cultivation: The engineered strain is cultivated in a minimal medium with formate as the sole carbon source. Growth is monitored via optical density (OD600).

- Analytics: Titers of the target bioproduct (e.g., chemicals or biomaterials) are quantified using High-Performance Liquid Chromatography (HPLC) or Gas Chromatography-Mass Spectrometry (GC-MS). Formate consumption is also tracked [4].

- Outcome: This engineering strategy boosts growth rates and bioproduction titers, enhancing the economic feasibility of C1 biomanufacturing as a circular production process [4].

Experimental Focus: Engineering Microbial Platforms for Heavy Metal Bioremediation and Plastic Degradation This protocol addresses multiple waste streams simultaneously, a core challenge in a circular economy.

- Objective: To engineer a microbial platform capable of endogenously biosynthesizing phosphomelanin for concurrent adsorption of heavy metals and degradation of plastics [4].

- Host Organism: A suitable microbial chassis (e.g., Pseudomonas or engineered E. coli) [4].

- Key Genetic Modification: Introduction and optimization of the biosynthetic pathway for phosphomelanin.

- Methodology:

- Pathway Engineering: Genes for phosphomelanin biosynthesis are identified and assembled in an operon within a plasmid vector.

- Fermentation: The engineered microbe is grown in a bioreactor, potentially using a waste-derived feedstock, to produce phosphomelanin.

- Application to Waste Streams: The microbial cells or isolated phosphomelanin are exposed to a mixed waste stream containing heavy metals (e.g., lead, cadmium) and plastic particles (e.g., PET).

- Analysis: Heavy metal adsorption is quantified using Inductively Coupled Plasma Mass Spectrometry (ICP-MS). Plastic degradation is monitored by measuring weight loss, changes in polymer structure via Fourier-Transform Infrared Spectroscopy (FTIR), or the release of monomers like ethylene glycol [4].

Table 3: Research Reagent Solutions for Circular Bioeconomy Experiments

| Reagent / Material | Function in Experimental Protocol |

|---|---|

| Formate Dehydrogenase (FDH) | Key enzyme for catalyzing the oxidation of formate, enabling its use as a carbon source in C1 metabolism [4]. |

| Synthetic Reductive Glycine Pathway | An engineered metabolic pathway that allows assimilation of one-carbon units (e.g., formate) for growth and bioproduction [4]. |

| Phosphomelanin Biosynthesis Pathway | A set of enzymes that produce phosphomelanin, a biopolymer capable of adsorbing heavy metals [4]. |

| Lignocellulosic Biomass | A complex, renewable feedstock derived from plant waste; requires pre-treatment and microbial consortia for efficient conversion to biofuels and chemicals [4]. |

| Diazotroph (e.g., Azotobacter vinelandii) | Nitrogen-fixing bacteria used in biohybrid systems to convert atmospheric N₂ into ammonia, reducing the need for energy-intensive synthetic fertilizers [4]. |

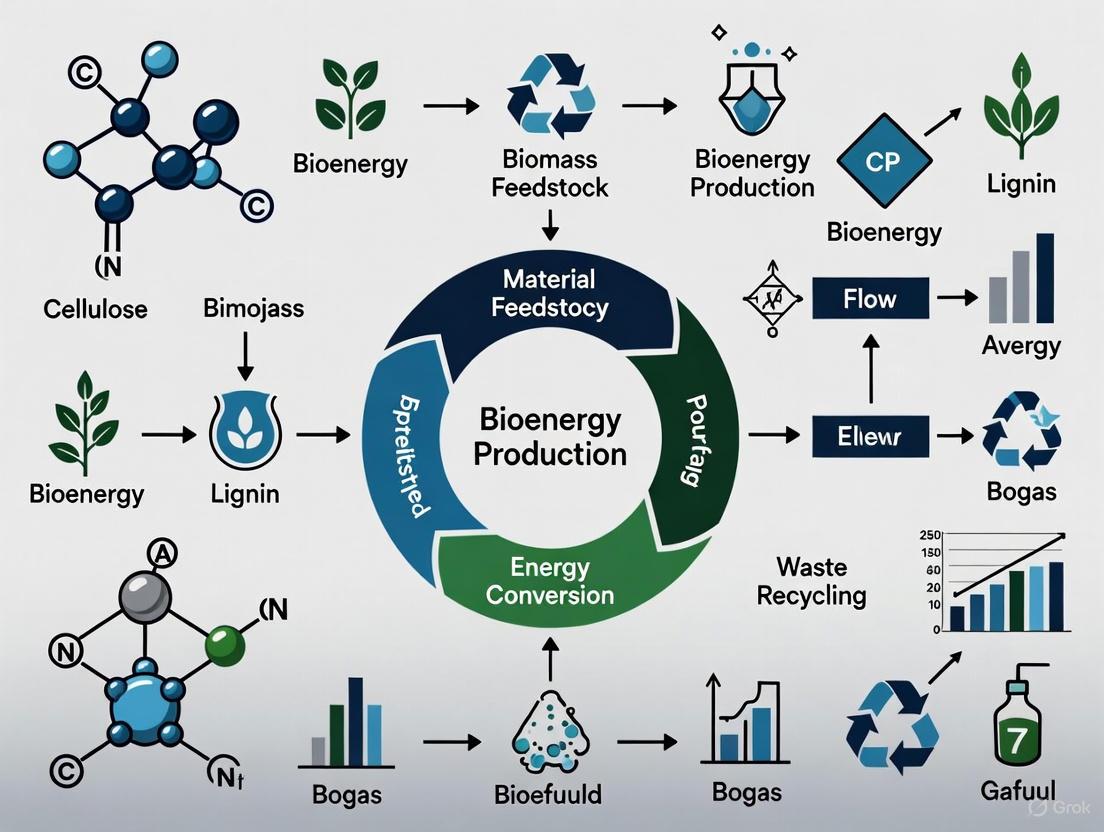

System Diagrams for Circular Resource Flows

The following diagrams illustrate the core logical relationships and material flows in linear versus circular economic models, with a specific focus on bioenergy and biotechnological processes.

Linear vs. Circular Economy System Flow

Bioenergy and Waste Valorization in a Circular System

The transition from a linear waste model to a circular resource model is an imperative backed by a compelling economic, environmental, and social case. The core principles of eliminating waste, circulating materials, and regenerating nature provide a robust framework for redesigning our systems [2]. As demonstrated, bioenergy and biotechnology are not merely components of this transition but are active drivers, turning pollution and waste into valuable resources through advanced scientific and engineering approaches [3] [4]. For researchers and scientists, the focus must now be on scaling these technologies, improving their economic competitiveness, and integrating them into synergistic systems that fully realize the vision of a circular economy, ultimately contributing to a resilient and regenerative future.

Global waste accumulation presents an unsustainable burden on planetary ecosystems, human health, and economic stability, simultaneously acting as a powerful driver for transitioning toward a circular bioeconomy. The linear "take-make-waste" economic model has led to a crisis where society discards approximately 2.01 billion tonnes of municipal solid waste annually, with 33% not managed in an environmentally safe manner [6]. Projections indicate this volume will grow to 3.4 billion tonnes by 2050, more than double population growth rates, with the most significant increases expected in Sub-Saharan Africa, South Asia, and the Middle East [6]. This escalating challenge frames an urgent research imperative: developing advanced bioenergy and biorefining technologies that transform waste from an environmental liability into a valuable feedstock within a circular economy framework.

The context of this waste crisis intersects directly with bioenergy research priorities. Modern bioenergy already provides approximately 9% of global energy demand, representing about half of total renewable energy use [7]. Its role in a decarbonized future is expected to expand significantly, with modern bioenergy's contribution needing to grow by a factor of three by 2030 to meet climate goals [7]. For researchers and drug development professionals investigating sustainable feedstocks, these converging trends highlight critical opportunities for integrating waste valorization technologies into broader bioeconomic strategies that support both energy security and material sustainability.

Quantitative Analysis of Global Waste Streams

Regional Disparities and Projections

Table 1: Global Waste Generation Metrics and Projections

| Metric | Current Value | Projected 2050 Value | Key Regional Variations |

|---|---|---|---|

| Total Municipal Solid Waste | 2.01 billion tonnes/year [6] | 3.4 billion tonnes/year [6] | Sub-Saharan Africa: Expected to triple [6] |

| Per Capita Waste Generation | 0.74 kg/person/day (global average) [6] | Varies by region | High-income countries: 19% increase by 2050 [6] |

| OECD Country Performance | Varies widely by nation [8] | - | U.S.: 951 kg/capita/year; Japan: 326 kg/capita/year [8] |

| Safely Managed Waste | 67% globally [6] | - | 33% not environmentally safe managed [6] |

The disparities in waste generation and management efficiency between regions and economic groupings reveal significant challenges for global sustainability. High-income countries, representing just 16% of the world's population, generate 34% (683 million tonnes) of global waste [6]. The OECD's 2025 Global Waste Index highlights extreme variations among developed economies: the United States generates a staggering 951 kg of municipal waste per capita annually, while Japan produces only 326 kg per capita [8]. These disparities reflect not only consumption patterns but also fundamental differences in waste management infrastructure and policy approaches.

Table 2: Waste Composition and Recovery Challenges

| Waste Stream | Annual Global Volume | Current Recovery/Recycling Rate | Environmental Impact |

|---|---|---|---|

| Plastic Waste | 400 million tonnes (2024) [6] | 9% successfully recycled [6] | Represents 10% of total waste; disrupts ecosystems [6] |

| Food Waste | 1.3 billion tonnes [6] | Limited composting | Contributes 10% of global GHGs; uses 25% of freshwater [6] |

| E-Waste | 62 million tonnes (2022) [6] | Increasing but insufficient | Growing 5x faster than recycling; 82% increase since 2010 [6] |

| Textile Waste | Significant resource consumption | Only 0.3% from recycled materials [6] | 8% of global GHGs; 215 billion litres water annually [6] |

The composition of global waste streams presents both critical challenges and significant opportunities for material and energy recovery. Plastic waste is particularly problematic, with recent data showing only 9% successfully recycled globally [6]. Food waste represents both a substantial resource efficiency failure and a major contributor to climate change, responsible for approximately 10% of global greenhouse gas emissions [6]. For researchers, these waste streams represent potential feedstocks for bioenergy production and material recovery through advanced conversion technologies.

The Circular Economy Framework

Principles and Pathways

The circular economy provides a conceptual and practical framework for addressing global waste challenges through a system "where materials never become waste and nature is regenerated" [2]. This model is based on three fundamental principles: (1) eliminating waste and pollution, (2) circulating products and materials at their highest value, and (3) regenerating nature [2]. Unlike the dominant linear economy, which follows a "take-make-waste" pattern, a circular economy maintains materials in continuous cycles through processes including maintenance, reuse, refurbishment, remanufacture, recycling, and composting [2].

For the bioenergy research community, this framework creates new paradigms for considering waste streams. The concept of "waste management" is shifting toward "materials recycling" with a focus on "keeping molecules in use for longer" rather than merely extracting energy from landfill-bound streams [9]. This approach broadens the products from waste conversion pathways to include not only energy but also chemicals, feedstocks, and materials that can replace virgin resources [9]. The European Union has demonstrated progress in this transition, increasing municipal waste recycling from 19% in 1995 to 48% in 2022, while reducing landfill from 61% to 23% over the same period [6].

Circular vs Linear Economy Models

Waste-to-Energy in the Circular Economy

Waste-to-Energy (WtE) technologies have evolved from simple waste reduction strategies to sophisticated processes that actively contribute to circular economy objectives. Modern WtE facilities provide "a holistic approach to resource recovery from non-recyclable, non-hazardous waste" by diverting materials from landfills, recovering metals and minerals, and producing renewable energy from the biodegradable fraction of waste [10]. These processes create an "indispensable link" in the circular economy by ensuring that waste streams that cannot be economically recycled are still utilized to generate value [10].

The material recovery potential of WtE is substantial. Modern plants can recover numerous materials from incinerated bottom ash, including "aggregates, minerals, ferrous and non-ferrous metals (copper, aluminium, zinc) and even precious metals, such as silver and gold" [10]. These recovered materials are essential for the green and digital transitions, as they provide key components for electronics, batteries, solar panels, and wind turbines without the energy-intensive extraction and processing of virgin materials [10]. Additionally, bottom ash itself can be used in construction applications as an aggregate for base layers in roads, bridges, sound walls, and concrete products, providing an alternative to virgin materials like gravel and sand [10].

Technological Pathways for Waste Valorization

Thermochemical Conversion Systems

Thermochemical conversion technologies represent mature pathways for extracting energy and materials from waste streams. Combustion-based WtE plants currently generate significant energy outputs, producing 43 billion kWh of electricity in Europe in 2019 alone, enough to provide power for 20 million citizens [10]. This energy, recognized as partly renewable, contributes to transitioning away from fossil fuels in electricity, district heating systems, and energy-intensive industries [10]. One significant advantage of energy produced from waste is its stability—it is "neither subject to price fluctuations of raw materials and fuels, nor vulnerable to relative supply problems" [10].

Advanced thermochemical pathways including gasification and pyrolysis are emerging with greater product flexibility. These technologies "produce useful intermediates (e.g., gasification for syngas production) that can in turn be used as industrial feedstocks for a range of applications" [9]. This offers added flexibility in terms of products from the energy recovery process and has "the potential to increase the circularity of the waste management and energy recovery system" [9]. These systems can be designed to produce renewable and low-carbon hydrogen and synthetic fuels, which are crucial for reaching climate objectives, particularly in hard-to-decarbonize sectors like heavy transport [10].

Waste Valorization Technology Pathways

Biological and Biotechnological Conversion

Biological conversion pathways offer promising approaches for valorizing organic waste fractions through microbial and enzymatic processes. Biotechnology is "increasingly poised to accelerate the transition from a petroleum-based linear economy to a sustainable and circular economy" by enabling the conversion of waste streams into valuable products [4]. Research advances include engineering microbial platforms capable of "endogenously biosynthesizing phosphomelanin for simultaneously heavy metals adsorption and plastics degradation" [4], representing integrated solutions for multiple waste challenges.

One-carbon assimilation technologies represent particularly innovative approaches for waste valorization. Recent research has demonstrated "fast growth and high-titer bioproduction from renewable formate via metal-dependent formate dehydrogenase in Escherichia coli" [4], enabling the use of C1 building blocks derived from waste streams. Other advances include the development of "computational algorithm that combines the strength of constraint-based and retrobiosynthesis methods to design pathways for bioproduct biosynthesis" [4], accelerating the engineering of biological systems for waste conversion. For drug development professionals, these platforms may offer sustainable routes to pharmaceutical precursors and intermediates.

Carbon Capture and Utilization (CCUS)

The integration of carbon capture, utilization, and storage (CCUS) technologies with WtE processes represents a frontier in circular waste management. These technologies have "the potential to significantly reduce the carbon footprint of the sector, while also constituting another way in which the sector contributes to the Circular Economy" [10]. The carbon dioxide produced from WtE activities can be utilized in "chemical products and plastics, for instance windows and other building materials that are produced from this carbon" [10].

Another utilization pathway for captured carbon is "the production of synthetic fuels, for instance methane and methanol, when combined with hydrogen produced also from WtE processes" [10]. This integrated approach creates synergistic value chains where multiple waste streams contribute to producing high-value fuels and chemicals. The Wuppertal, Germany project demonstrates this principle, where Waste-to-Hydrogen powers 20 public transport buses, saving "more than 700 tons of CO2 per year" [10].

Experimental Protocols for Waste Valorization Research

Material Characterization Methodology

Comprehensive waste characterization represents the foundational step in developing effective valorization strategies. Researchers should employ standardized protocols for fractionating complex waste streams into process-relevant categories. The following sequential protocol provides a framework for systematic waste analysis:

Sample Collection and Preparation: Apply quartering techniques to obtain representative samples from heterogeneous waste streams. For municipal solid waste, minimum sample sizes of 100kg are recommended, with sub-sampling for specific analysis. Stabilize biodegradable fractions through refrigeration or preservation to maintain composition integrity.

Proximate Analysis: Determine moisture content via gravimetric analysis after drying at 105°C until constant weight. Measure volatile matter content through thermal treatment at 950°C in an inert atmosphere. Quantify fixed carbon by difference and ash content through complete combustion at 750°C.

Ultimate Analysis: Utilize elemental analyzers to determine carbon, hydrogen, nitrogen, and sulfur content (CHNS analysis). Calculate oxygen content by difference. For bioenergy applications, measure chlorine and heavy metal concentrations using ICP-MS to assess contamination potential.

Biochemical Composition: Characterize carbohydrate content using quantitative hydrolysis protocols followed by HPLC-RI detection. Determine lignin content using acid-detergent fiber methods. For lipid-rich wastes, utilize Soxhlet extraction with appropriate solvents.

Calorific Value Determination: Measure higher heating value (HHV) using bomb calorimetry according to ASTM D5868 standards. Estimate lower heating value (LHV) through calculation accounting for hydrogen content and moisture.

Biological Conversion Experimental Workflow

For researchers investigating biological waste conversion pathways, the following protocol outlines a standardized approach for evaluating and optimizing microbial conversion systems:

Feedstock Pretreatment: Apply mechanical (milling, extrusion), thermal (autoclaving, steam explosion), chemical (acid/alkali treatment), or biological (enzymatic hydrolysis) pretreatment to enhance biodegradability. Quantify effectiveness through compositional analysis before and after treatment.

Inoculum Development: Select appropriate microbial strains (e.g., Paracoccus denitrificans for ethylene glycol metabolism [4] or engineered E. coli for formate assimilation [4]). Maintain strains on appropriate agar slants and develop precultures in optimized media. For anaerobic processes, ensure strict oxygen-free conditions using anaerobic chambers or nitrogen sparging.

Bioconversion Optimization: Employ design of experiment (DoE) methodologies to optimize critical parameters including temperature, pH, nutrient supplementation, and inoculum-to-substrate ratio. Monitor metabolic activity through off-gas analysis (CO2, CH4, H2) and substrate consumption rates.

Product Recovery and Analysis: Separate biomass through centrifugation at 8,000×g for 15 minutes. Extract intracellular products using solvent systems appropriate to target molecules (e.g., chloroform:methanol for lipids). Analyze metabolites using HPLC, GC-MS, or LC-MS systems with appropriate standards.

Process Scaling: Evaluate performance across scales from shake flasks (100mL) to benchtop bioreactors (1-5L) with controlled aeration, agitation, and feeding strategies. Monitor dissolved oxygen, pH, and substrate consumption in real-time where possible.

Research Reagent Solutions for Waste Valorization

Table 3: Essential Research Reagents for Waste Conversion Studies

| Reagent/Category | Function in Research | Application Examples |

|---|---|---|

| Formate Dehydrogenase | Enables C1 assimilation from formate [4] | Engineering synthetic formatotrophic E. coli strains [4] |

| Lipoate-protein Ligase A (LplA) | Boosts lipoylation of energy metabolism enzymes [4] | Enhancing energy metabolism in diverse organisms [4] |

| NAD-dependent Dehydrogenases | Facilitates ethylene glycol catabolism [4] | Bacterial growth on PET monomer ethylene glycol [4] |

| Specialized Anaerobic Media | Maintains oxygen-free conditions for sensitive microbes | Anaerobic digestion studies; methanogen cultivation |

| Composite Extraction Solvents | Recovers intracellular products from microbial biomass | Lipid recovery for biodiesel production; metabolite extraction |

| PCR Reagents for Strain Verification | Confirms genetic modifications in engineered strains | Validating pathway engineering in microbial platforms |

The research reagents and tools listed in Table 3 represent essential components for experimental work in waste valorization and bioenergy. Formate dehydrogenase enzymes have been particularly important in advancing C1-based biomanufacturing, where recent research has demonstrated that introducing "a faster FDH in synthetic formatotrophic E. coli" can "boost growth rates and bioproduction titers from formate as sole carbon source" [4]. Similarly, NAD-dependent dehydrogenases have enabled efficient bacterial metabolism of plastic monomers, with recent discovery of "NAD-dependent alcohol and aldehyde dehydrogenases in the soil bacterium Paracoccus denitrificans for ethylene glycol catabolism" [4].

For researchers establishing waste valorization laboratories, additional essential equipment includes anaerobic chambers for oxygen-sensitive microbial work, bioreactor systems with precise environmental control, analytical instrumentation including HPLC and GC-MS for product quantification, and molecular biology tools for strain engineering. The emerging toolkit also includes computational resources for pathway design, with recent advances including algorithms that "combine the strength of constraint-based and retrobiosynthesis methods to design pathways for bioproduct biosynthesis" [4].

The unsustainable burden of global waste accumulation presents both a critical challenge and a significant opportunity for the research community. As detailed in this analysis, current waste streams represent underutilized reservoirs of energy and materials that can be harnessed through advanced conversion technologies within a circular economy framework. The quantitative data presented reveals both the scale of the challenge and the potential for innovation across thermochemical, biological, and integrated CCUS pathways.

For researchers and drug development professionals, waste valorization represents a frontier in sustainable science that aligns with broader bioeconomic transitions. The experimental protocols and research reagents outlined provide foundational methodologies for advancing this field. Priority research directions should include: (1) developing integrated biorefining approaches that maximize value from heterogeneous waste streams, (2) advancing synthetic biology tools for engineering robust microbial platforms, (3) optimizing carbon capture and utilization technologies for synergistic waste processing, and (4) creating computational frameworks for evaluating system-level sustainability and circularity.

As the global community works toward climate goals and resource security, the transformation of waste from an environmental burden to a valuable resource represents both a scientific imperative and an opportunity for innovation across multiple disciplines, particularly within the bioenergy and bioprocessing sectors that interface directly with drug development and pharmaceutical production.

Biotechnology, leveraging microbial and enzymatic processes, is a powerful catalyst for advancing the circular bioeconomy. This whitepaper provides an in-depth technical analysis of how biological tools enable the transformation of waste streams—from synthetic plastics to lignocellulosic biomass—into bioenergy and valuable biochemicals. The document synthesizes current research, presents quantitative performance data in structured tables, details standardized experimental protocols, and models key metabolic pathways. Aimed at researchers and scientists, this guide underscores the critical role of biotechnology in creating sustainable, closed-loop systems for resource utilization, directly supporting bioenergy initiatives within the circular economy framework.

The escalating environmental crisis, driven by resource depletion and pollution from persistent waste like synthetic plastics and agro-industrial residues, necessitates a transition from a linear economic model to a circular one [11] [12] [13]. In this context, biotechnology emerges as a pivotal catalyst, offering innovative tools to convert low-value waste into high-value products, thereby reducing dependence on fossil fuels and minimizing environmental impact [12]. Microbial and enzymatic processes are at the forefront of this transition, enabling the valorization of heterogeneous waste streams that are difficult to manage with conventional methods [13].

The circular bioeconomy framework integrates these biotechnological tools to support sustainable resource regeneration and waste recovery. This whitepaper explores two primary domains: the biorecycling of synthetic plastics and the bioconversion of lignocellulosic biomass into bioenergy and co-products. Furthermore, it examines emerging applications, such as the production of bioplastics like polyhydroxyalkanoates (PHAs) from organic waste and the use of anaerobic digestion for integrated energy and nutrient recovery [12]. For researchers and drug development professionals, understanding these processes' mechanisms, efficiencies, and experimental setups is crucial for innovating and scaling sustainable bio-based solutions.

Enzymatic Depolymerization of Plastic Waste

Current Scope and Performance

The enzymatic depolymerization of synthetic plastics represents a promising biological route for waste management. Microbial enzymes, either as purified biocatalysts or in whole-cell systems, can hydrolyze specific polymers into their constituent monomers, which can be repolymerized into new materials of comparable quality to virgin feedstocks [11]. Table 1 summarizes the performance of enzymatic degradation for major plastic types.

Table 1: Performance Metrics for Enzymatic Depolymerization of Common Plastics

| Polymer Type | Example Enzyme(s) | Key Performance Metrics | Challenges |

|---|---|---|---|

| Polyethylene Terephthalate (PET) | PET hydrolase, cutinase | Effective depolymerization to terephthalic acid and ethylene glycol; process efficiency is well-established [11]. | PET constitutes only ~7% of unrecycled plastic waste [11]. |

| Polyurethanes (PUR) | Porin, urethanase | Principal unrecycled waste fraction; identified as a next target for enzyme-based depolymerization [11]. | Effective primarily on ideal polyester-based polymers; more recalcitrant to biodegradation [11]. |

| Polyolefins (PE, PP) | --- | -- | Highly recalcitrant C-C backbone; current enzyme tools are largely ineffective [11]. |

| Polylactic Acid (PLA) | Proteinase K | Efficient degradation into lactic acid monomers; optimal temperature around 50°C; rate decreases with increasing molecular weight and D-lactide content [14]. | Requires daily medium change to maintain pH and prevent enzyme denaturation due to lactic acid buildup [14]. |

Experimental Protocol: Enzymatic Hydrolysis of PLA with Proteinase K

The following protocol, adapted from quantitative enzymatic degradation studies, allows for the efficient depolymerization of Polylactic Acid (PLA) [14].

- 1. Reagent Preparation:

- Buffer Solution: Prepare a 50 mM Tris-HCl buffer, pH 8.0.

- Enzyme Solution: Dissolve Proteinase K in the Tris-HCl buffer to a stock concentration of 0.1 mg/mL. Keep on ice.

- Substrate: Use PLA films or particles of known weight and molecular weight.

- 2. Reaction Setup:

- Place the PLA substrate (e.g., 10 mg) into a suitable reaction vessel.

- Add the Tris-HCl buffer to maintain a homogeneous suspension.

- Initiate the reaction by adding the Proteinase K solution to a final concentration of 0.1 mg/mL.

- Incubate the reaction mixture at 50°C with constant agitation (e.g., 150 rpm).

- 3. Process Control:

- To prevent a drastic pH drop and enzyme denaturation due to lactic acid formation, replace the reaction medium (buffer and enzyme) every 24 hours [14].

- 4. Monitoring and Analysis:

- Gravimetric Analysis: At regular intervals, remove samples, wash, dry, and weigh to determine weight loss.

- Product Quantification: Analyze the reaction medium for released lactic acid monomers using High-Performance Liquid Chromatography (HPLC).

- Molecular Weight Analysis: Use Gel Permeation Chromatography (GPC) to track changes in the molecular weight of the remaining polymer.

The workflow and key factors influencing the degradation rate are summarized in the diagram below.

Bioconversion of Lignocellulosic Biomass to Bioenergy and Co-Products

Integrated Biorefining for Ethanol, Xylitol, and PAC Co-production

Lignocellulosic biomass, such as sugarcane bagasse (SCB), rice straw (RS), and corn cob (CC), is an abundant renewable resource for bioenergy production. A key technical challenge is the resistant nature of lignocellulose, which requires pretreatment to enhance enzymatic accessibility [15] [16]. To improve economic viability, integrated biorefining strategies that co-produce high-value chemicals alongside bioethanol are essential [15].

An optimized process for the co-production of ethanol, xylitol, and phenylacetylcarbinol (PAC) using Candida magnoliae demonstrates this approach. The process involves three main stages: diluted acid pretreatment, enzymatic hydrolysis, and microbial fermentation/biocatalysis [15]. The diagram below illustrates this integrated workflow and the role of the microbial catalyst.

Experimental Protocol: Optimized Pretreatment and Hydrolysis of Biomass

This protocol details the optimized conditions for processing sugarcane bagasse (SCB), rice straw (RS), and corn cob (CC) using Response Surface Methodology (RSM) [15].

- 1. Diluted Acid Pretreatment:

- Milling: Reduce the biomass to a particle size of 1-2 mm.

- Acid Impregnation: Treat the biomass with diluted sulfuric acid (H₂SO₄) at the optimal concentration determined by RSM (e.g., 3.36% w/v for SCB, 3.77% for RS, 3.89% for CC).

- Reaction: Incubate the mixture in boiling water at 95°C for the optimized time (e.g., 113 min for SCB, 109 min for RS, 112 min for CC) [15].

- Separation: After treatment, separate the solid residue (rich in cellulose and lignin) from the liquid xylose-rich hydrolysate via filtration.

- 2. Enzymatic Hydrolysis:

- Solid Loading: Load the pretreated solid into a bioreactor at the optimal concentration (e.g., 12.1% w/v for SCB, 10.9% for RS, 12.0% for CC).

- Enzyme Cocktail: Add a commercial cocktail containing cellulase and hemicellulase enzymes. Key activities include endoglucanase, exoglucanase, β-glucosidase, and xylanase.

- Hydrolysis: Carry out the reaction at 50°C and pH 4.8-5.0 with agitation for the optimized duration (e.g., 93 h for SCB, 61 h for RS, 90 h for CC) [15].

- Recovery: Recover the glucose-rich hydrolysate for subsequent fermentation.

The Scientist's Toolkit: Key Reagents for Lignocellulosic Bioconversion

Table 2: Essential Research Reagents for Biomass Pretreatment and Hydrolysis

| Reagent / Material | Function / Role | Technical Notes |

|---|---|---|

| Sugarcane Bagasse (SCB), Rice Straw (RS), Corn Cob (CC) | Primary feedstocks; sources of cellulose, hemicellulose, and lignin. | Composition varies: Cellulose (38-50%), Hemicellulose (23-32%), Lignin (10-25%) [15]. |

| Sulfuric Acid (H₂SO₄) | Catalyst for diluted acid pretreatment; hydrolyzes hemicellulose into xylose. | Concentration optimized at ~3.4-3.9% w/v; avoids need for acid recovery step at this concentration [15]. |

| Cellulase Enzyme Cocktail | Hydrolyzes cellulose to glucose. Contains endoglucanase, exoglucanase, and β-glucosidase. | Critical for achieving high glucose yields; β-glucosidase prevents cellobiose inhibition [15]. |

| Hemicellulase / Xylanase | Hydrolyzes hemicellulose (xylan) into xylose. Contains endoxylanase and β-xylosidase. | Used to maximize sugar release from the hemicellulosic fraction [15]. |

| Candida magnoliae | Microbial biocatalyst for fermentation. Converts xylose to xylitol and glucose to ethanol; also degrades inhibitors. | Strain TISTR 5664 demonstrated 65% xylitol and 86% ethanol yields; tolerates/degrades furfural, HMF, and acetic acid [15]. |

Expanding the Impact: Other Key Biotechnological Pathways

Beyond plastic depolymerization and lignocellulosic ethanol, biotechnology enables a diverse portfolio of processes central to the circular bioeconomy. Key advancements include:

- Production of Bioplastics: Microorganisms like Bacillus and Halomonas species can convert agricultural and industrial waste (e.g., algal biodiesel waste, asparagus peels) into polyhydroxyalkanoates (PHAs), which are biodegradable polymers [12]. Using Mixed Microbial Cultures (MMCs) can leverage existing wastewater treatment infrastructure, reducing production costs. Industrial PHA production is already feasible, with capacities reaching 2,000 tons annually for applications in packaging, agriculture, and medicine [12].

- Anaerobic Digestion (AD) and Bioenergy: AD is a mature biotechnology that converts organic waste (e.g., activated sludge, brewery effluent) into biogas (for energy) and digestate (as biofertilizer), effectively closing nutrient and energy loops [12]. Innovations include integrating AD with photobioreactors to create carbon-neutral systems and recovering high-value compounds like β-glucans and curdlan from process streams [12].

- Bio-coordinated Physicochemical Pretreatment (BCPP): Combining biological pretreatments (e.g., with fungi) with mild physicochemical methods can enhance the enzymatic hydrolysis of lignocellulosic biomass. BCPP reduces inhibitor formation, lowers chemical use, and shortens processing time compared to biological treatment alone, typically increasing sugar yields by more than 30% [16].

The integration of microbial and enzymatic processes into waste management and production systems is a cornerstone of the circular bioeconomy. This whitepaper has detailed how enzymatic depolymerization can address the plastic waste crisis and how integrated biorefining can transform lignocellulosic biomass into bioenergy and valuable co-products like xylitol. The quantitative data, standardized protocols, and visualizations provided herein offer researchers a technical foundation for further innovation.

While challenges in scalability, cost-effectiveness, and processing efficiency remain, ongoing research in enzyme engineering, metabolic pathway optimization, and process integration is rapidly advancing the field. The continued development and deployment of these biotechnological solutions are imperative for decoupling economic activity from resource depletion and environmental degradation, ultimately paving the way for a sustainable, bio-based future.

The transition to a sustainable energy system necessitates a shift away from fossil resources and towards renewable alternatives. Within the circular economy model, biomass feedstocks—particularly agricultural residues and the organic fraction of municipal solid waste (OFMSW)—play a pivotal role by converting waste streams into valuable energy and products, thereby closing material loops [17]. The global biomass power capacity reached 122 GW in 2020, with projections suggesting the biomass market will exceed USD 210.5 billion by 2030 [18]. This growth is driven by the dual imperative of reducing greenhouse gas emissions and managing the vast quantities of organic waste produced globally; for instance, approximately 931 million tons of food waste was generated in 2019, predominantly from households [17]. Effectively characterizing and utilizing a diverse portfolio of feedstocks is foundational to designing efficient and sustainable conversion processes within the bioenergy sector [19].

Feedstock Characterization and Analytical Foundations

A deep understanding of biomass composition is critical for determining the optimal conversion pathway and maximizing process efficiency. The chemical and structural architecture of plant cell walls dictates how biomass behaves during biological or thermal deconstruction [19].

Key Analytical Techniques for Biomass Characterization

Leading research institutions employ a suite of advanced analytical techniques for comprehensive biomass characterization [19]:

- Chemical Analyses: Standardized laboratory analytical procedures (LAPs) for summative mass closure of feedstocks and process intermediates.

- Chromatographies: Techniques like High-Performance Liquid Chromatography (HPLC) for quantifying monomeric sugars, carbohydrate degradation products (e.g., furfural), and other soluble compounds in hydrolysates.

- Spectroscopies: Near-Infrared (NIR) spectroscopy for rapid, non-destructive prediction of biomass composition, correlated with wet chemical data.

- Mass Spectrometries: Identification and quantification of complex mixture components, such as those in bio-oils.

Standardized Laboratory Analytical Procedures (LAPs)

Standardized methods are essential for generating reproducible and comparable data. The key procedures for biomass compositional analysis include [20]:

- Preparation of Biomass Samples: Methods for sample drying, size reduction, and representative sampling to achieve uniform particle size.

- Determination of Total Solids and Ash: Procedures for measuring moisture content via oven drying and ash content through dry oxidation at 550–600°C.

- Extractives in Biomass: Quantification of non-structural, soluble materials (e.g., water-soluble sugars) that can interfere with subsequent analyses.

- Structural Carbohydrates and Lignin in Biomass: A two-step acid hydrolysis to fractionate biomass into quantifiable forms, separating carbohydrate polymers from lignin.

- Enzymatic Saccharification: Testing the digestibility of native or pretreated biomass to glucose, cellobiose, and xylose to evaluate conversion efficacy.

Table 1: Key Biomass Compositional Analysis Laboratory Procedures (LAPs)

| Procedure Name | Primary Objective | Key Outputs |

|---|---|---|

| Sample Preparation | Obtain uniform, representative biomass particles | Milled biomass (e.g., <2mm screen) |

| Total Solids/Ash | Determine moisture and inorganic content | % Moisture, % Ash (of dry weight) |

| Extractives | Remove and quantify non-structural components | % Water/Ethanol Extractives |

| Structural Analysis | Quantify main structural components | % Glucan, % Xylan, % Lignin |

| Enzymatic Hydrolysis | Assess biochemical conversion potential | Sugar release rates and yields |

Feedstock Types and Properties

Agricultural Residues

Agricultural residues, such as straws, stalks, and husks, are a major biomass source. India alone produces approximately 500 million tons of agricultural residue annually [17]. These feedstocks are typically characterized by their high polysaccharide content (cellulose and hemicellulose) encased in a recalcitrant lignin matrix, which presents a challenge for conversion but also an opportunity for high biofuel yields post-pretreatment.

Municipal Solid Waste and its Organic Fraction (OFMSW)

The organic fraction of municipal solid waste (OFMSW), largely consisting of food and garden waste, constitutes about 60% of biowaste [17]. Despite global efforts, over 20% of biowaste in regions like Europe and America still ends up in landfills, contributing significantly to greenhouse gas emissions [17]. OFMSW is a heterogeneous feedstock with high moisture content and varying composition, requiring robust preprocessing and separation techniques.

Table 2: Comparison of Primary Biomass Feedstock Types

| Feedstock Characteristic | Agricultural Residues | Organic Fraction of MSW (OFMSW) |

|---|---|---|

| Examples | Corn stover, rice straw, sugarcane bagasse | Food waste, yard trimmings |

| Global Availability | ~500 million tons/year (India only) [17] | ~931 million tons/year (global food waste, 2019) [17] |

| Key Components | Cellulose, Hemicellulose, Lignin | Carbohydrates, Lipids, Proteins |

| Advantages | Abundant, dedicated supply chains | Waste diversion, reduced landfill use |

| Challenges | Seasonal availability, logistical costs | Heterogeneous composition, contamination |

Experimental Workflow for Feedstock Assessment

The following diagram illustrates the logical workflow for the characterization and evaluation of biomass feedstocks, from initial preparation to conversion potential assessment.

The Researcher's Toolkit: Essential Reagents and Materials

Successful biomass characterization relies on a suite of specialized reagents, instruments, and analytical tools.

Table 3: Essential Research Reagents and Materials for Biomass Analysis

| Item Name | Function/Application | Technical Notes |

|---|---|---|

| Sulfuric Acid (72% & 4%) | Two-stage acid hydrolysis for depolymerizing structural carbohydrates [20]. | High purity required; dilution to 4% is critical before autoclaving. |

| HPLC with Refractive Index Detector | Quantification of monomeric sugars (glucose, xylose) and degradation products in hydrolysates [20]. | Use de-ashing cartridges to prevent false signals from salts. |

| Enzyme Cocktails | Enzymatic saccharification to determine biomass digestibility and conversion extent. | Typically contain cellulases, β-glucosidases, and sometimes hemicellulases. |

| Near-Infrared (NIR) Spectrometer | Rapid, non-destructive prediction of biomass composition [19] [20]. | Requires calibration models developed from wet chemical data. |

| Neutral Detergent Fiber (NDF) Solutions | Traditional fiber analysis (Note: Not recommended for biofuel conversion prediction) [20]. | Methods designed for animal feed; may not correlate with biofuels data. |

| Reference Biomass Materials | Quality control and method validation to ensure analytical accuracy [20]. | Homogenous materials with well-characterized composition from standards bodies. |

Integration into the Circular Economy Framework

The valorization of agricultural and municipal waste is a cornerstone of the circular economy, which aims to redefine growth by focusing on positive society-wide benefits through the decoupling of economic activity from the consumption of finite resources [21]. The evolution of waste management from a purely sustainable perspective towards a circular economy approach is evident in the growing scientific literature on these topics [17].

Circular Strategies and Design Guidelines

To fully integrate these feedstocks into a circular system, products and processes must be designed for circularity from the outset. The "circular strategies scanner" provides a taxonomy of strategies, ranging from reinvent (dematerialization) and rethink (business model innovation) to strategies focused on the life cycle like reducing resource use, and end-of-use strategies like recycling, repair, remanufacture, and reuse [21]. For biomass systems, this translates to designing conversion pathways that maximize resource efficiency and output valorization. For instance, a sustainability assessment of a rice straw supply chain in Italy found that extending the lifetime of digestate from an aerobic digestion plant was the most sustainable and circular alternative, while carbon capture for microalgae cultivation was the least, highlighting that not all circular alternatives offer equal benefits and that trade-offs exist [22].

Optimization and Sustainability Challenges

Optimizing the biomass supply chain (BSC) is critical for economic and environmental viability. Key challenges include feedstock availability, cost, and quality, transportation expenses, and logistical systems [18]. While many optimization models prioritize economic goals, there is a growing need to integrate environmental objectives and social aspects, which have received less research attention [18]. Future optimization efforts must also account for the intermittent nature of other renewables like solar and wind, positioning biomass as a stable backbone for a future hybrid renewable energy system [18].

A diverse feedstock portfolio, anchored by agricultural residues and municipal solid waste, is essential for building a resilient and sustainable bioenergy sector within the circular economy. The effective utilization of these feedstocks hinges on rigorous, standardized characterization to unlock their full potential and guide optimal conversion processes. As the field advances, the integration of advanced analytical techniques, robust sustainability assessments, and optimized supply chain models will be paramount in transitioning from a linear "take-make-dispose" model to a circular system that views waste as a valuable resource.

Pathways to Innovation: Methodologies for Waste Valorization and Biofuel Production

The escalating challenge of global plastic pollution, coupled with a dependence on fossil resources, demands innovative strategies for sustainable materials management. Enzymatic polymer recycling has emerged as a transformative technology that aligns directly with the principles of the circular bioeconomy. This process utilizes biological catalysts—enzymes—to depolymerize plastic waste into its fundamental building blocks under mild conditions [23]. Unlike conventional mechanical recycling which often produces lower-quality materials, or energy-intensive chemical recycling, enzymatic recycling enables the selective recovery of pure monomers suitable for reproducing virgin-quality plastics or upcycling into higher-value materials [24] [23]. This technology offers a promising pathway for valorizing complex plastic waste streams, including colored or contaminated items, that are unsuitable for traditional recycling methods [24]. By transforming waste into valuable feedstock, enzymatic recycling closes the loop in a circular economy, reduces energy consumption and greenhouse gas emissions, and decreases reliance on fossil carbon [24] [25]. The integration of this process within a broader bioenergy context, where waste biomass can be a source for both bio-based polymers and the energy required for their processing, further enhances its sustainability profile [26].

Technical Mechanisms of Enzymatic Depolymerization

Enzymatic degradation of polymers is a surface erosion process catalyzed by specific microbial enzymes. The primary enzymes involved are hydrolases, such as cutinases, lipases, and specific depolymerases, which target the ester bonds in polyesters [27]. These enzymes are produced by a diverse range of microorganisms, including bacterial species such as Ideonella sakaiensis, Pseudomonas, and Bacillus, as well as fungal species like Aspergillus, Penicillium, and Fusarium [27]. These microbes secrete extracellular enzymes to break down solid polymer particles into smaller, water-soluble oligomers and monomers that can be absorbed as a carbon source [27] [28]. The degradation process can occur under both aerobic (with oxygen) and anaerobic (without oxygen) conditions, with aerobic processes generally achieving complete breakdown more rapidly [27].

Reaction Kinetics and Mechanistic Models

The enzymatic degradation of solid polymers is a heterogeneous reaction, where a soluble enzyme acts upon an insoluble substrate. This complexity requires specialized kinetic models beyond classical Michaelis-Menten kinetics. Two primary models have been developed to describe the time-resolved degradation of polymer microparticles:

- Shrinking Particle Model (SPM): This model applies when the entire particle is degraded uniformly. The reaction kinetics are typically zero-order, and the particle size decreases progressively until it disappears [29].

- Shrinking Core Model (SCM): This model describes a surface-limited reaction where an outer layer of the particle is degraded, leaving an intact core. The kinetics are often first-order, and the process involves enzyme diffusion through the layer of already-degraded substrate [29].

The degradation kinetics are influenced by the specific polymer-enzyme pair. For instance, the degradation of polycaprolactone (PCL) by cutinase follows the SPM with zero-order kinetics, while the degradation of poly(butylene adipate-co-terephthalate) (PBAT) by the same enzyme follows the SCM with first-order kinetics [29]. For native polyhydroxyalkanoates (PHAs), studies using a Quartz Crystal Microbalance (QCM) have revealed that the degradation rate constant for short-chain-length PHA (scl-PHA) depolymerases acting on poly-3-hydroxybutyrate (PHB) is approximately twice as high as that for medium-chain-length PHA (mcl-PHA) depolymerases acting on polyhydroxyoctanoate (PHO) [28].

The following diagram illustrates the general mechanism and two kinetic models of enzymatic depolymerization.

Quantitative Performance Data

The advancement of enzymatic recycling is underscored by significant improvements in process economics and efficiency. Recent techno-economic analyses demonstrate that through strategic process innovations, the cost of enzyme-recycled PET can be reduced below that of virgin PET, a critical milestone for industrial adoption [24]. The following table summarizes key quantitative benchmarks for enzymatic PET recycling compared to conventional production.

Table 1: Performance and Economic Metrics for Enzymatic PET Recycling

| Metric | Enzymatic PET Recycling (Current Study) | Virgin PET Production (U.S. Domestic) | References |

|---|---|---|---|

| Modeled Production Cost | $1.51/kg | $1.87/kg | [24] |

| Reduction in Annual Running Costs | 74% (compared to previous enzymatic process) | — | [24] |

| Reduction in Energy Use | 65% (compared to previous enzymatic process) | — | [24] |

| Reduction in Acid/Base Additions | >99% (compared to previous enzymatic process) | — | [24] |

| Typical Depolymerization Conditions | 40–72 °C, pH 7–9, 1 atm | High temperature/pressure | [30] |

| Technology Readiness Level (TRL) | 4–5 (Pilot to demonstration scale) | 9 (Fully mature) | [30] |

These performance gains are largely attributed to integrated process innovations that optimize reaction conditions and separation technologies, making the enzymatic pathway not only environmentally favorable but also economically competitive [24].

Experimental Protocols for Enzymatic Depolymerization

Laboratory-Scale PET Depolymerization

This protocol describes a standard procedure for depolymerizing PET in a stirred-tank bioreactor, based on modeled industrial processes and lab-scale studies [30] [24].

Feedstock Preparation:

- Obtain post-consumer PET (e.g., bottles, packaging) and shred it into small flakes (< 5 mm).

- Amorphize the PET flakes via thermal pre-treatment (e.g., heating above the glass transition temperature followed by rapid quenching) to reduce crystallinity, which significantly enhances enzymatic accessibility [30].

Reaction Setup:

- Load the amorphous PET flakes into a bioreactor at a solids loading of 5–15% (w/w) in a suitable aqueous buffer (e.g., phosphate or Tris-HCl) [30] [24].

- Add the engineered hydrolase enzyme (e.g., PETase, MHETase) at a typical dosage of 0.5–5 mg enzyme per gram of PET [30].

- Maintain the reaction temperature at the enzyme's optimum, typically between 60–72 °C for thermostable variants, and control pH between 7.0–9.0 using an automated titrator with base (e.g., NaOH) to counteract acidification from TPA production [30] [24].

- Run the depolymerization reaction with constant agitation for 10–48 hours [30].

Product Recovery:

- After digestion, filter the hydrolysate to remove any undegraded solids and denature/remove the enzyme.

- Acidify the filtrate to pH ~2.5 with a strong acid (e.g., H2SO4) to precipitate terephthalic acid (TPA).

- Recover the high-purity TPA crystals via continuous centrifugation or filtration.

- The remaining liquor, containing ethylene glycol (EG), can be neutralized and purified via membrane filtration and distillation to recover the EG co-product [30].

Microfluidic Analysis of Degradation Kinetics

This protocol leverages microfluidics and image analysis for real-time, high-resolution kinetic studies of polymer microparticle degradation [29].

Polymer Microparticle Preparation:

- Prepare microparticles (15–25 μm) of the target polyester (e.g., PCL, PBAT) using standard emulsion-solvent evaporation or milling techniques.

Microfluidic Device Operation:

- Load the microparticles into a custom-designed microfluidic device that physically separates and immobilizes them.

- Continuously perfuse the device with a buffer solution containing the depolymerase enzyme (e.g., cutinase from Humicola insolens).

- Maintain a constant temperature and flow rate.

Data Acquisition and Modeling:

- Use in-situ microscopy to capture time-resolved images of the microparticles during degradation.

- Employ image processing software to measure the change in particle size (for SPM) or the thickness of the degraded layer (for SCM) over time.

- Fit the extracted time-resolved data to the generalized SPM or SCM equations to determine the kinetic parameters (e.g., rate constants, reaction order) for the specific polymer-enzyme system [29].

The workflow for this advanced kinetic analysis is depicted below.

The Scientist's Toolkit: Key Research Reagents and Materials

Successful research and development in enzymatic polymer recycling rely on a specific set of biological, chemical, and analytical tools. The following table details essential reagents and their functions.

Table 2: Essential Research Reagents for Enzymatic Polymer Recycling Studies

| Reagent/Material | Function and Application in Research | References |

|---|---|---|

| Engineered PET Hydrolases (PETases) | Core biocatalysts for hydrolyzing PET into soluble intermediates (MHET, BHET). Often engineered for enhanced thermostability and activity. | [30] [24] |

| MHETase & BHETase | Complementary enzymes that further hydrolyze the primary products of PETase (MHET and BHET) into the final monomers, TPA and ethylene glycol. | [30] |

| Cutinase from H. insolens | A robust model enzyme used in kinetic studies for degrading various aliphatic-aromatic polyesters like PBAT and PCL. | [29] |

| PHA Depolymerases | Specific enzymes for degrading biodegradable polyhydroxyalkanoates (PHAs). Critical for studying the breakdown of bioplastics. | [28] |

| Amorphous PET Feedstock | Substrate for depolymerization assays. Thermal pre-treatment to reduce crystallinity is essential for achieving high degradation yields. | [30] |

| Quartz Crystal Microbalance (QCM) | A sensitive analytical sensor for real-time monitoring of mass changes in thin polymer films during enzymatic degradation, providing detailed kinetic data. | [28] |

| Microfluidic Devices | Lab-on-a-chip platforms for high-throughput, time-resolved analysis of enzymatic degradation kinetics of immobilized polymer microparticles. | [29] |

Current Challenges and Future Research Directions

Despite rapid progress, several challenges must be addressed to realize the full industrial potential of enzymatic recycling. Key hurdles include the limited operational stability and activity of native enzymes under industrial conditions, the high cost of enzyme production, and the need for efficient product separation and recovery [30] [24]. Furthermore, while promising for polyesters like PET, the enzymatic degradation of other major plastics such as polyolefins (PP, PE) remains a significant challenge [23].

Future research is poised to focus on several key areas:

- Advanced Enzyme Engineering: Utilizing directed evolution, computational protein design, and rational design to create next-generation enzymes with superior activity, thermostability (operating closer to the polymer's glass transition temperature), and tolerance to acidic pH and high product concentrations [30].

- Process Integration and Intensification: Developing innovative reactor designs and process configurations that reduce water, energy, and chemical consumption. This includes exploring continuous processes and improved downstream separations [24] [30].

- Expanding Polymer Scope: Intensifying the search for and engineering of enzymes capable of degrading a broader range of polymers, including polyurethanes (PUR) and polyamides (PA) [23].

- Synergy with AI and Modeling: Leveraging artificial intelligence and machine learning to accelerate enzyme discovery and optimization, predict process outcomes, and manage complex supply chains for plastic waste [26].

In conclusion, enzymatic polymer recycling represents a cornerstone technology for a sustainable circular bioeconomy. By breaking down complex waste into valuable chemical feedstocks, it creates a closed-loop system that minimizes environmental impact and conserves resources. Continued multidisciplinary research in enzyme engineering, process design, and systems integration is essential to scale this transformative technology and address the global plastic pollution crisis.

The increasing global energy demand, fueled by economic expansion, intensifies concerns over fossil fuel depletion and environmental degradation. Currently, nearly 80% of global energy remains derived from fossil fuels, contributing to a record high of nearly 37.4 to 37.8 billion tonnes of carbon dioxide emissions [31]. Concurrently, municipal solid waste (MSW) generation presents a mounting environmental challenge, with approximately 2.01 billion tons produced worldwide annually—a figure projected to rise to 3.40 billion tons by 2050 [31]. This dual crisis of waste accumulation and energy scarcity has catalyzed interest in advanced waste-to-energy technologies that align with circular economy principles.

Thermochemical conversion technologies represent a promising pathway for transforming waste biomass into valuable energy and products, thereby supporting a circular bioeconomy model. These processes—primarily pyrolysis, gasification, and torrefaction—enable the valorization of diverse feedstocks, including household, industrial, and agricultural waste, into renewable fuels and chemicals [32] [31]. By converting waste streams into energy resources, thermochemical technologies address both waste management challenges and energy security needs while reducing greenhouse gas emissions and fossil fuel dependency. This review examines the technical frontiers of these conversion technologies, their applications, and their integration within sustainable biomass utilization systems.

Fundamental Principles of Thermochemical Conversion

Thermochemical conversion encompasses a suite of technologies that use thermal energy to transform biomass into valuable energy products through chemical reactions. These processes occur under different temperature and oxygen conditions, yielding distinct product portfolios.

Table 1: Comparison of Major Thermochemical Conversion Processes

| Parameter | Torrefaction | Pyrolysis | Gasification |

|---|---|---|---|

| Temperature Range | 200-300°C [33] [34] | 300-800°C [33] [35] | Typically 800-1000°C [31] |

| Atmosphere | Inert or oxygen-deficit [34] | Oxygen-free [35] | Limited oxygen/steam [31] |

| Primary Products | Torrefied biomass (solid) [33] | Bio-oil, biochar, syngas [35] | Syngas (CO, H₂, CH₄) [31] |

| Solid Yield | 70-80% [33] | 25-40% (high-temperature) [33] | 10-20% (ash) [31] |

| Energy Content of Products | 20-24 MJ/kg [34] | Bio-oil: 15-20 MJ/kg; Biochar: 25-30 MJ/kg | Syngas: up to 10.9 MJ/m³ [31] |

| Process Objective | Biomass pretreatment & solid fuel production | Liquid bio-oil production | Syngas production for power/heat |

The core transformation mechanisms involve dehydration, depolymerization, isomerization, aromatization, and decarboxylation reactions that break down complex biomass polymers (cellulose, hemicellulose, lignin) into simpler compounds [35]. Biomass composition significantly influences conversion efficiency; cellulose decomposes at 315-400°C, hemicellulose at 220-315°C, and lignin, the most stable component, degrades between 160-900°C [35]. The inorganic components (ash) in biomass, particularly high in sewage sludge (19-50%) and algae (up to 48%), can reduce process efficiency and product quality [35].

Figure 1: Thermochemical Conversion Pathways and Products. This diagram illustrates the primary thermochemical processes, their operating temperature ranges, and resulting products with applications in the circular economy.

Technological Deep Dive: Processes and Parameters

Torrefaction: Biomass Pretreatment

Torrefaction is a thermal pretreatment process involving the slow heating of biomass in an inert or oxygen-deficit environment to temperatures between 200-300°C [34]. During this process, biomass undergoes significant physical and chemical transformations. The process typically begins with moisture evaporation at temperatures up to 150°C, followed by decomposition reactions above 200°C that primarily affect hemicellulose, with partial devolatilization and carbonization [34]. This results in a solid uniform product with lower moisture and higher energy content than raw biomass.

Key Operational Parameters:

- Temperature: The most critical parameter, with typical range of 200-300°C

- Residence time: Generally 20-40 minutes for effective torrefaction

- Heating rate: Typically around 10°C/min to maintain reactor temperature

- Biomass particle size: Influences reaction kinetics and heat transfer

- Atmosphere: Inert environment (usually nitrogen) prevents oxidation

Product Characteristics: Torrefaction increases the energy density of biomass by approximately 30%, with calorific values rising from 18-19 MJ/kg to 20-24 MJ/kg [34]. The process reduces moisture content to 1-3% (wet basis) and creates a hydrophobic material due to the loss of hydroxyl groups, significantly improving storage stability [34]. The torrefied biomass also exhibits increased brittleness, reducing grinding energy requirements by 80-90% compared to raw biomass [33].

Pyrolysis: Bio-Oil Production

Pyrolysis involves thermal decomposition of biomass at temperatures above 300°C in complete absence of oxygen [35]. The process consists of three stages: moisture evaporation, primary decomposition, and secondary decomposition (oil cracking and polymerization) [35]. Depending on operating parameters, pyrolysis can be categorized as slow, fast, or flash pyrolysis, with varying product distributions.

Process Parameters and Their Impact:

Table 2: Influence of Key Parameters on Pyrolysis Products

| Parameter | Impact on Process | Effect on Products |

|---|---|---|

| Temperature | Determines decomposition extent | Higher temps favor gas production; moderate temps (400-550°C) maximize bio-oil |

| Heating Rate | Affects reaction pathways | Fast heating rates favor bio-oil; slow rates favor biochar |

| Residence Time | Influences secondary reactions | Short vapor residence time maximizes bio-oil; longer times favor gas |

| Biomass Type | Affects product composition | High cellulose/hemicellulose increases oil; high lignin increases char |

| Particle Size | Impacts heat transfer | Smaller particles improve heat transfer and reaction rates |

Optimized pyrolysis of refuse-derived fuel can yield up to 67.9 wt% liquid oil, while the char and gas fractions vary based on feedstock and process conditions [31]. The bio-oil produced has a lower heating value (15-20 MJ/kg) compared to fossil fuels and requires upgrading for many applications [35].

Gasification: Syngas Production

Gasification converts carbonaceous materials into synthetic gas (syngas) through partial oxidation at high temperatures (typically 800-1000°C) [31]. The process involves multiple reaction steps including drying, pyrolysis, oxidation, and reduction, ultimately producing a flammable gas mixture rich in CO, H₂, and CH₄.

Gasification Performance Metrics:

- Cold Gas Efficiency (CGE): Ratio of chemical energy in syngas to feedstock energy

- Syngas Heating Value: Ranges from 4-10.9 MJ/m³ for air-blown gasification [31]

- Carbon Conversion: Percentage of feedstock carbon converted to gas phase

- Tar Production: Undesirable byproduct that requires cleanup

Gasification produces syngas with heating values up to 10.9 MJ/m³, suitable for power generation, chemical synthesis, or direct thermal applications [31]. The process is particularly advantageous for heterogeneous feedstocks like municipal solid waste and refuse-derived fuels, though it requires sophisticated gas cleaning systems to remove contaminants such as tars, particulate matter, and alkaline compounds.

Experimental Protocols and Methodologies

Laboratory-Scale Torrefaction Procedure

Materials and Equipment:

- Raw biomass feedstock (wood chips, agricultural residues)

- Tubular reactor with temperature control

- Nitrogen gas supply for inert atmosphere

- Condensation system for volatile collection

- Analytical balance for mass yield determination

- Calorimeter for heating value analysis

Step-by-Step Protocol:

- Feedstock Preparation: Reduce biomass to uniform particle size (1-3 mm) using a grinder. Determine initial moisture content via oven drying at 105°C for 24 hours.

- Reactor Loading: Place 50-100g of prepared biomass in the reactor vessel. Seal the system and purge with nitrogen at 1-2 L/min for 15 minutes to establish oxygen-free environment.

- Thermal Treatment: Heat the reactor to target temperature (200-300°C) at a controlled rate of 10°C/min. Maintain temperature for desired residence time (20-40 minutes).

- Volatile Collection: Direct evolved gases through a condensation system maintained at 0-5°C to capture condensable volatiles.

- Product Recovery: After processing, cool the reactor under continuous nitrogen flow. Collect and weigh the solid product (torrefied biomass).

- Product Analysis: Determine mass yield, then analyze for:

- Proximate composition (moisture, volatile matter, fixed carbon, ash)

- Ultimate analysis (C, H, O, N, S content)

- Higher heating value using bomb calorimeter

- Hydrophobicity via moisture uptake tests

Data Analysis: Calculate mass yield (MY) and energy yield (EY) using: MY (%) = (Mass of torrefied biomass / Mass of raw biomass) × 100 EY (%) = MY × (HHVtorrefied / HHVraw) × 100

Analytical Methods for Product Characterization

Proximate Analysis:

- Moisture Content: Oven drying at 105°C until constant weight

- Volatile Matter: Weight loss after heating to 950°C in covered crucible for 7 minutes

- Ash Content: Residue after combustion at 750°C for 4-6 hours

- Fixed Carbon: Calculated by difference: 100% - (Moisture + Volatiles + Ash)

Ultimate Analysis:

- Elemental Composition (CHNS): Determined using elemental analyzer

- Oxygen Content: Calculated by difference: 100% - (C + H + N + S + Ash)

Thermogravimetric Analysis (TGA):

- Heating rate: 10°C/min under inert atmosphere

- Temperature range: 30-900°C

- Records mass loss patterns indicating thermal stability and decomposition stages

Bio-oil Characterization:

- Water Content: Karl Fischer titration

- Viscosity: Rotational viscometer at 40°C

- pH: Standard pH meter

- Chemical Composition: GC-MS analysis for organic compounds

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Research Materials and Analytical Tools

| Reagent/Equipment | Function | Application Examples |

|---|---|---|

| Thermogravimetric Analyzer (TGA) | Measures mass changes vs. temperature/time | Kinetic studies, decomposition behavior [36] |

| Elemental Analyzer | Determines CHNS composition | Ultimate analysis of feedstocks and products [31] |

| Bomb Calorimeter | Measures higher heating value (HHV) | Fuel quality assessment [31] [34] |

| Gas Chromatograph-Mass Spectrometer (GC-MS) | Identifies and quantifies volatile compounds | Bio-oil composition, gas analysis [35] |

| Fixed Bed Reactor | Laboratory-scale thermal processing | Process parameter optimization [35] [34] |

| Nitrogen Gas | Creates inert atmosphere | Prevents oxidation during pyrolysis/torrefaction [34] |

Applications in the Circular Economy

Thermochemical conversion technologies play a pivotal role in closing material loops within the circular economy by transforming waste streams into valuable energy and products. In agricultural systems, biochar application enhances crop yields by 19.9–36.9% and contributes to soil improvement and carbon sequestration [37]. Biochar also demonstrates remarkable efficiency in environmental remediation, immobilizing heavy metals in soil with over 90% efficiency and removing contaminants from wastewater with efficiencies of 84.0–90.0% for heavy metals and 96.5% for organic pollutants [37].

The integration of thermochemical processes into waste management systems enables significant diversion of municipal solid waste from landfills. Refuse-derived fuel (RDF) production from non-recyclable waste fractions provides an alternative fuel source with calorific values of 8–20 MJ/kg, suitable for industrial applications [31]. In cement manufacturing, co-processing with alternative fuels achieves thermal substitution rates of 50–60% in rotary kilns and 80–100% in calciners, substantially reducing fossil fuel consumption [31].

Techno-economic assessments reveal the economic viability of these approaches, with production costs as low as $116.0/ton for biochar and $30.0/ton for hydrochar [37]. Life cycle analyses further demonstrate environmental benefits, including greenhouse gas emission reductions of 1.5 to 3.5 tCO2-eq per ton of biochar produced [37].

Figure 2: Circular Economy Integration of Thermochemical Conversion. This diagram illustrates how waste biomass is transformed through thermochemical processes into valuable products that complete material cycles, returning carbon to soils or providing renewable energy.